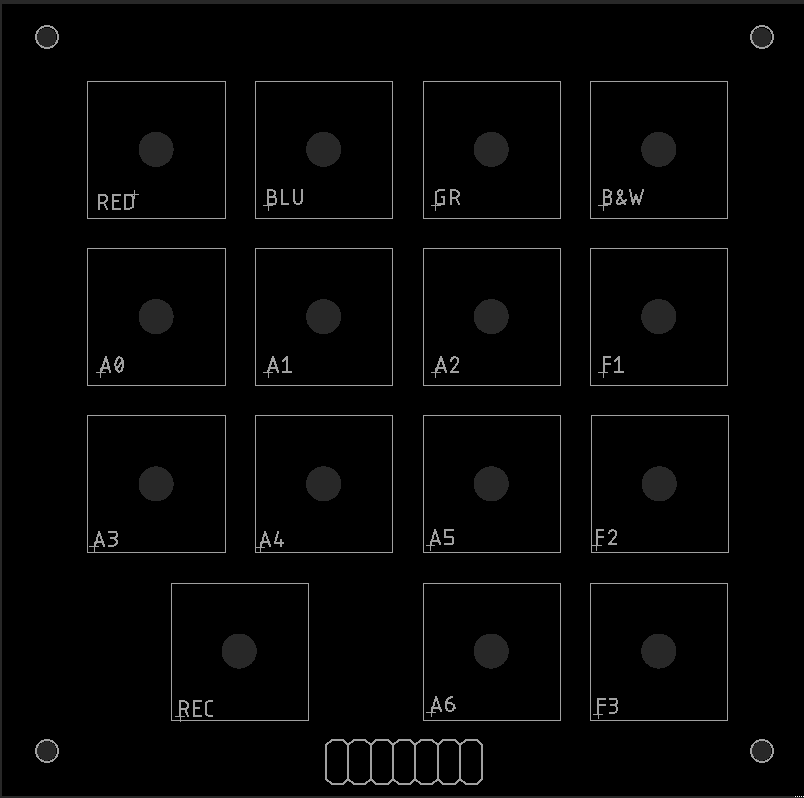

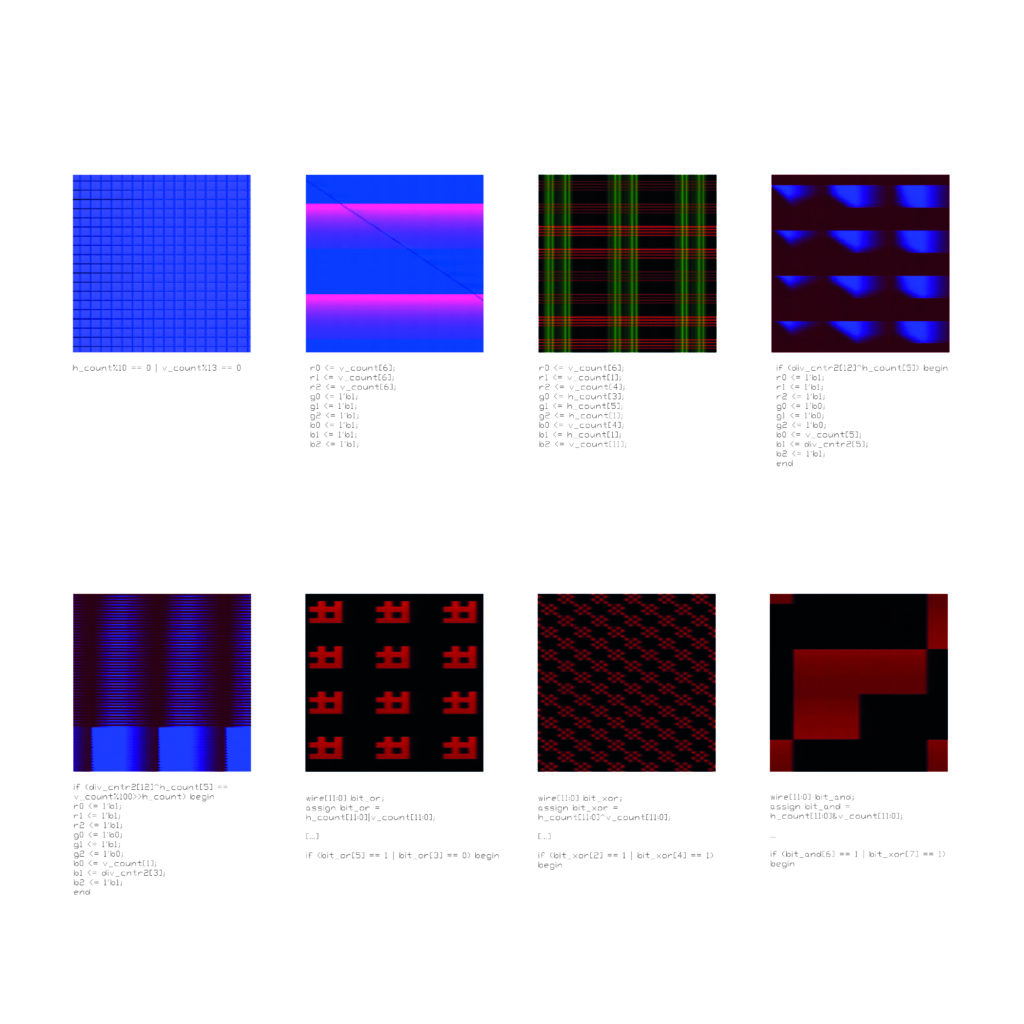

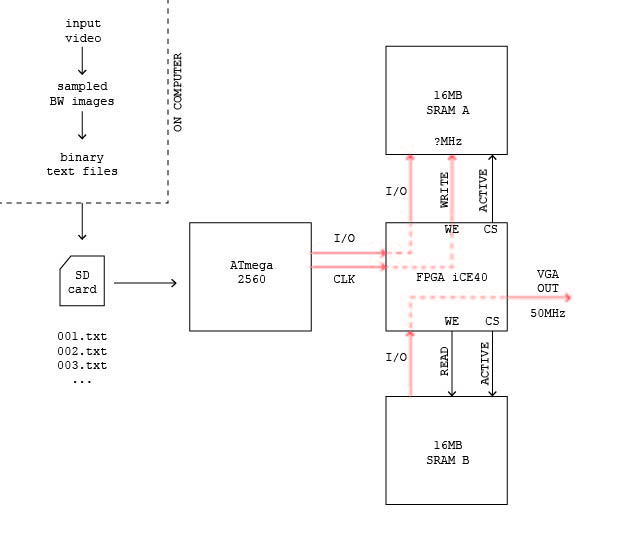

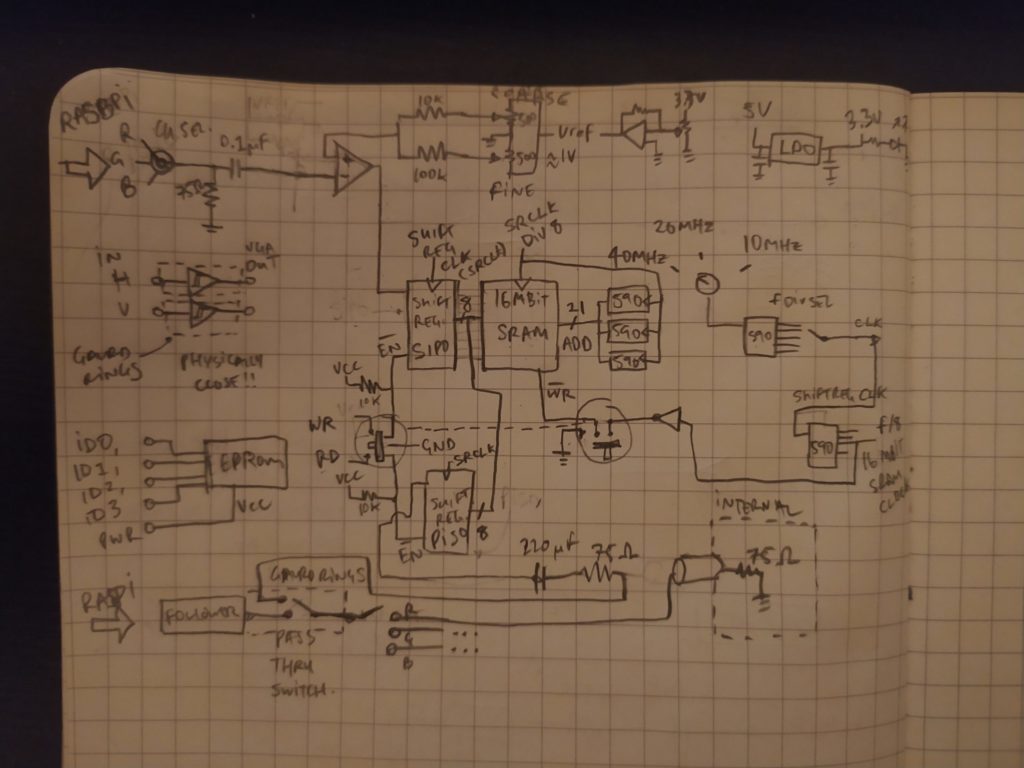

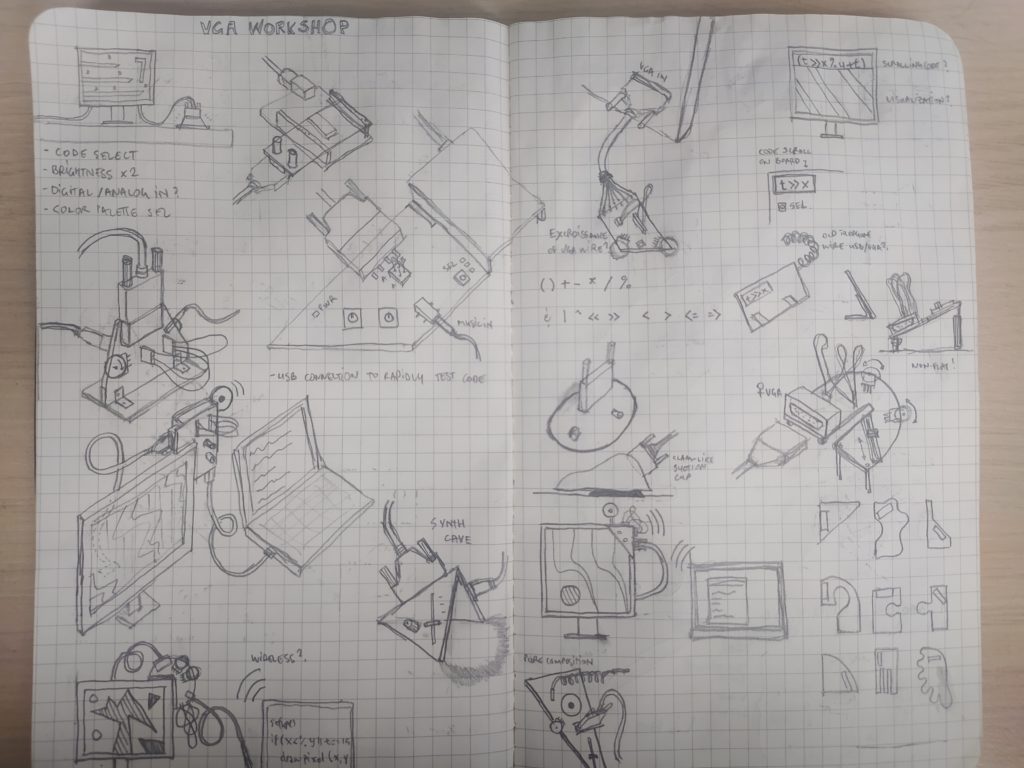

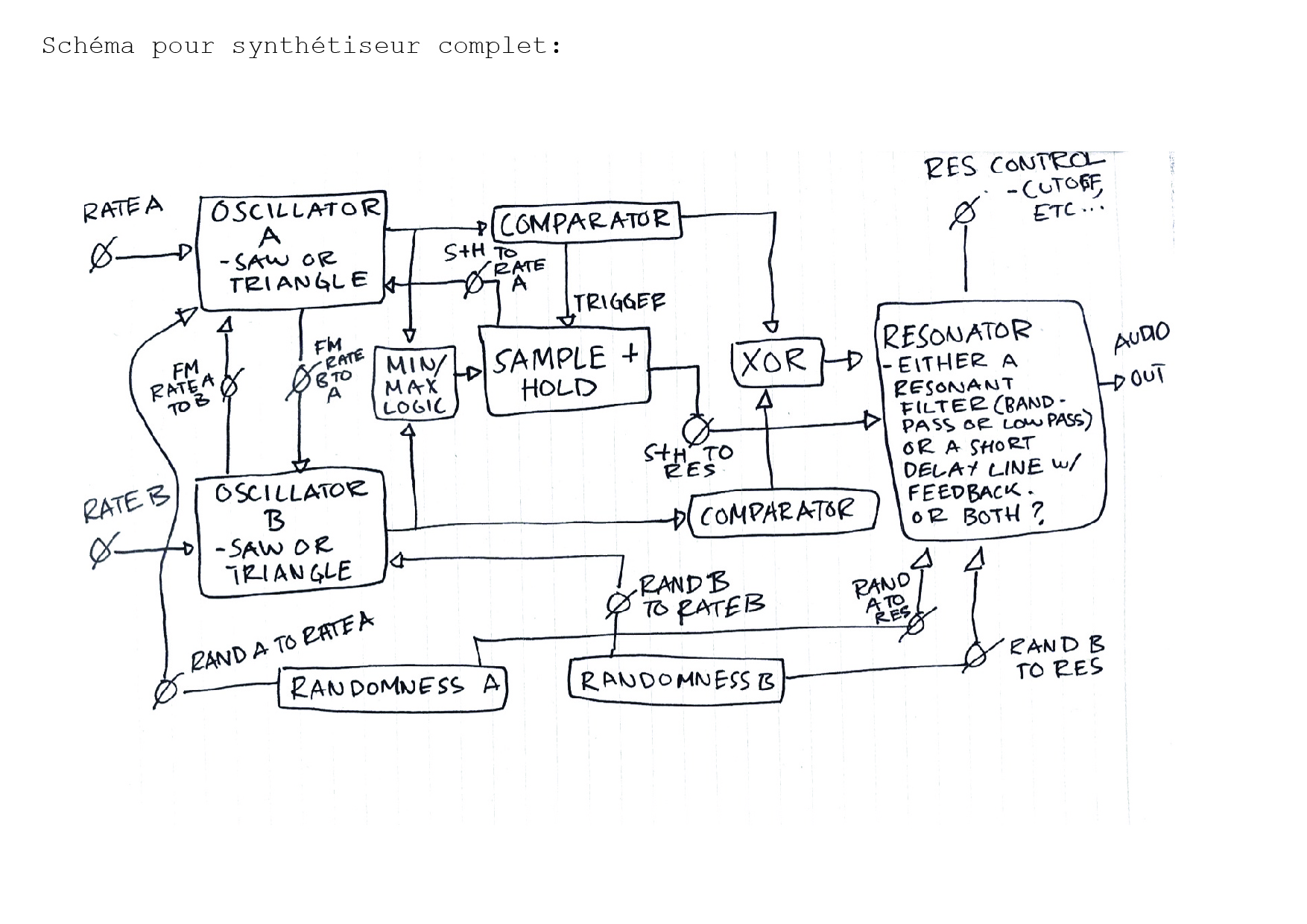

Thoughts on this as a product now that SD card seems possible :

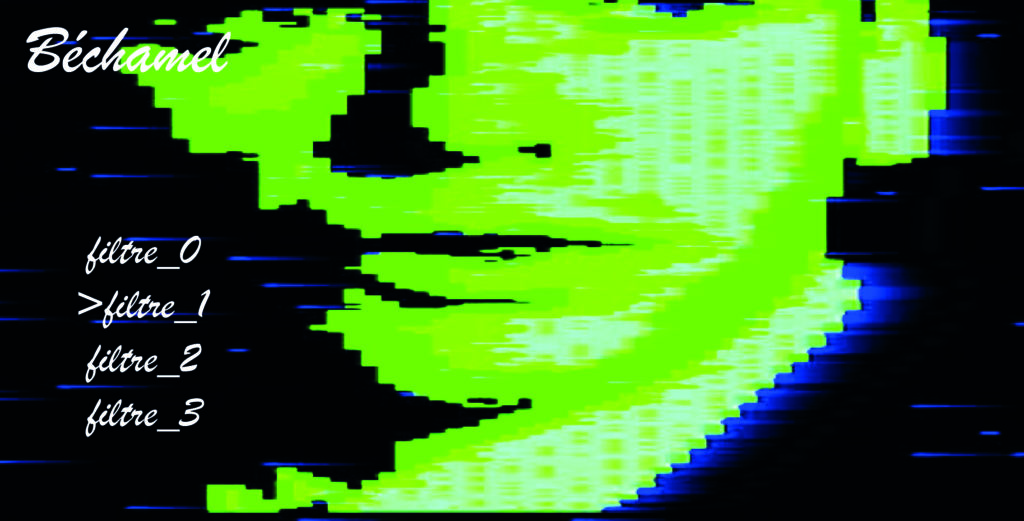

- I could put “sprites” like the bechamel logo and some numbers in some location in memory.

- I could be able to save screen shots on the SD card with a button combo.

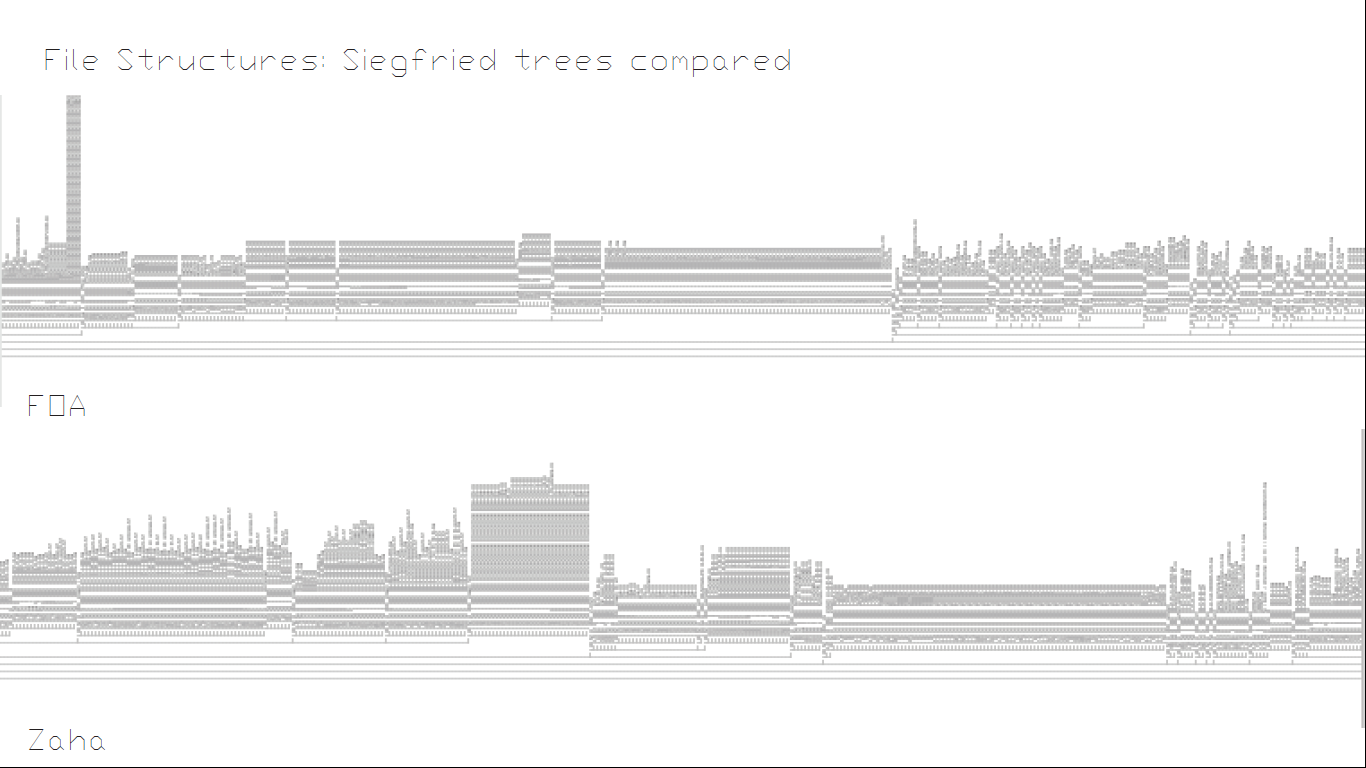

- Could there be a kind of database, which would be like how rhino saves files of 3D models one is working on ?

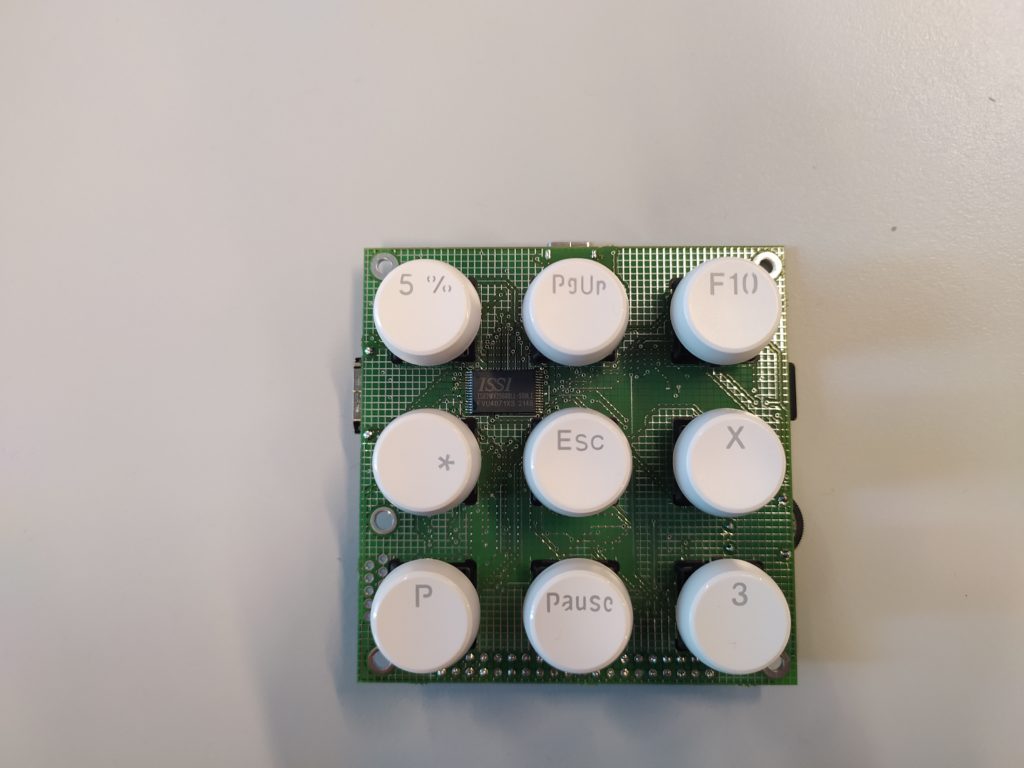

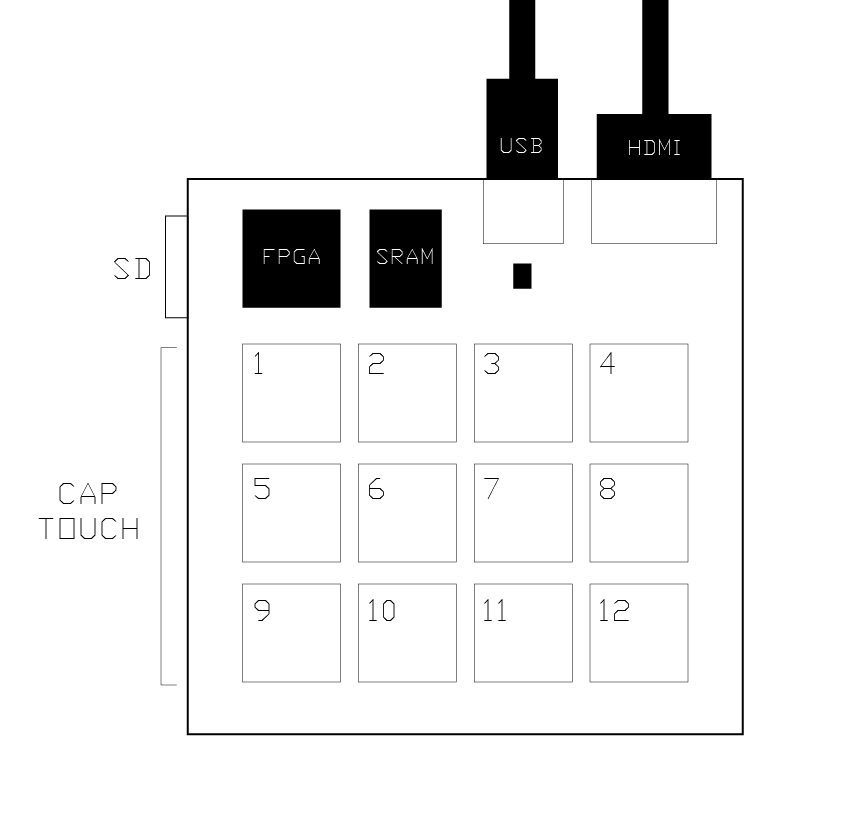

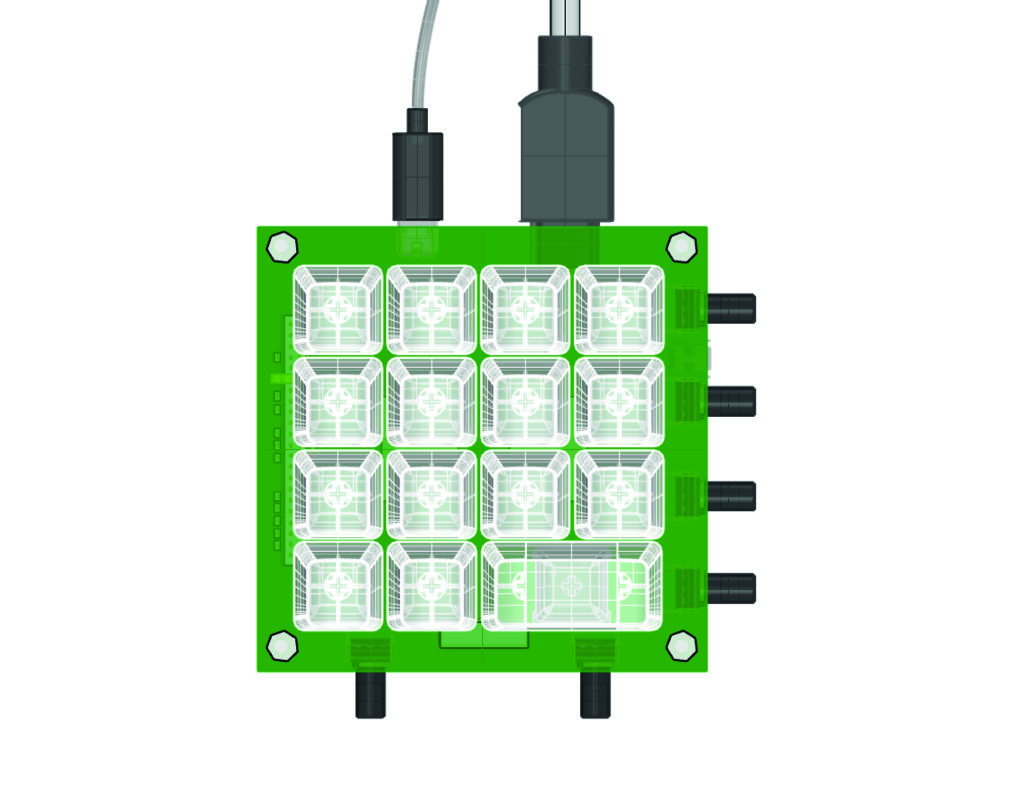

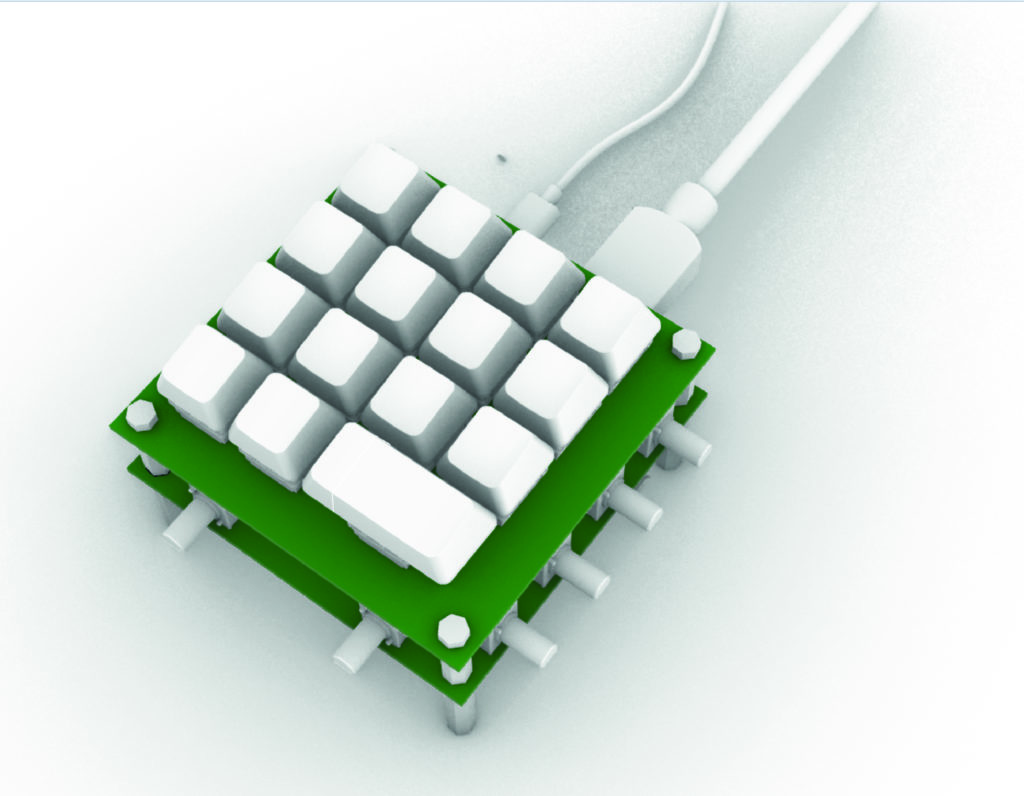

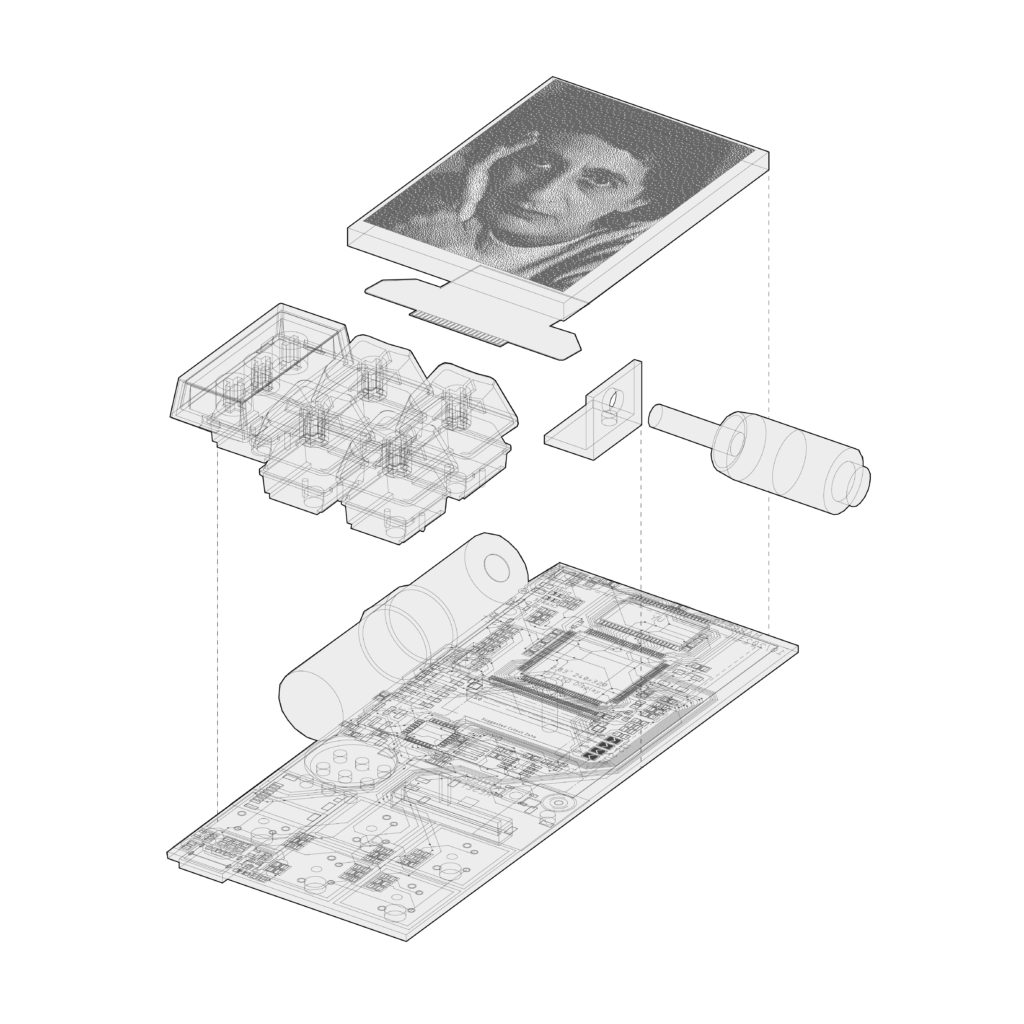

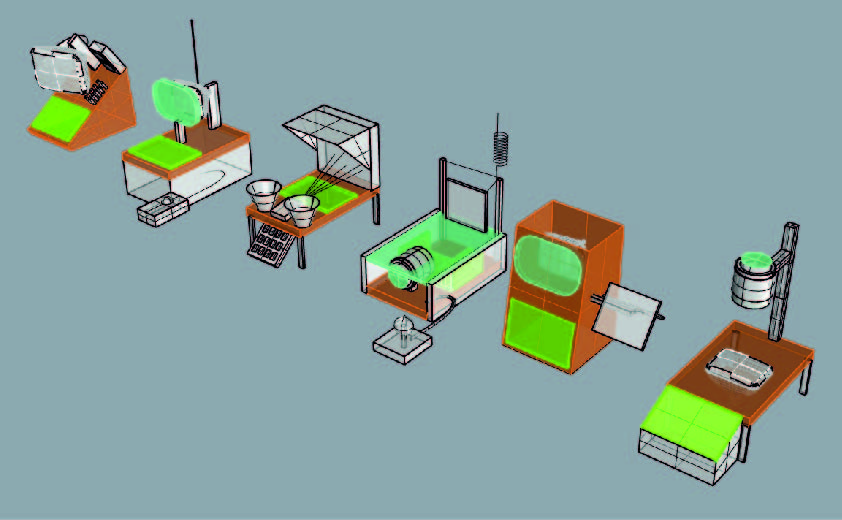

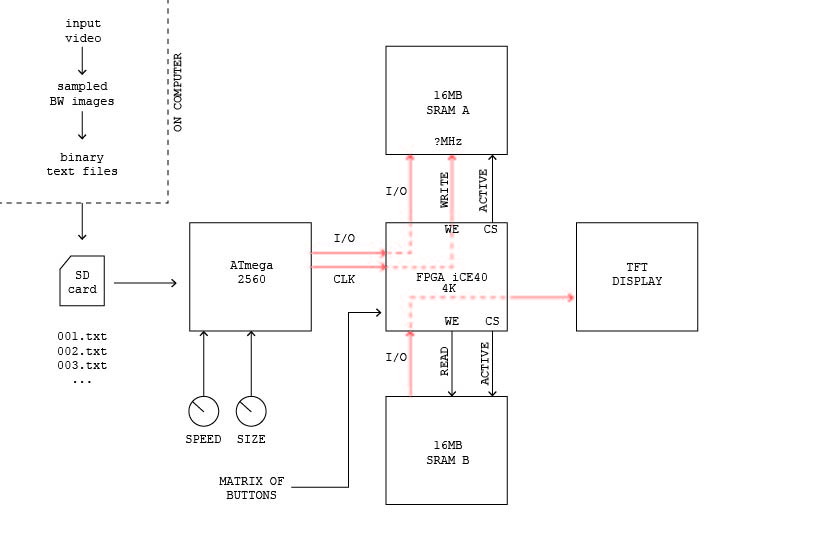

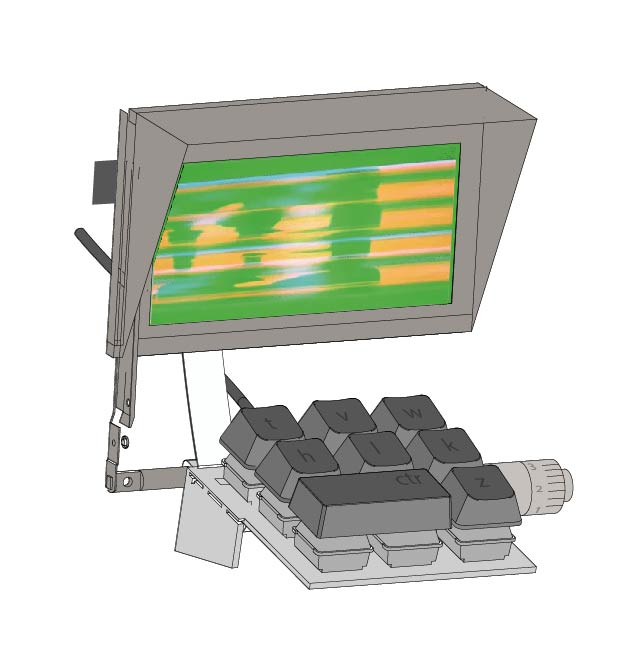

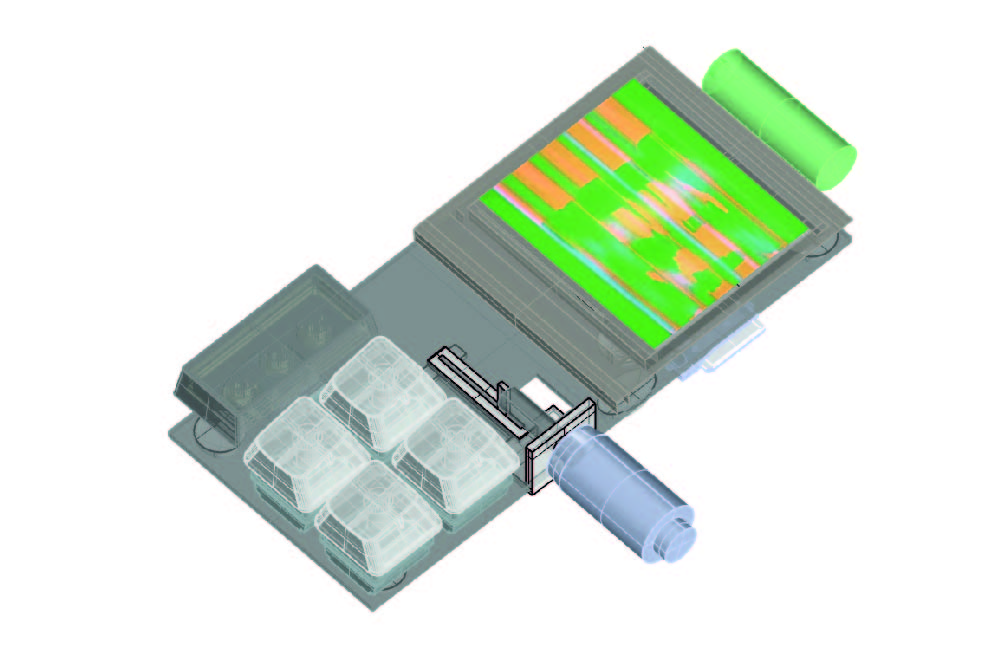

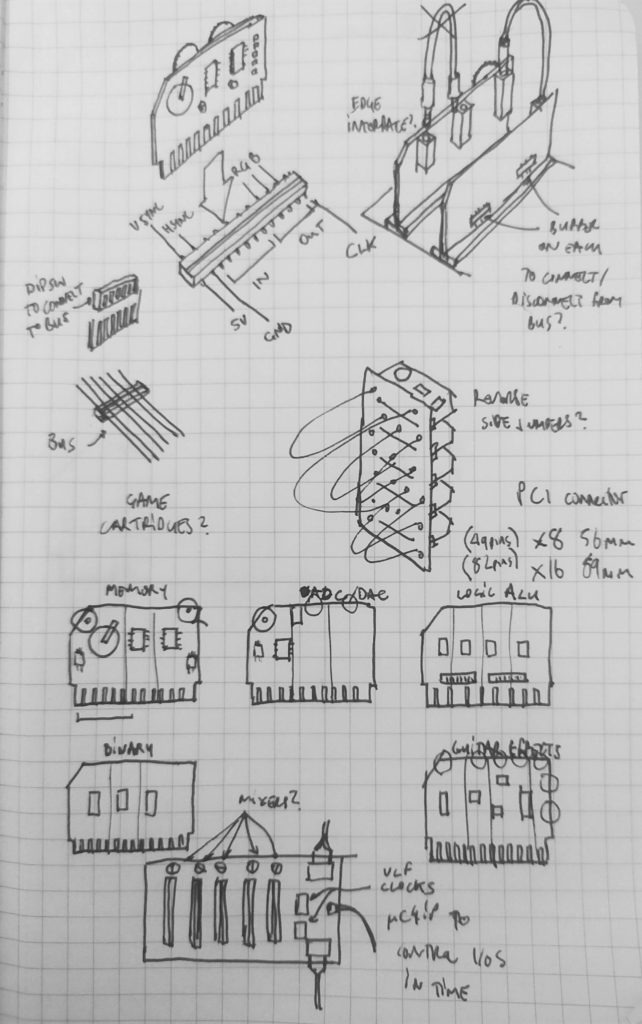

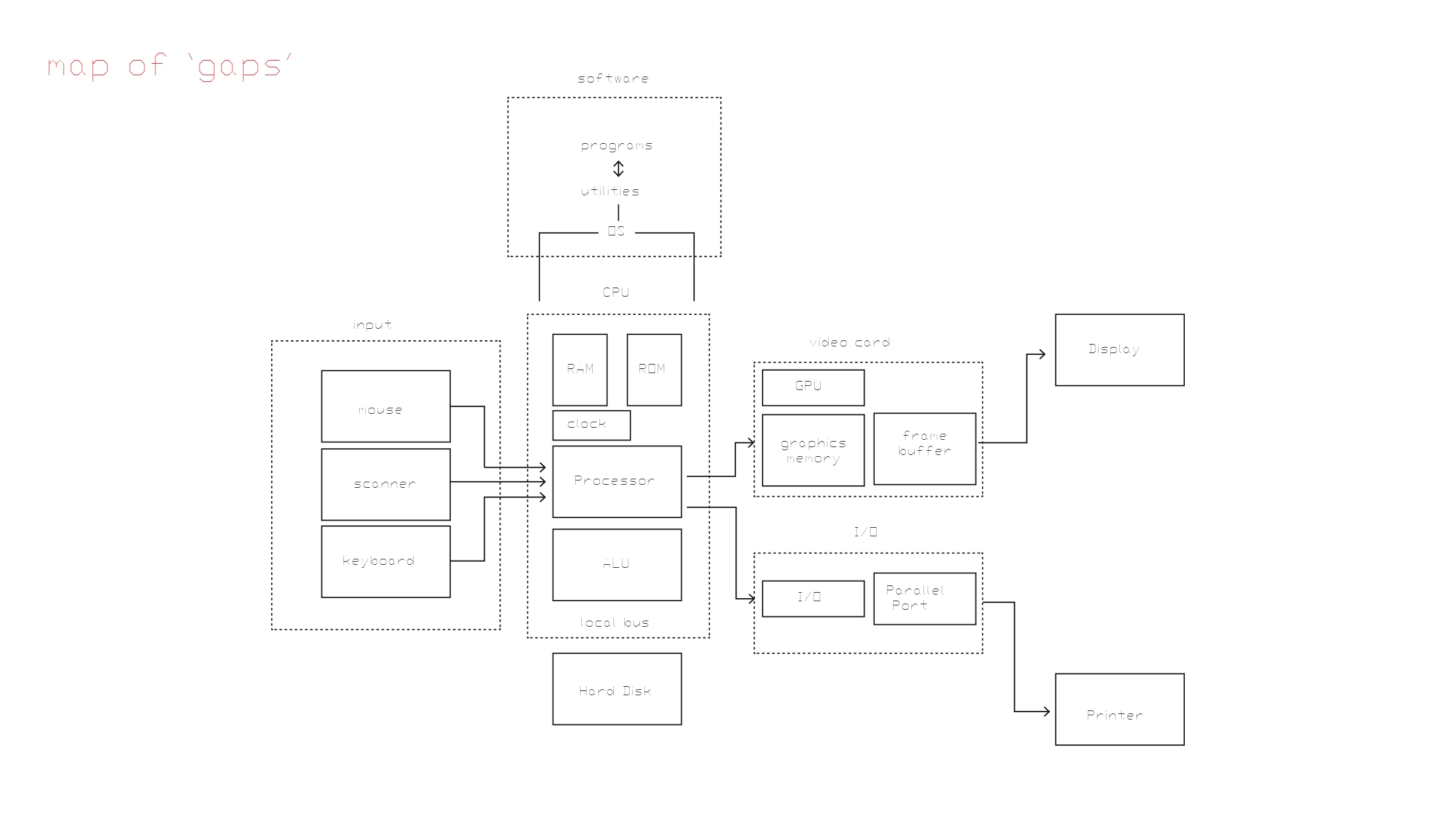

- Am I making a mini computer (ALU, slow big memory, fast SRAM, user interface, screen output) ? What do I think about a scroll wheel and a mini screen then ?

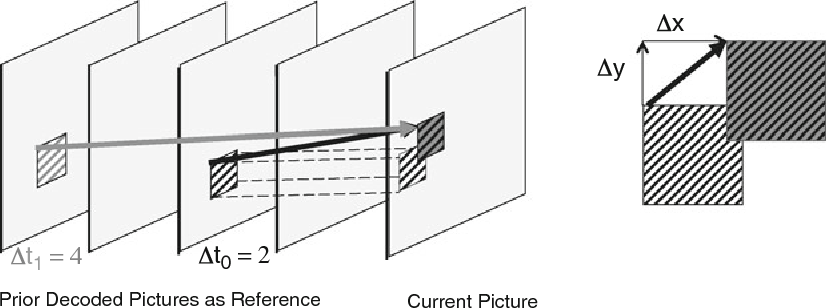

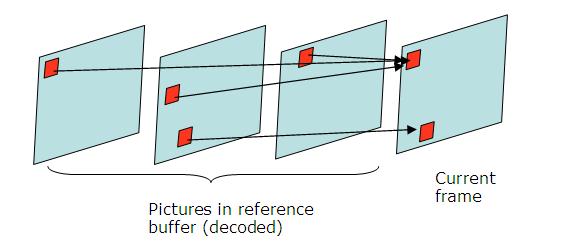

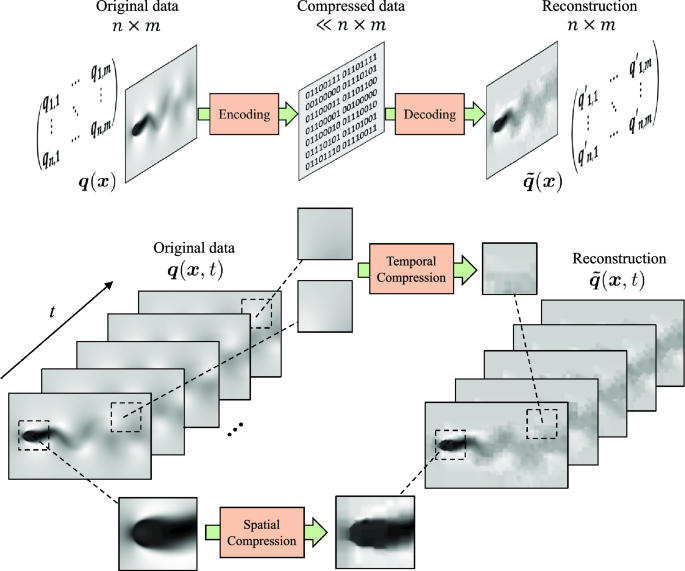

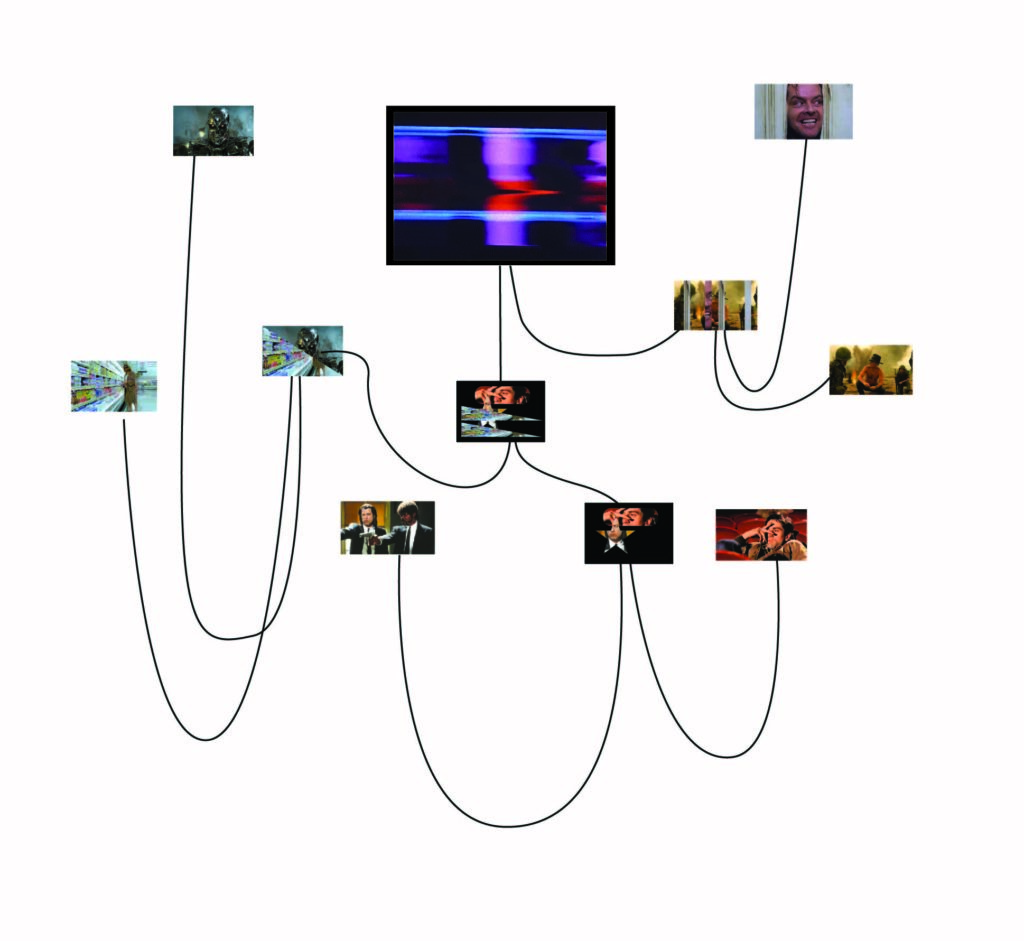

- What could I do with a stack of images from the SD card ?

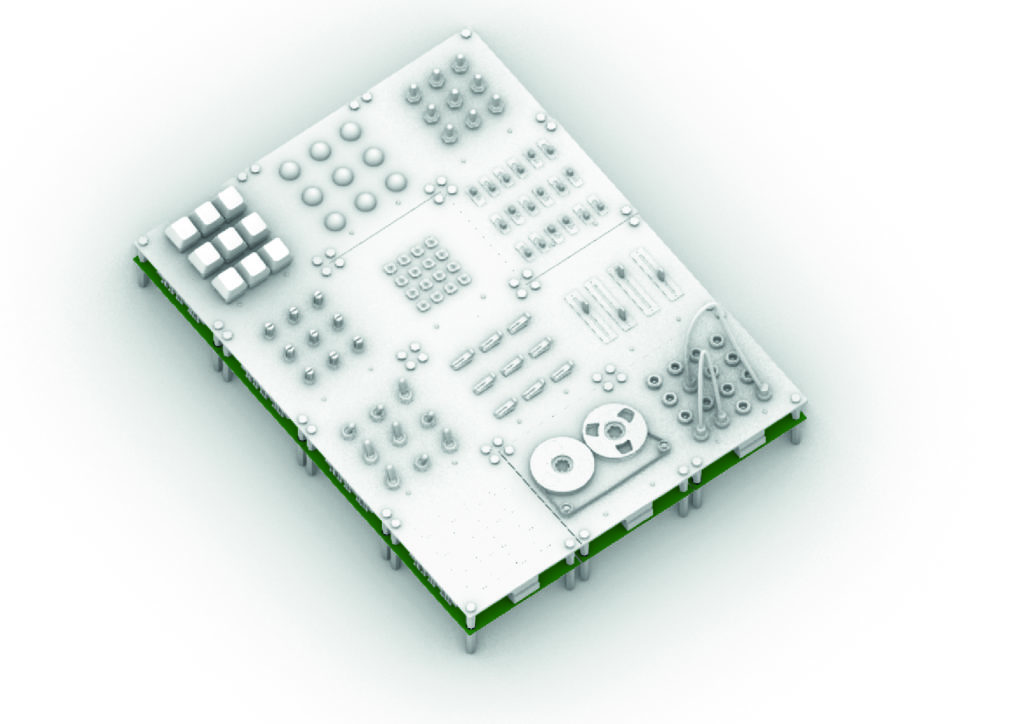

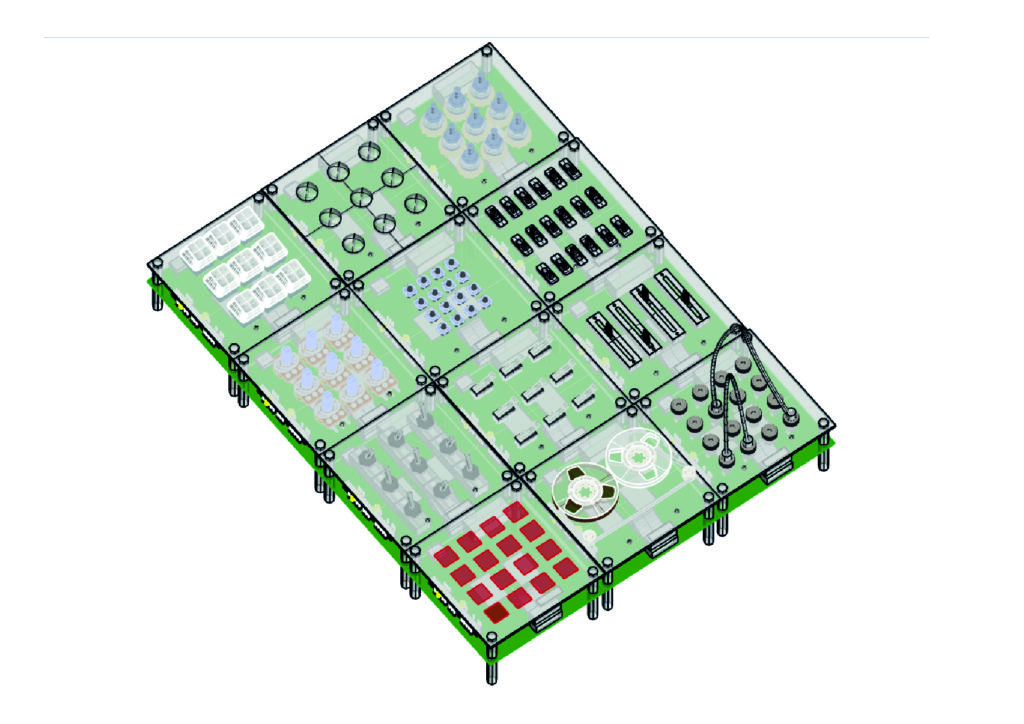

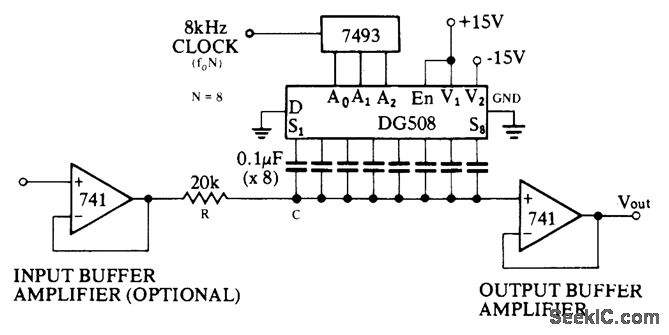

Just a reminder of what a fully fleshed out video system looks like with the Gameduino : https://excamera.com/files/gameduino/synth/doc/gen/poster.pdf

*********

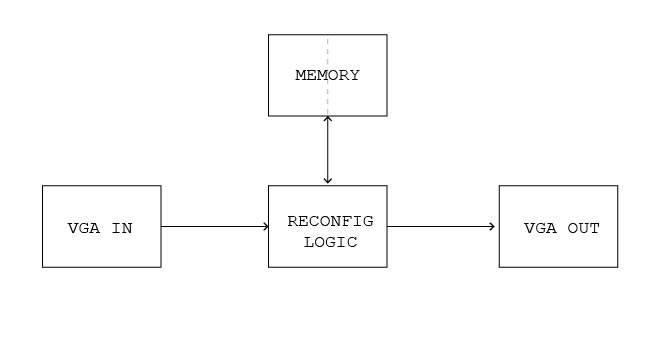

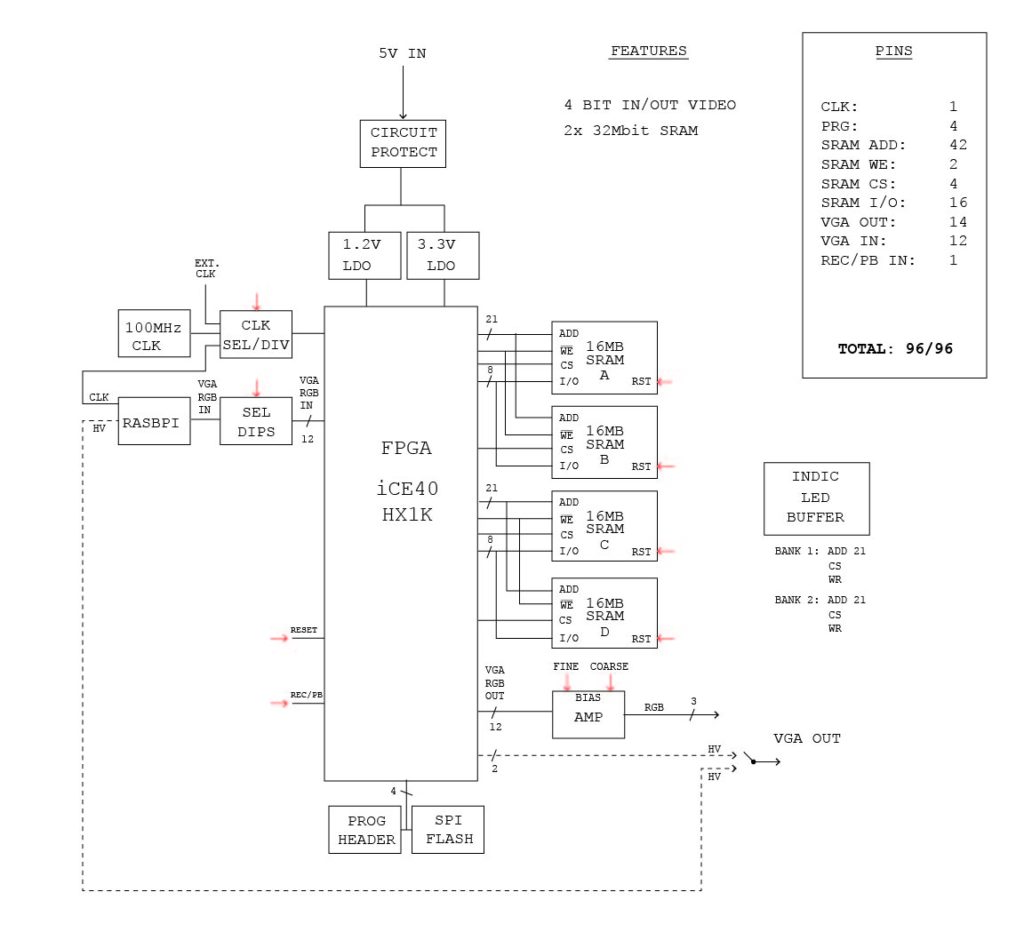

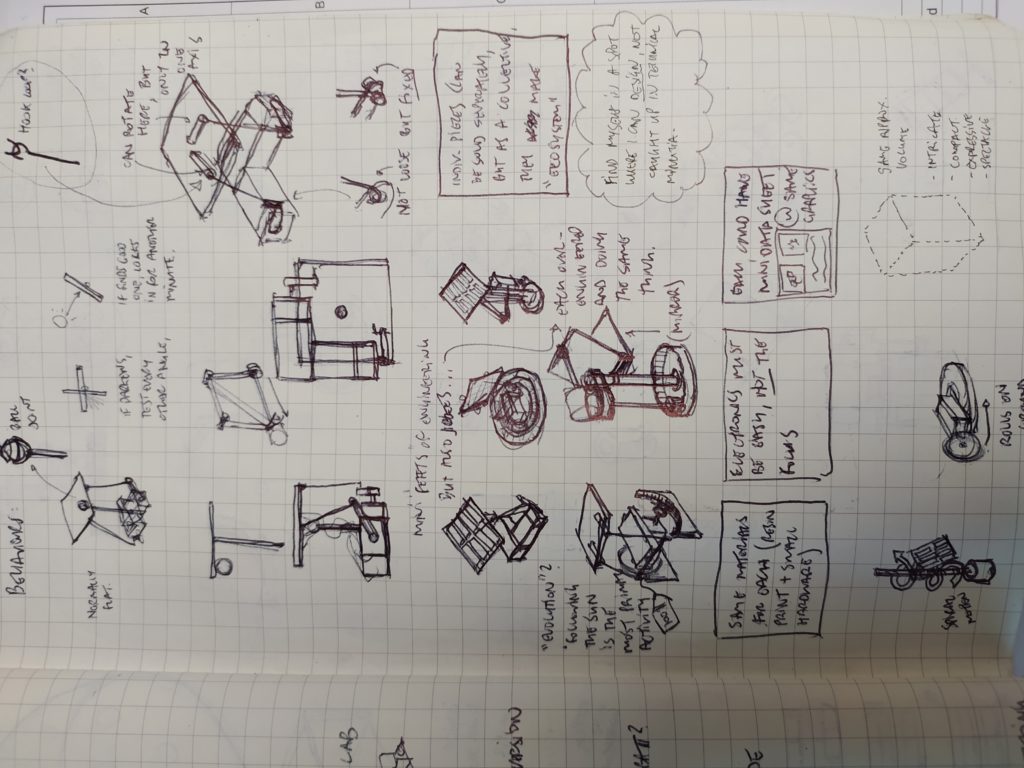

Checking-in with my project goals for 2024.

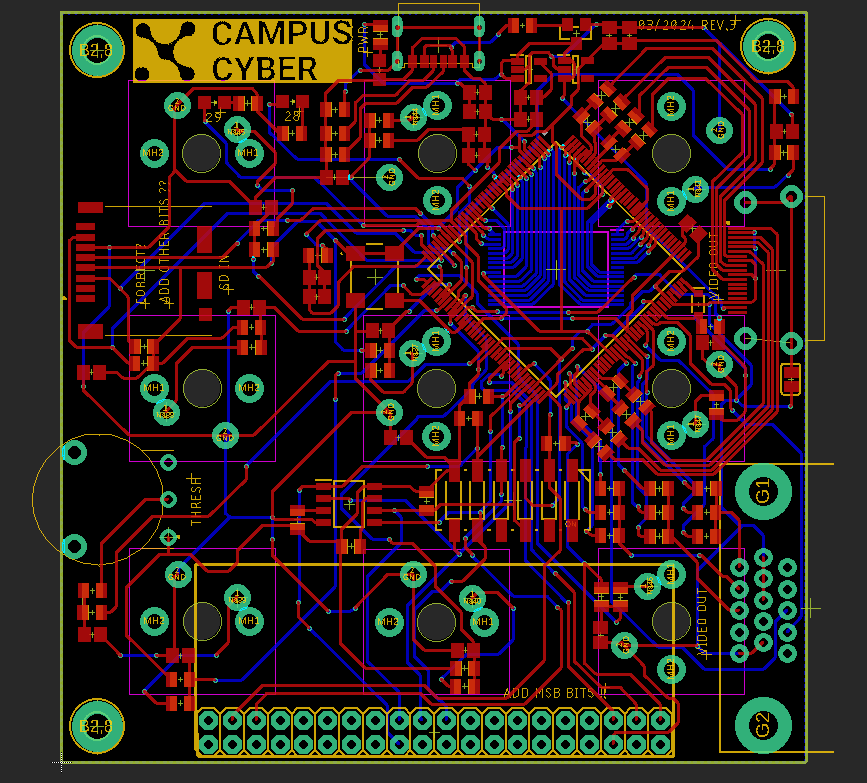

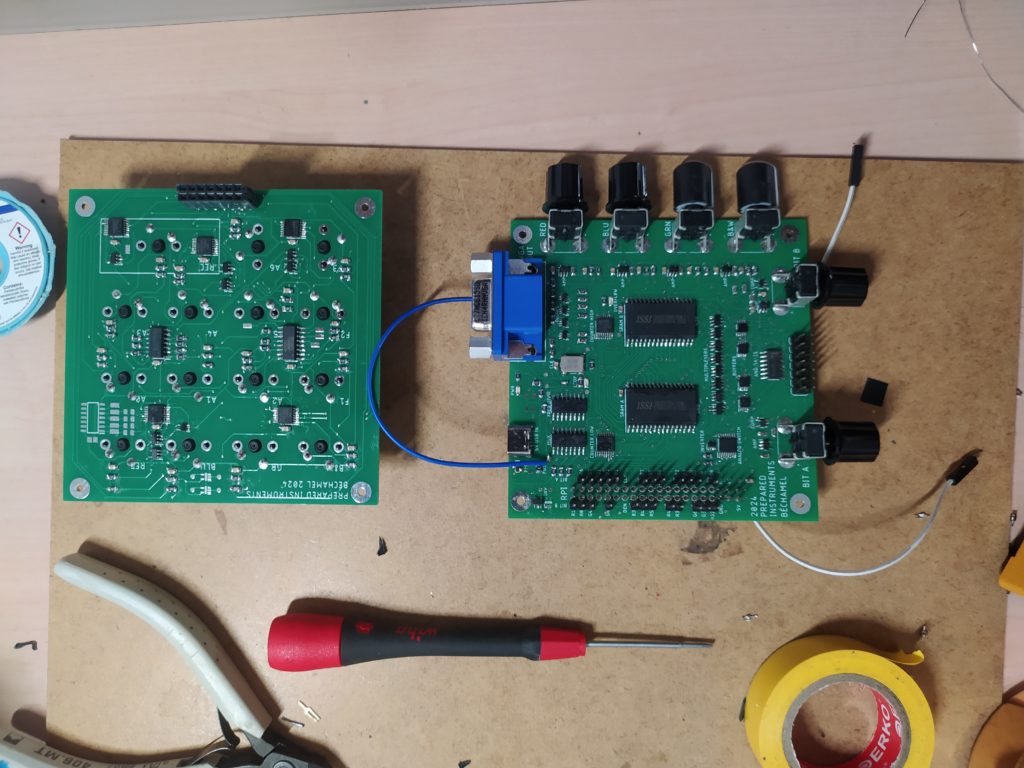

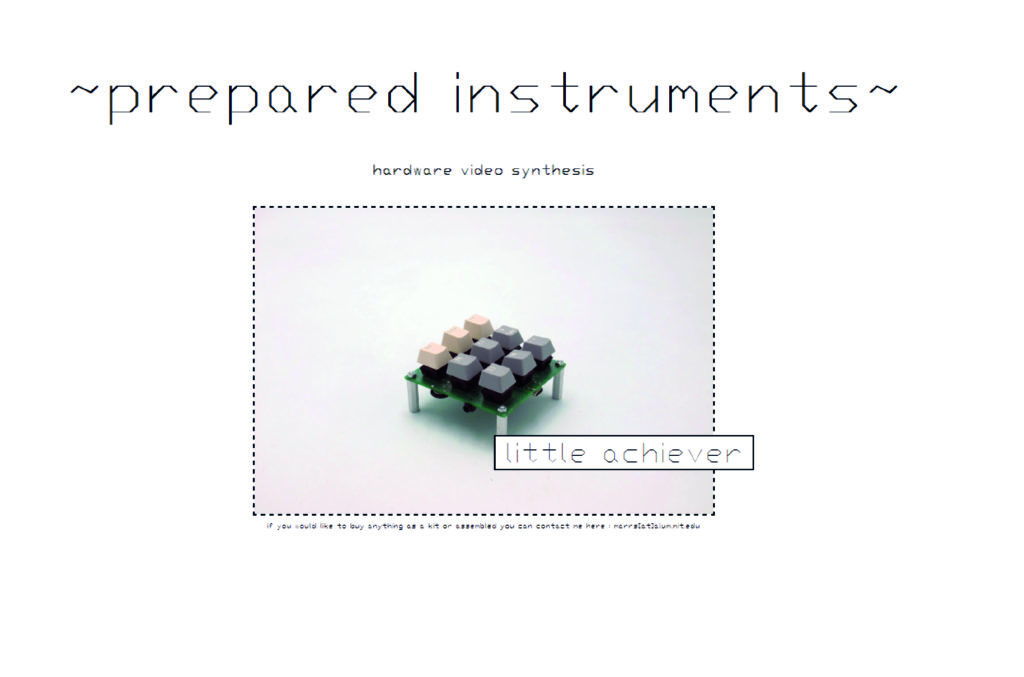

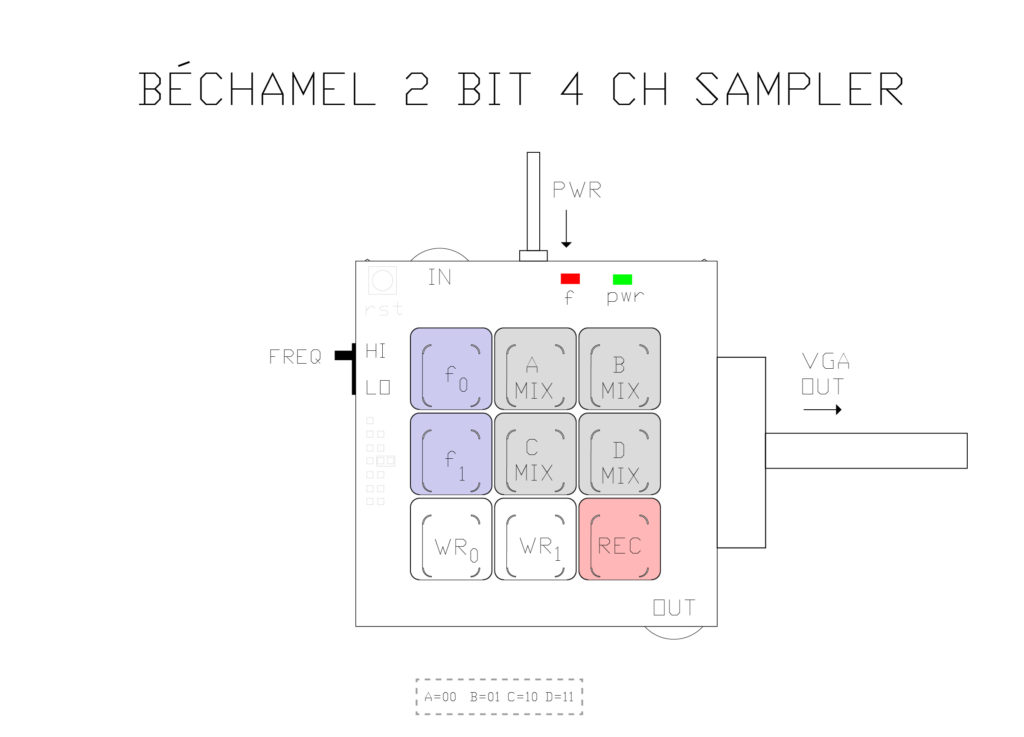

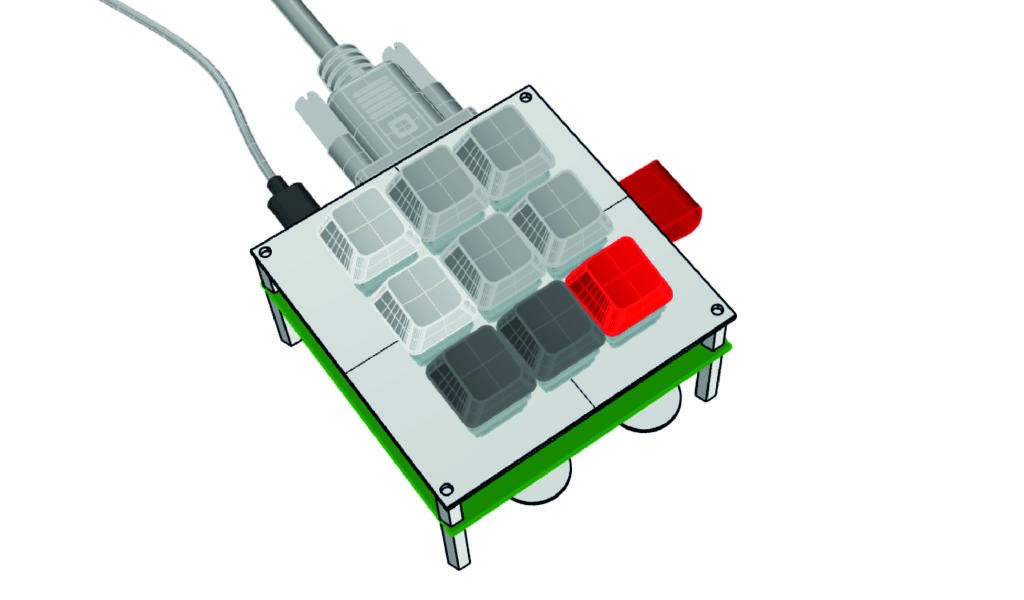

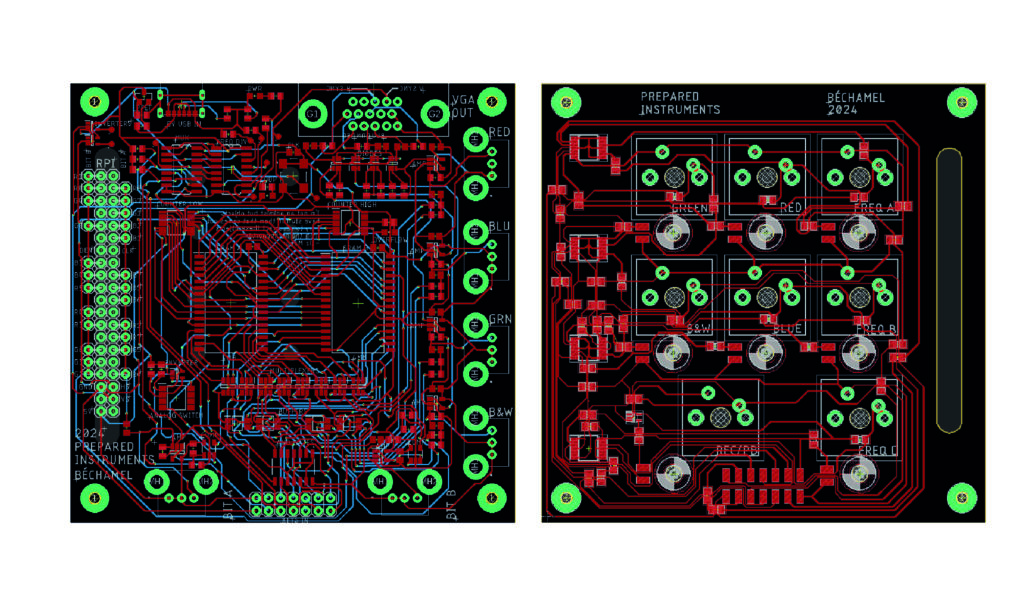

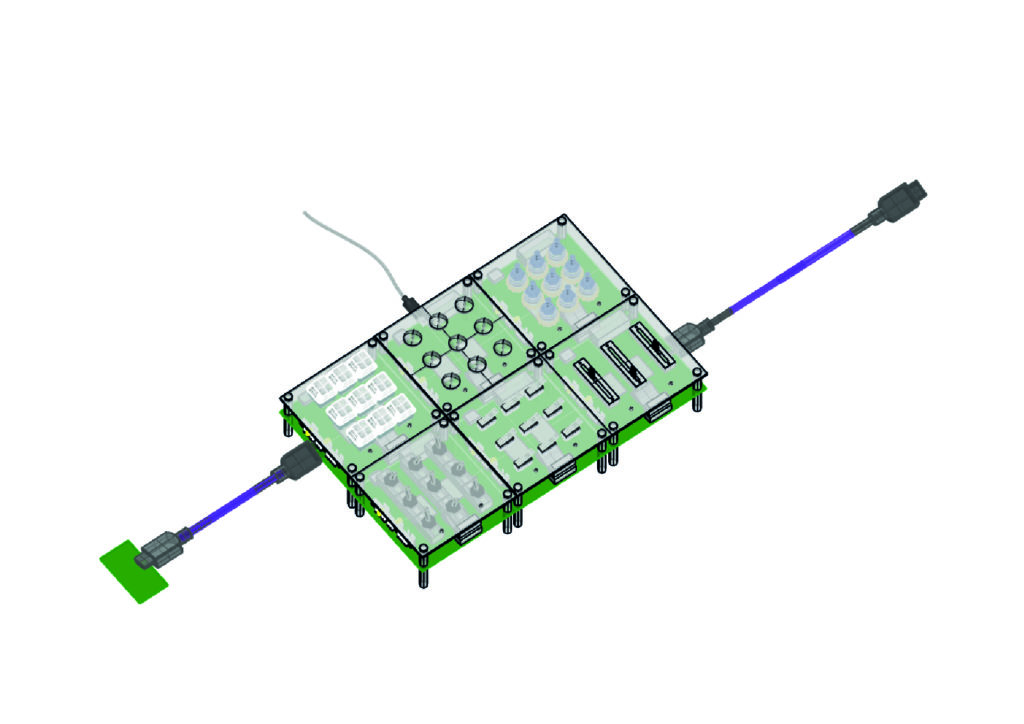

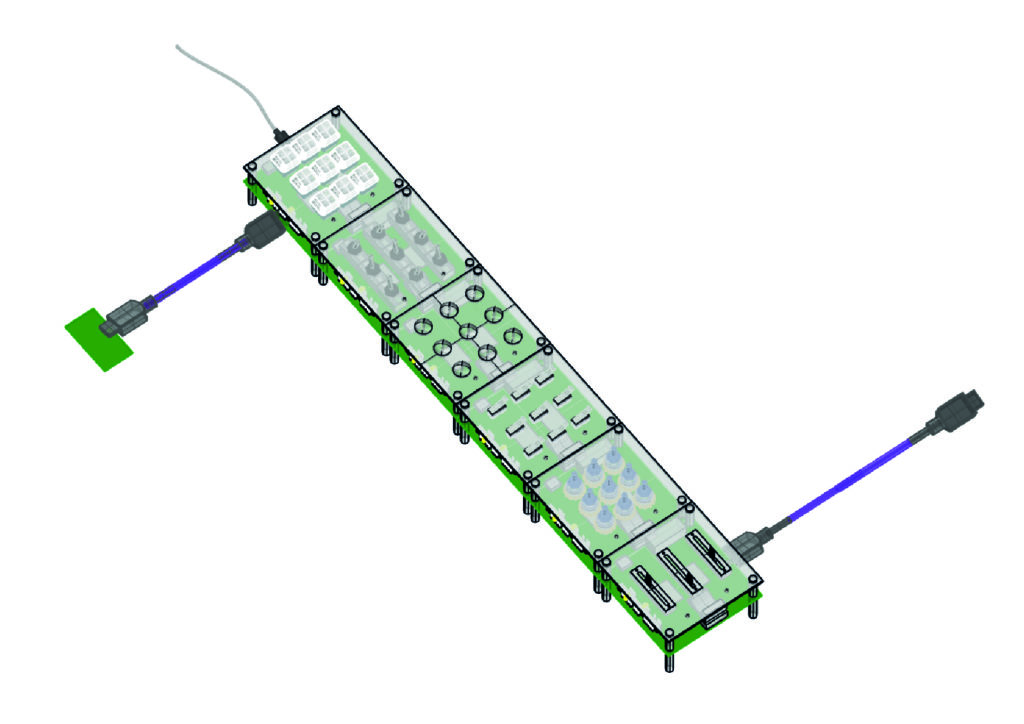

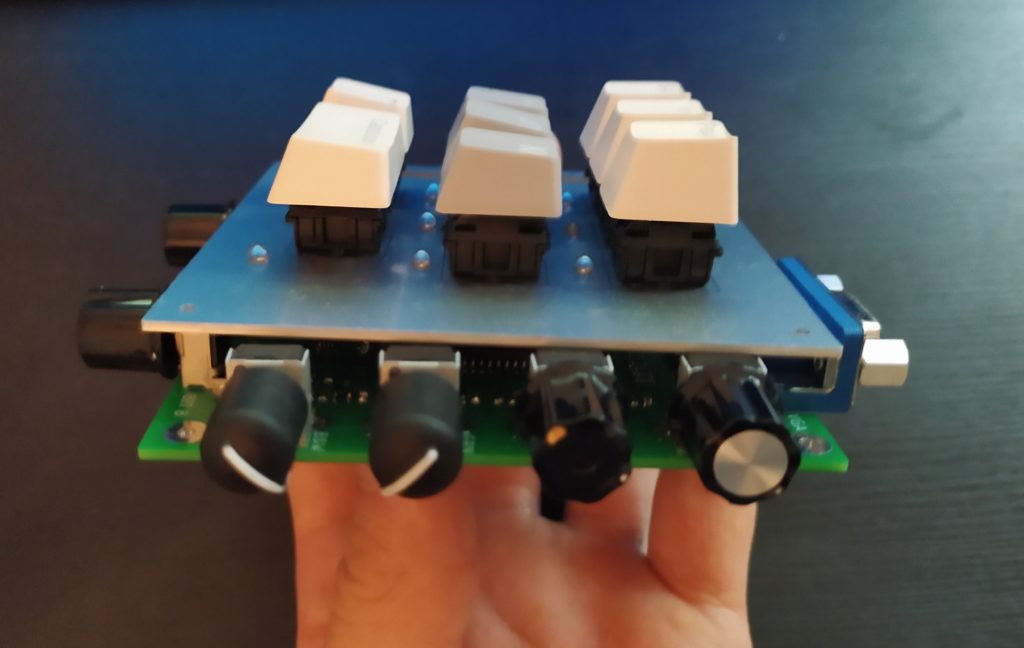

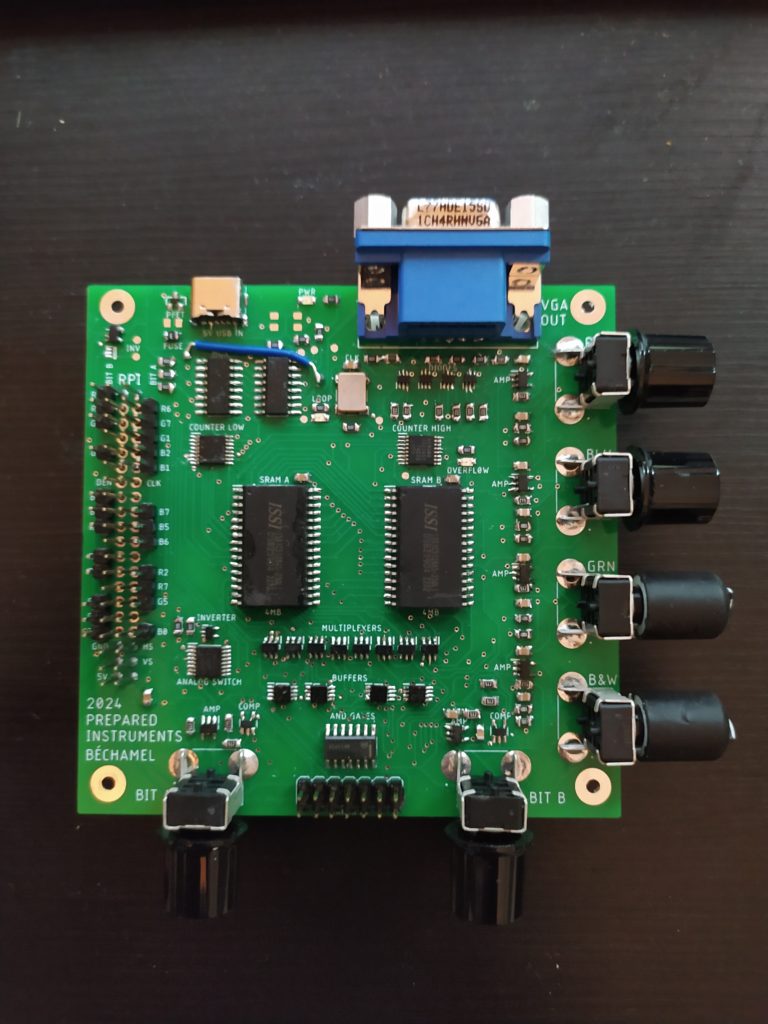

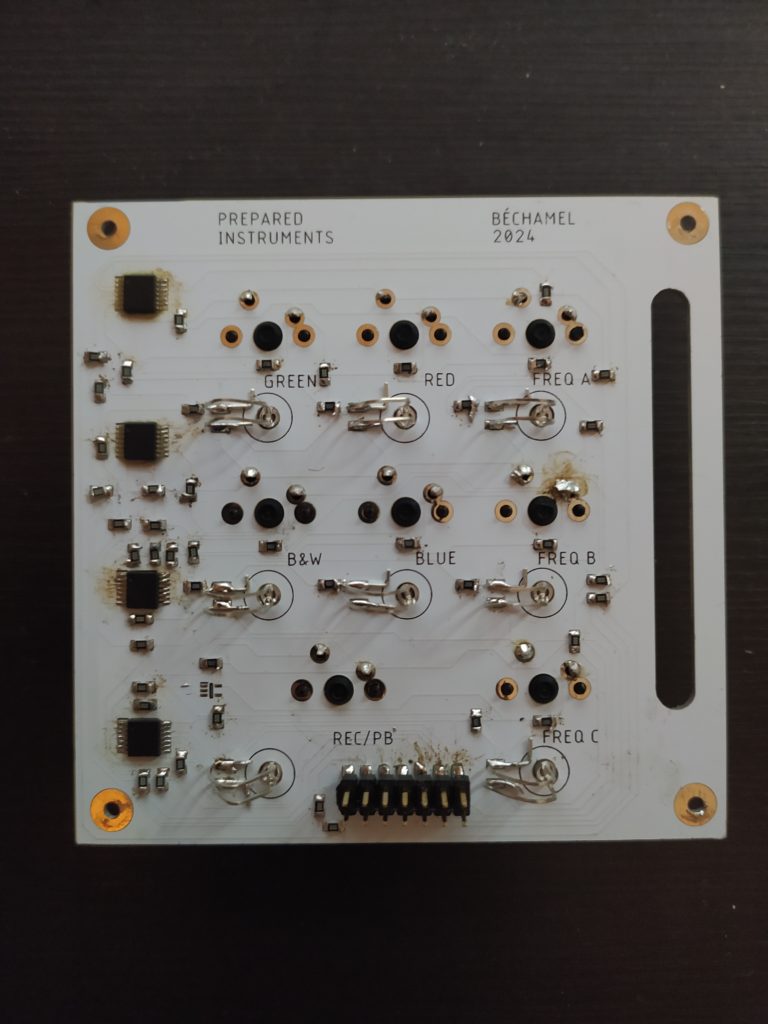

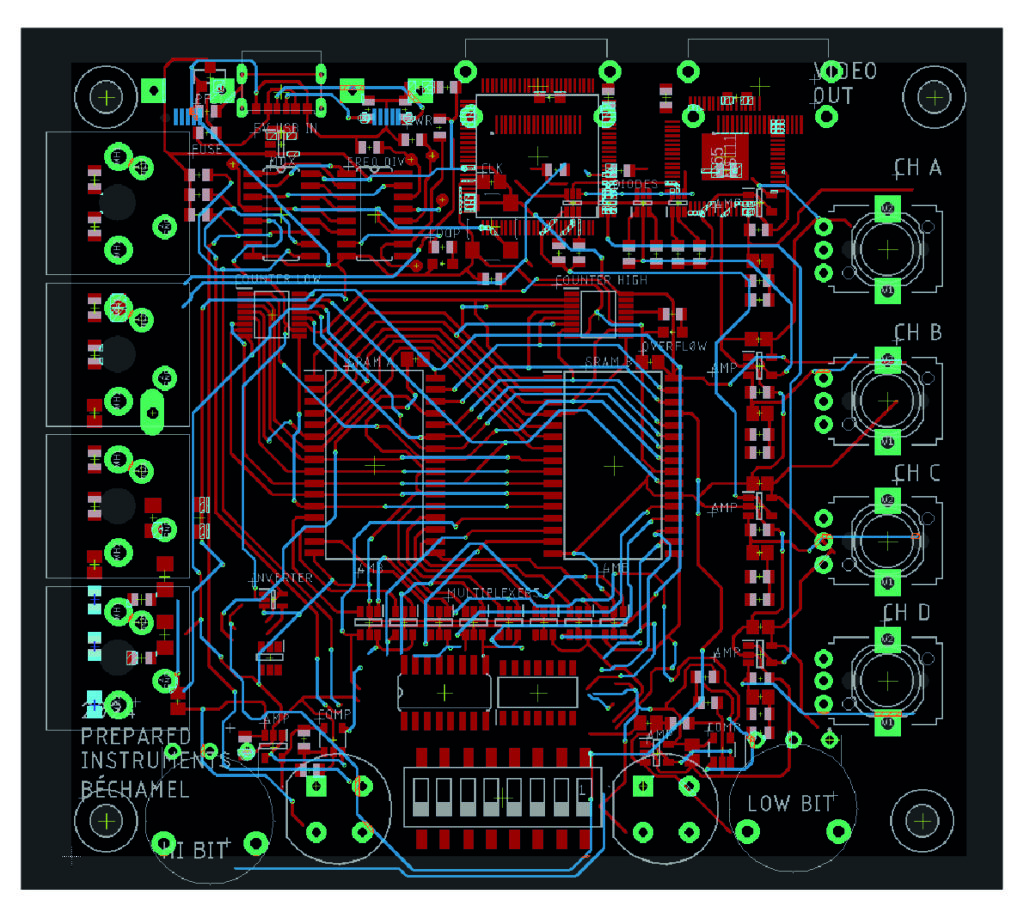

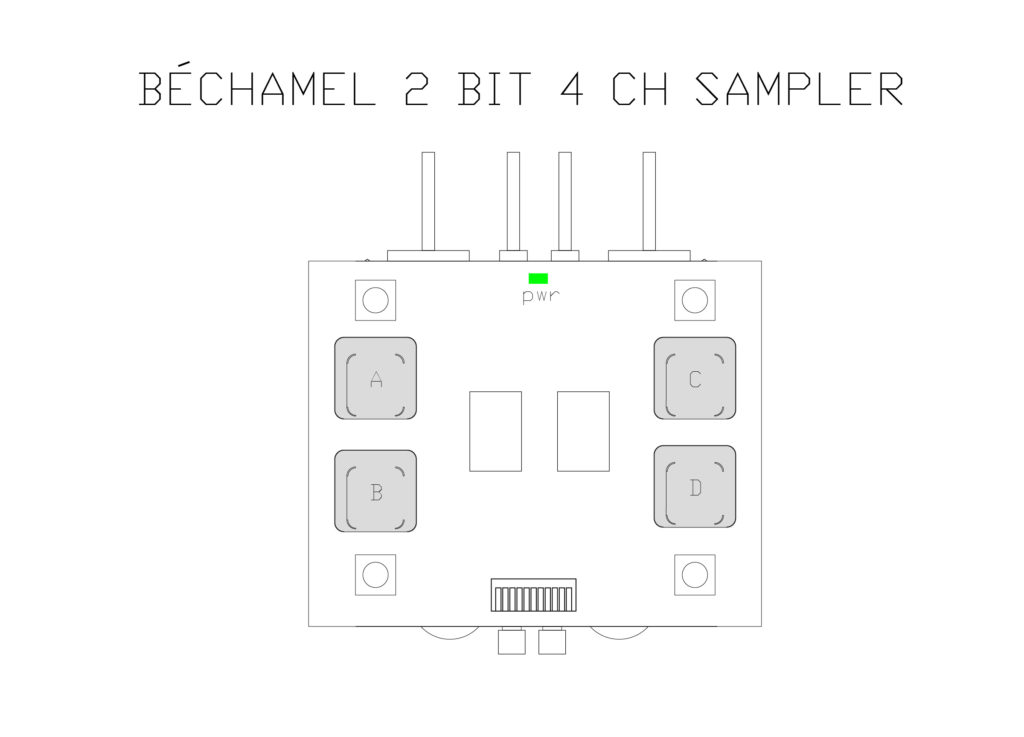

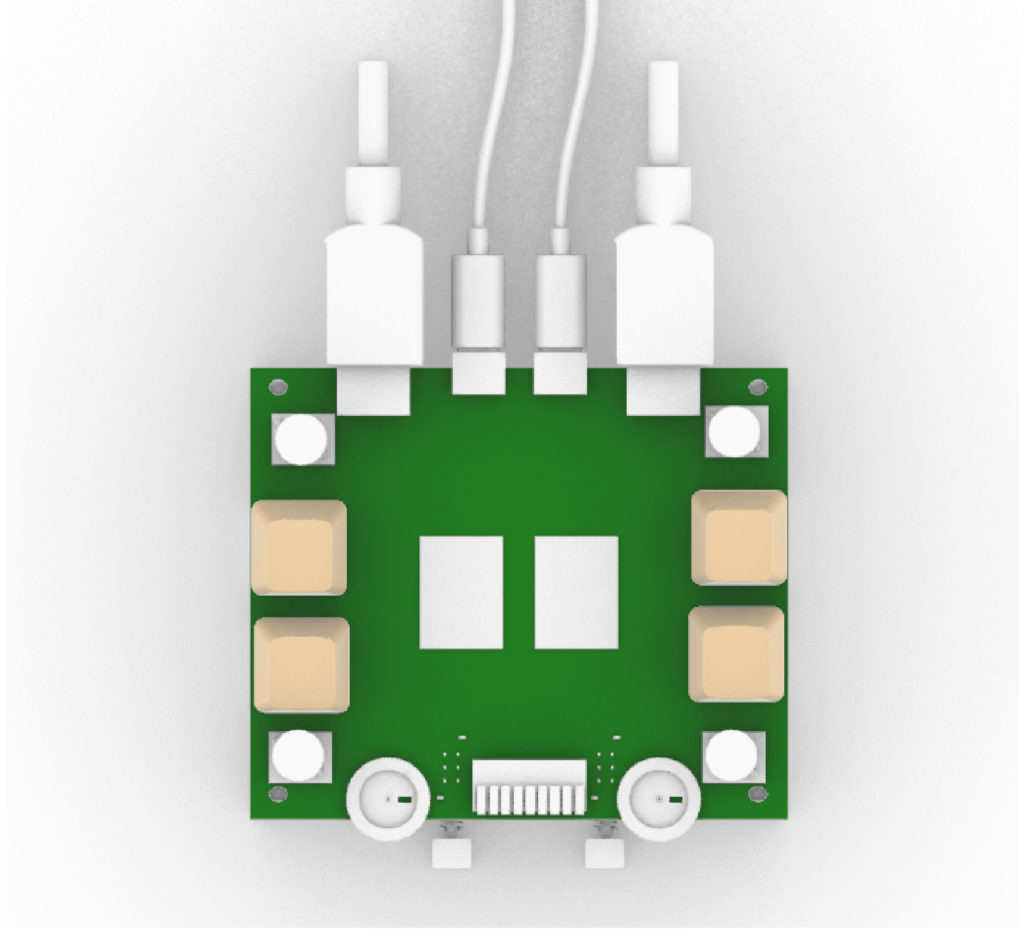

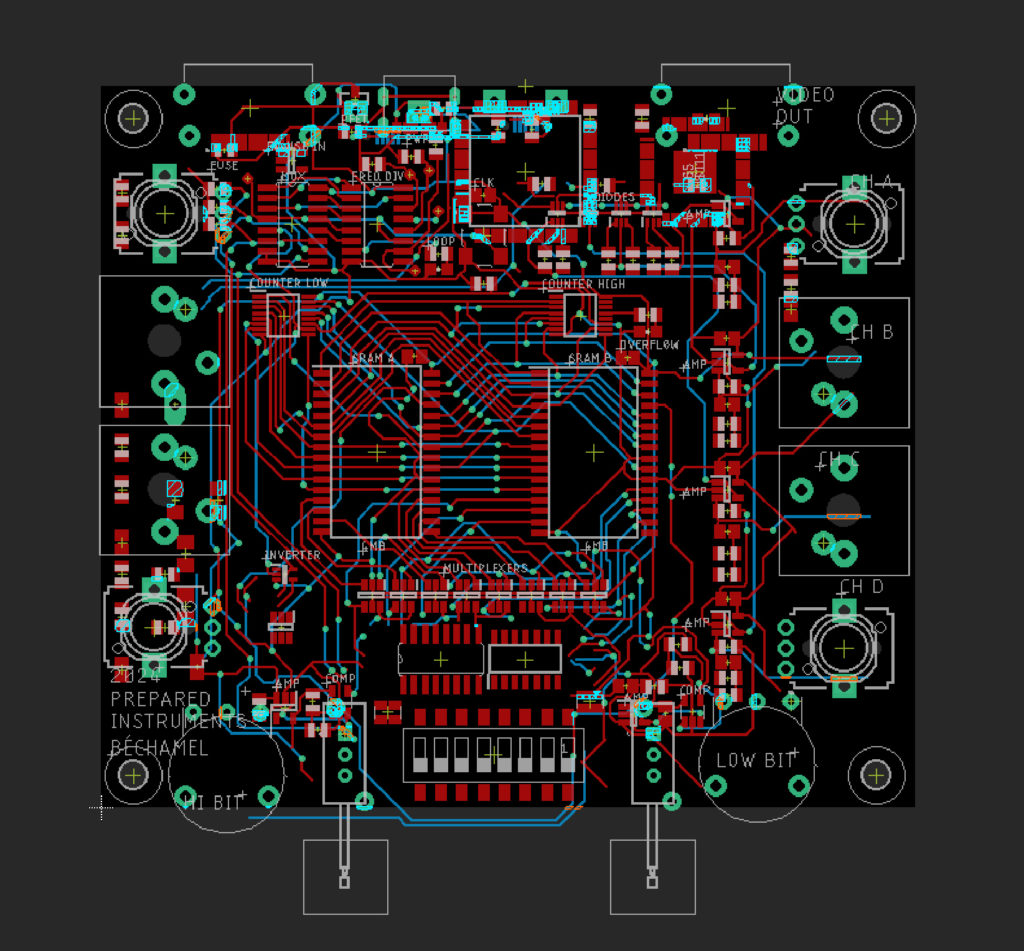

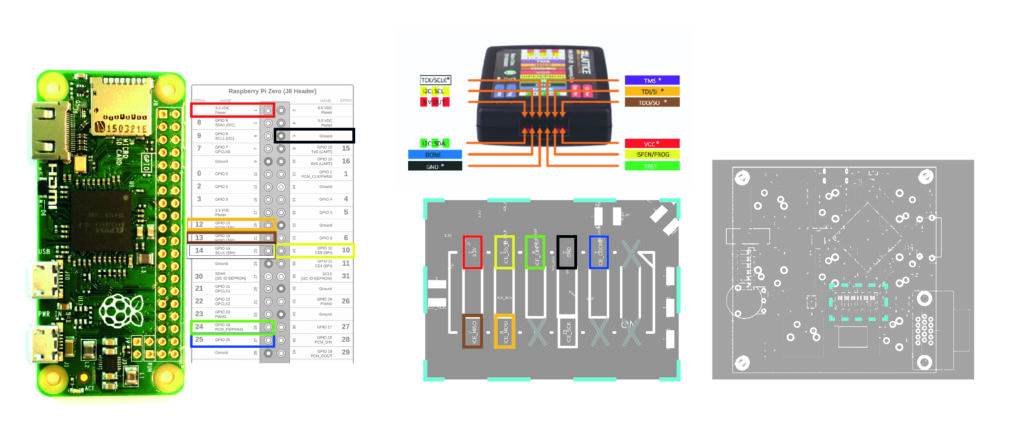

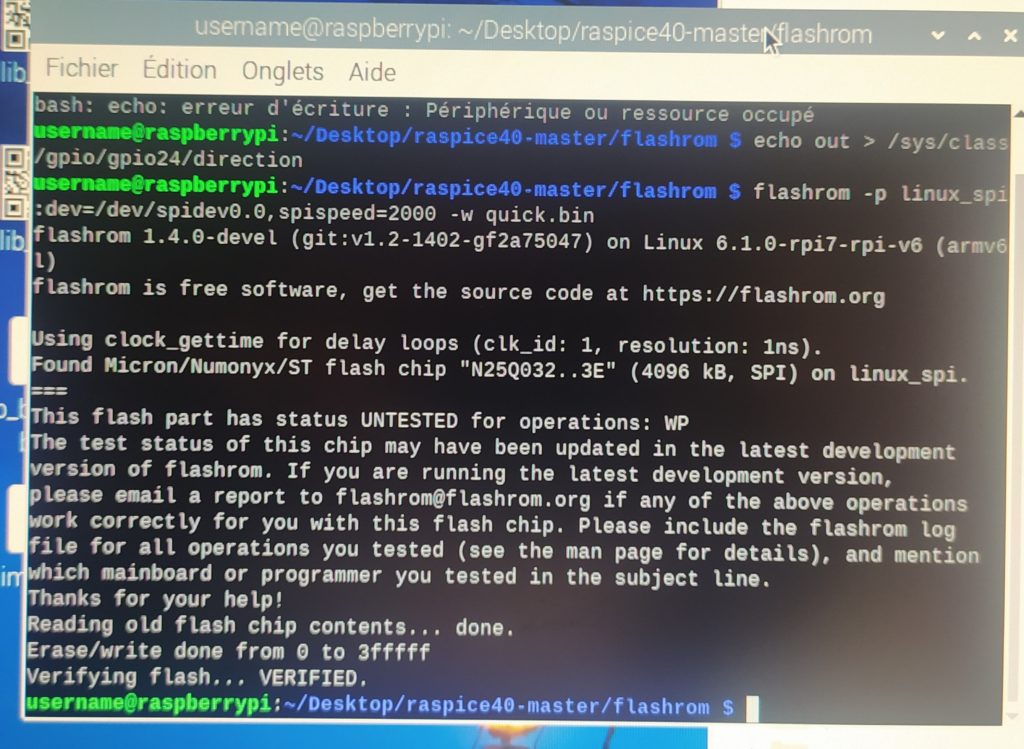

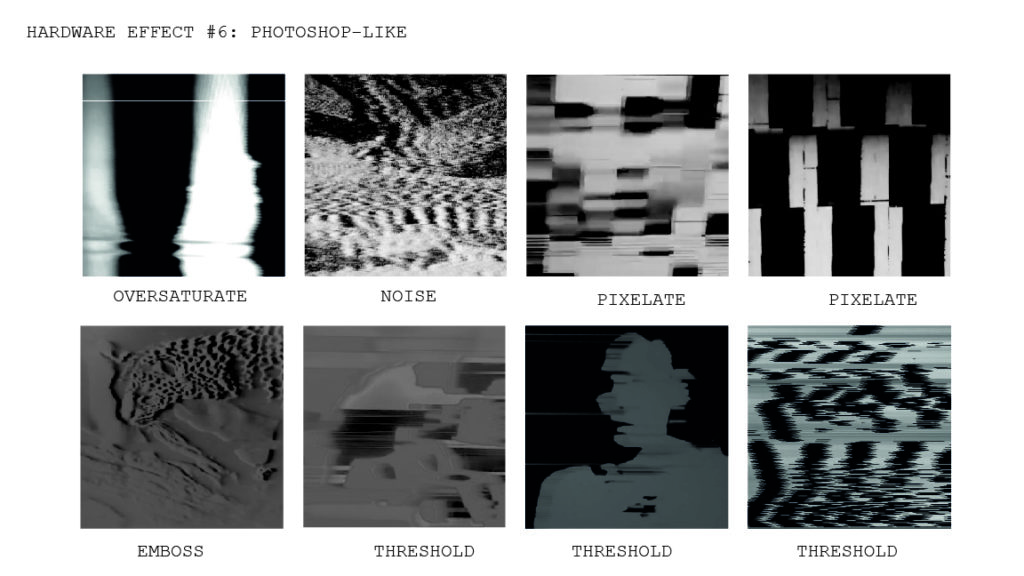

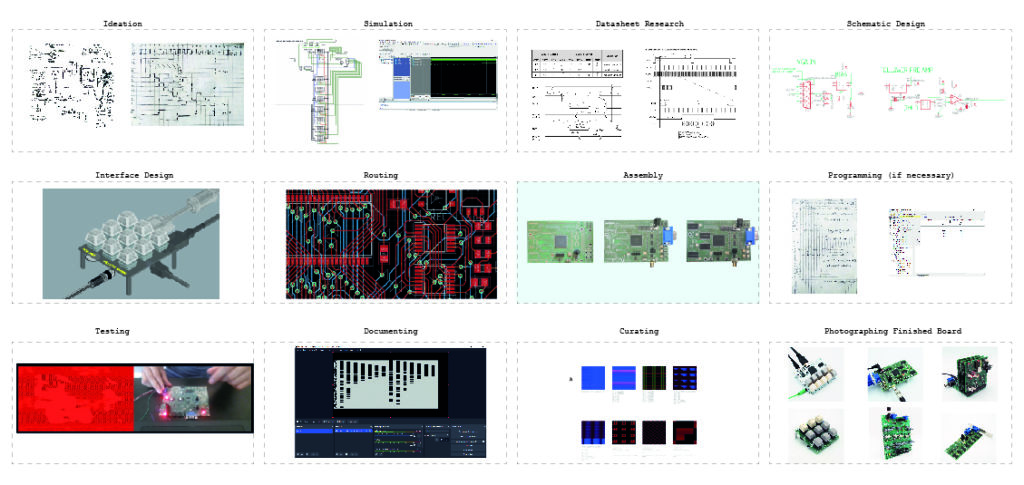

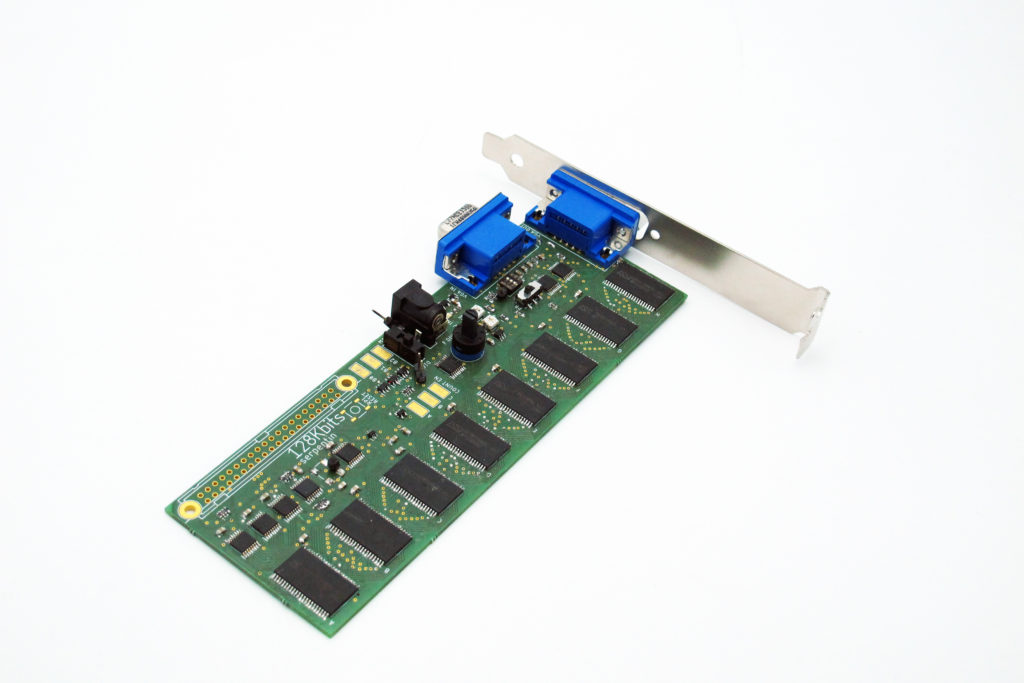

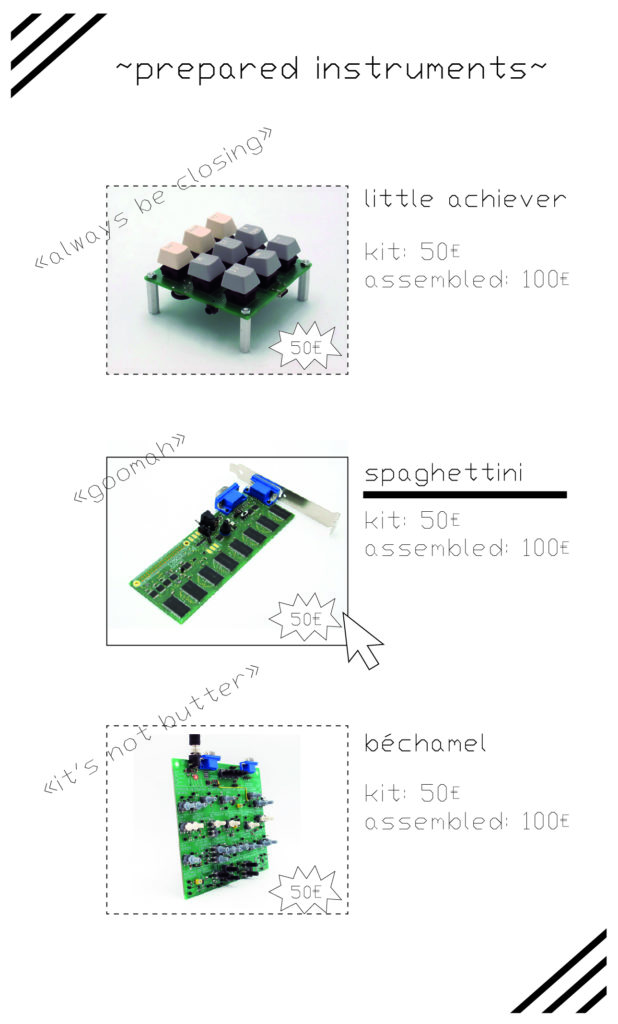

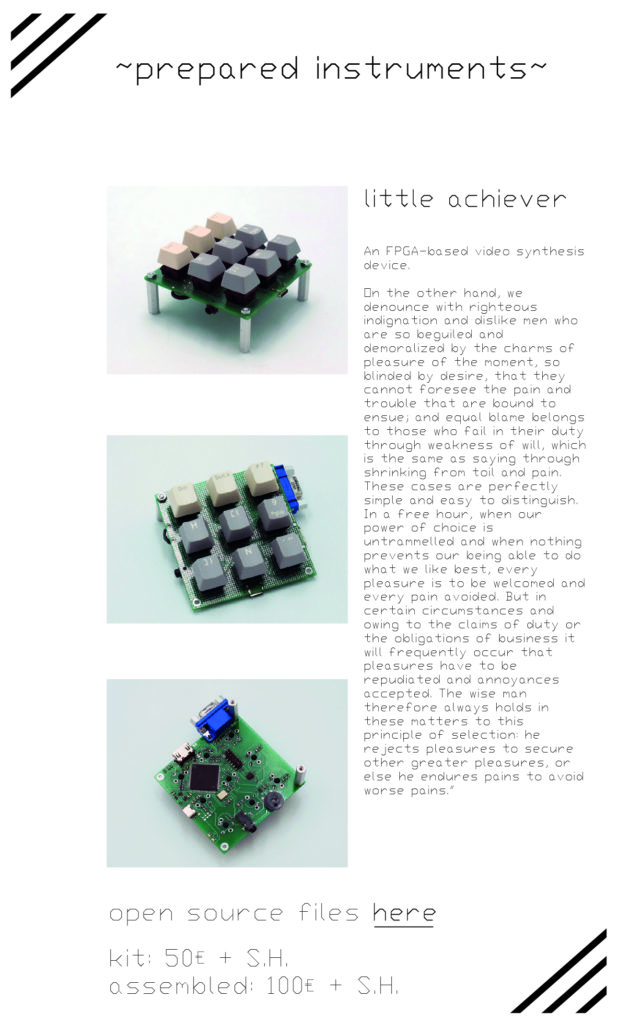

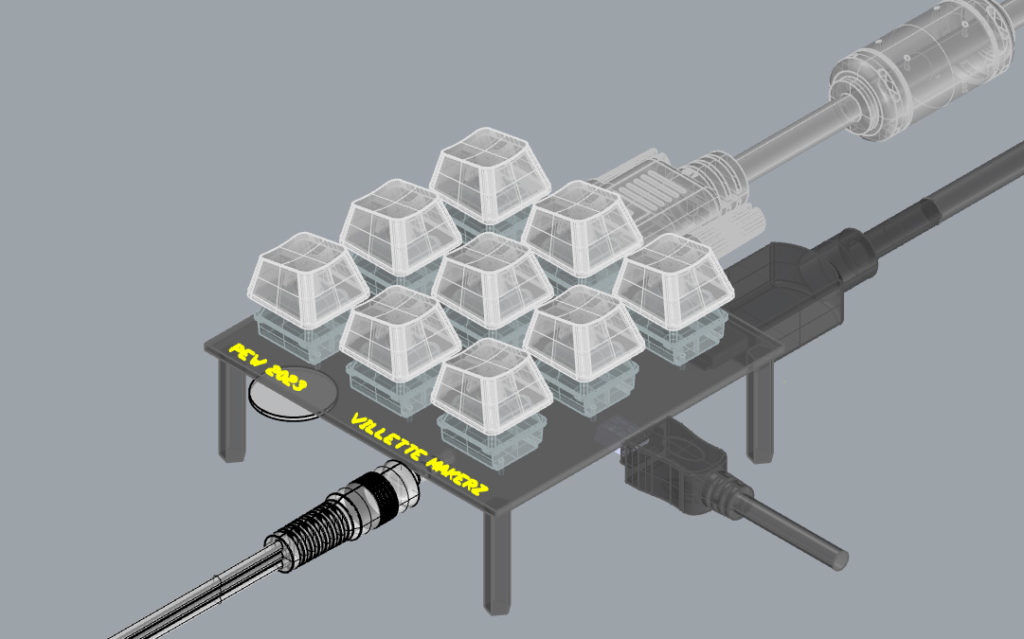

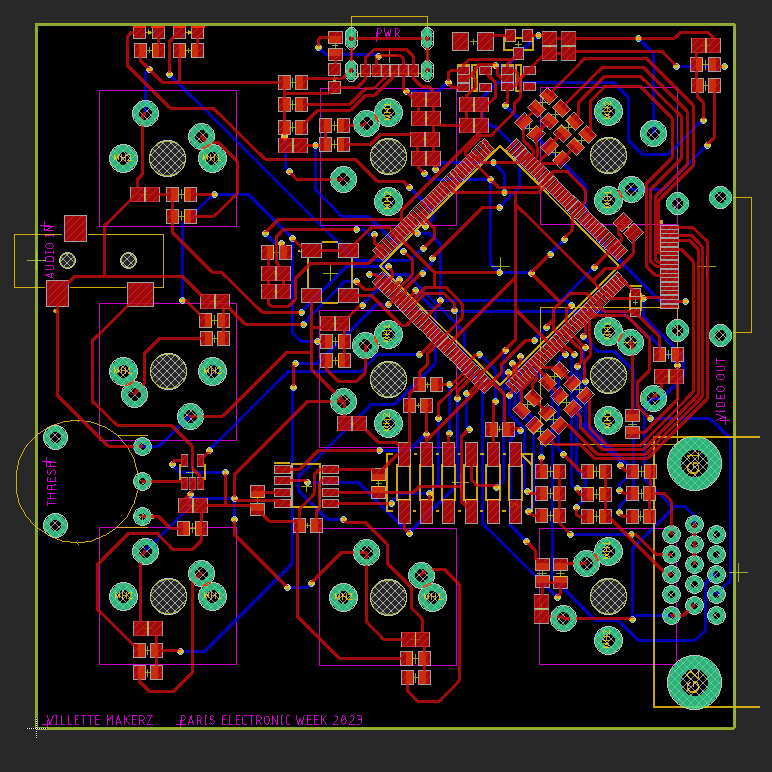

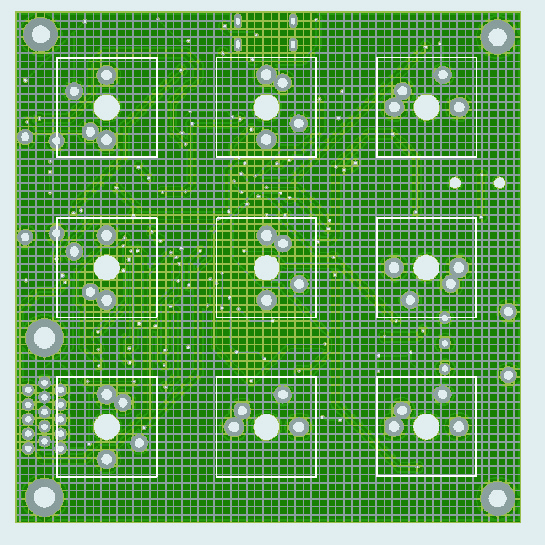

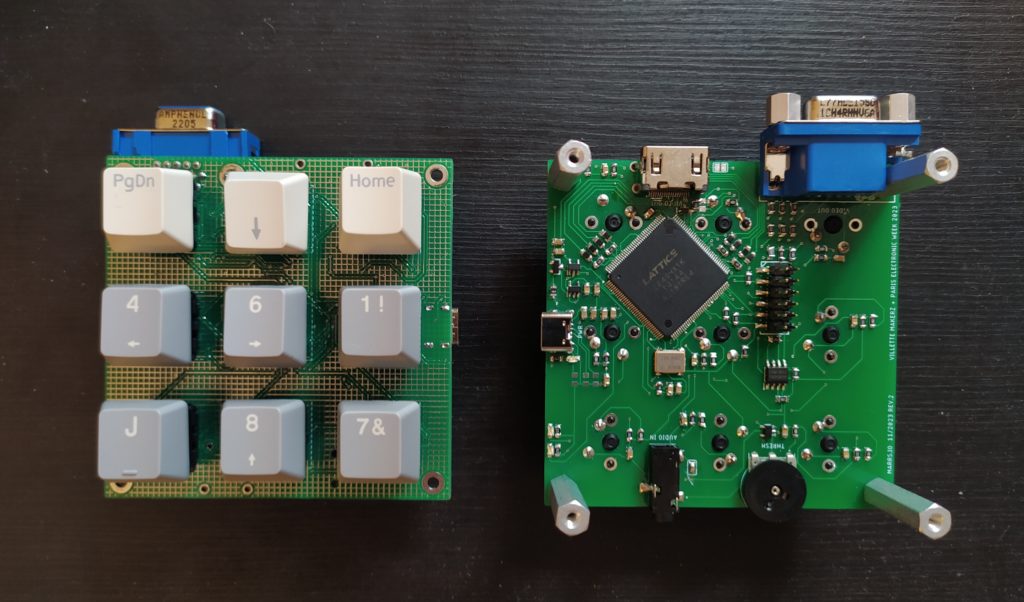

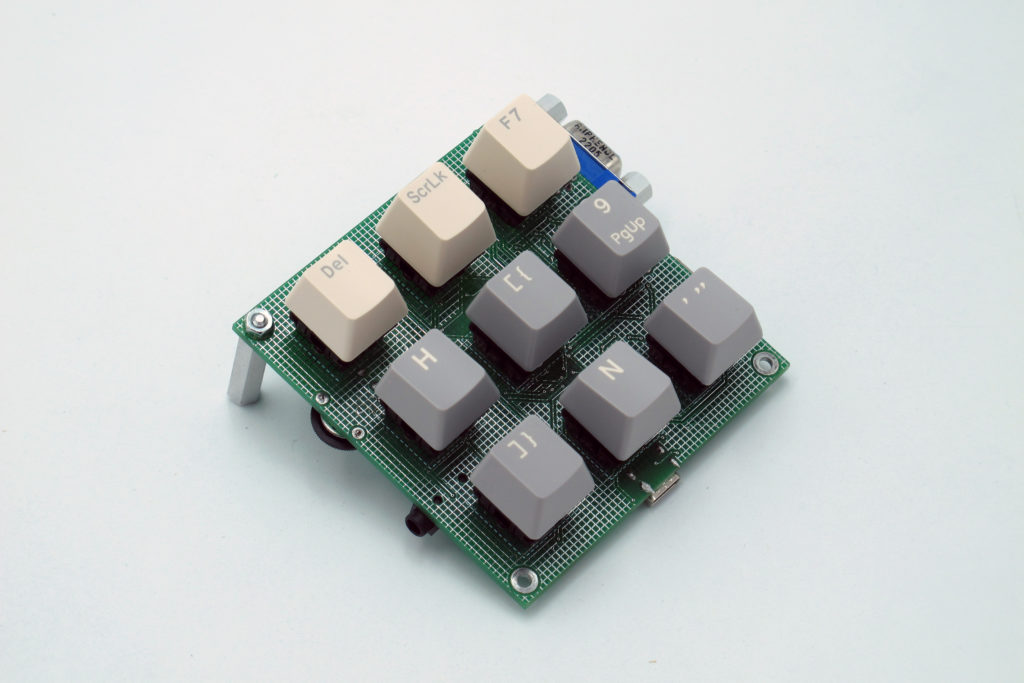

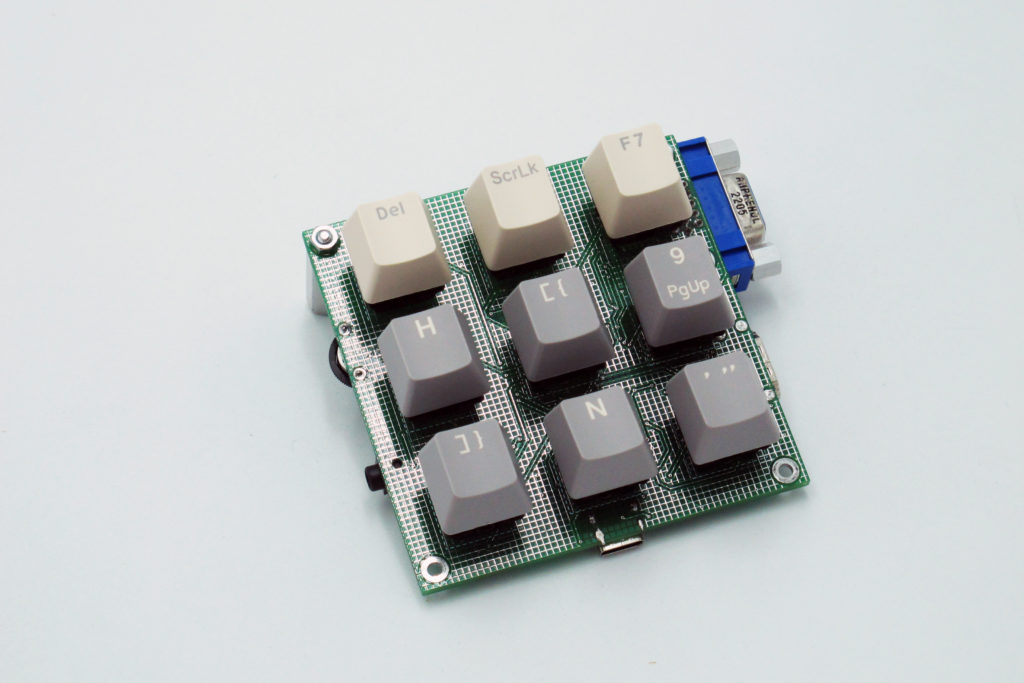

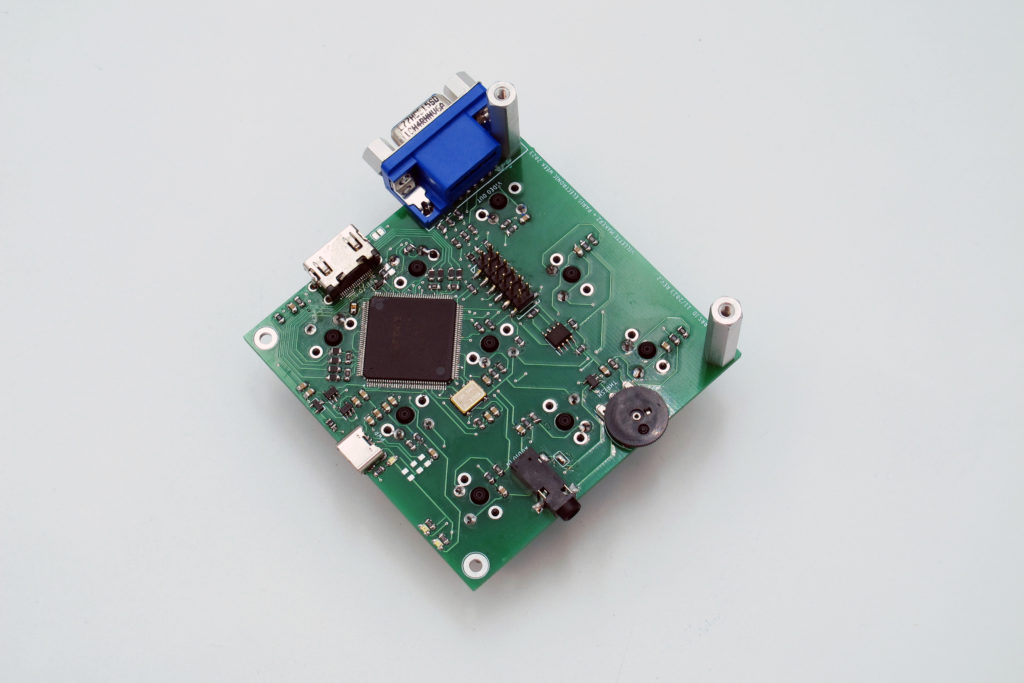

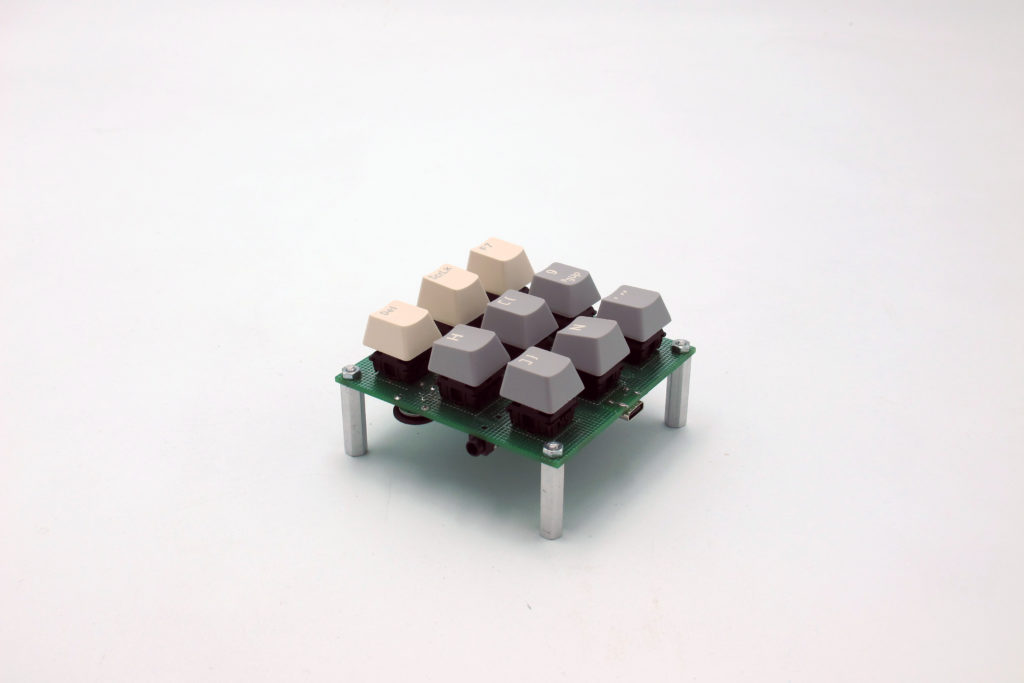

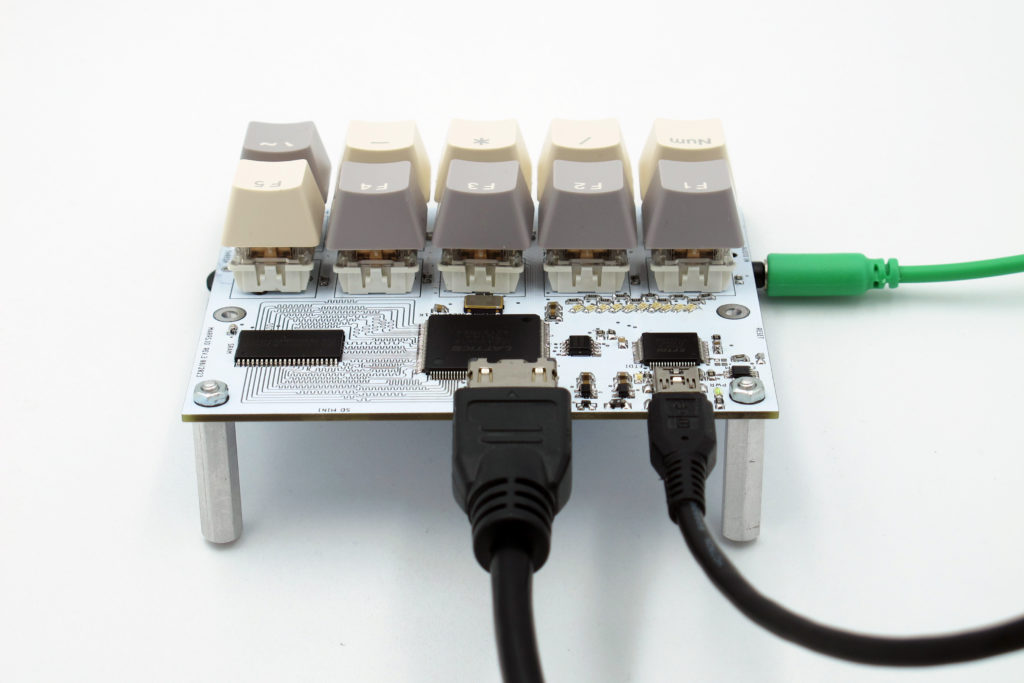

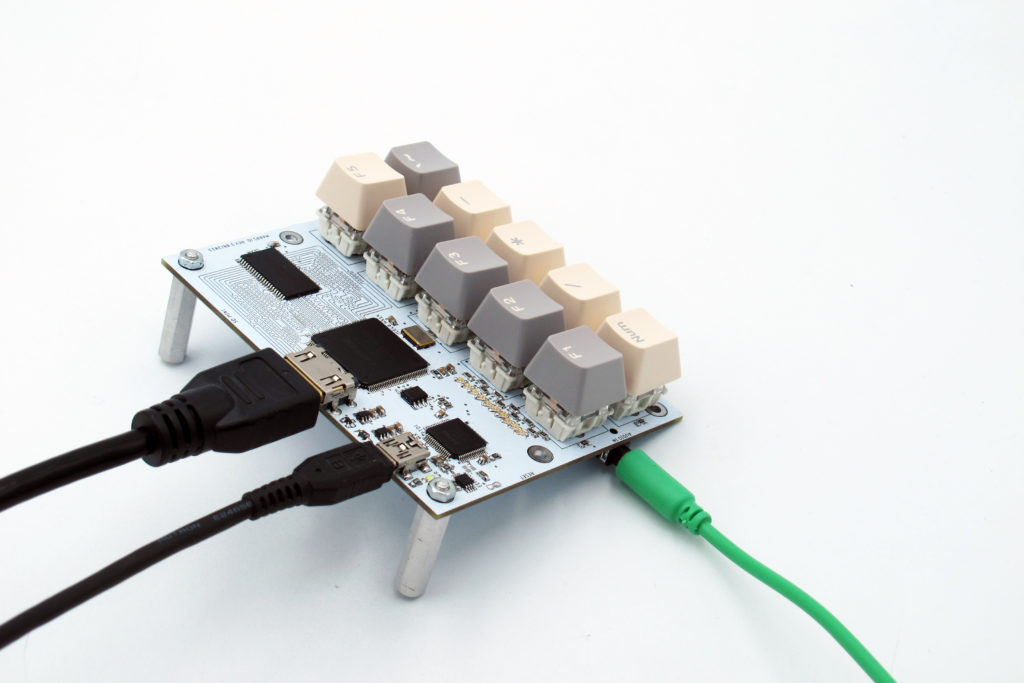

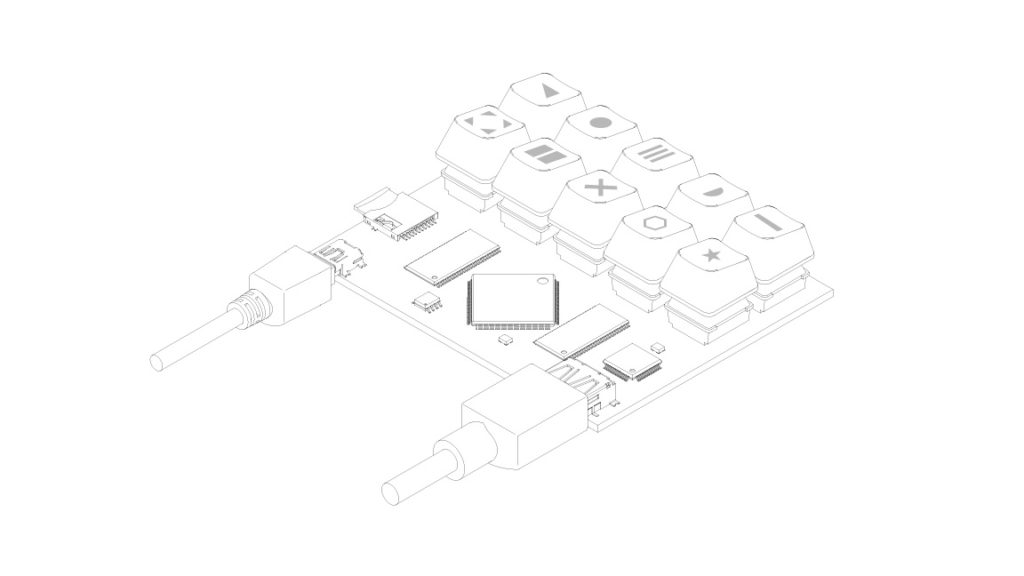

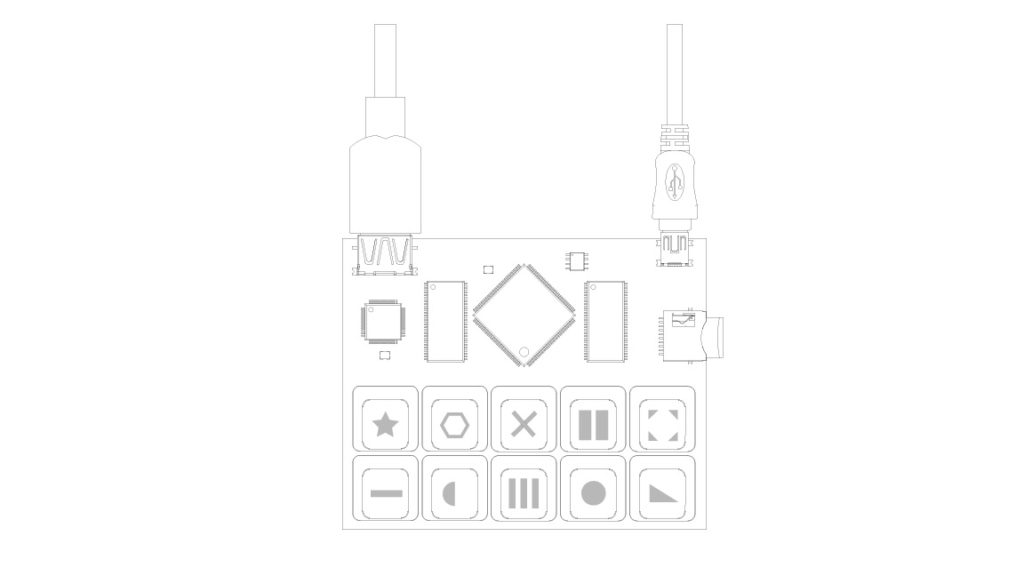

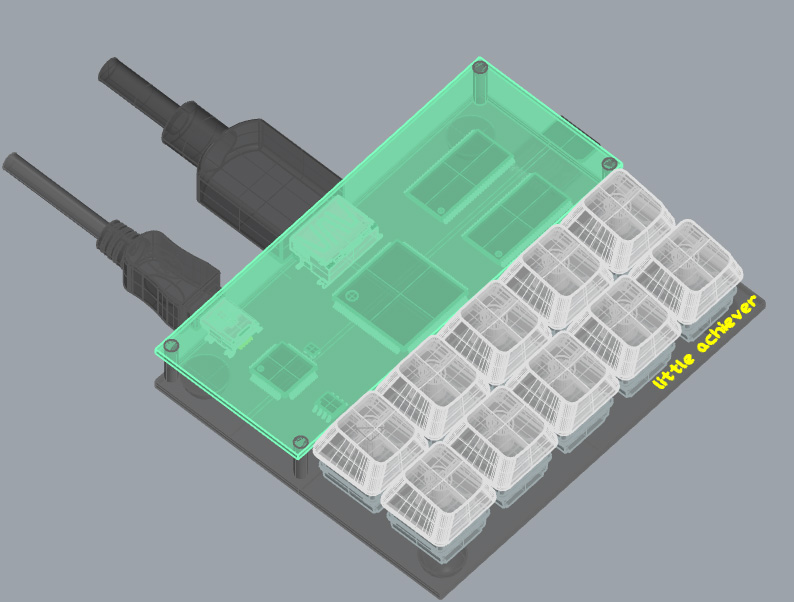

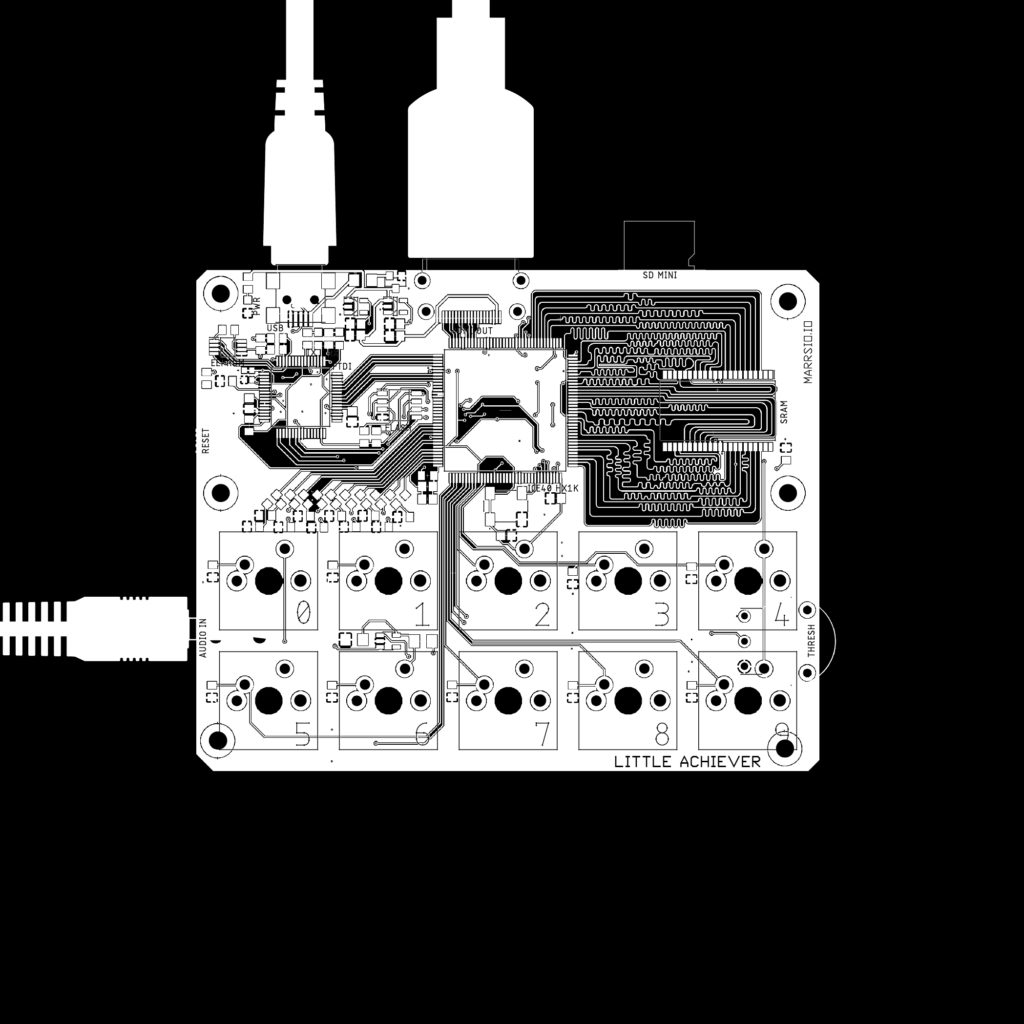

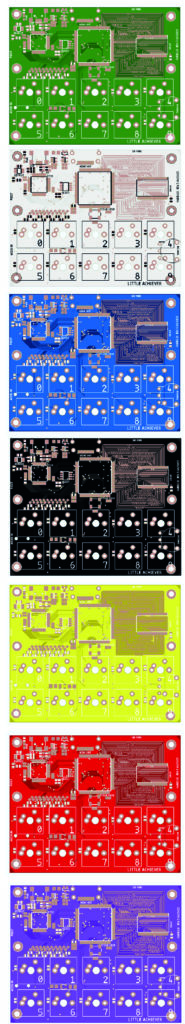

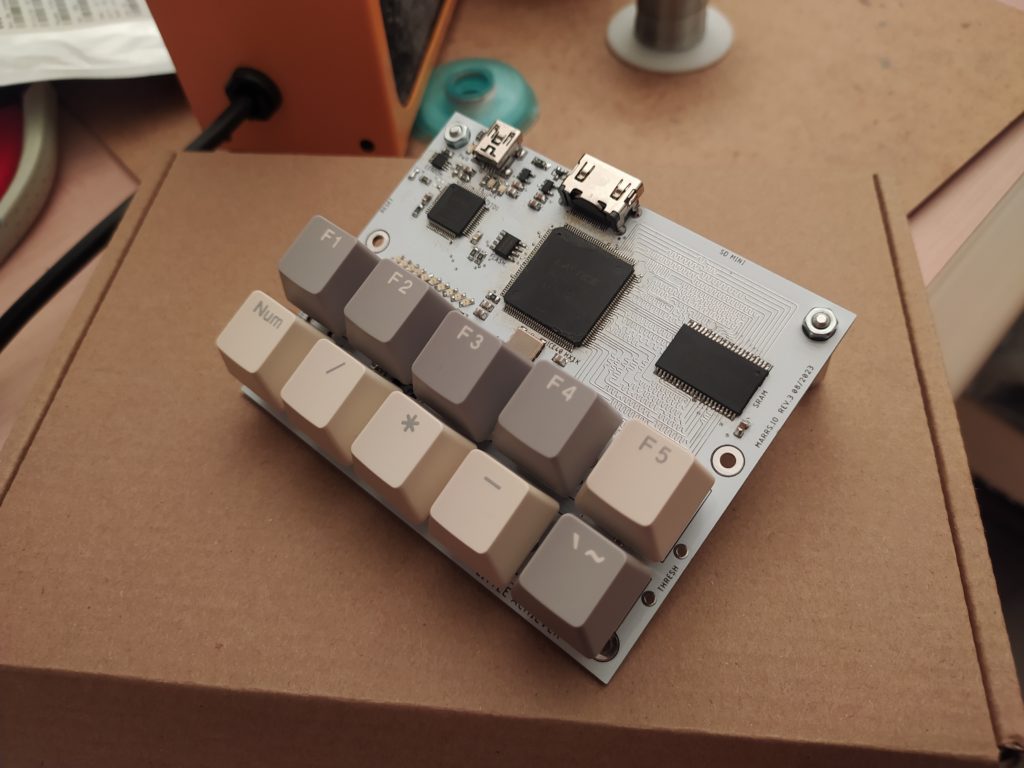

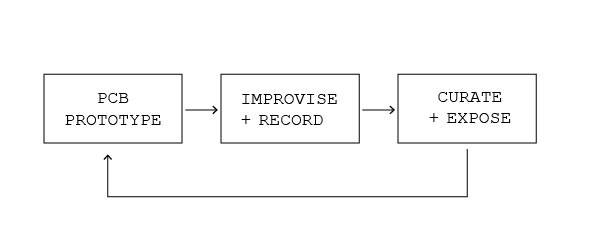

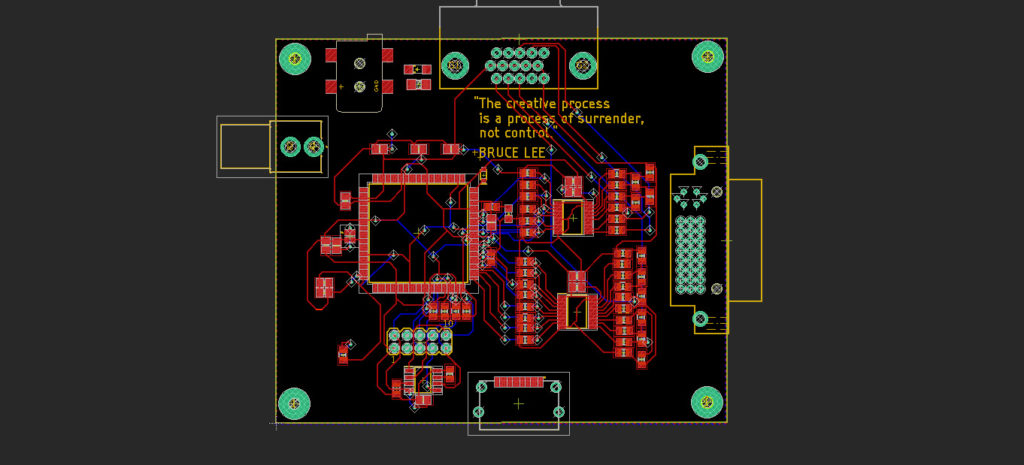

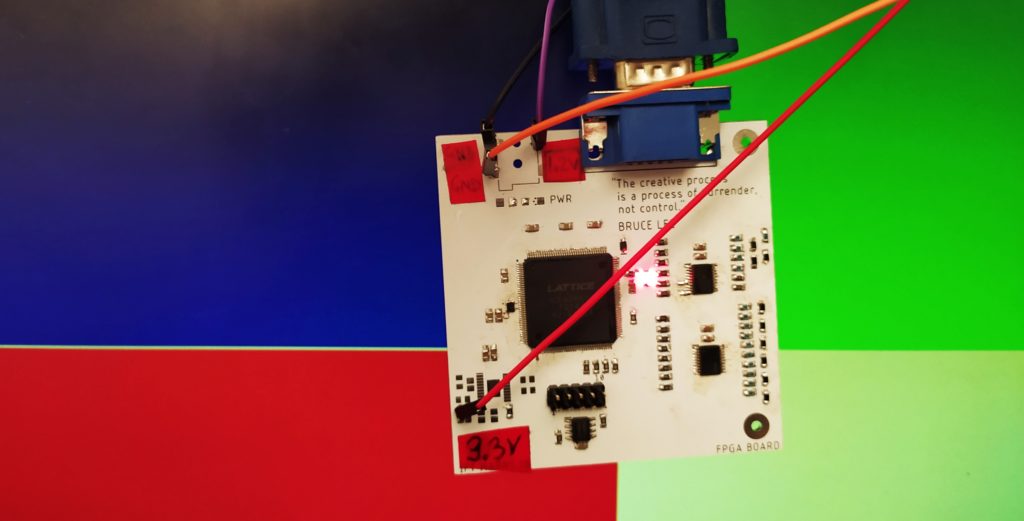

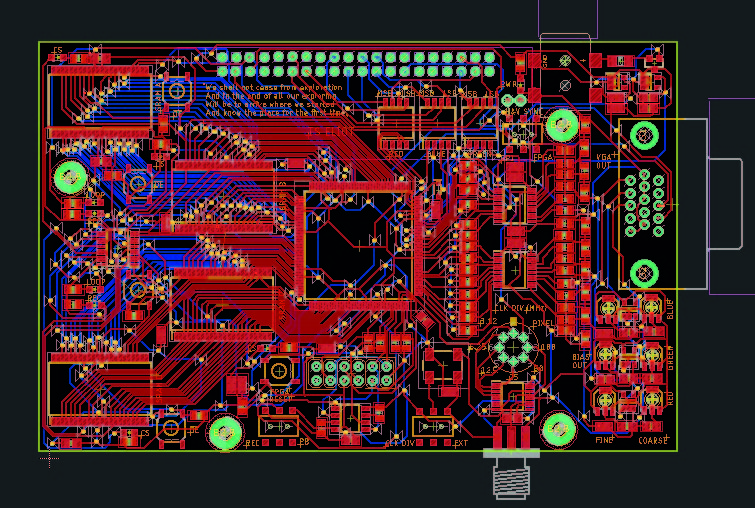

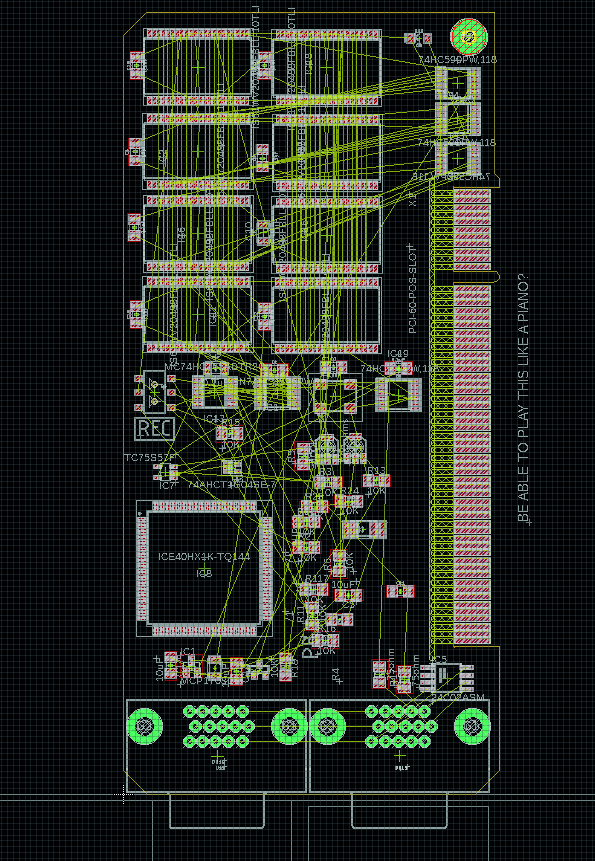

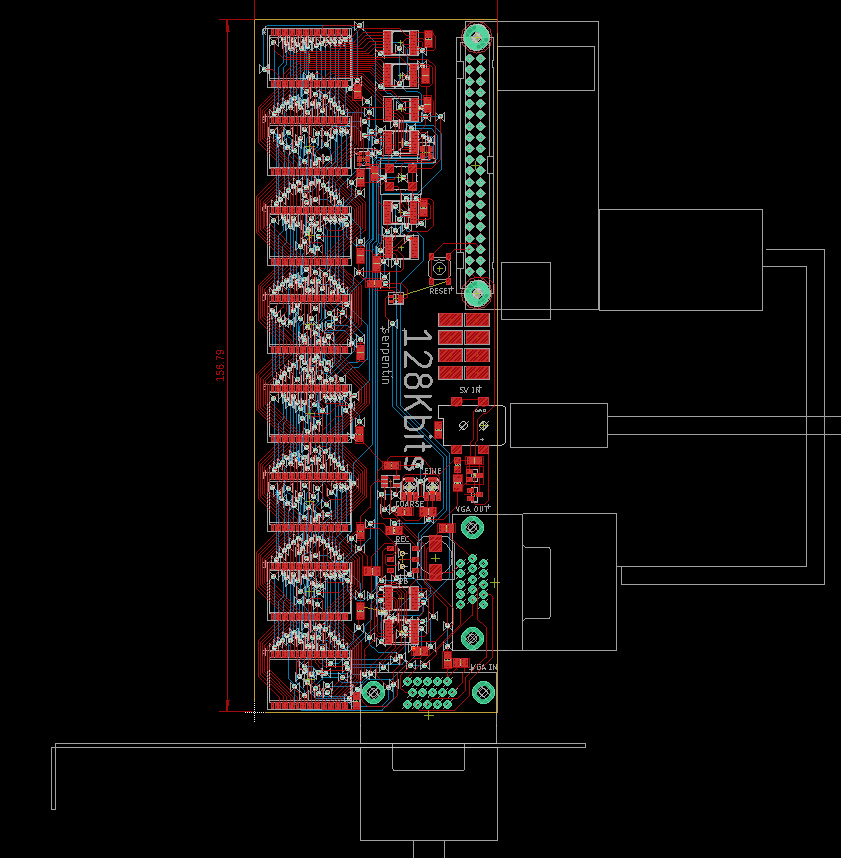

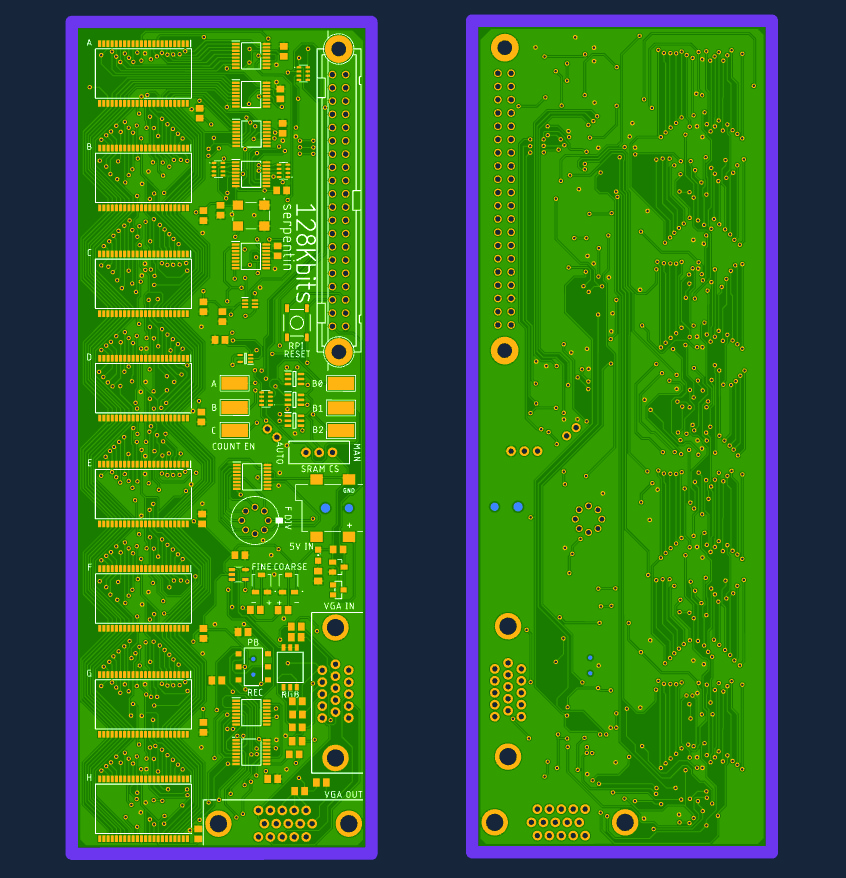

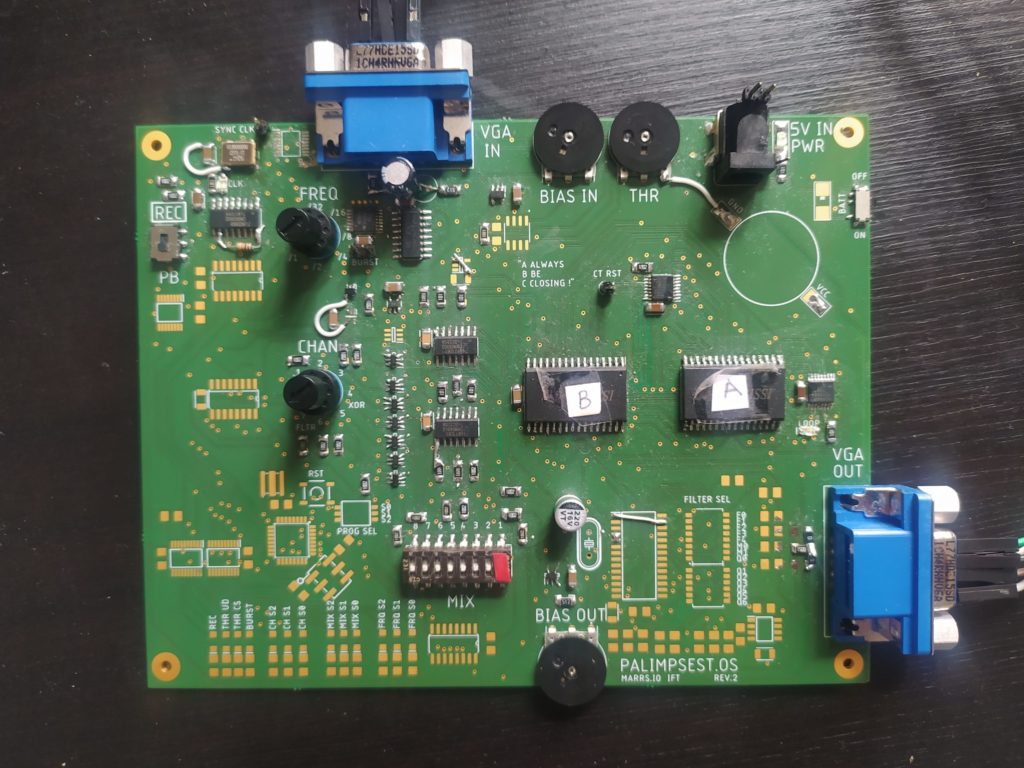

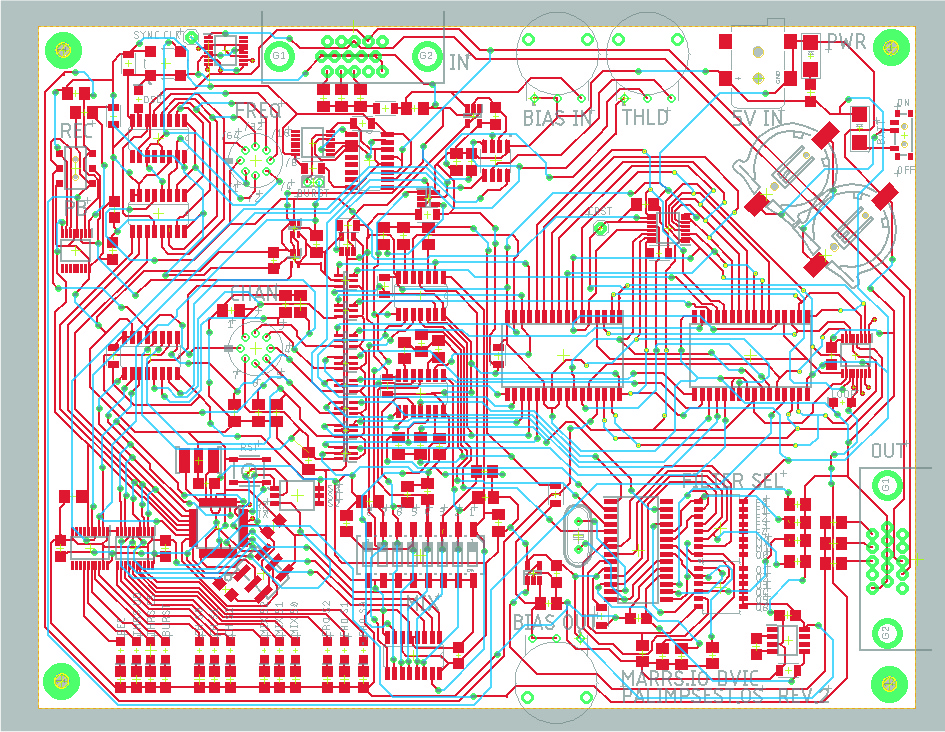

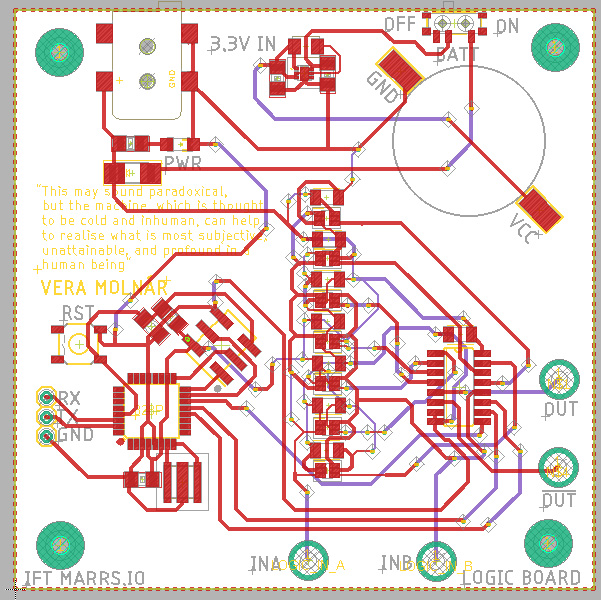

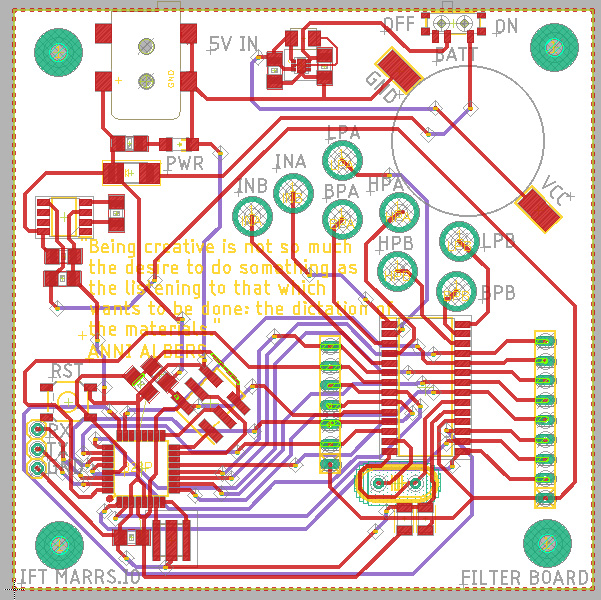

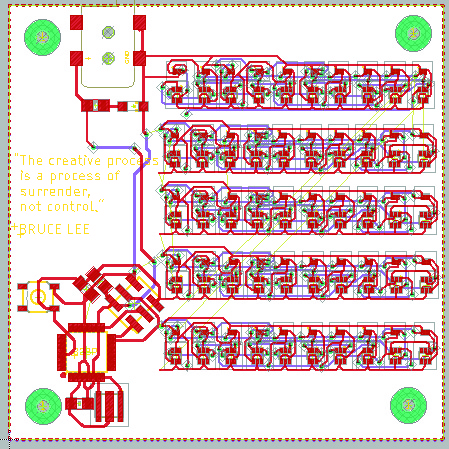

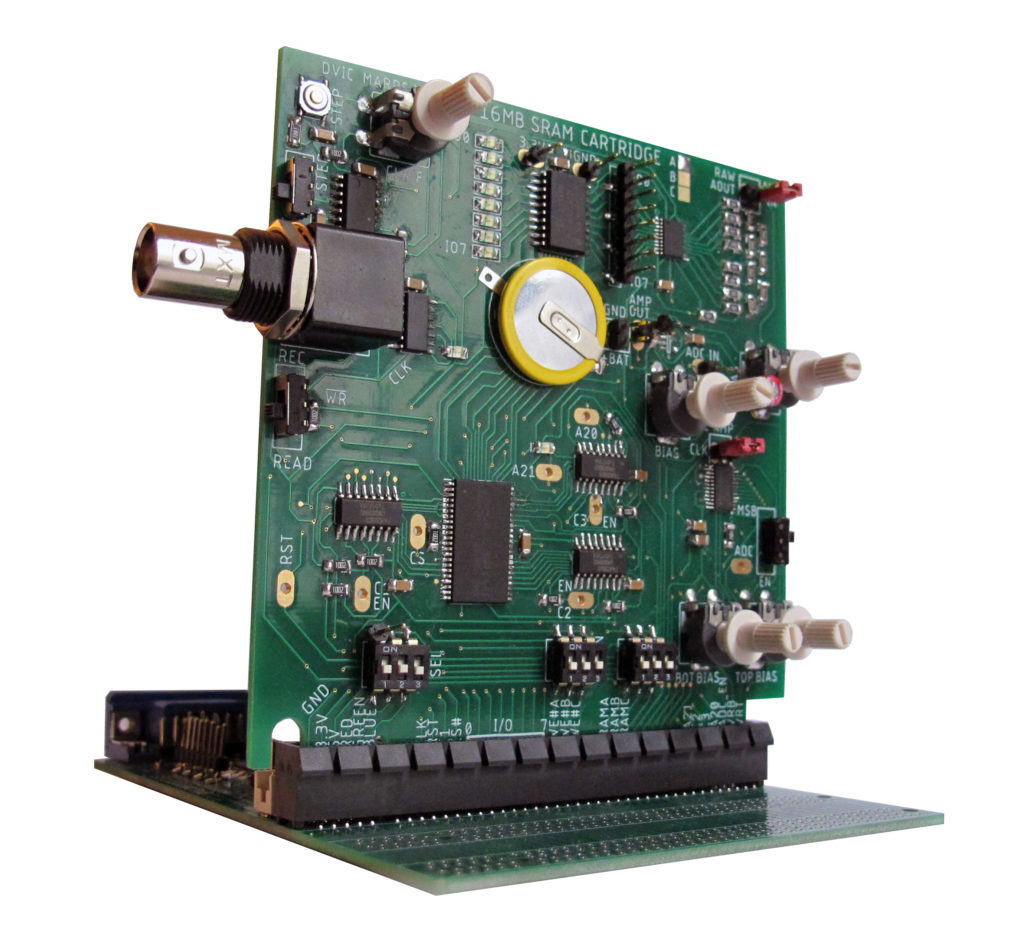

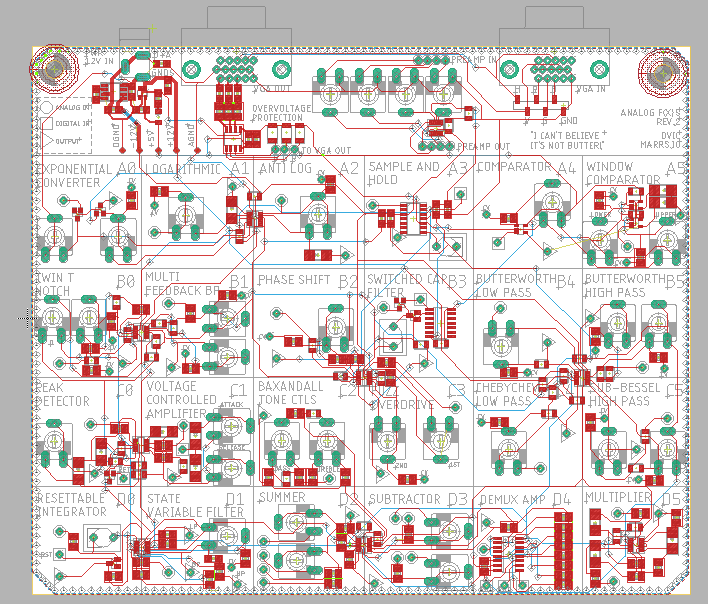

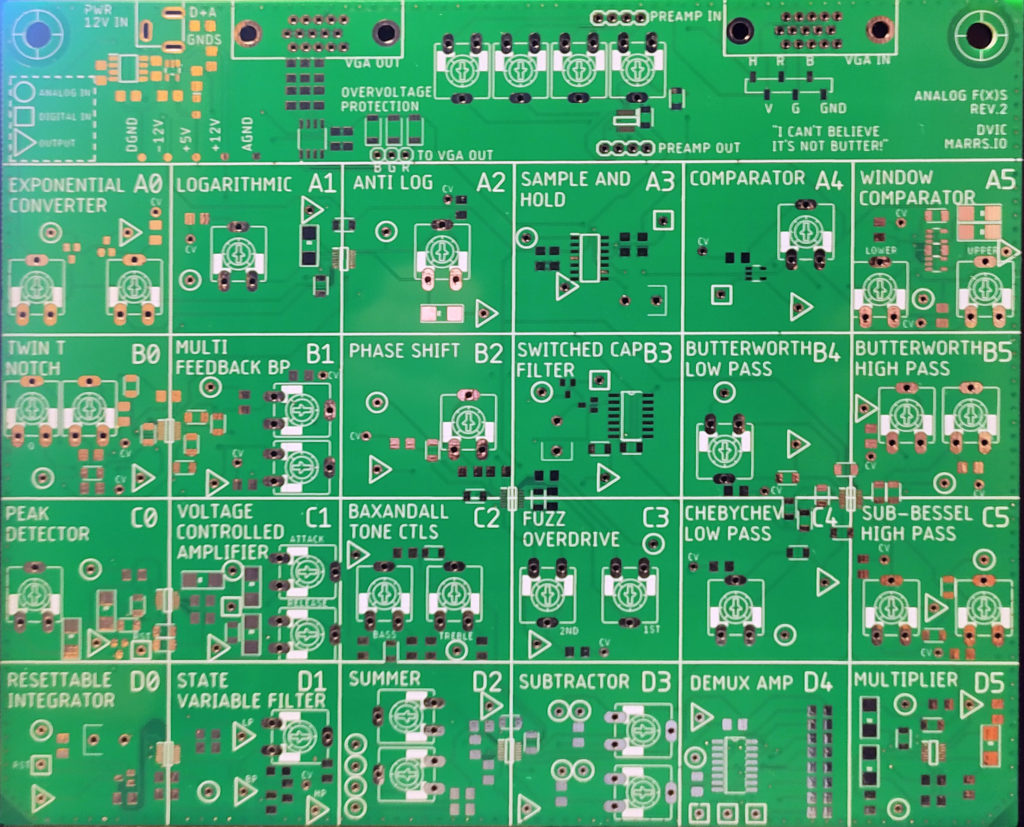

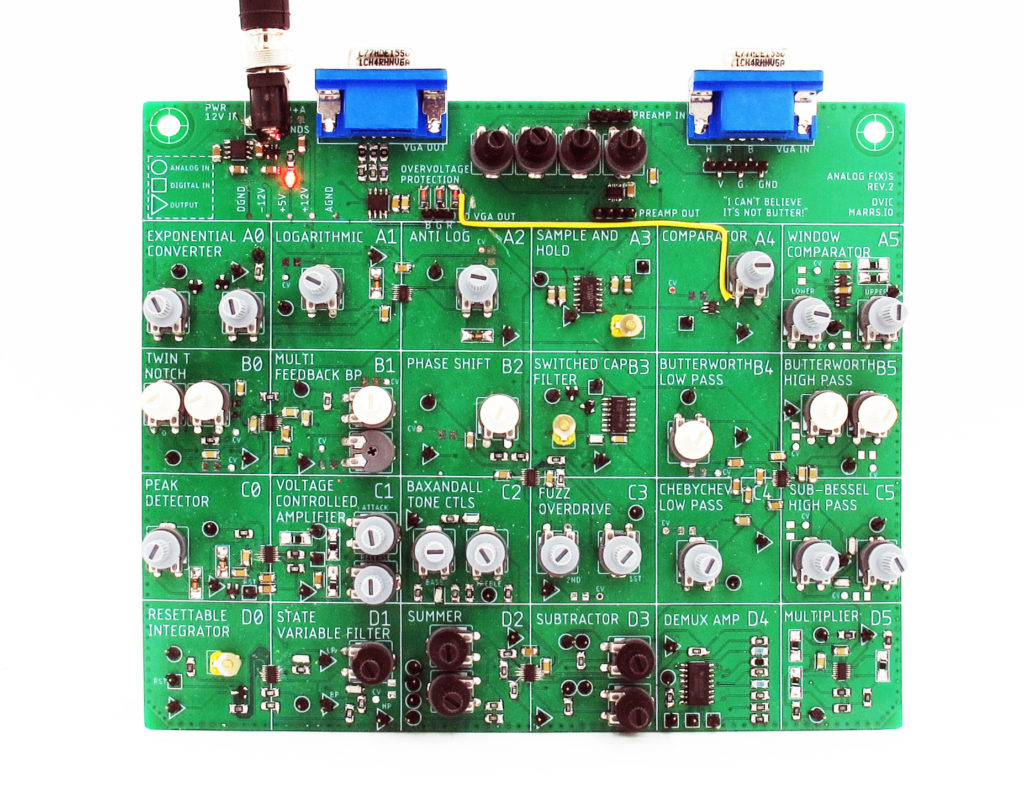

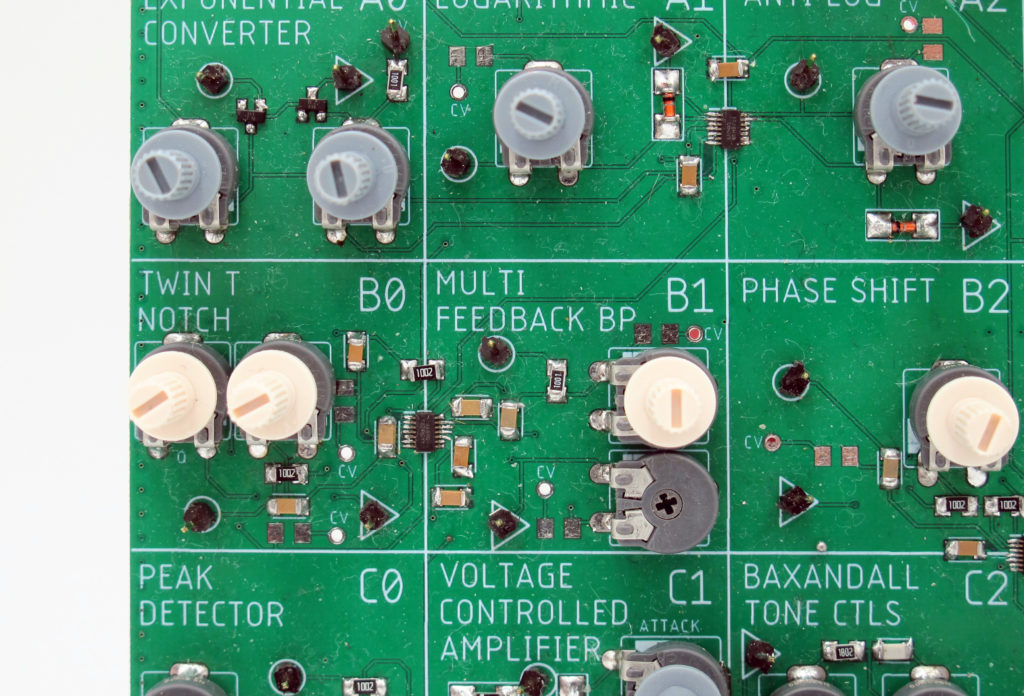

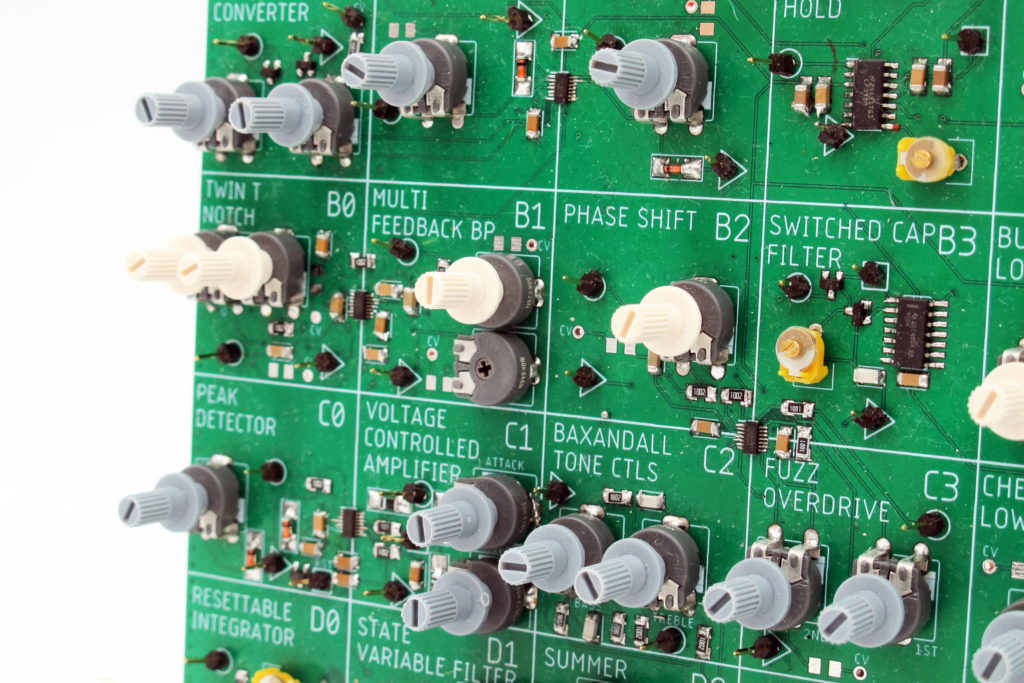

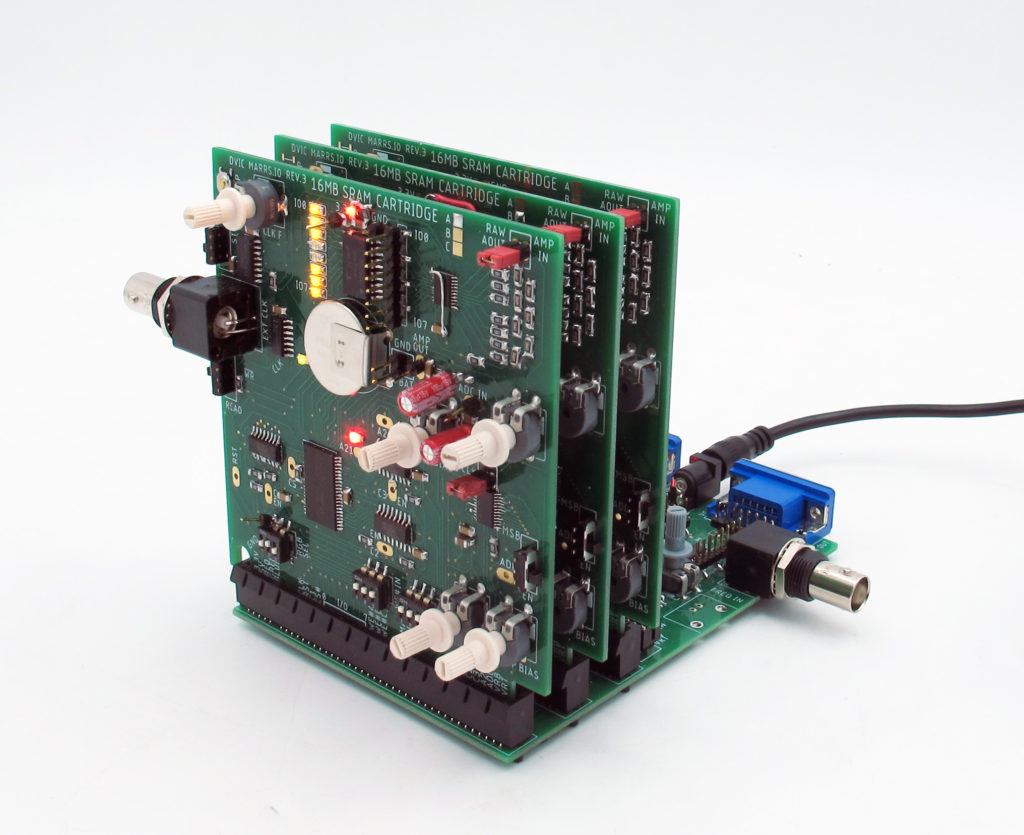

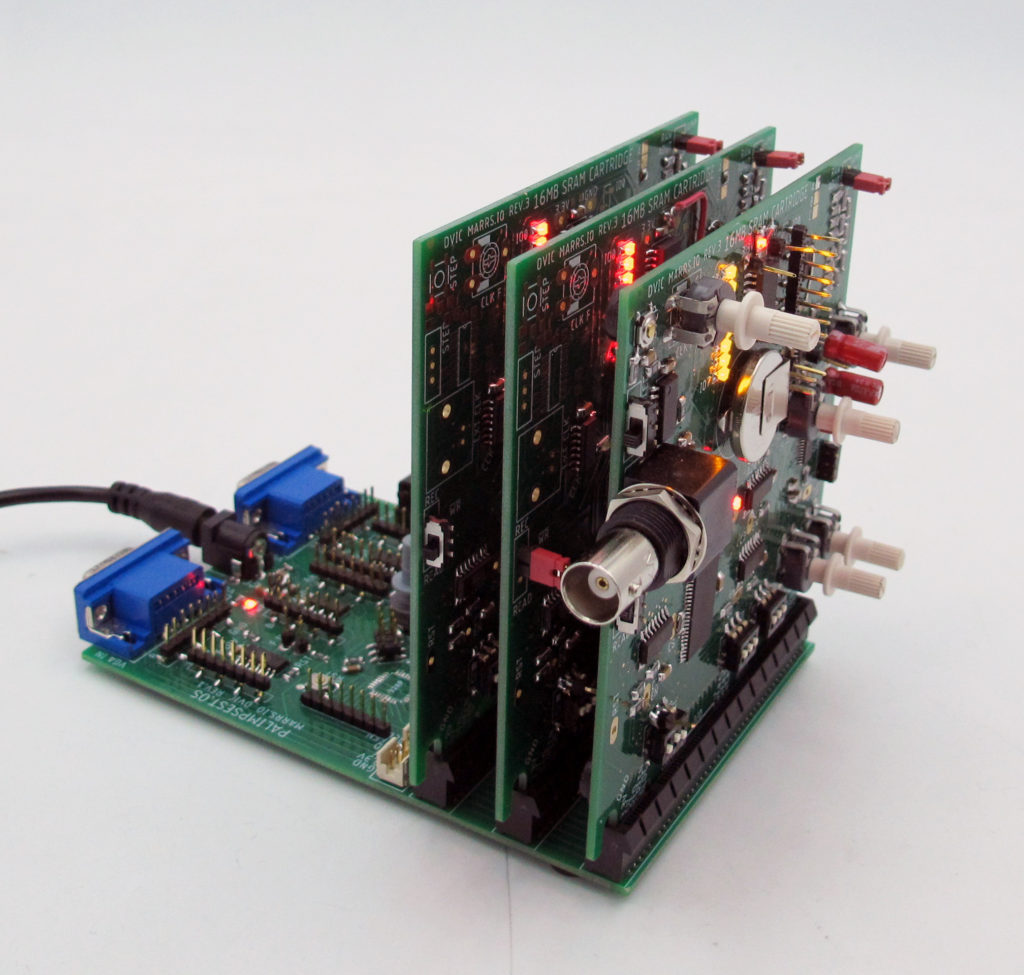

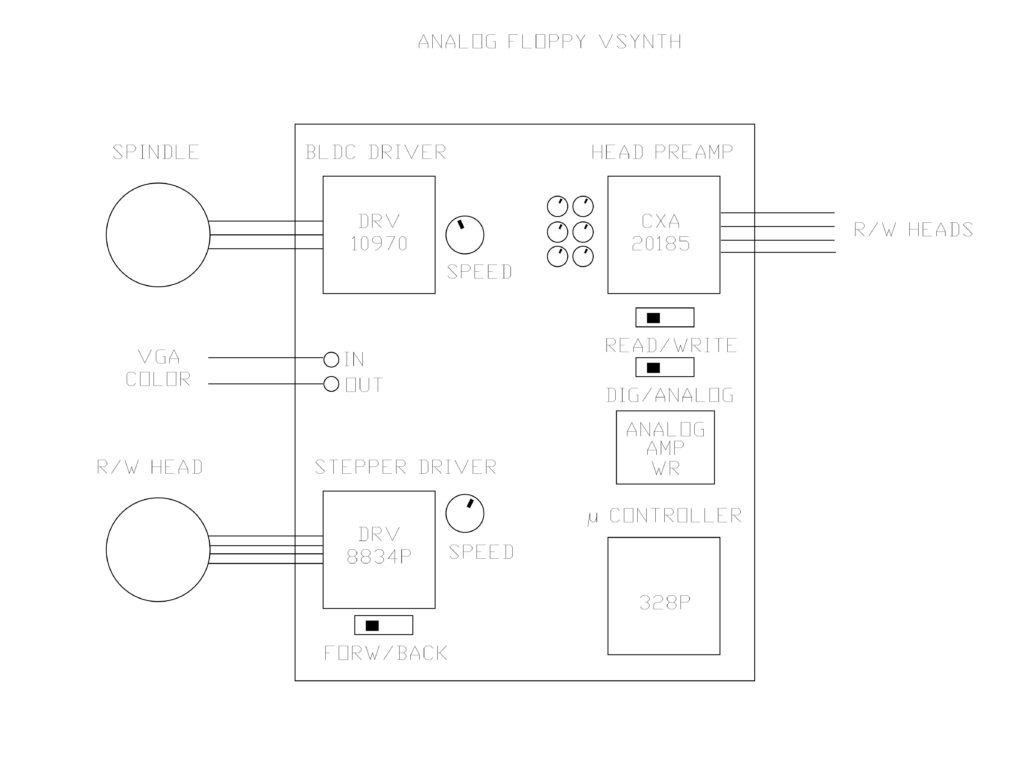

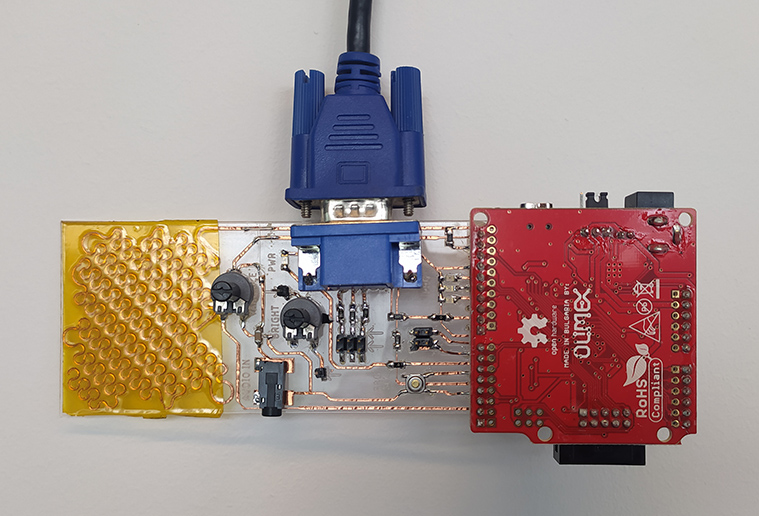

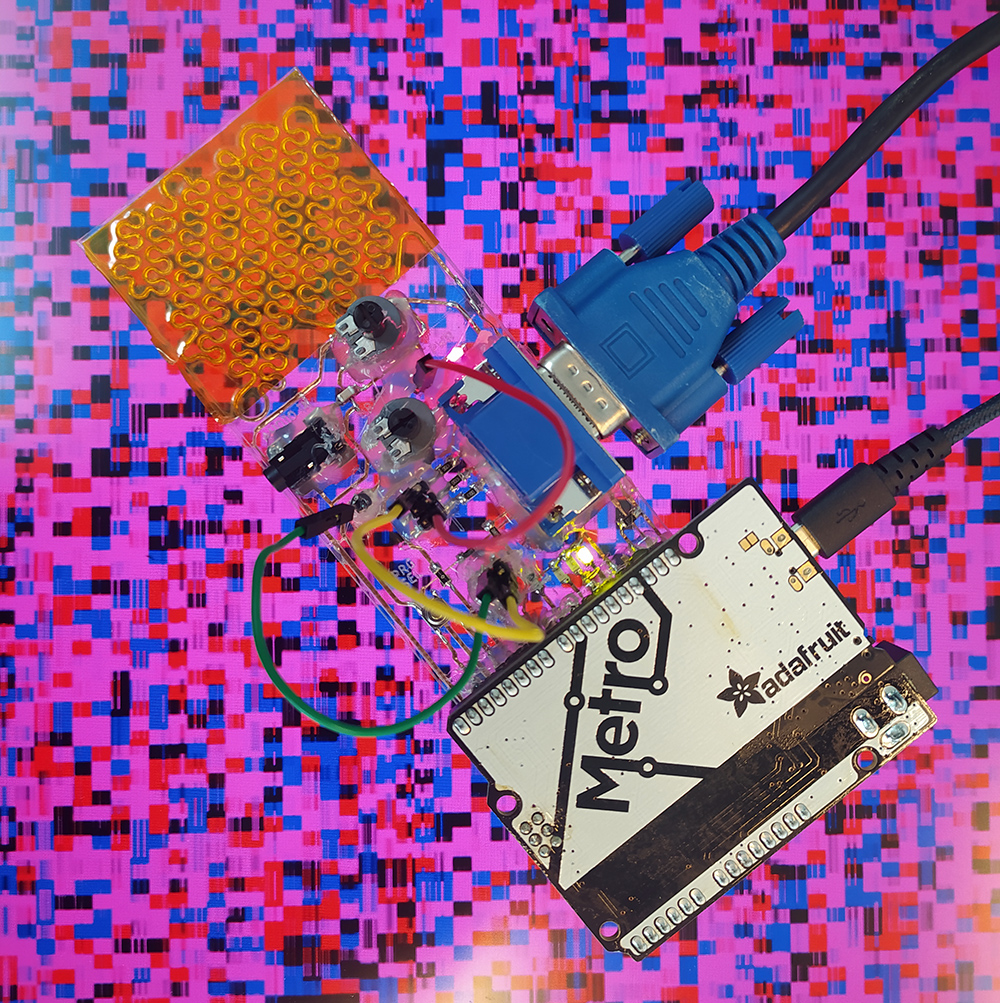

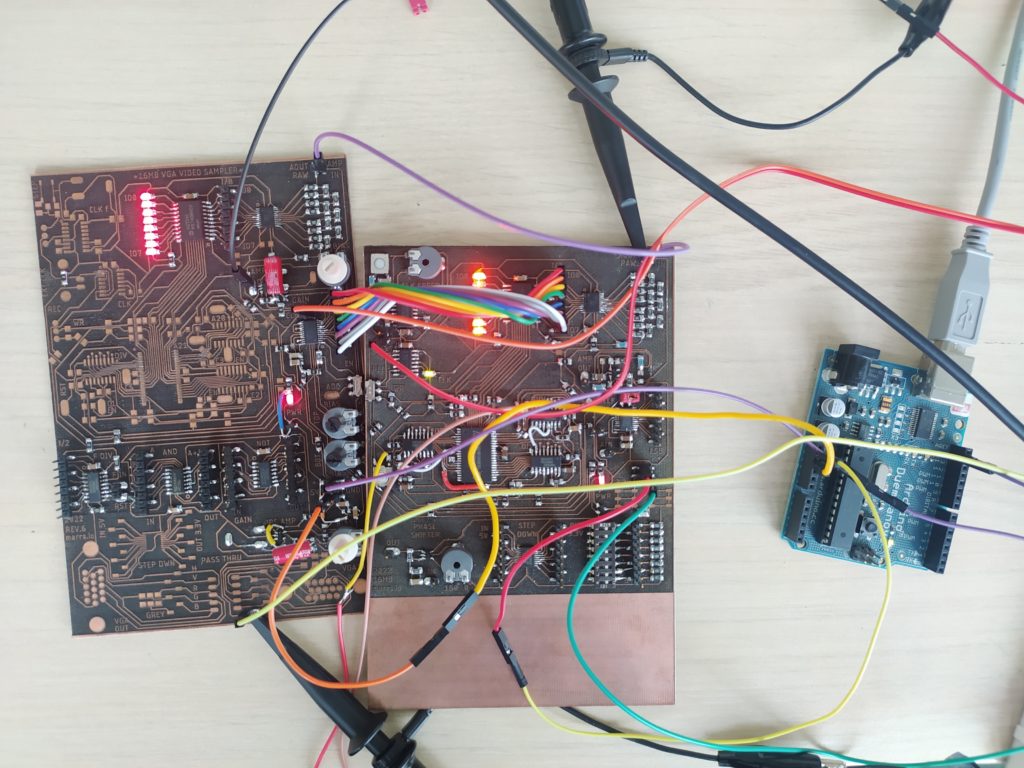

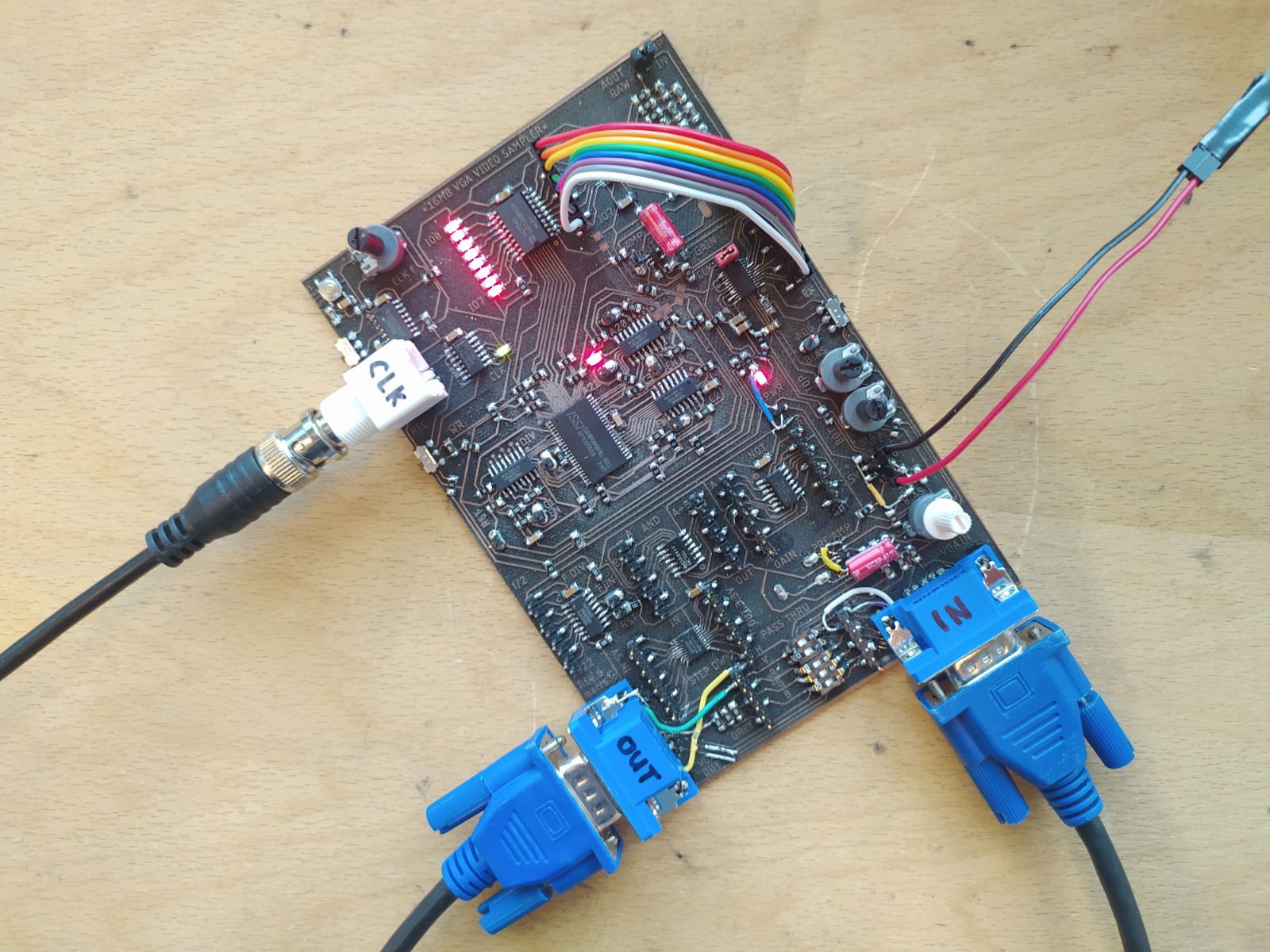

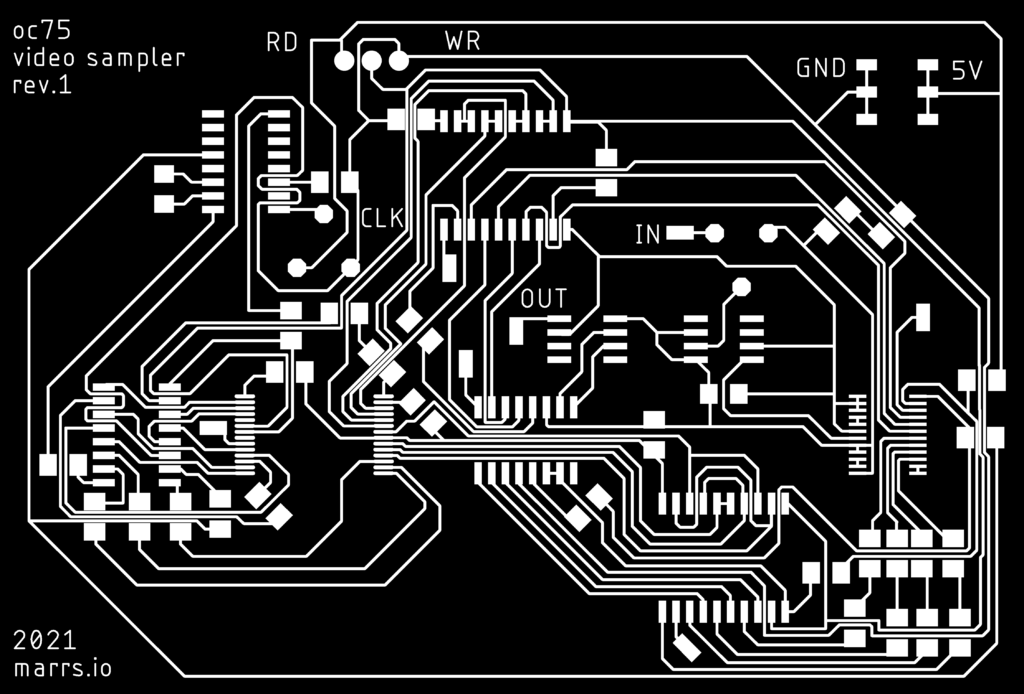

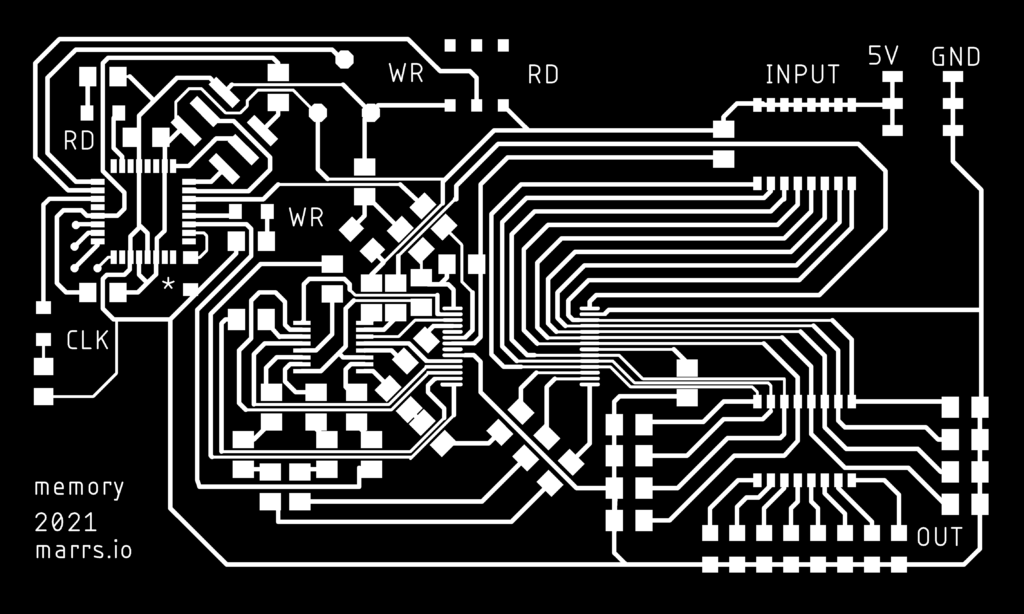

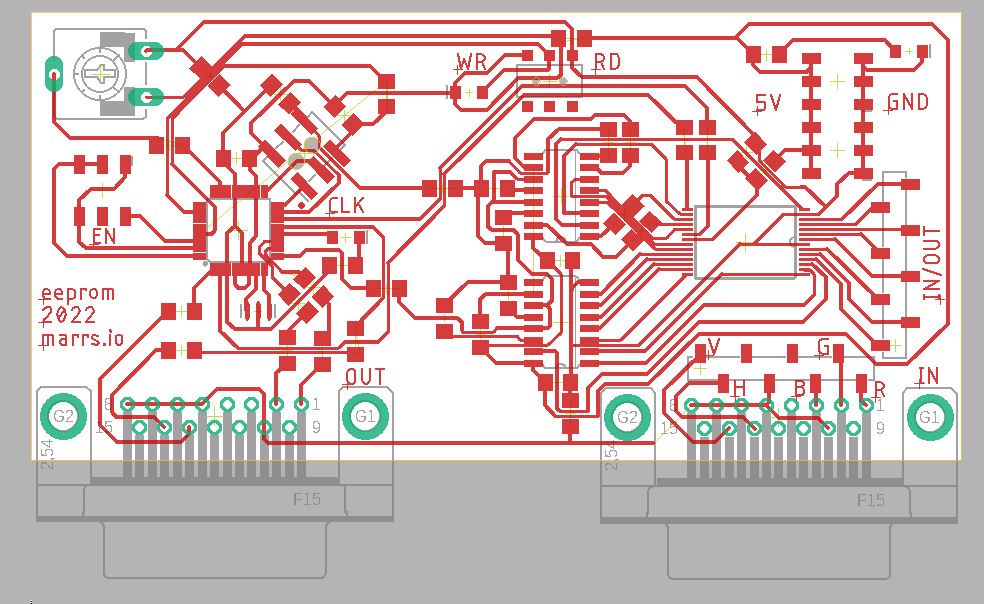

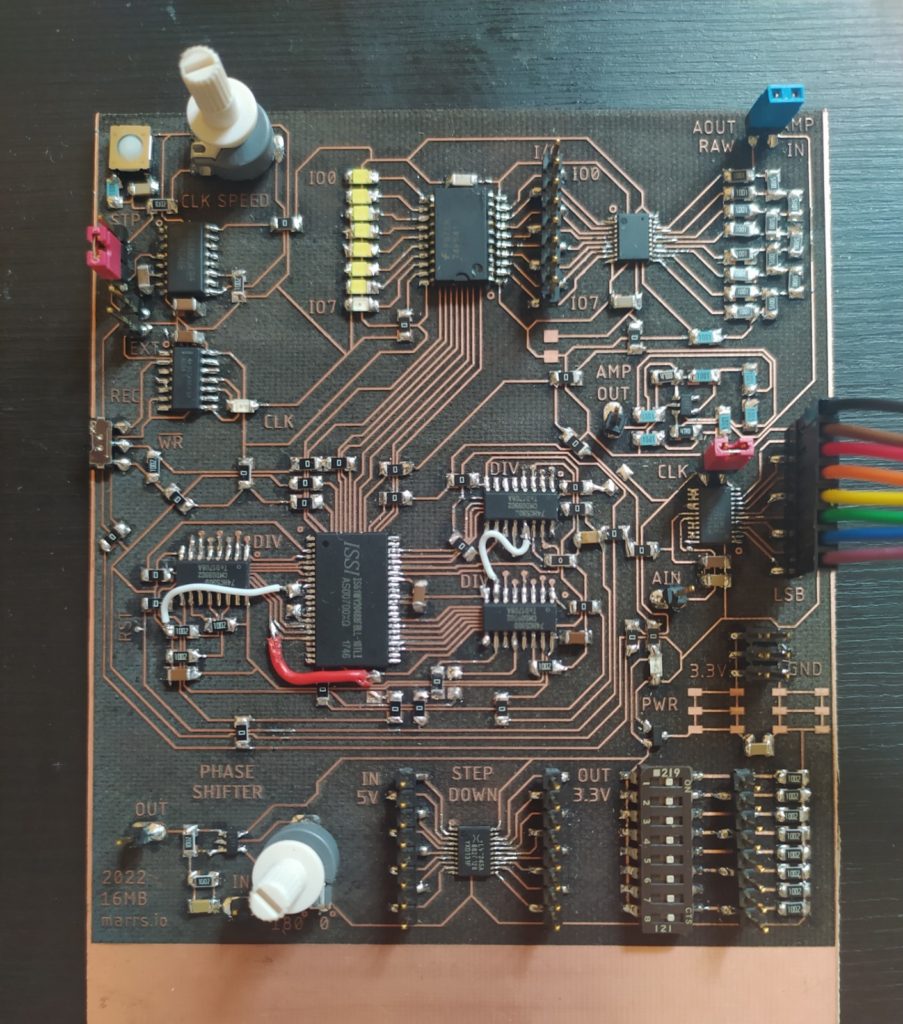

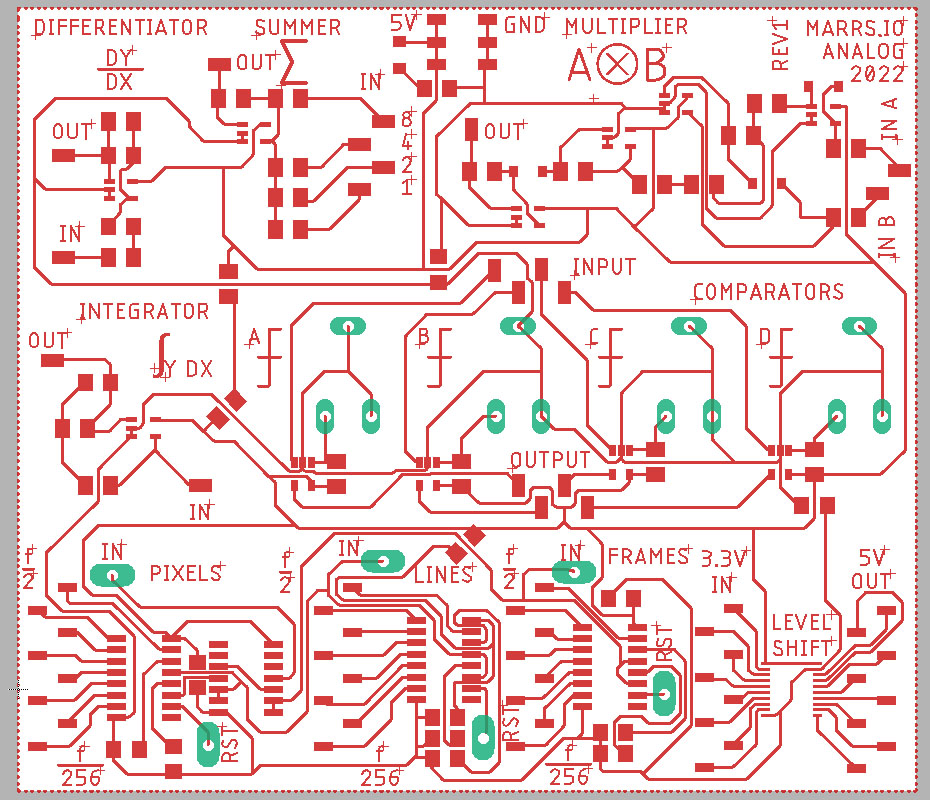

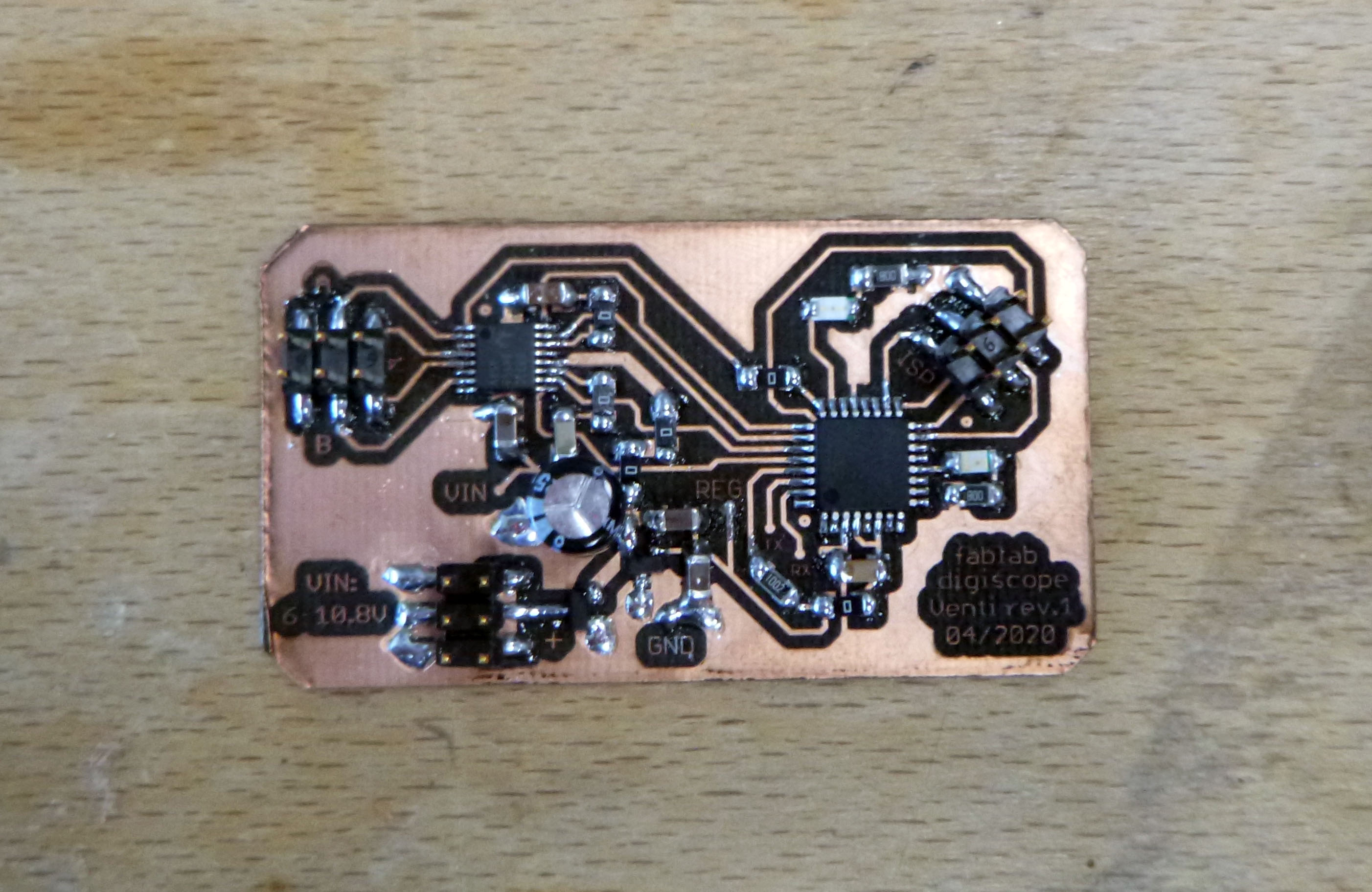

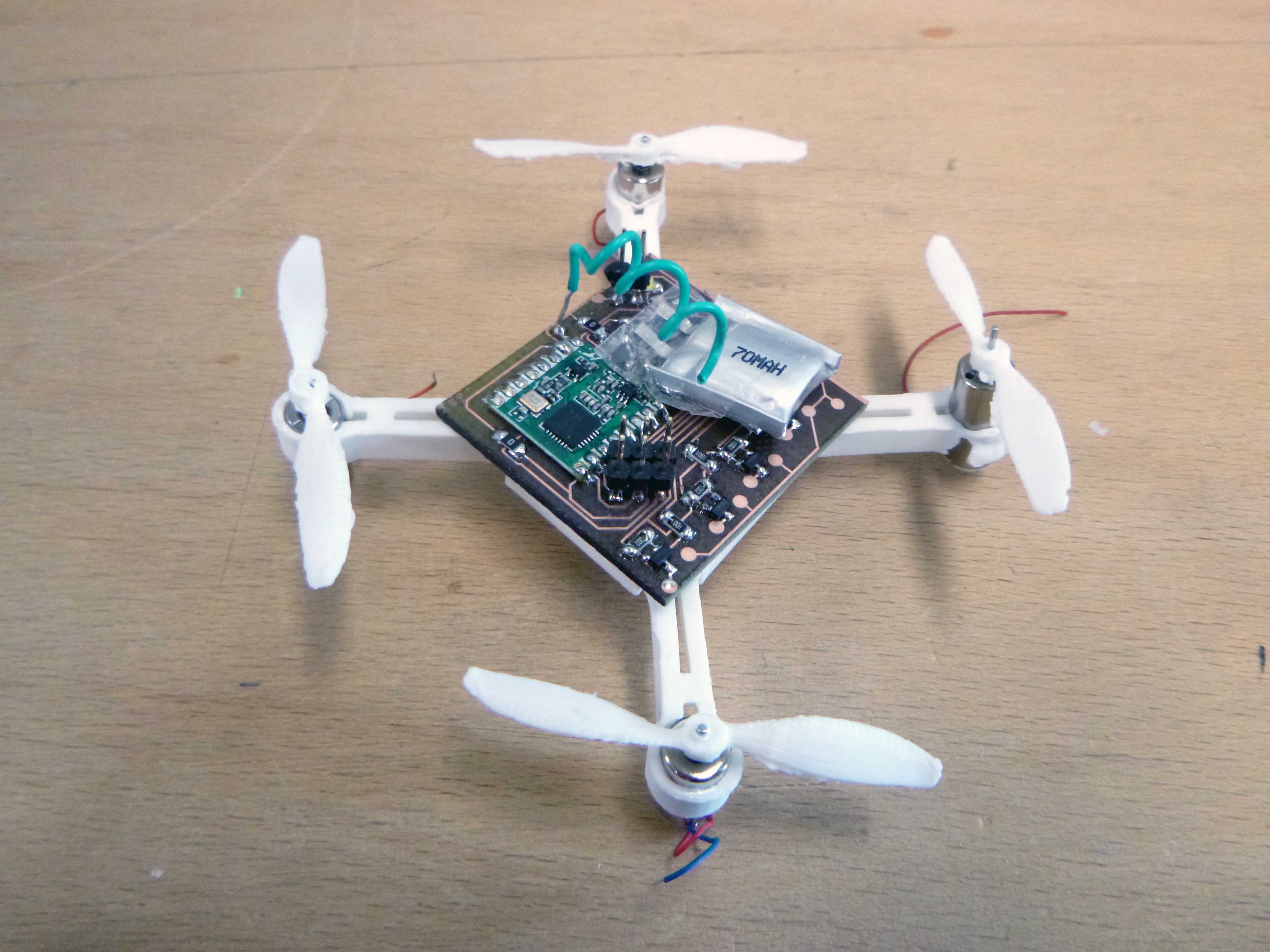

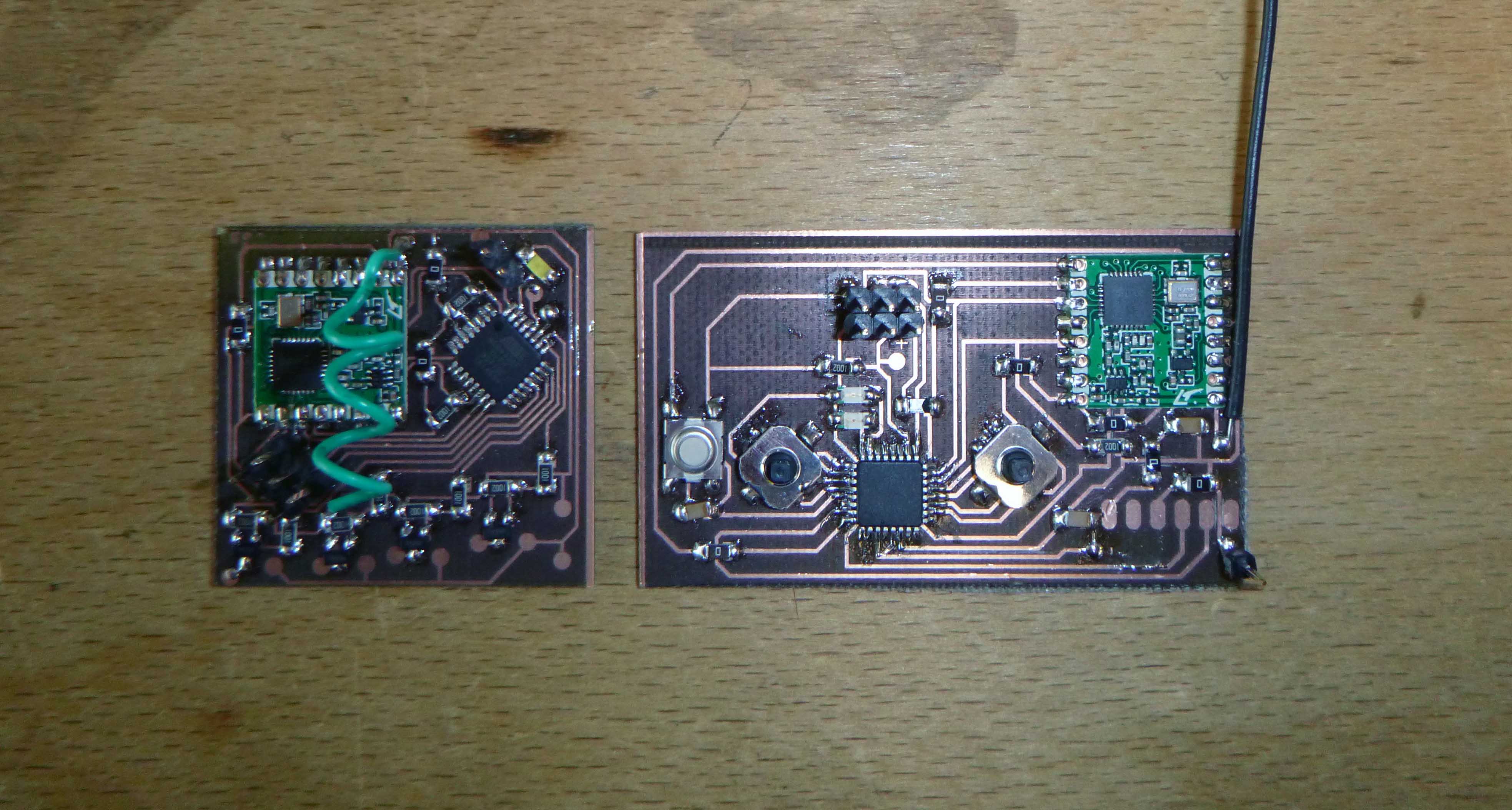

- This year the goal was to have a finished open-source project that could be shared with people online or as a kit/product via prepared instruments.com. I would be able to show it to students as an example of a finished design/engineering project that I have completed. The idea would be to stabilize the design, to stop making endless boards, and begin exploring more verilog codes that run on it.

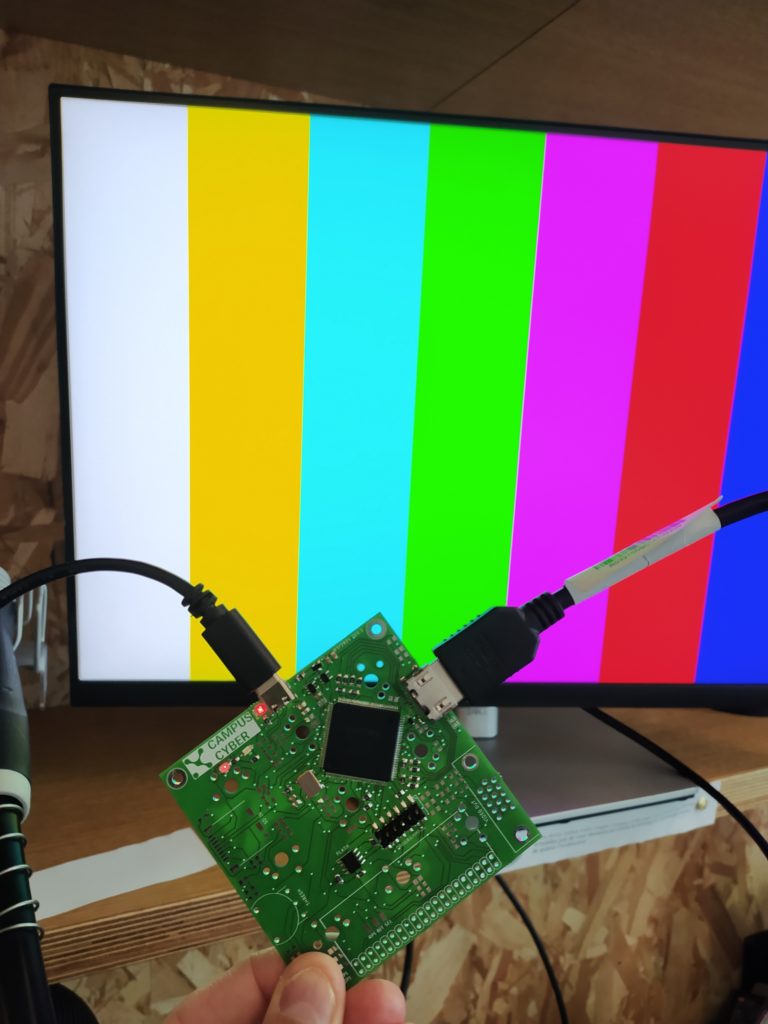

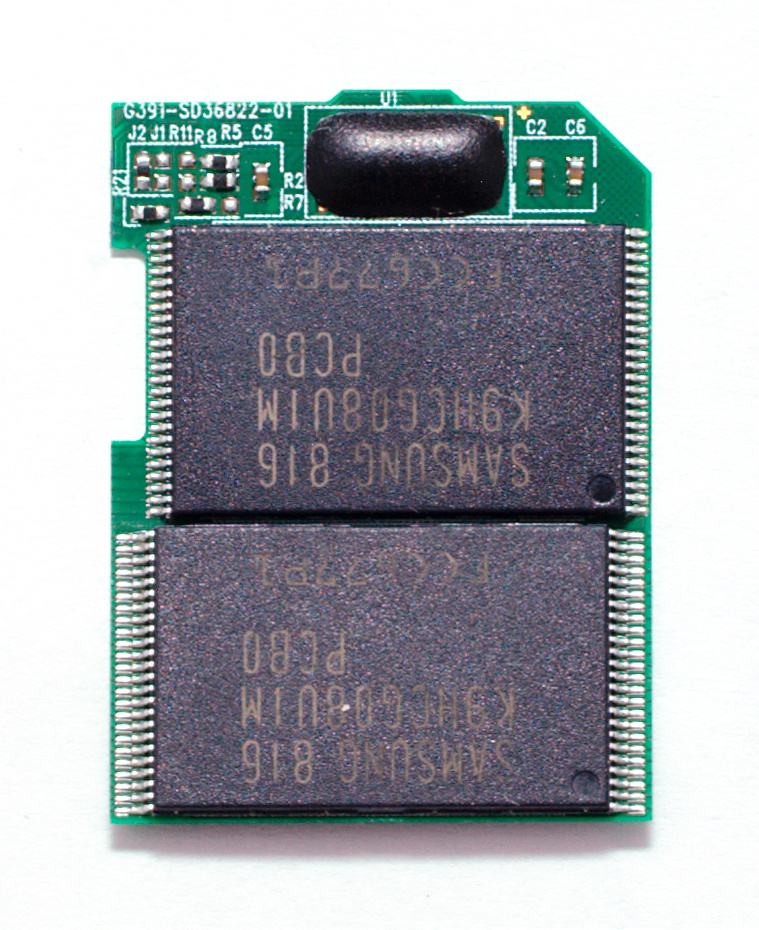

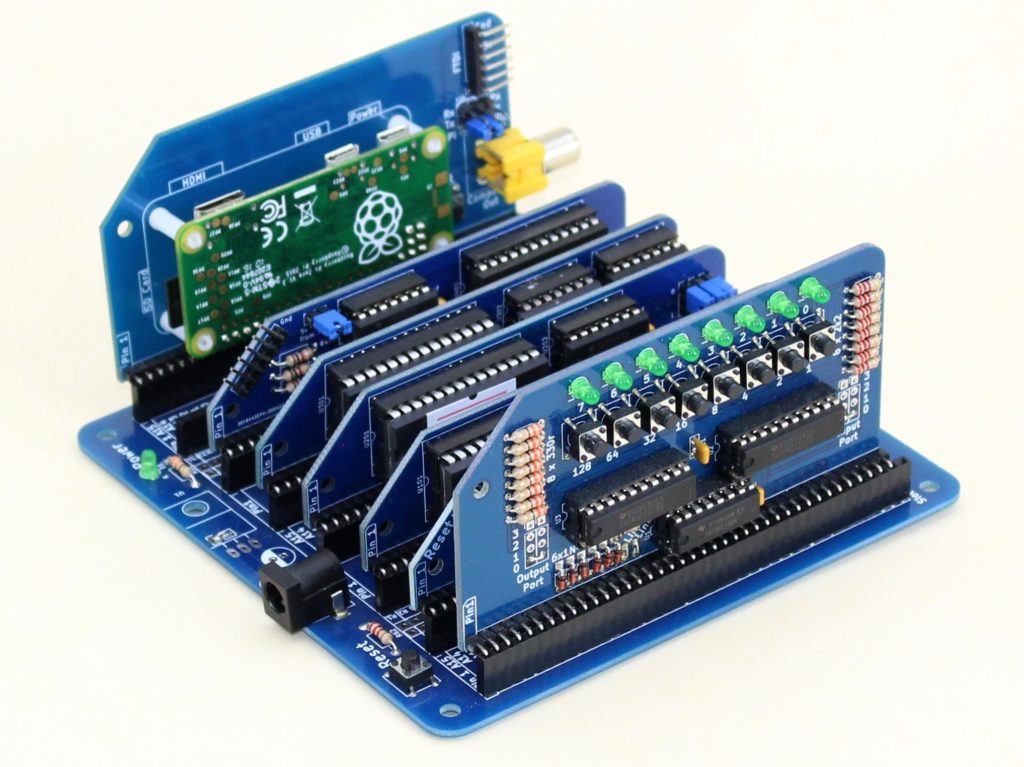

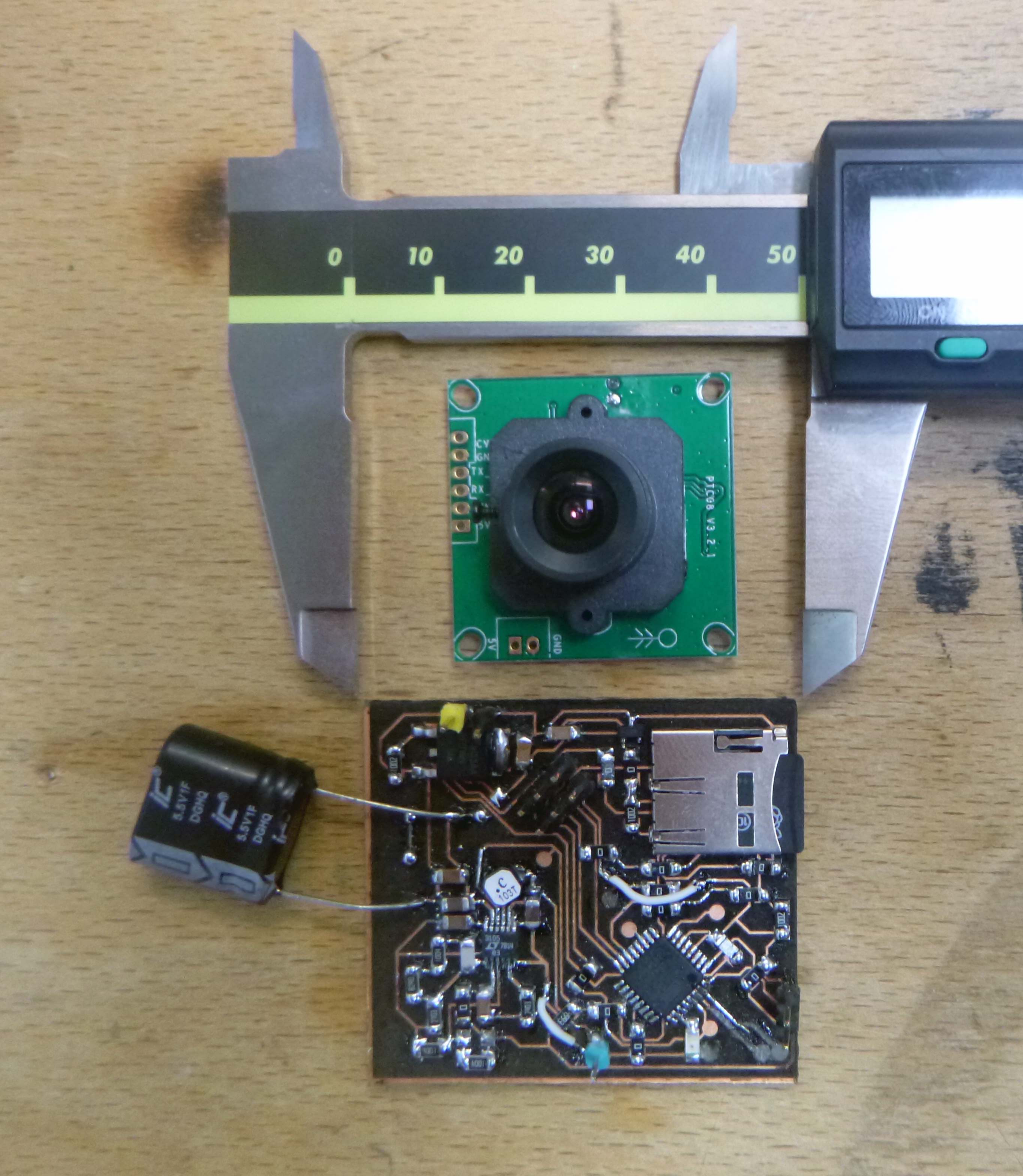

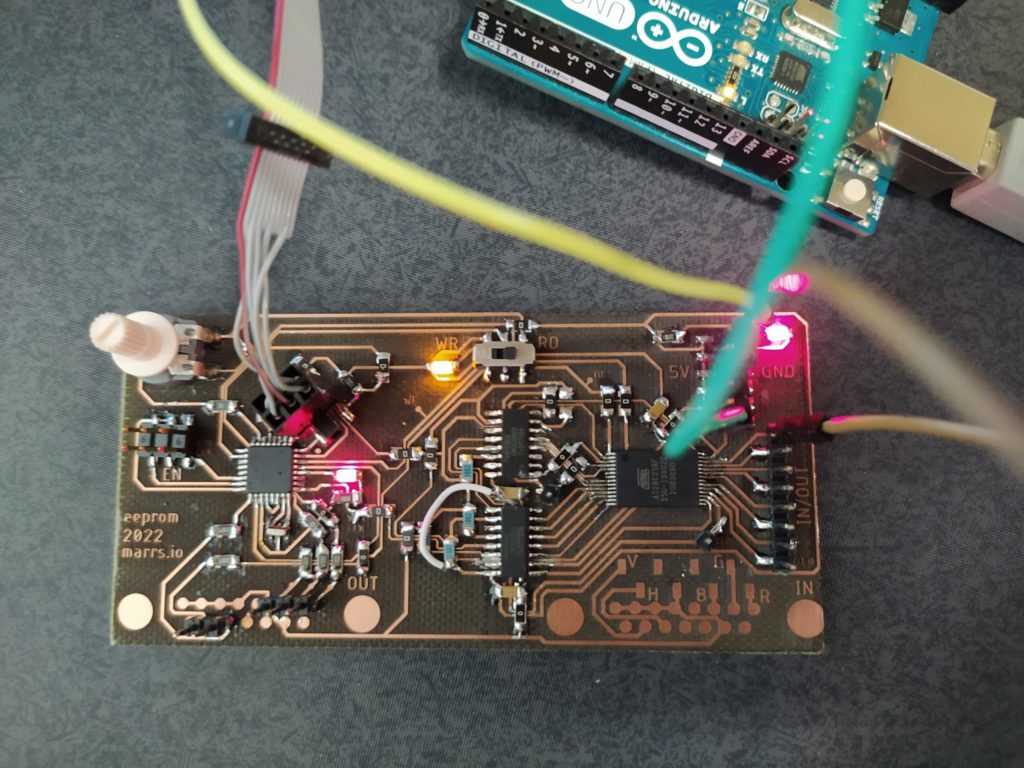

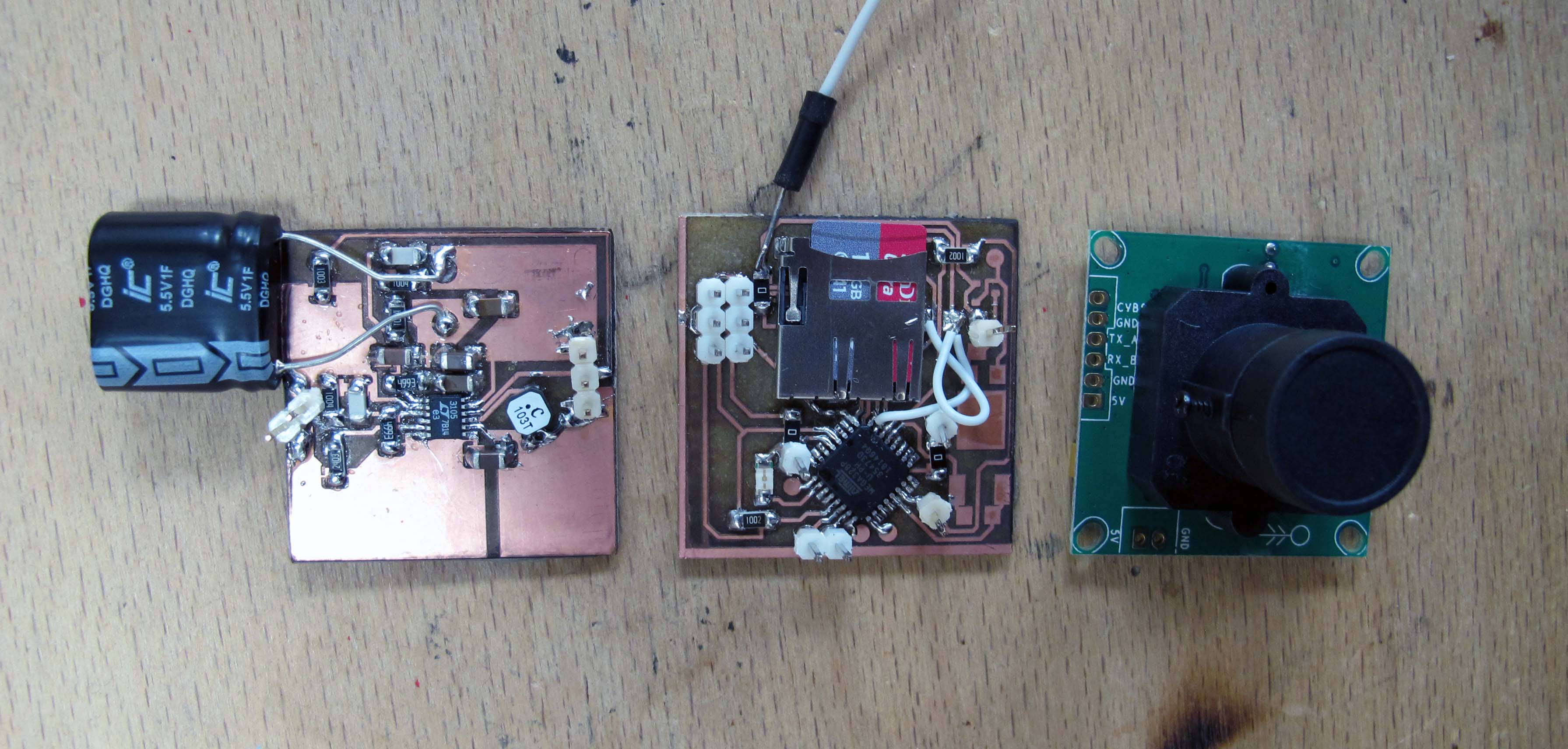

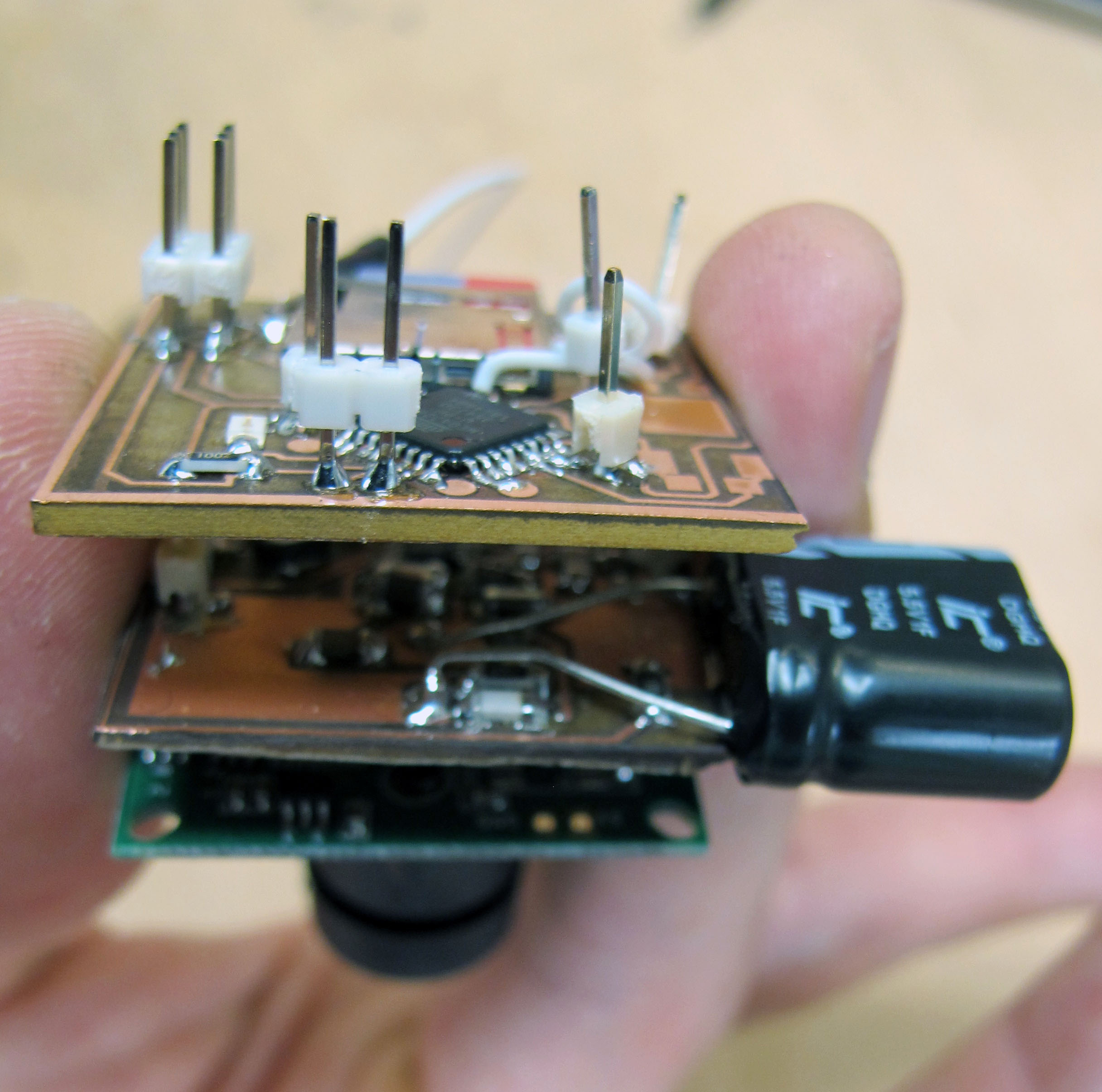

Currently, the Cyber Campus version of the board is basically complete enough to transition into just trying new code. There is just the SD card that remains before the object has a feel of being an independent finished object that isn’t dependent on any other products (like rpi) to function.

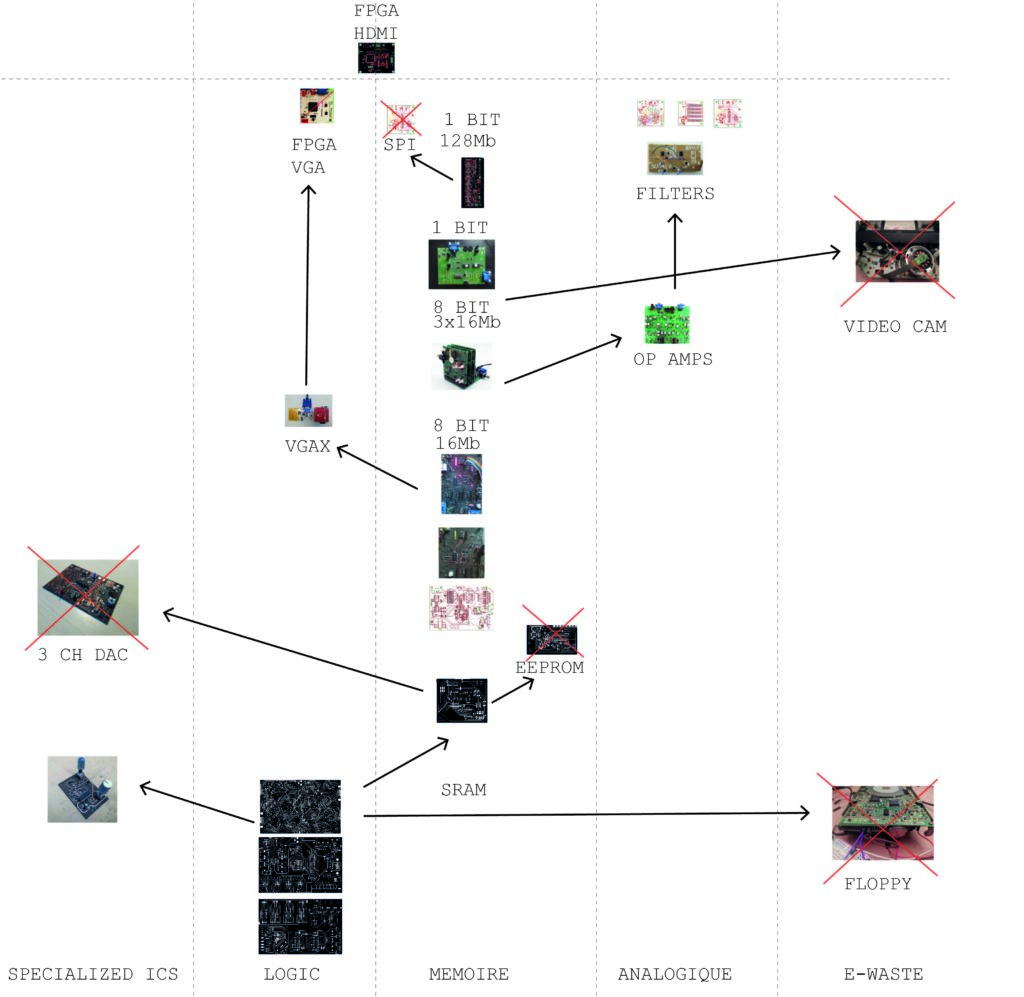

Perhaps a distinction between the product, art and workshop kit would be useful :

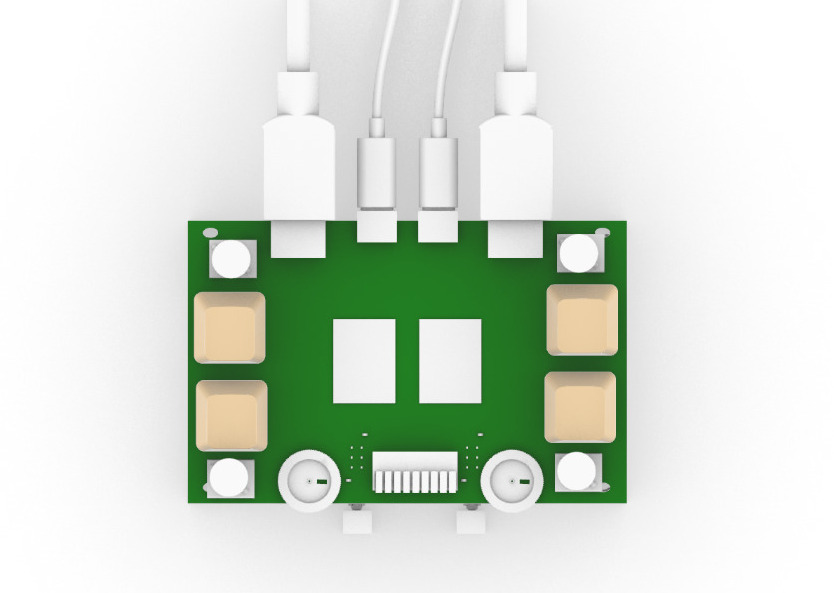

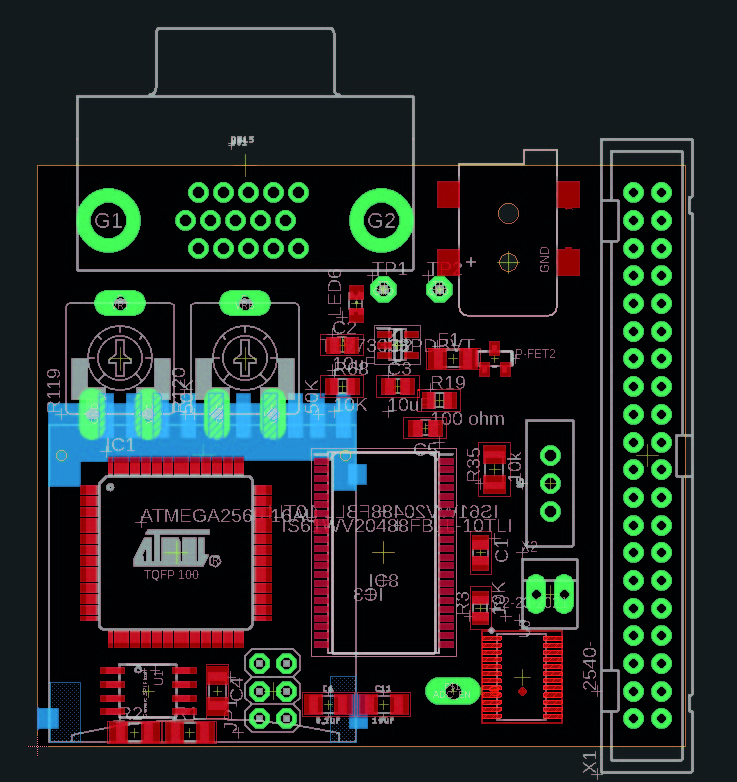

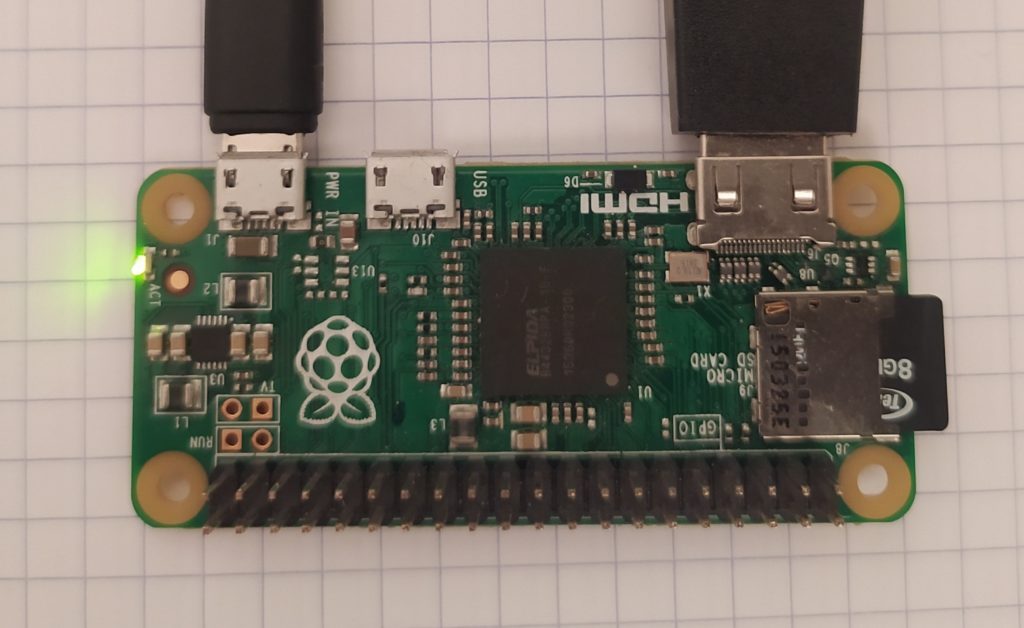

Kit : reprogrammable, built around the rpi, solderable by beginners, etc.

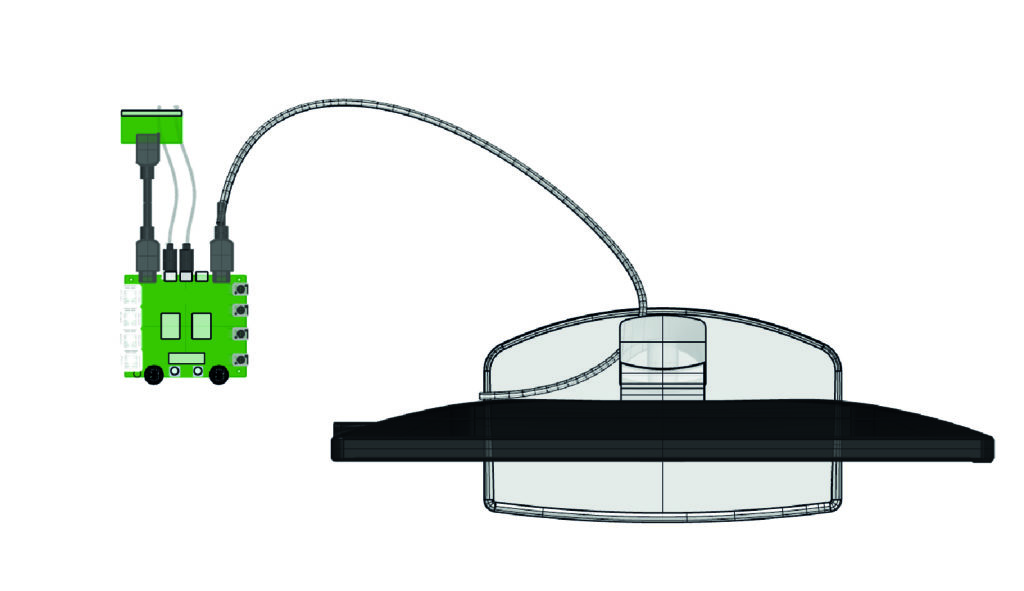

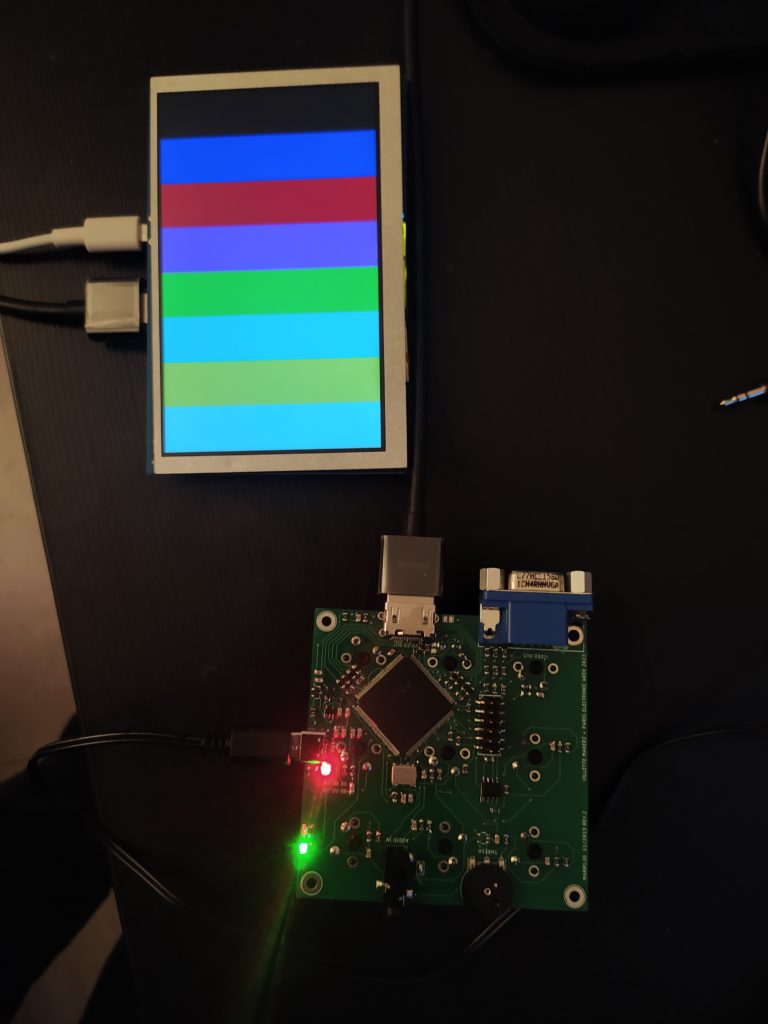

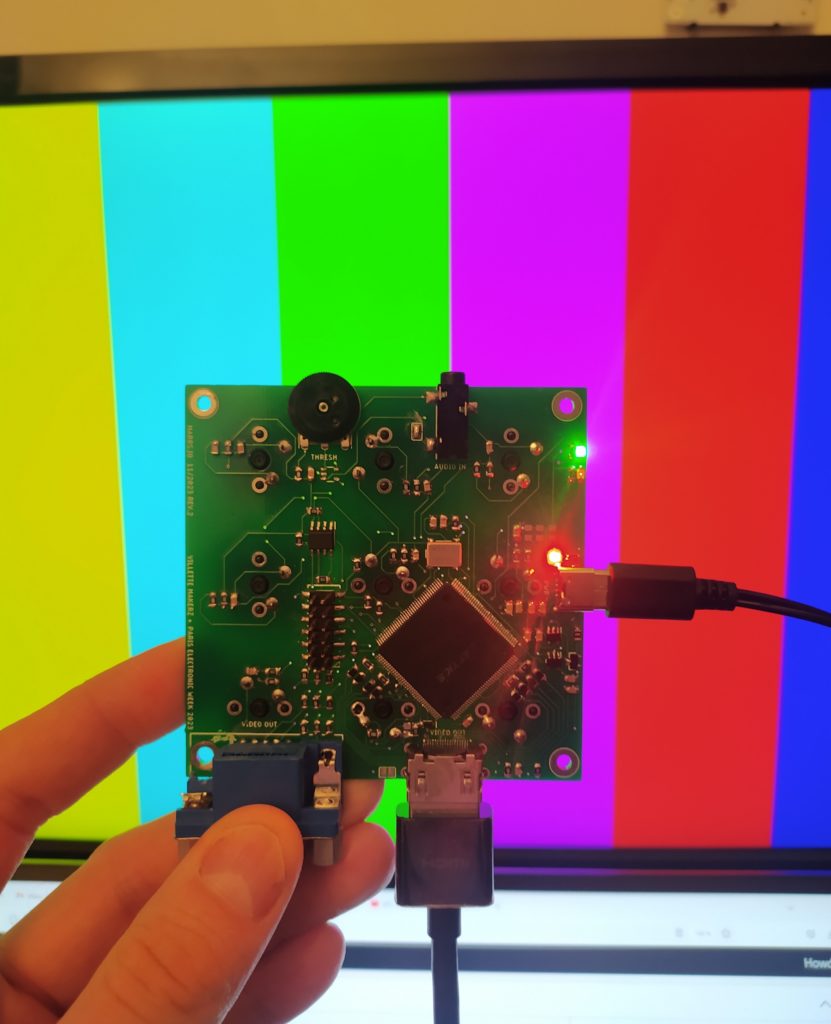

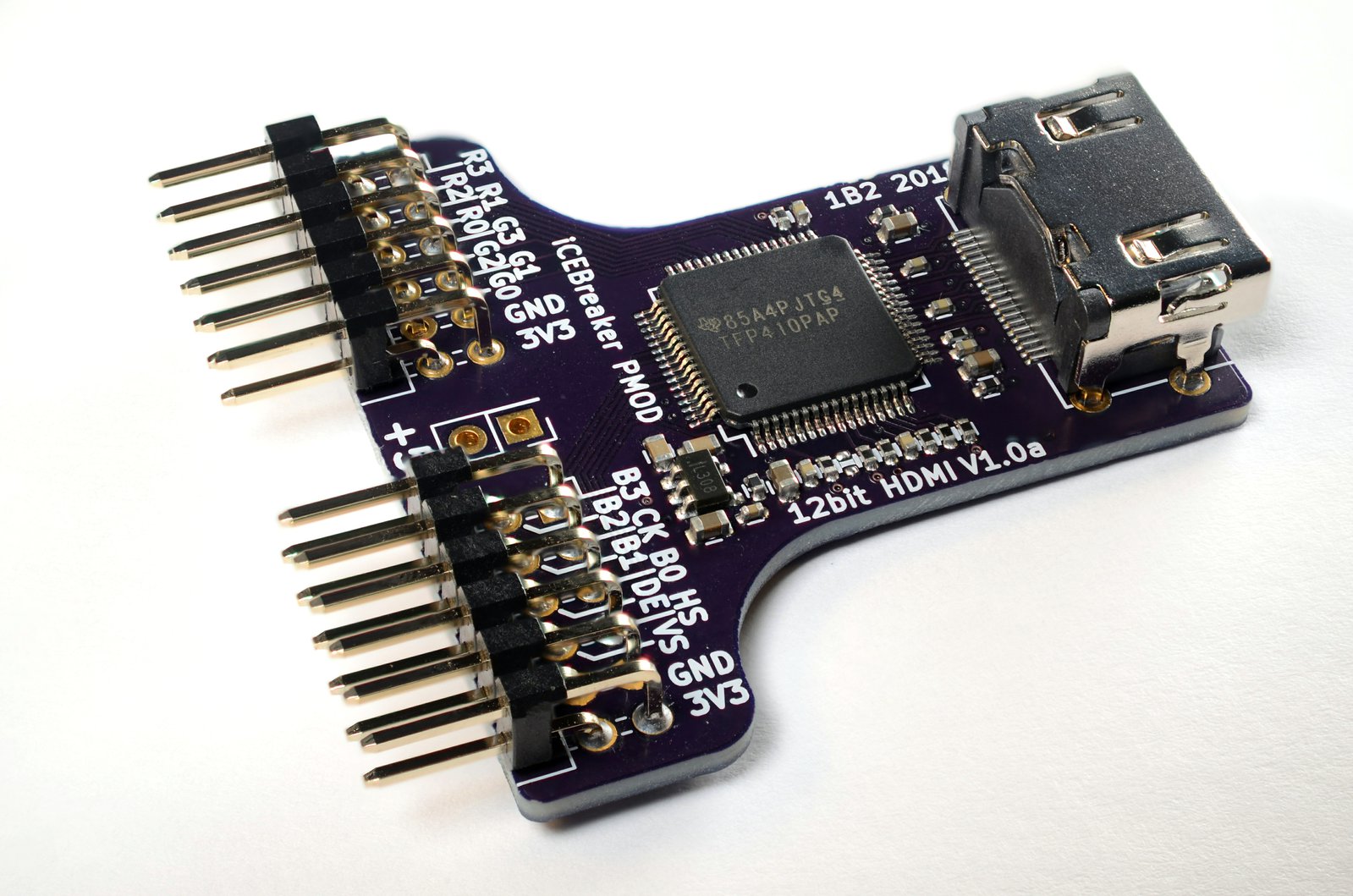

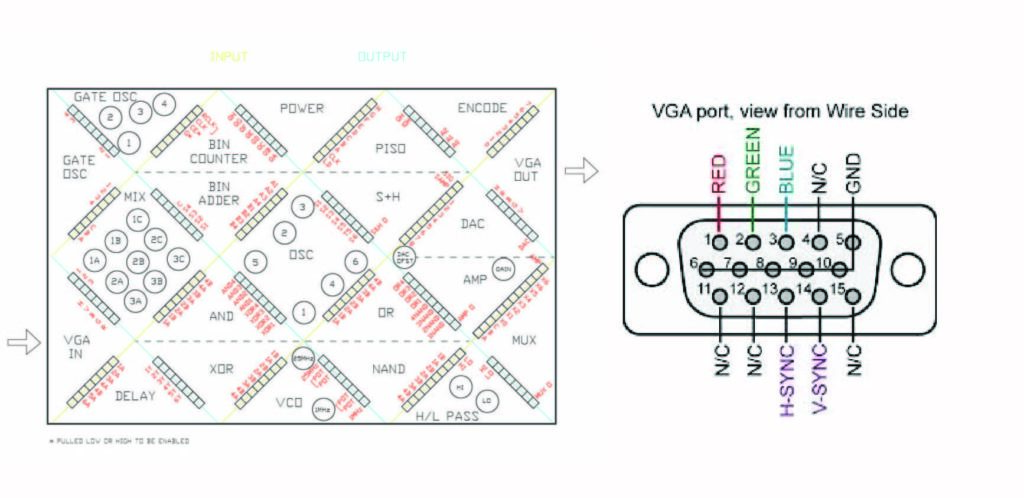

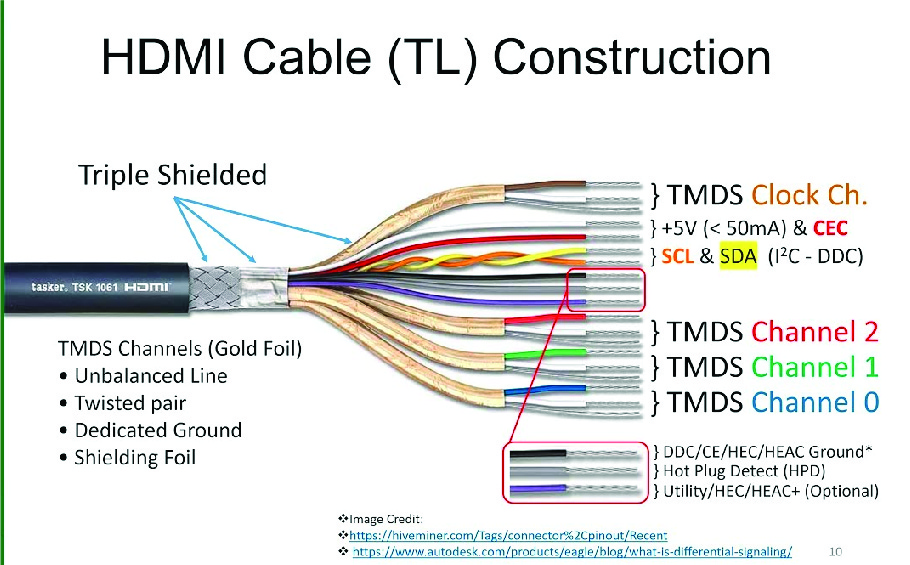

Product : HDMI IN (a compromise would be that chip that handles everything like the TFP401PZP) and HDMI OUT, plug and play with modern tech. Has a larger FPGA to be able to do more cool stuff.

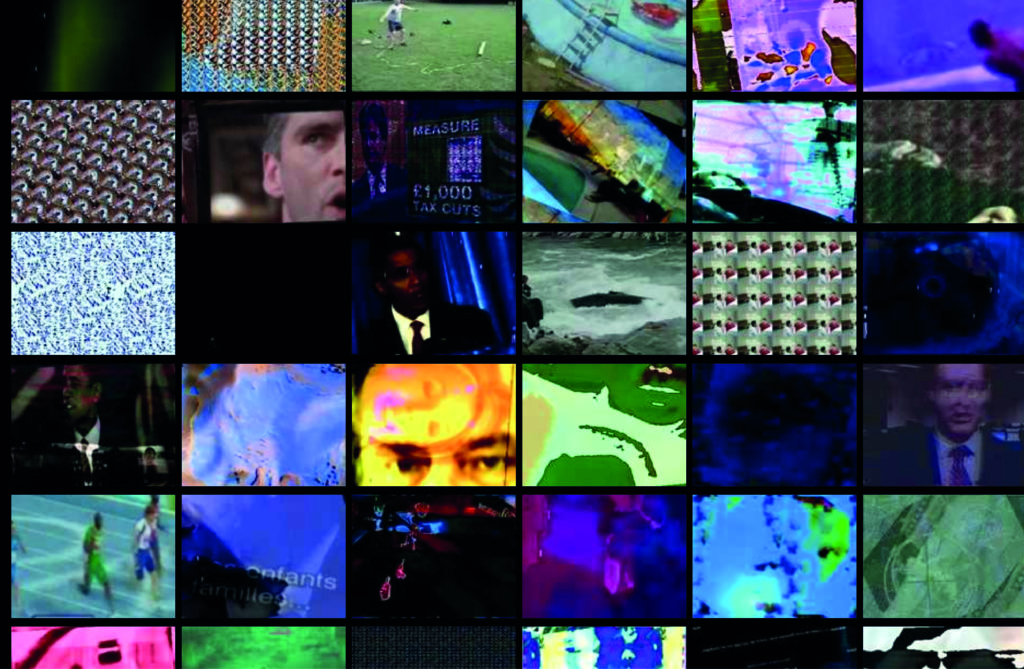

Art : The Cyber Campus version has everything I need to have fun with new codes, especially ones that interact with time and sequence (like temporal compression?), like differences between images in time impacting the kinds of transformations instead of staying with just static filters.

*********

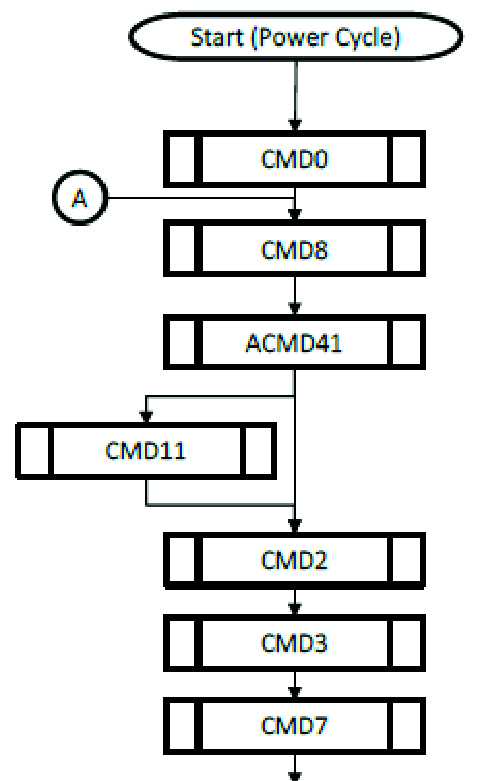

I need to make the SD card code more generalizable with a function that takes CMD IN.

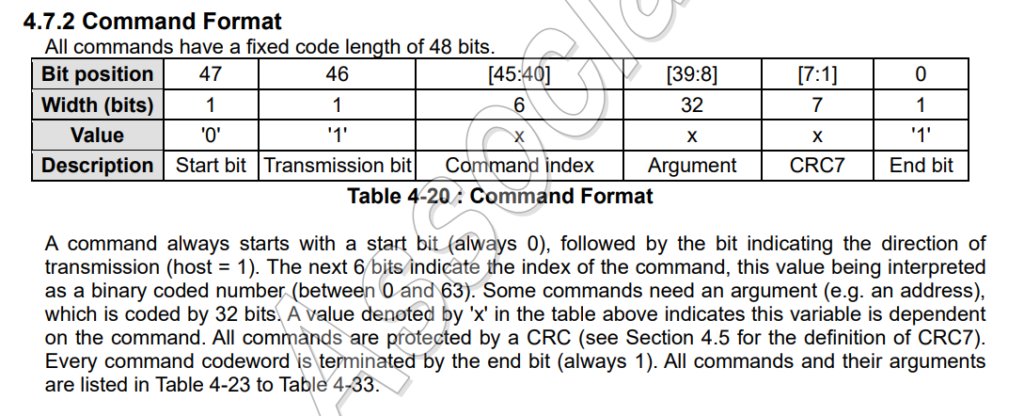

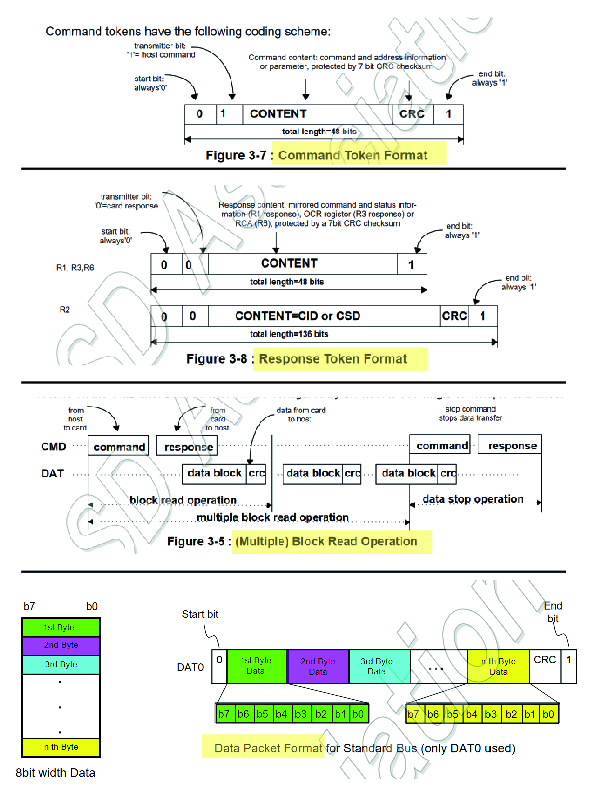

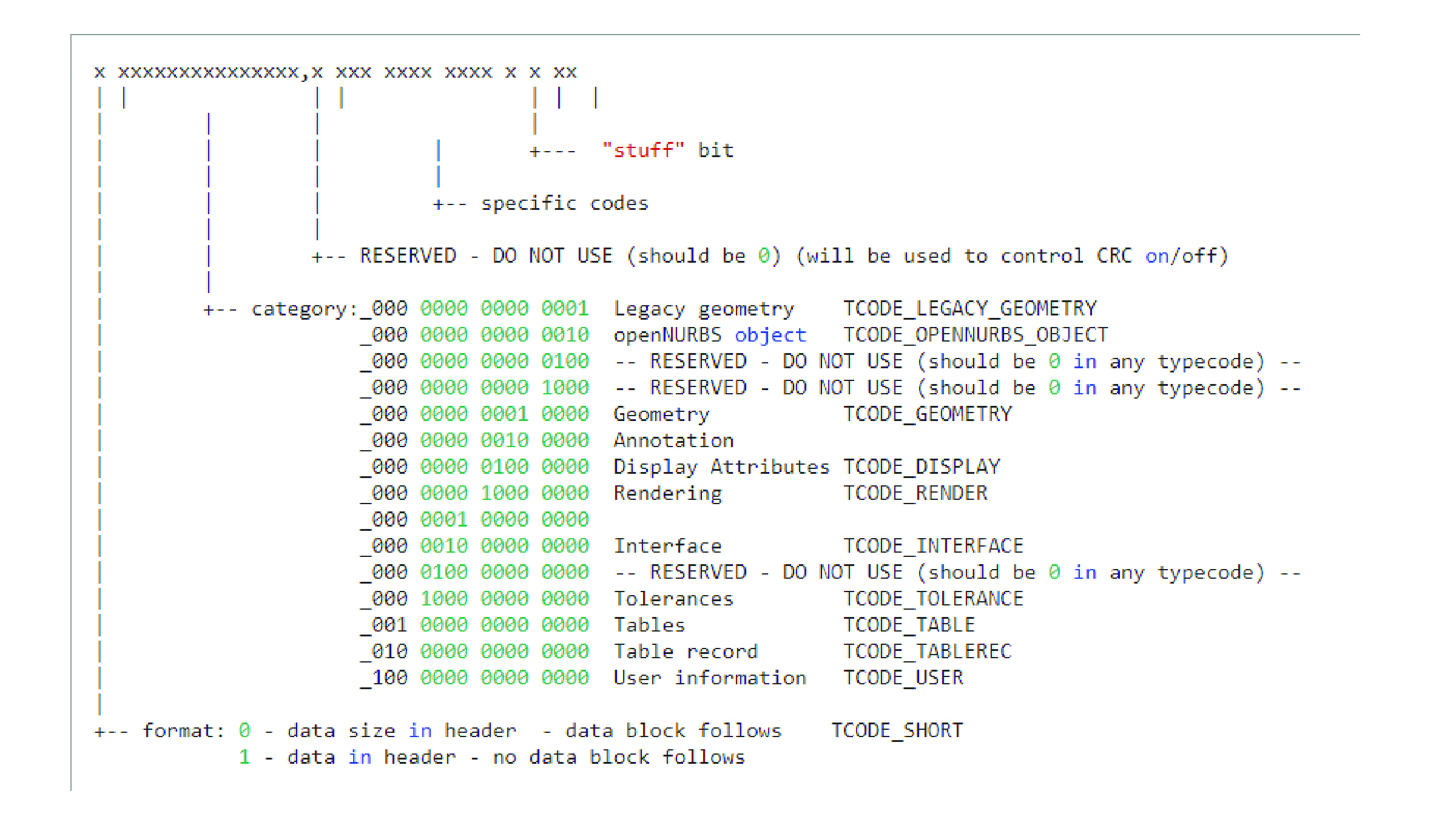

Here is the command format :

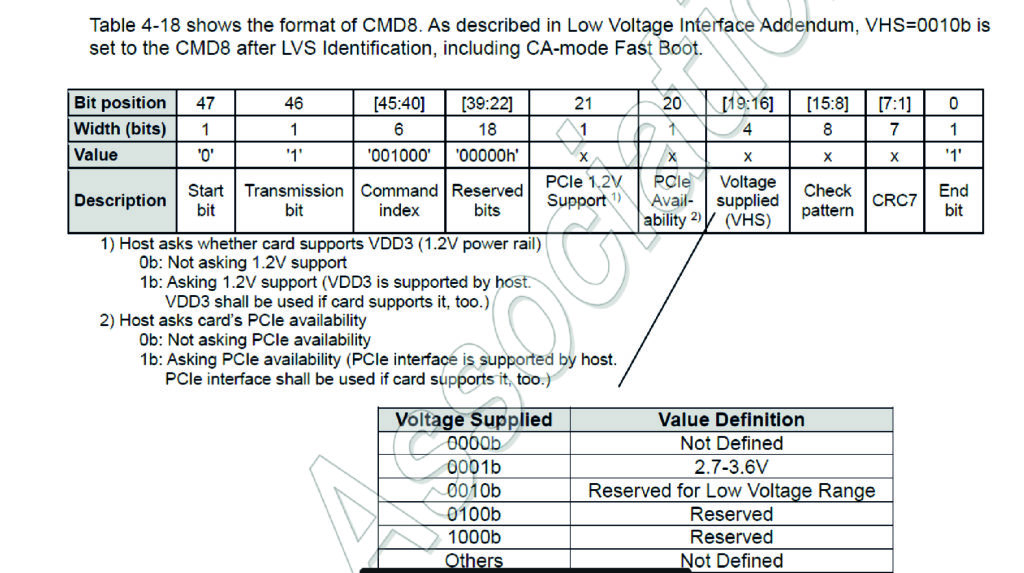

For example CMD8, the first byte is 01001000 with : 0 (start bit) + 1 (tx bit) + 010000 (six bits of the CMD number 8 in binary). After this are 32 bits of arguments (such as address you want to select) the 6 bit CRC7 and then 1.

NOTE ** I may need to change the speed from 50KHz to 100KHz or 200KHz for things to work. I am unclear about when I need to send ticks but forum user writes this :

; There must be 8 clocks after

; * a command with no response

; * the response of a command with a response

; * the end of a read data block

; * the CRC status token on a writeHere is the sequence of commands I have so far :

//TICKS

parameter TICKS = 48'b11111111_11111111_11111111_11111111_11111111_11111111;

//CMD0 “GO_IDLE_STATE”

parameter CMD0 = 48'b01000000_00000000_00000000_00000000_00000000_10010101;

//CMD8 “SEND_IF_COND”

parameter CMD8 = 48'b01001000_00000000_00000000_00000001_10101010_10000111;

//CMD55 “APP_CMD”

parameter CMD55 = 48'b01110111_00000000_00000000_00000000_00000000_01100101;

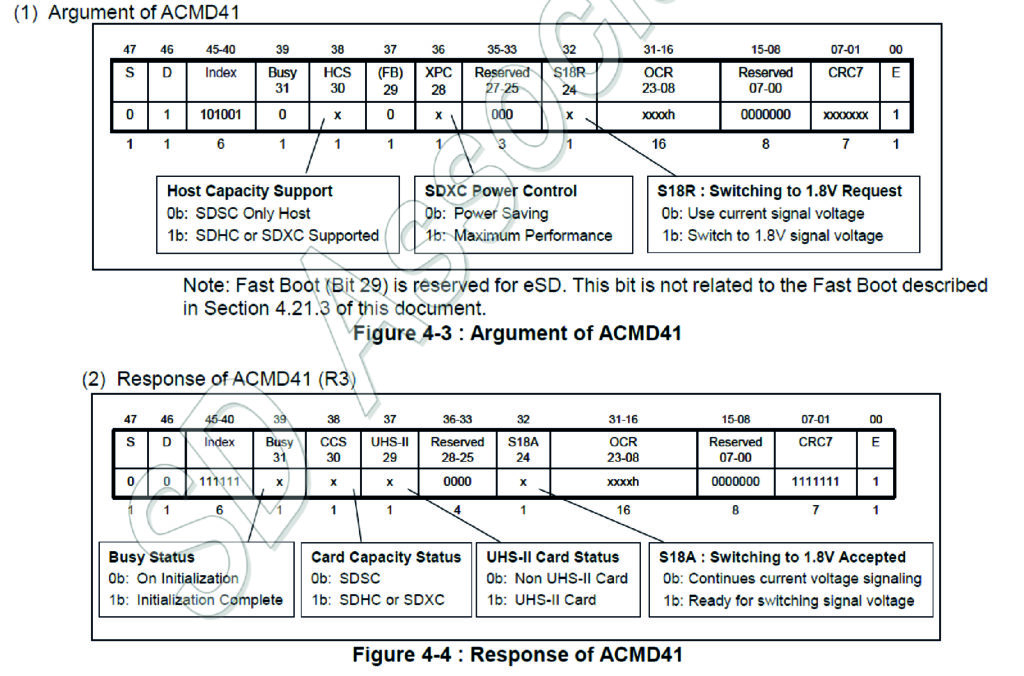

//ACMD41 “SD_SEND_OP_COND”

parameter ACMD41 = 48'b01101001_01000000_00010000_00000000_00000000_11001101;

//CMD2 “ALL_SEND_CID”

parameter CMD2 = 48'b01000010_00000000_00000000_00000000_00000000_01001101;

//CMD3 “SEND_RELATIVE_ADDR”

parameter CMD3 = 48'b01000011_00000000_00000000_00000000_00000000_00100001;

//CMD7 “SELECT/DESELECT_CARD”

parameter CMD7 = 48'b01000111_00000000_00000000_00000000_00000000_CRC+1; // need to generate my own CRC for this

//CMD17 “READ_SINGLE_BLOCK”

parameter CMD17 = 48'b01010001_00000000_00000000_00000000_00000000_CRC+1; NOTE ** There is a read multiple block command CMD18 READ_MULTIPLE_BLOCK that takes a 32 bit address and continuously transfers data blocks until interrupted by the STOP_TRANSMISSION command. By default sends 512 bytes followed by a CRC.

I am currently breaking up the code into cycles of 48 clock pulses to send and receive commands in sequence.

counter <= (counter==47) ? 0 : counter+1; // to count the steps in the sending of a single CMD

phase <= (counter==47) ? phase+1: phase; // to count how many CMDs we have sentEach command is currently sent in order by checking the phase. For example :

if (phase == 8) begin

rec <= 1; // set CMD to output

CMD <= ACMD41[counter]; // iterate through the 48 bit command

endListening to input is tougher because of my poor understanding of inout, I am using inout to define the CMD pin. If we are receiving it is put in a high Z state.

assign CMD = rec ? CMD : 1'bz;I am not sure if this will work :

if (phase == 9) begin

rec <= 0; // set CMD inout pin to high Z

data_in[counter] <= CMD; //store the data in data_in

endHere I’m trying to check if a ready bit 31 is still unset :

if ((data_in & (1<<31))==0)Here I’m trying to compose the CMD7 by concatenating the appropriate bytes.

//CMD7 “SELECT/DESELECT_CARD”

if (phase == 16) begin

rec <= 1;

RCA[15:0] = data_in[31:15]; // retrieve the RCA from the previous response

CMD7[47:0] = {8'b01000111,RCA[15:0],16'b0000000000000000,CRC+1}; // compose CMD7 from parts

CMD <= CMD7[counter]; // send the command

end****

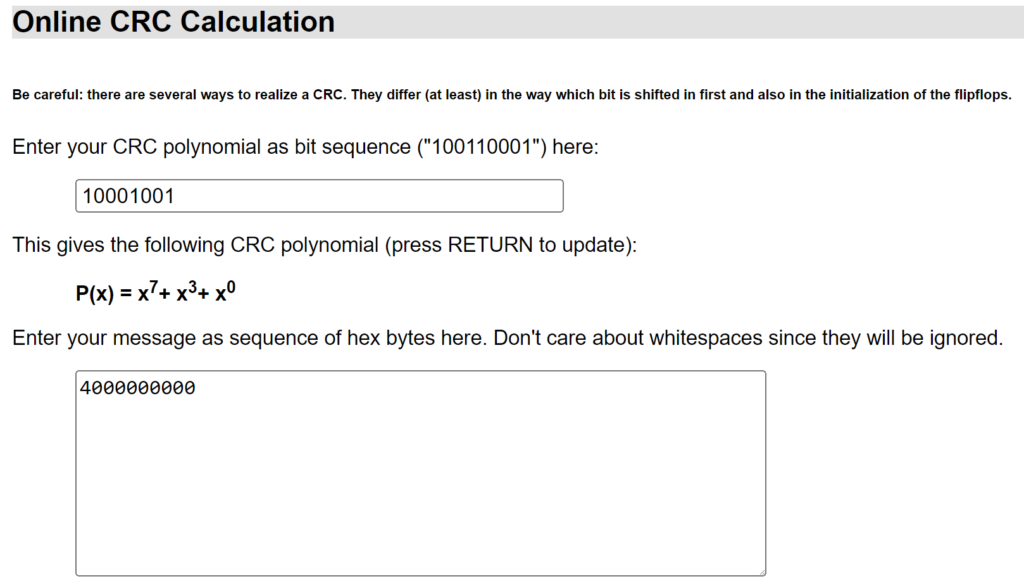

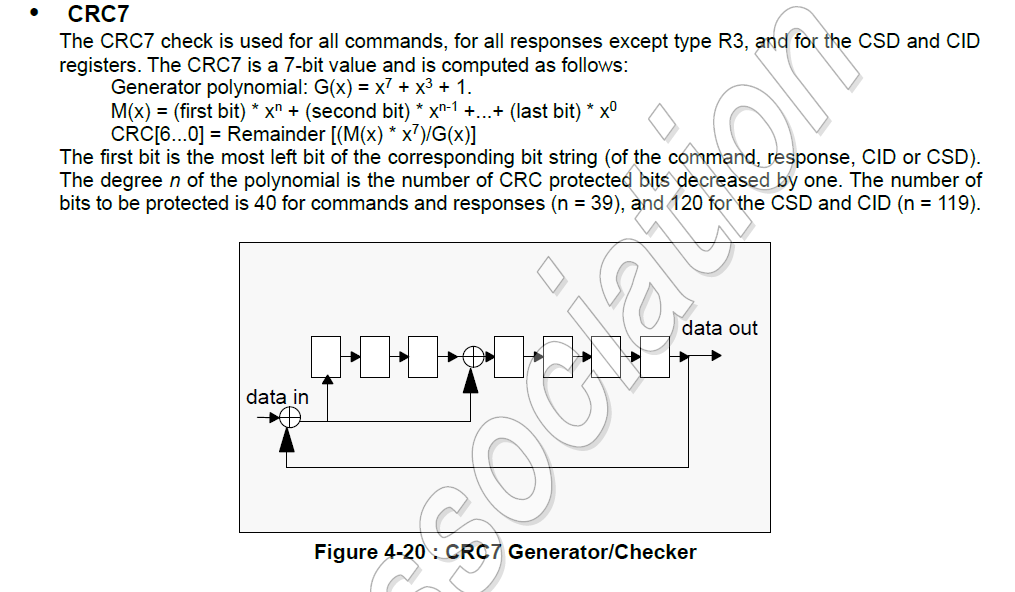

I’m on this site to calculate the CRC7 (https://www.ghsi.de/pages/subpages/Online%20CRC%20Calculation/)

- First I enter the CRC polynomial which for the SD card is x7 +x3 + 1

- Then I translate the 5 bytes I want to send into hex

- The 7 bit value generated at the end of the page is then added to the end of the message plus the end bit (1)

I need to figure out how to incorporate the CRC in verilog for certain commands however :

The above website automatically generates this verilog code that takes one bit at a time :

// ==========================================================================

// CRC Generation Unit - Linear Feedback Shift Register implementation

// (c) Kay Gorontzi, GHSi.de, distributed under the terms of LGPL

// ==========================================================================

module CRC_Unit(BITVAL, BITSTRB, CLEAR, CRC);

input BITVAL; // Next input bit

input BITSTRB; // Current bit valid (Clock)

input CLEAR; // Init CRC value

output [6:0] CRC; // Current output CRC value

reg [6:0] CRC; // We need output registers

wire inv;

assign inv = BITVAL ^ CRC[6]; // XOR required?

always @(posedge BITSTRB or posedge CLEAR) begin

if (CLEAR) begin

CRC = 0; // Init before calculation

end

else begin

CRC[6] = CRC[5];

CRC[5] = CRC[4];

CRC[4] = CRC[3];

CRC[3] = CRC[2] ^ inv;

CRC[2] = CRC[1];

CRC[1] = CRC[0];

CRC[0] = inv;

end

end

endmoduleI am not sure exactly how to feed this module one bit at a time. I also feel unsure about how to properly incorporate modules from different files.

****

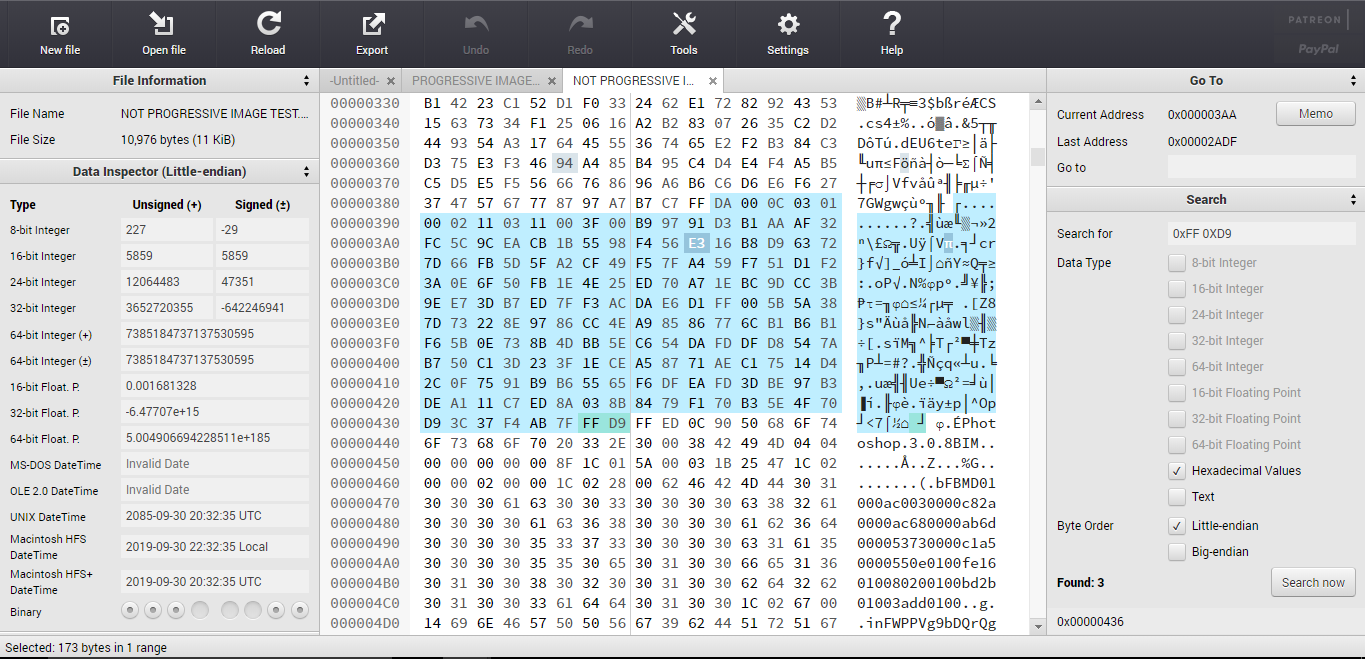

Here is my test code (once the timescale is uncommented) that I’m hoping will not require CRC (I’ll just look on the oscilloscope to see what the RCA is and then use that). It is the simplest possible setup.

Possible things that need changing :

- I am not waiting to see if bit 31 is set after sending

ACMD41, so I probably will need to add a delay here ? *EDIT* I am getting a busy bit 31 the first time I ask at the moment. - 8 clock ticks instead of 48 ? *EDIT* DONE

- No clock ticks after certain commands?

- The RCA (and CRC) if it is not 0001

- The block address (and CRC) if it is not 0

//-----------------------------------------------------------------

// - Attempt at SD 1 bit communication -

//CMD0 “GO_IDLE_STATE”

//CMD8 “SEND_IF_COND”

//CMD55 “APP_CMD”, ACMD41 “SD_SEND_OP_COND” with argument 40100000 (HCS=1, voltage = 3.3).

//The R3 response has HCS and the supported voltages set. Repeat until bit 31 of the response is 1.

//CMD2 “ALL_SEND_CID” with argument 00000000. The R2 response has the CID. I ignore it.

//CMD3 “SEND_RELATIVE_ADDR” with argument 00000000. The R6 response contains the RCA and some status that I ignore.

//The card is now in the stand-by state. Reading a block is accomplished by

//CMD7 “SELECT/DESELECT_CARD” with argument bits 31-16 = the RCA you were given, 15-0 = 0. The R1b response I ignore.

//CMD17 “READ_SINGLE_BLOCK” with argument = the block address.

//The R1 response I ignore, but there will also be the block data.

//Keep toggling the clock, and you’ll eventually see a start bit followed by a block of data and a CRC.

//-----------------------------------------------------------------

`default_nettype none // disable implicit definitions by Verilog

//`timescale 1us/1ns

module top(

input wire clk100,

input wire reset,

//input reg DAT,

output reg SCK,

output reg CMD

);

//CMD0 “GO_IDLE_STATE”

parameter CMD0 = 48'b01000000_00000000_00000000_00000000_00000000_10010101;

//CMD8 “SEND_IF_COND”

parameter CMD8 = 48'b01001000_00000000_00000000_00000001_10101010_10000111;

//CMD55 “APP_CMD”

parameter CMD55 = 48'b01110111_00000000_00000000_00000000_00000000_01100101;

//ACMD41 “SD_SEND_OP_COND”

parameter ACMD41 = 48'b01101001_01000000_00010000_00000000_00000000_11001101;

//CMD2 “ALL_SEND_CID”

parameter CMD2 = 48'b01000010_00000000_00000000_00000000_00000000_01001101;

//CMD3 “SEND_RELATIVE_ADDR”

parameter CMD3 = 48'b01000011_00000000_00000000_00000000_00000000_00100001;

//CMD7 “SELECT/DESELECT_CARD”

parameter CMD7 = 48'b01000111_00000000_00000001_00000000_00000000_11011101; // ASSUMING RCA IS 0001

//CMD17 “READ_SINGLE_BLOCK”

parameter CMD17 = 48'b01010001_00000000_00000000_00000000_00000000_01010101; // ASSUMING ADDR ZERO EXISTS

//CMD18 “READ_MULTIPLE_BLOCK”

parameter CMD18 = 48'b01010010_00000000_00000000_00000000_00000000_11100001; // ASSUMING ADDR ZERO EXISTS

//some counters

reg [9:0] counter=0;

reg [9:0] phase=0;

reg [7:0] q=0;

// divide 100MHz clock by 255 to equal 196.0784315 KHz which is in the 100KHz - 400KHz range

always @(posedge clk100) begin

q <= q+1;

if(q == 0) begin

SCK <= ~SCK;

end

end

//to count 48 SCK cycles and also how many which step of the communication sequence we're on

always @(posedge SCK) begin

//send 8 ticks

if (phase == 0) begin

counter <= counter+1;

if (counter <= 7) begin

CMD <= 1'b1;

end

else begin

counter<=0;

phase<=phase+1;

end

end

//send CMD0

if (phase == 1) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= CMD0[47-counter];

end

else begin

counter<=0;

phase<=phase+1;

end

end

//send 8 clock ticks while CMD high

if (phase == 2) begin

counter <= counter+1;

if (counter <= 7) begin

CMD <= 1'b1;

end

else begin

counter<=0;

phase<=phase+1;

end

end

//send CMD8

if (phase == 3) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= CMD8[47-counter];

end

else begin

counter<=0;

phase<=phase+1;

end

end

//set CMD to input

if (phase == 4) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= 1'bz;

end

else begin

counter<=0;

phase<=phase+1;

end

end

//NEED THIS ? send 8 clock ticks while CMD high

if (phase == 5) begin

counter <= counter+1;

if (counter <= 7) begin

CMD <= 1'b1;

end

else begin

counter<=0;

phase<=phase+1;

end

end

//send CMD55

if (phase == 6) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= CMD55[47-counter];

end

else begin

counter<=0;

phase<=phase+1;

end

end

//listen to response

if (phase == 7) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= 1'bz;

end

else begin

counter<=0;

phase<=phase+1;

end

end

//NEED THIS ? send 8 clock ticks while CMD high

if (phase == 8) begin

counter <= counter+1;

if (counter <= 7) begin

CMD <= 1'b1;

end

else begin

counter<=0;

phase<=phase+1;

end

end

//send ACMD41

if (phase == 9) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= ACMD41[47-counter];

end

else begin

counter<=0;

phase<=phase+1;

end

end

//listen to response and check bit 31 is 1

if (phase == 10) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= 1'bz;

end

else begin

counter<=0;

phase<=phase+1;

end

end

//send CMD2

if (phase == 11) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= CMD2[47-counter];

end

else begin

counter<=0;

phase<=phase+1;

end

end

//listen to 136 bit CID CMD from SD

if (phase == 12) begin

counter <= counter+1;

if (counter <= 135) begin

CMD <= 1'bz;

end

else begin

counter<=0;

phase<=phase+1;

end

end

//send CMD3

if (phase == 13) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= CMD3[47-counter];

end

else begin

counter<=0;

phase<=phase+1;

end

end

if (phase == 14) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= 1'bz;

end

else begin

counter<=0;

phase<=phase+1;

end

end

//CMD7 “SELECT/DESELECT_CARD”

if (phase == 15) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= CMD7[47-counter];

end

else begin

counter<=0;

phase<=phase+1;

end

end

//listen to CMD from SD

if (phase == 16) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= 1'bz;

end

else begin

counter<=0;

phase<=phase+1;

end

end

//CMD17 “READ_SINGLE_BLOCK” with argument = the block address.

if (phase == 17) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= CMD17[47-counter];

end

else begin

counter<=0;

phase<=phase+1;

end

end

if (phase == 18) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= 1'bz;

end

else begin

counter<=0;

phase<=phase+1;

end

end

// Should start to see data coming in on the DAT pin !!

if (phase >= 19) begin

// DAT pin

end

end

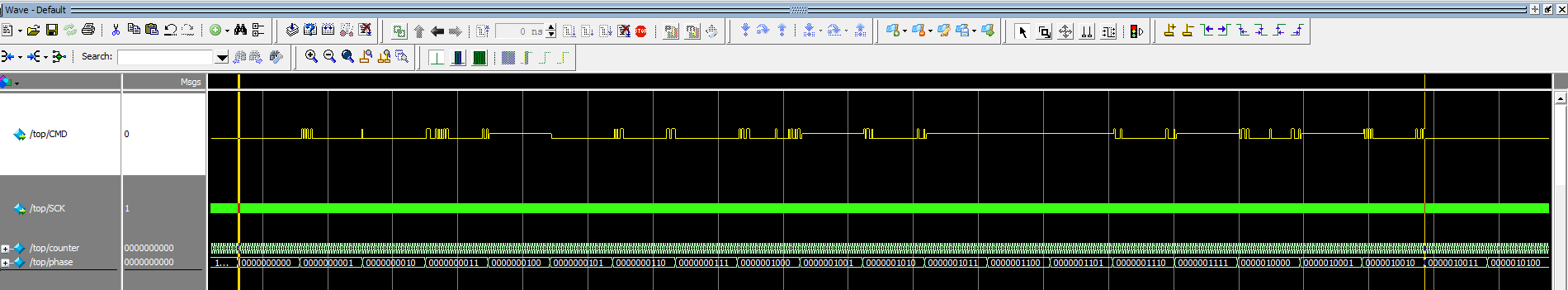

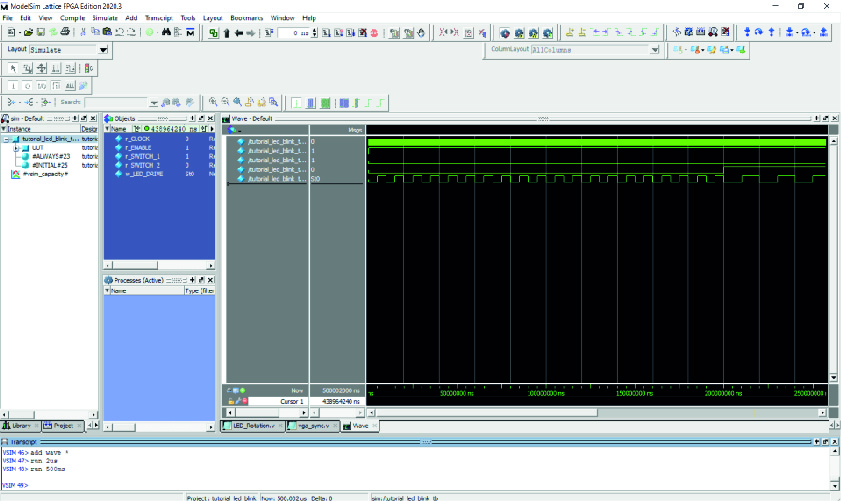

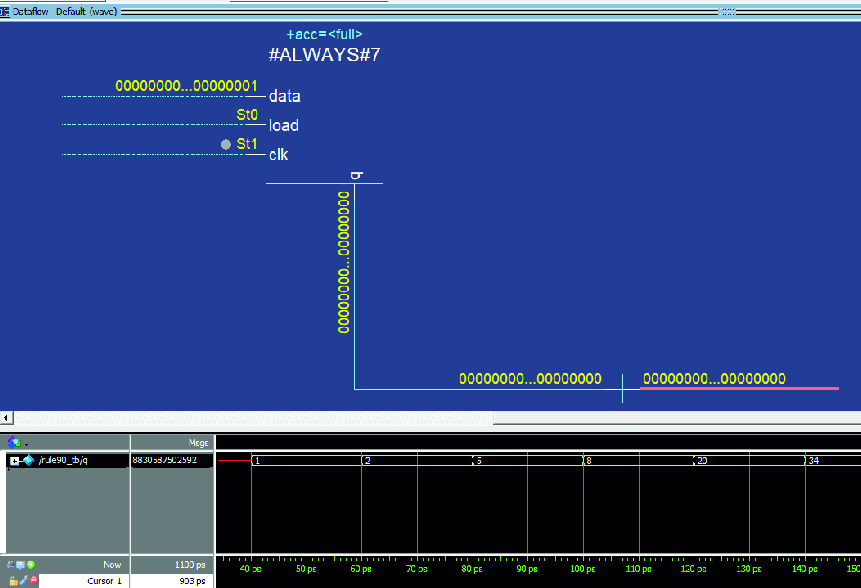

endmoduleThe sequence for ModelSim was :

- Open ModelSim, reselect the licence.dat file

- Open a “new project”

- Click Add Existing Files (pick only the test bench verilog file) and then Close

- Now Compilation > Compile All

- Now Simulation > Start Simulation

- In the console type <<view wave>>…

- …then <<add wave * >>… (note the space between wave and *)

- I right clicked on the SCK signal and selected Clock and then set the speed.

- …and a time period for example : <<run 10000ms>>.

I should have been able to see that the bits were the wrong order and that the clock ticks were with CMD low instead of HIGH here !!

*****

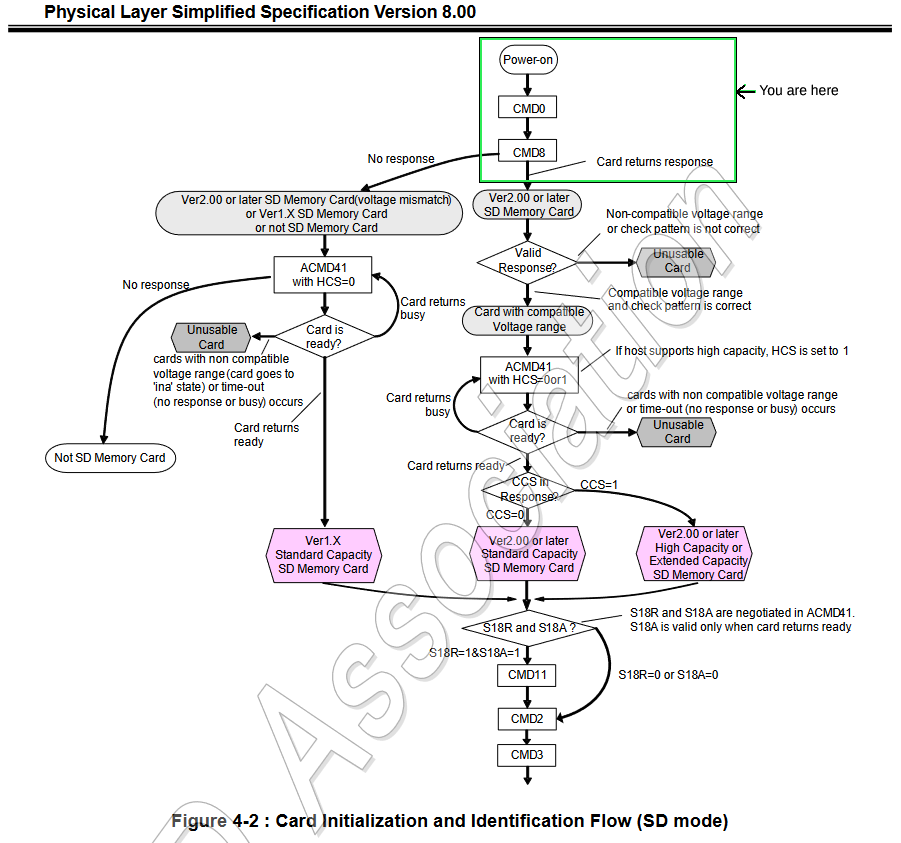

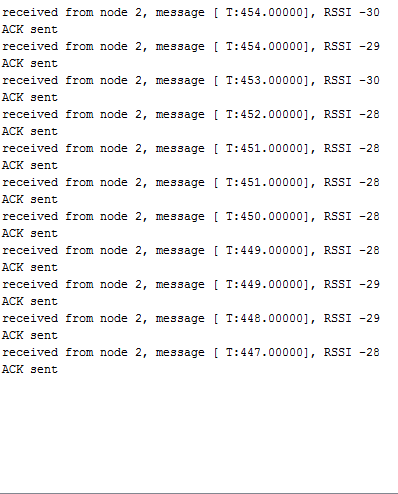

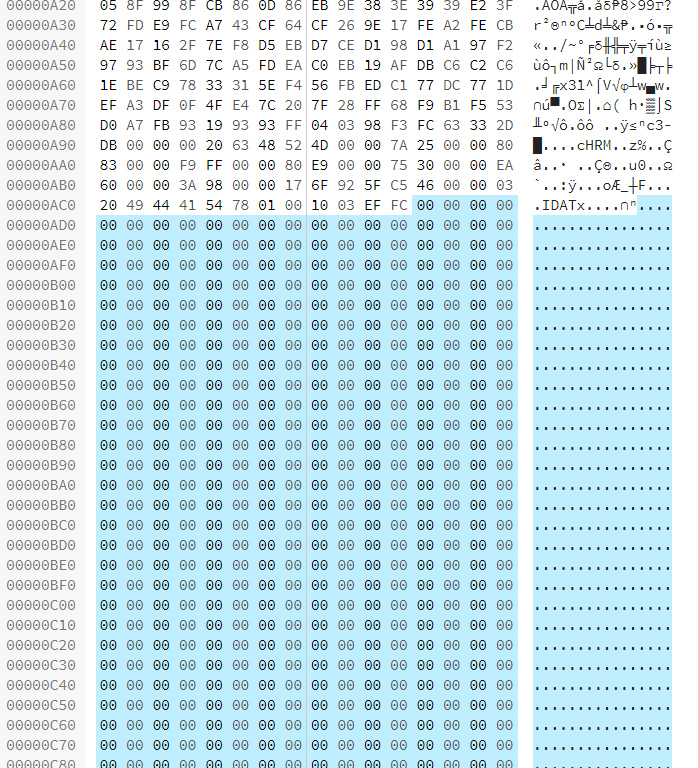

So I have gotten as far as CMD0 -> CMD8 -> CMD55 -> ACM41

At this point the SD card returns a busy bit 31, and when I ask again and again it eventually tries to talk while I am controlling the CMD pin and communications break down. Reading the documentation it looks like I can just keep pulsing the clock between 100-400KHz and delaying before checking the busy bit again (so getting rid of the 5x checks I do back to back and adding a seriously long delay could be the answer). This is the next step !

Here is the code so far :

//-----------------------------------------------------------------

// - Attempt at SD 1 bit communication -

//CMD0 “GO_IDLE_STATE”

//CMD8 “SEND_IF_COND”

//CMD55 “APP_CMD”, ACMD41 “SD_SEND_OP_COND” with argument 40100000 (HCS=1, voltage = 3.3).

//The R3 response has HCS and the supported voltages set. Repeat until bit 31 of the response is 1.

//CMD2 “ALL_SEND_CID” with argument 00000000. The R2 response has the CID. I ignore it.

//CMD3 “SEND_RELATIVE_ADDR” with argument 00000000. The R6 response contains the RCA and some status that I ignore.

//The card is now in the stand-by state. Reading a block is accomplished by

//CMD7 “SELECT/DESELECT_CARD” with argument bits 31-16 = the RCA you were given, 15-0 = 0. The R1b response I ignore.

//CMD17 “READ_SINGLE_BLOCK” with argument = the block address.

//The R1 response I ignore, but there will also be the block data.

//Keep toggling the clock, and you’ll eventually see a start bit followed by a block of data and a CRC.

//-----------------------------------------------------------------

`default_nettype none // disable implicit definitions by Verilog

//`timescale 1us/1ns

module top(

input wire clk100,

input wire reset,

//input reg DAT,

output reg SCK,

output reg CMD

);

//CMD0 “GO_IDLE_STATE”

parameter CMD0 = 48'b01000000_00000000_00000000_00000000_00000000_10010101;

//CMD8 “SEND_IF_COND”

parameter CMD8 = 48'b01001000_00000000_00000000_00000001_10101010_10000111;

//CMD55 “APP_CMD”

parameter CMD55 = 48'b01110111_00000000_00000000_00000000_00000000_01100101;

//ACMD41 “SD_SEND_OP_COND”

parameter ACMD41 = 48'b01101001_01000000_00010000_00000000_00000000_11001101;

//CMD2 “ALL_SEND_CID”

parameter CMD2 = 48'b01000010_00000000_00000000_00000000_00000000_01001101;

//CMD3 “SEND_RELATIVE_ADDR”

parameter CMD3 = 48'b01000011_00000000_00000000_00000000_00000000_00100001;

//CMD7 “SELECT/DESELECT_CARD”

parameter CMD7 = 48'b01000111_00000000_00000001_00000000_00000000_11011101; // ASSUMING RCA IS 0001

//CMD17 “READ_SINGLE_BLOCK”

parameter CMD17 = 48'b01010001_00000000_00000000_00000000_00000000_01010101; // ASSUMING ADDR ZERO EXISTS

//CMD18 “READ_MULTIPLE_BLOCK”

parameter CMD18 = 48'b01010010_00000000_00000000_00000000_00000000_11100001; // ASSUMING ADDR ZERO EXISTS

//some counters

reg [9:0] counter=0;

reg [9:0] phase=0;

reg [7:0] q=0;

// divide 100MHz clock by 255 to equal 196.0784315 KHz which is in the 100KHz - 400KHz range

always @(posedge clk100) begin

q <= q+1;

if(q == 0) begin

SCK <= ~SCK;

end

end

//to count 48 SCK cycles and also how many which step of the communication sequence we're on

always @(posedge SCK) begin

//send 8 ticks

if (phase == 0) begin

counter <= counter+1;

if (counter <= 7) begin

CMD <= 1'b1;

end

else begin

counter<=0;

phase<=phase+1;

end

end

//send CMD0

if (phase == 1) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= CMD0[47-counter];

end

else begin

counter<=0;

phase<=phase+1;

end

end

//send 8 clock ticks while CMD high

if (phase == 2) begin

counter <= counter+1;

if (counter <= 7) begin

CMD <= 1'b1;

end

else begin

counter<=0;

phase<=phase+1;

end

end

//send CMD8

if (phase == 3) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= CMD8[47-counter];

end

else begin

counter<=0;

phase<=phase+1;

end

end

//set CMD to input

if (phase == 4) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= 1'bz;

end

else begin

counter<=0;

phase<=phase+1;

end

end

//NEED THIS ? send 8 clock ticks while CMD high

if (phase == 5) begin

counter <= counter+1;

if (counter <= 7) begin

CMD <= 1'b1;

end

else begin

counter<=0;

phase<=phase+1;

end

end

//send CMD55

if (phase == 6) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= CMD55[47-counter];

end

else begin

counter<=0;

phase<=phase+1;

end

end

//listen to response

if (phase == 7) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= 1'bz;

end

else begin

counter<=0;

phase<=phase+1;

end

end

//NEED THIS ? send 8 clock ticks while CMD high

if (phase == 8) begin

counter <= counter+1;

if (counter <= 7) begin

CMD <= 1'b1;

end

else begin

counter<=0;

phase<=phase+1;

end

end

//send ACMD41

if (phase == 9) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= ACMD41[47-counter];

end

else begin

counter<=0;

phase<=phase+1;

end

end

//listen to response and check bit 31 is 1

if (phase == 10) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= 1'bz;

end

else begin

counter<=0;

phase<=phase+1;

end

end

// START OF SEND CMD55 + ACMD41 again (X2)

//START OF CONTINUOUS CLOCK BEFORE POLLING AGAIN

//END OF CONTINUOUS CLOCK BEFORE POLLING AGAIN

//

//NEED THIS ? send 8 clock ticks while CMD high

if (phase == 11) begin

counter <= counter+1;

if (counter <= 7) begin

CMD <= 1'b1;

end

else begin

counter<=0;

phase<=phase+1;

end

end

//send CMD55

if (phase == 12) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= CMD55[47-counter];

end

else begin

counter<=0;

phase<=phase+1;

end

end

//listen to response

if (phase == 13) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= 1'bz;

end

else begin

counter<=0;

phase<=phase+1;

end

end

//NEED THIS ? send 8 clock ticks while CMD high

if (phase == 14) begin

counter <= counter+1;

if (counter <= 7) begin

CMD <= 1'b1;

end

else begin

counter<=0;

phase<=phase+1;

end

end

//send ACMD41

if (phase == 15) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= ACMD41[47-counter];

end

else begin

counter<=0;

phase<=phase+1;

end

end

//listen to response and check bit 31 is 1

if (phase == 16) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= 1'bz;

end

else begin

counter<=0;

phase<=phase+1;

end

end

// END OF SEND CMD55 + ACMD41 again (x2)

// START OF SEND CMD55 + ACMD41 again (x3)

//NEED THIS ? send 8 clock ticks while CMD high

if (phase == 17) begin

counter <= counter+1;

if (counter <= 7) begin

CMD <= 1'b1;

end

else begin

counter<=0;

phase<=phase+1;

end

end

//send CMD55

if (phase == 18) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= CMD55[47-counter];

end

else begin

counter<=0;

phase<=phase+1;

end

end

//listen to response

if (phase == 19) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= 1'bz;

end

else begin

counter<=0;

phase<=phase+1;

end

end

//NEED THIS ? send 8 clock ticks while CMD high

if (phase == 20) begin

counter <= counter+1;

if (counter <= 7) begin

CMD <= 1'b1;

end

else begin

counter<=0;

phase<=phase+1;

end

end

//send ACMD41

if (phase == 21) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= ACMD41[47-counter];

end

else begin

counter<=0;

phase<=phase+1;

end

end

//listen to response and check bit 31 is 1

if (phase == 22) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= 1'bz;

end

else begin

counter<=0;

phase<=phase+1;

end

end

// END OF SEND CMD55 + ACMD41 again (x3)

// START OF SEND CMD55 + ACMD41 again (x4)

//NEED THIS ? send 8 clock ticks while CMD high

if (phase == 23) begin

counter <= counter+1;

if (counter <= 7) begin

CMD <= 1'b1;

end

else begin

counter<=0;

phase<=phase+1;

end

end

//send CMD55

if (phase == 24) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= CMD55[47-counter];

end

else begin

counter<=0;

phase<=phase+1;

end

end

//listen to response

if (phase == 25) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= 1'bz;

end

else begin

counter<=0;

phase<=phase+1;

end

end

//NEED THIS ? send 8 clock ticks while CMD high

if (phase == 26) begin

counter <= counter+1;

if (counter <= 7) begin

CMD <= 1'b1;

end

else begin

counter<=0;

phase<=phase+1;

end

end

//send ACMD41

if (phase == 27) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= ACMD41[47-counter];

end

else begin

counter<=0;

phase<=phase+1;

end

end

//listen to response and check bit 31 is 1

if (phase == 28) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= 1'bz;

end

else begin

counter<=0;

phase<=phase+1;

end

end

// END OF SEND CMD55 + ACMD41 again (x4)

// START OF SEND CMD55 + ACMD41 again (x5)

//NEED THIS ? send 8 clock ticks while CMD high

if (phase == 29) begin

counter <= counter+1;

if (counter <= 7) begin

CMD <= 1'b1;

end

else begin

counter<=0;

phase<=phase+1;

end

end

//send CMD55

if (phase == 30) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= CMD55[47-counter];

end

else begin

counter<=0;

phase<=phase+1;

end

end

//listen to response

if (phase == 31) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= 1'bz;

end

else begin

counter<=0;

phase<=phase+1;

end

end

//NEED THIS ? send 8 clock ticks while CMD high

if (phase == 32) begin

counter <= counter+1;

if (counter <= 7) begin

CMD <= 1'b1;

end

else begin

counter<=0;

phase<=phase+1;

end

end

//send ACMD41

if (phase == 33) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= ACMD41[47-counter];

end

else begin

counter<=0;

phase<=phase+1;

end

end

//listen to response and check bit 31 is 1

if (phase == 34) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= 1'bz;

end

else begin

counter<=0;

phase<=phase+1;

end

end

// END OF SEND CMD55 + ACMD41 again (x5)

//ADD TICKS HERE ??????????

//send CMD2

if (phase == 35) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= CMD2[47-counter];

end

else begin

counter<=0;

phase<=phase+1;

end

end

//listen to 136 bit CID CMD from SD

if (phase == 36) begin

counter <= counter+1;

if (counter <= 135) begin

CMD <= 1'bz;

end

else begin

counter<=0;

phase<=phase+1;

end

end

//send CMD3

if (phase == 37) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= CMD3[47-counter];

end

else begin

counter<=0;

phase<=phase+1;

end

end

if (phase == 38) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= 1'bz;

end

else begin

counter<=0;

phase<=phase+1;

end

end

//CMD7 “SELECT/DESELECT_CARD”

if (phase == 39) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= CMD7[47-counter];

end

else begin

counter<=0;

phase<=phase+1;

end

end

//listen to CMD from SD

if (phase == 40) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= 1'bz;

end

else begin

counter<=0;

phase<=phase+1;

end

end

//CMD17 “READ_SINGLE_BLOCK” with argument = the block address.

if (phase == 41) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= CMD17[47-counter];

end

else begin

counter<=0;

phase<=phase+1;

end

end

if (phase == 42) begin

counter <= counter+1;

if (counter <= 47) begin

CMD <= 1'bz;

end

else begin

counter<=0;

phase<=phase+1;

end

end

// Should start to see data coming in on the DAT pin !!

if (phase >= 43) begin

// DAT pin

end

end

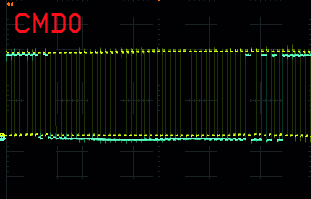

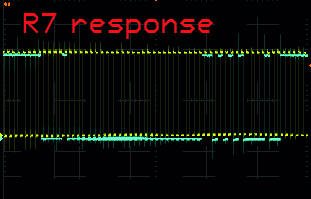

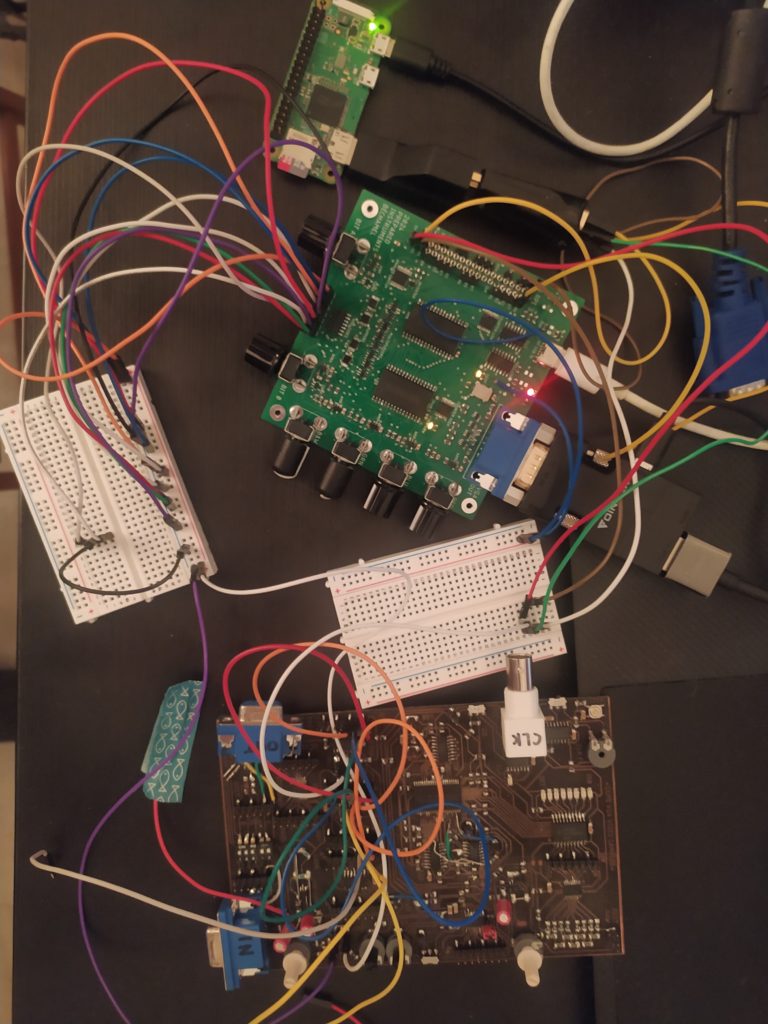

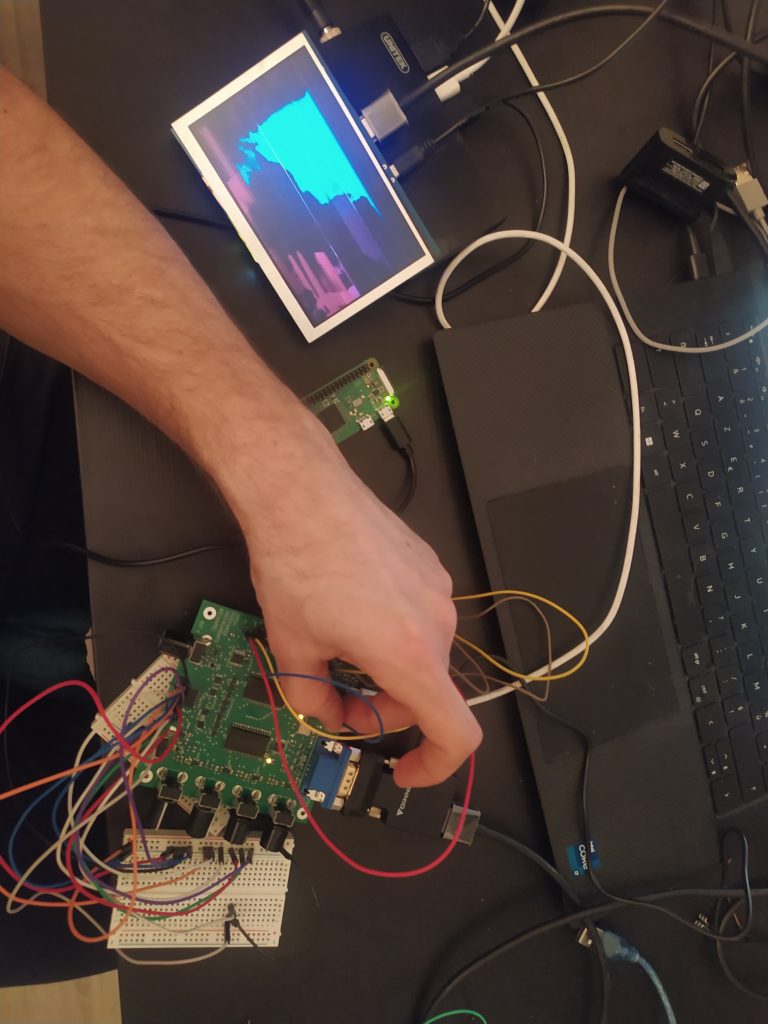

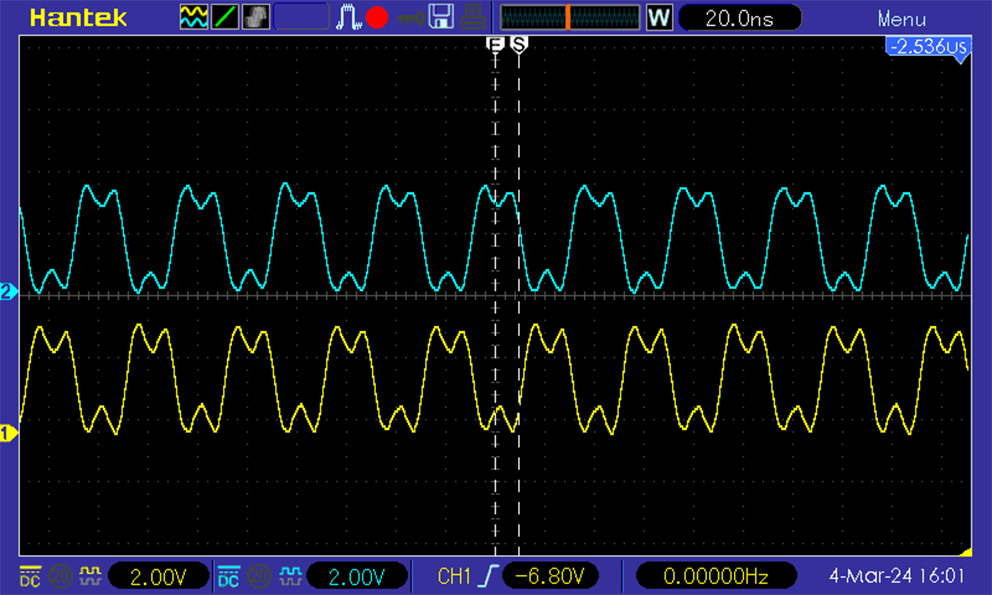

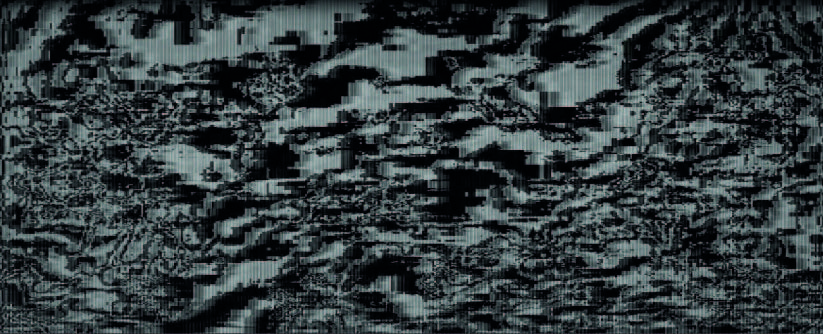

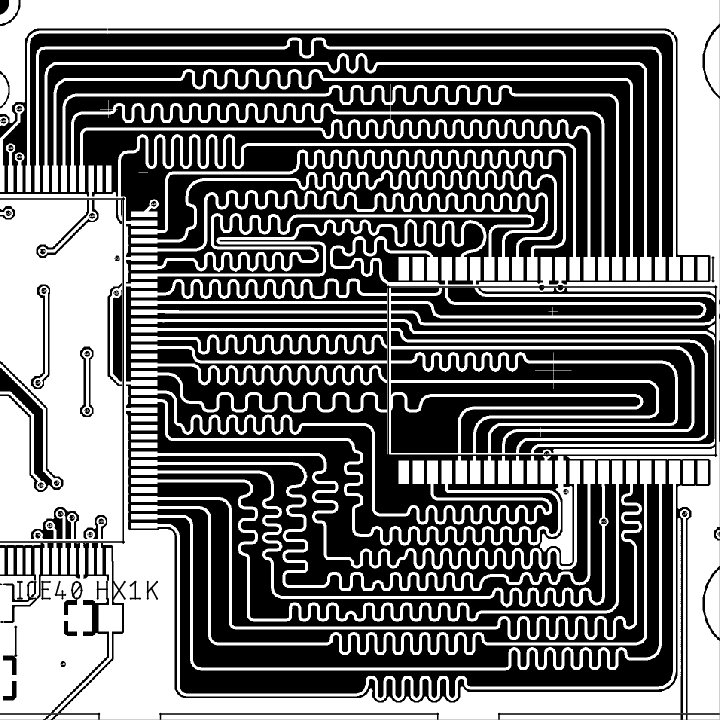

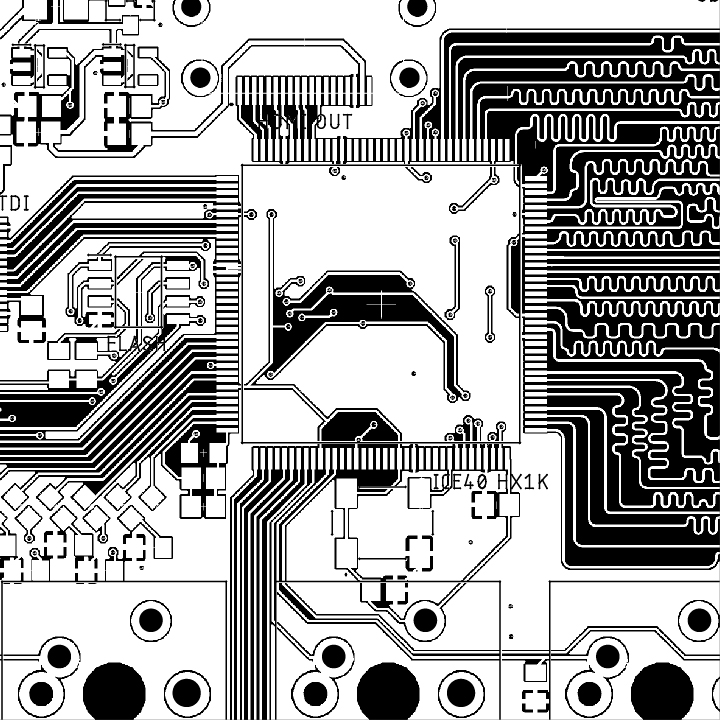

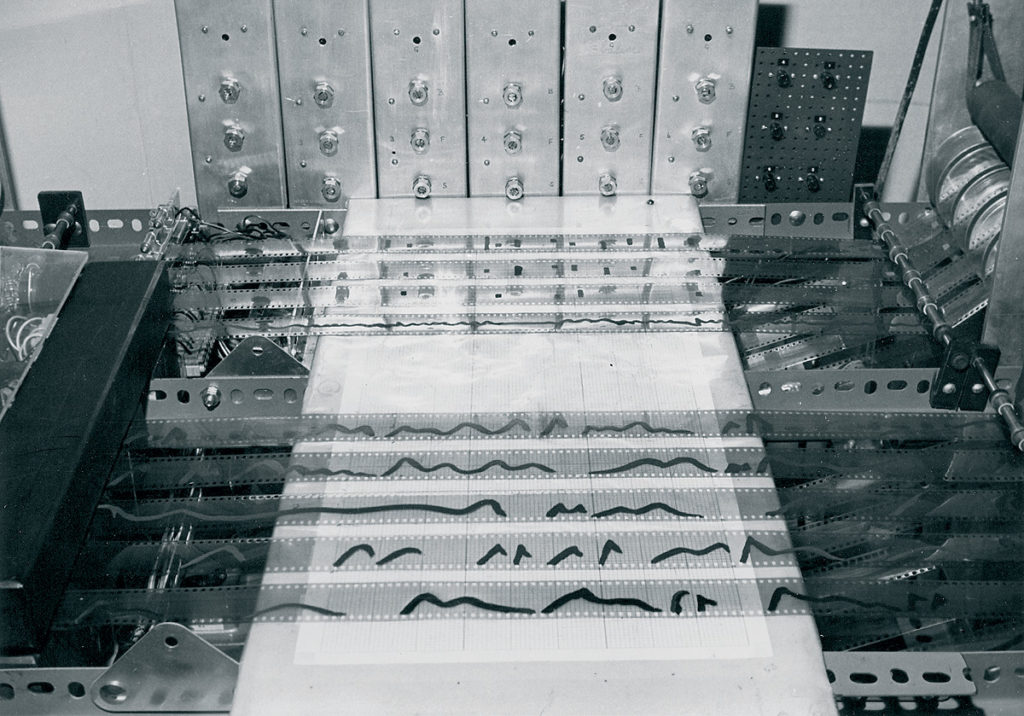

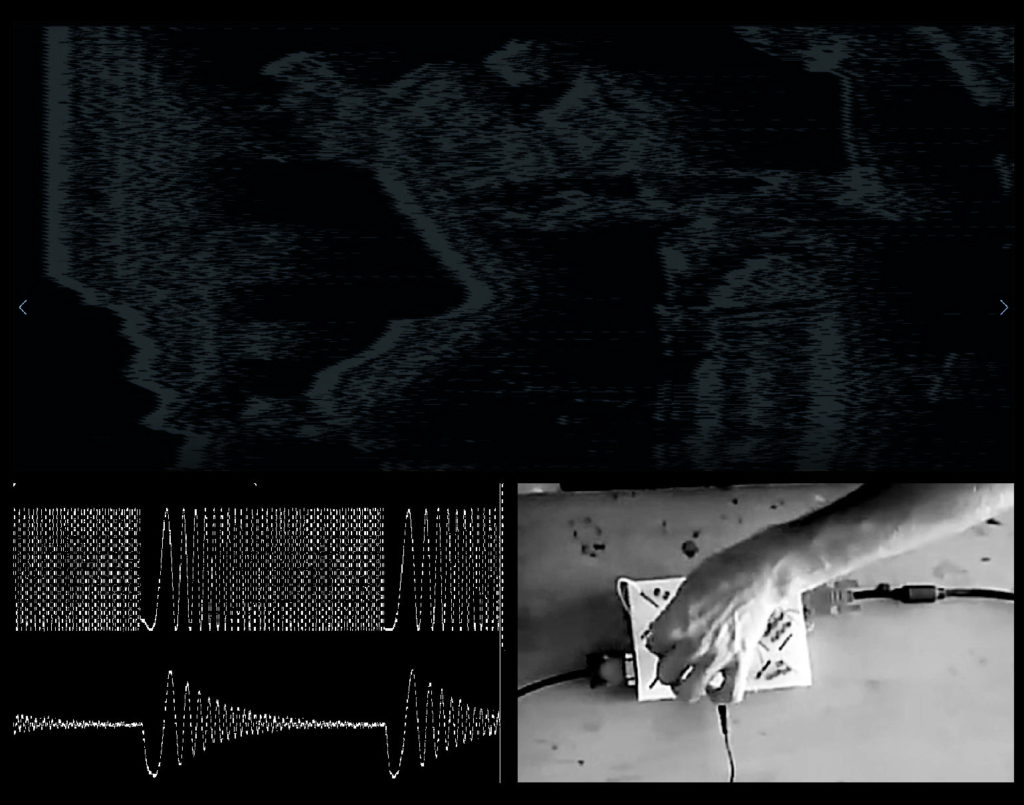

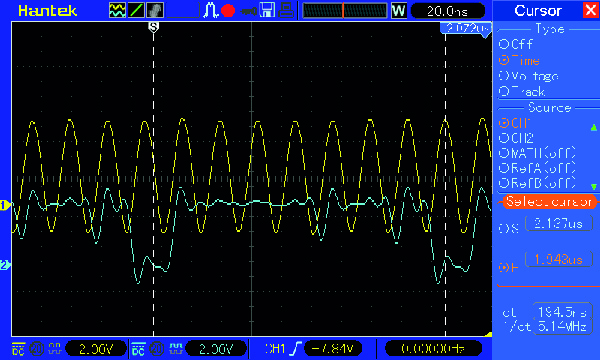

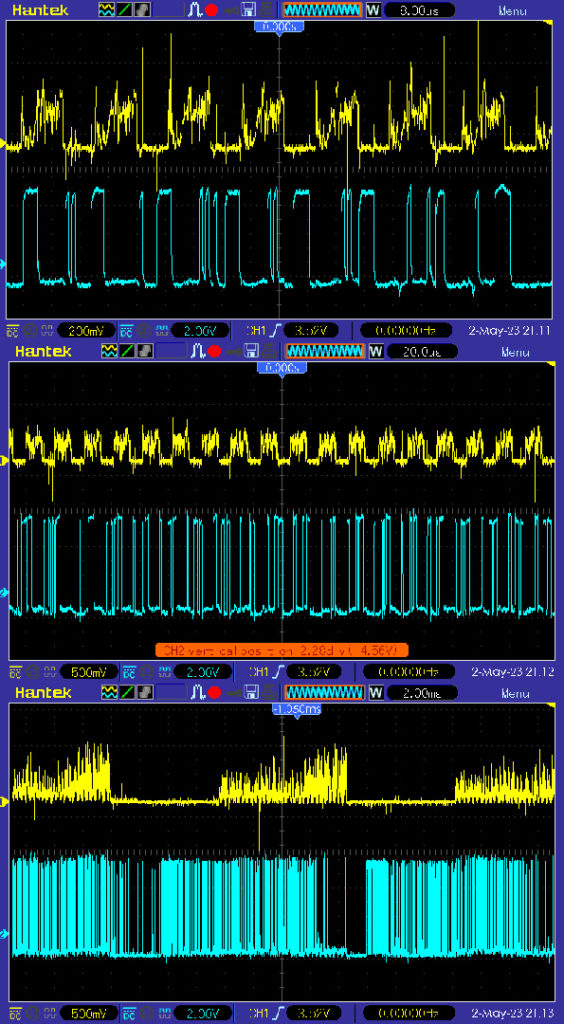

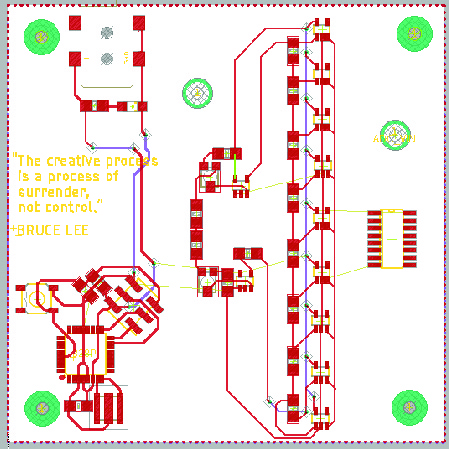

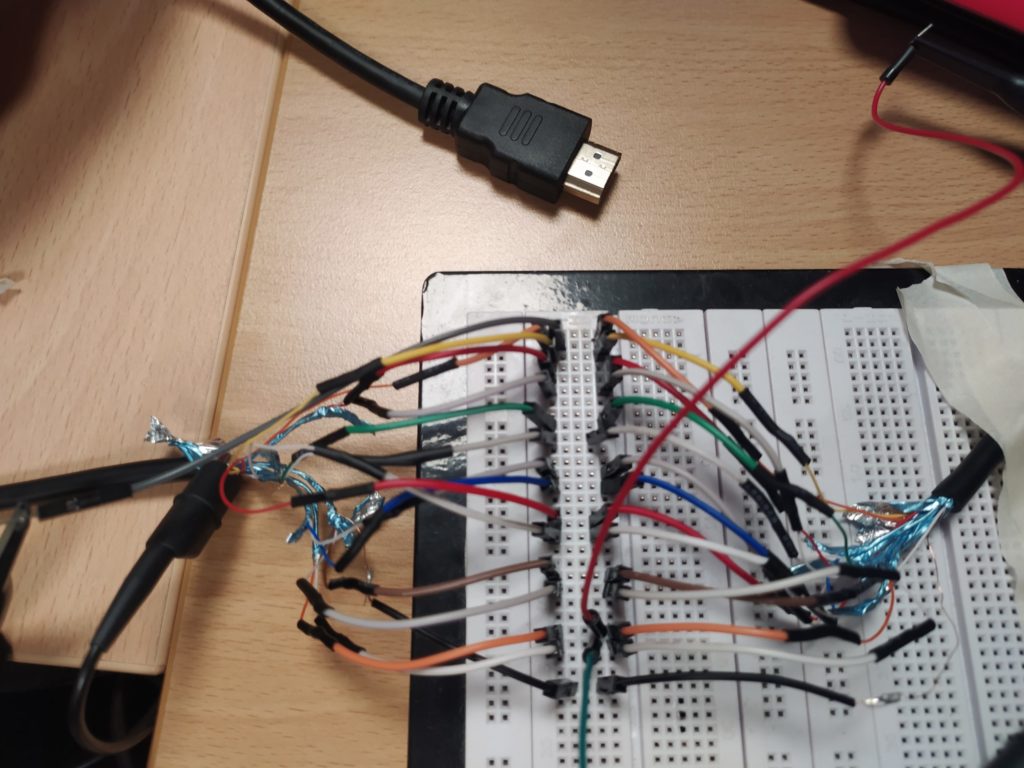

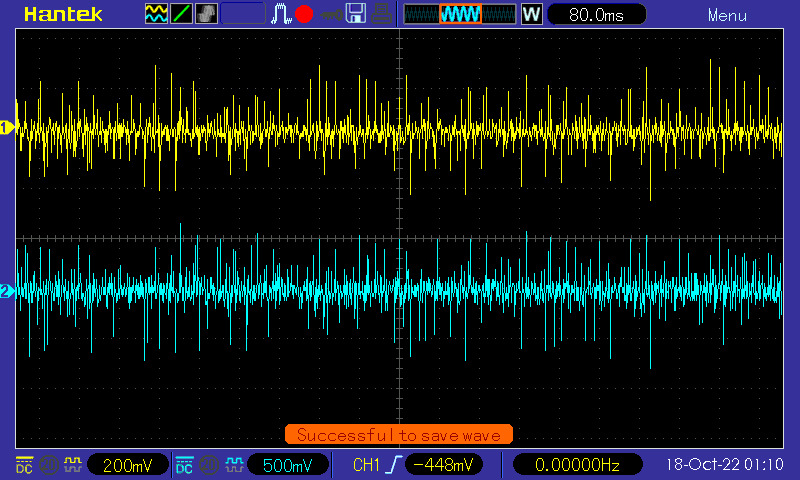

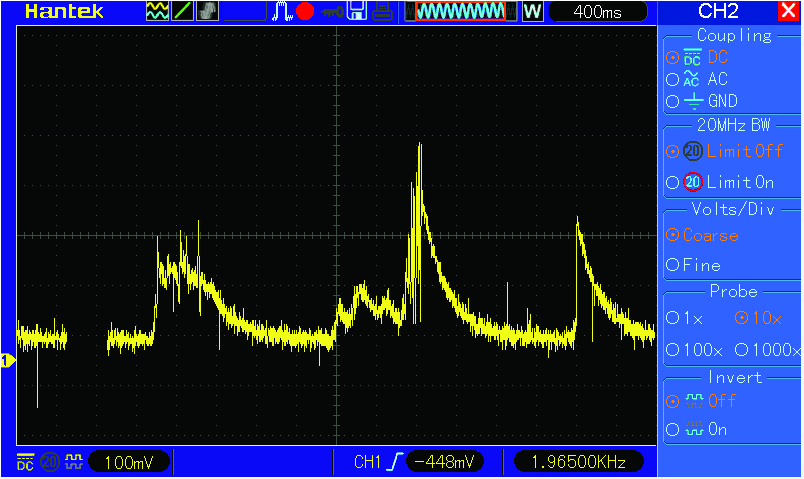

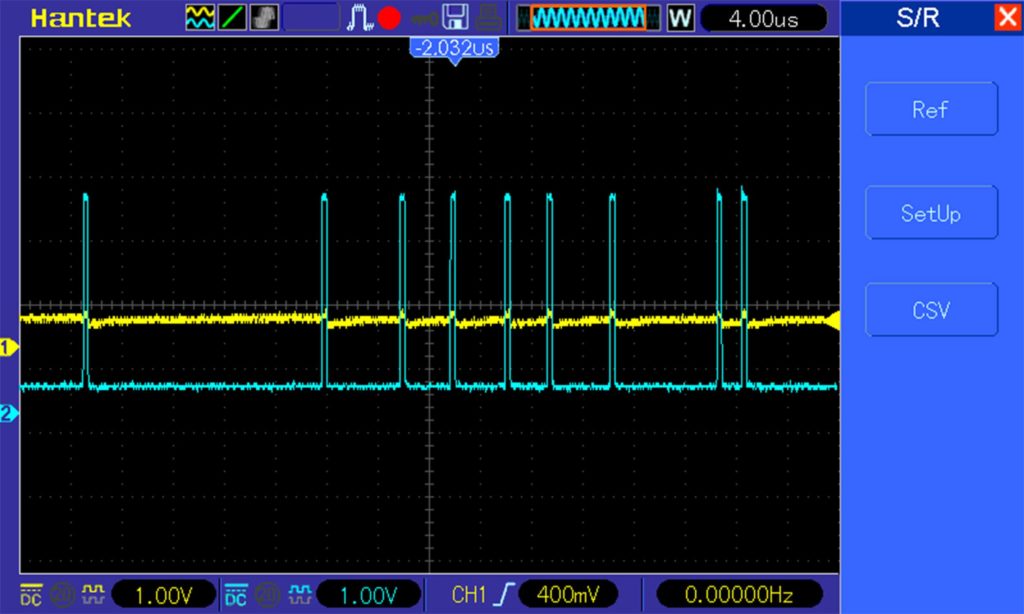

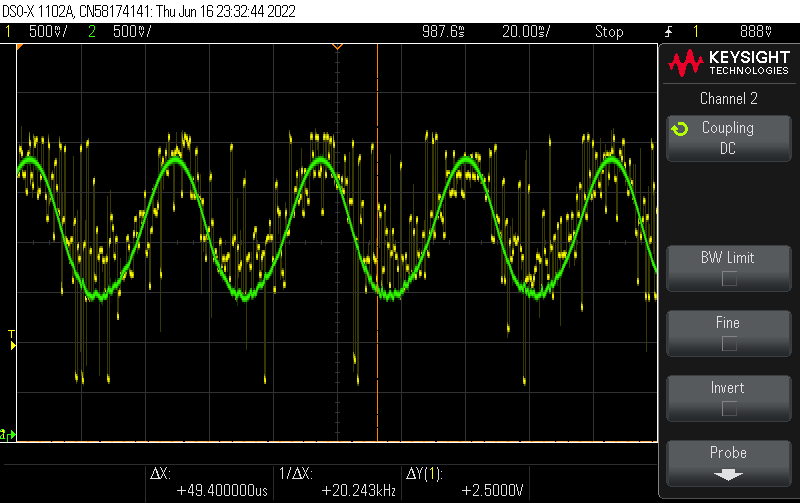

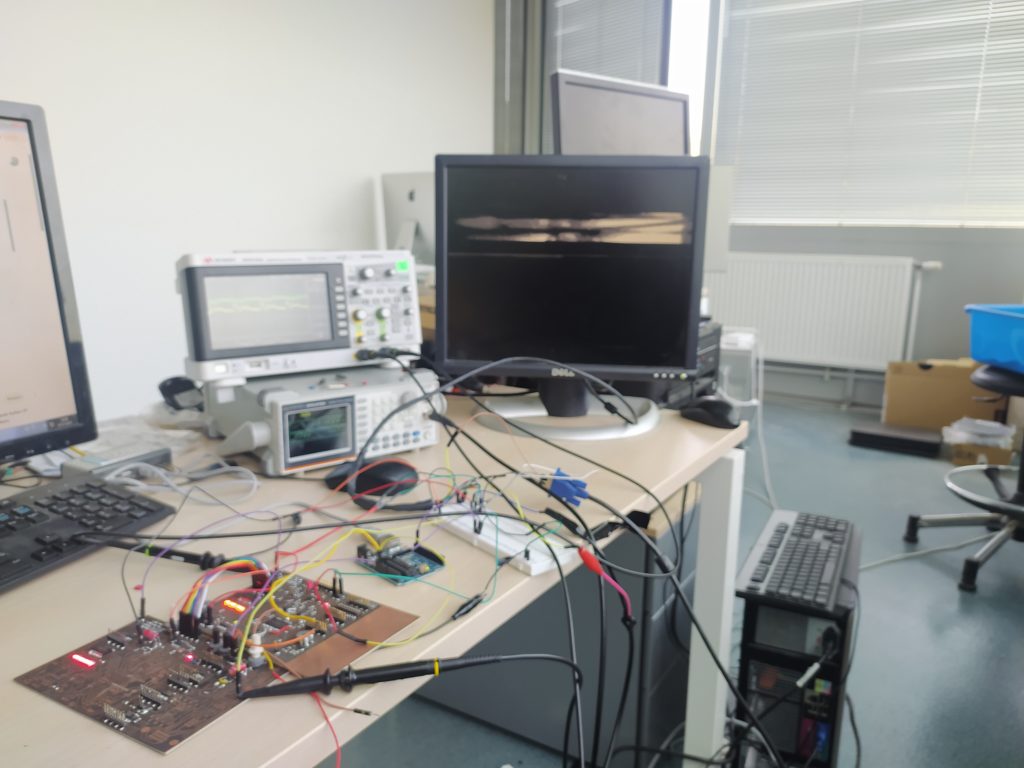

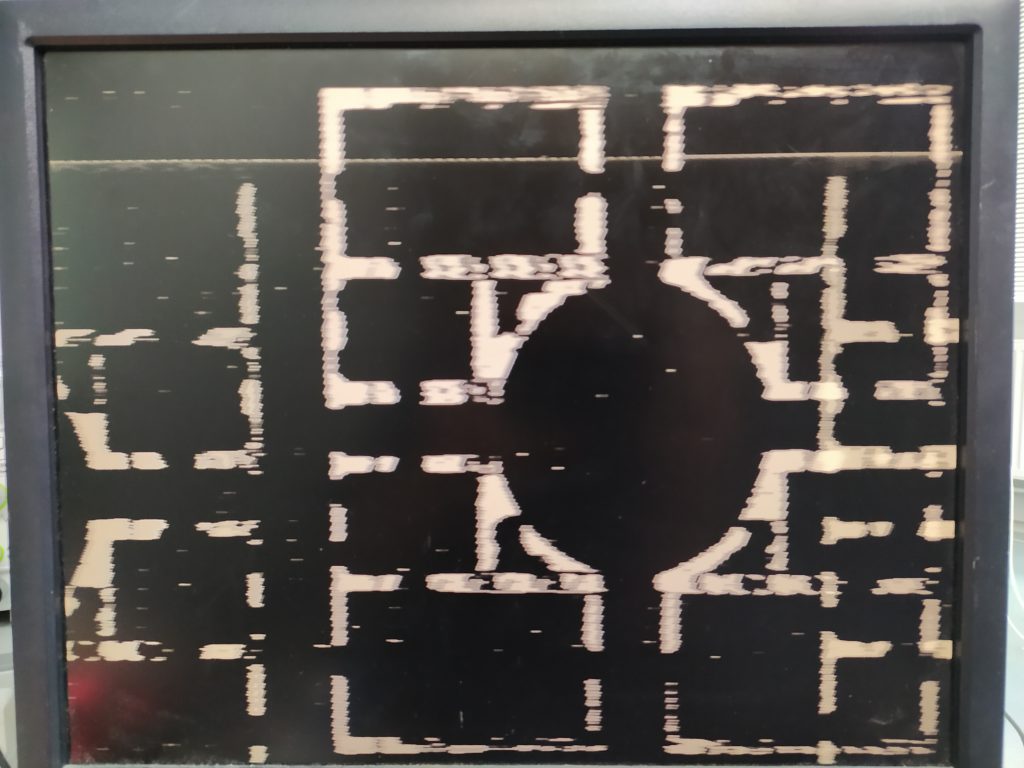

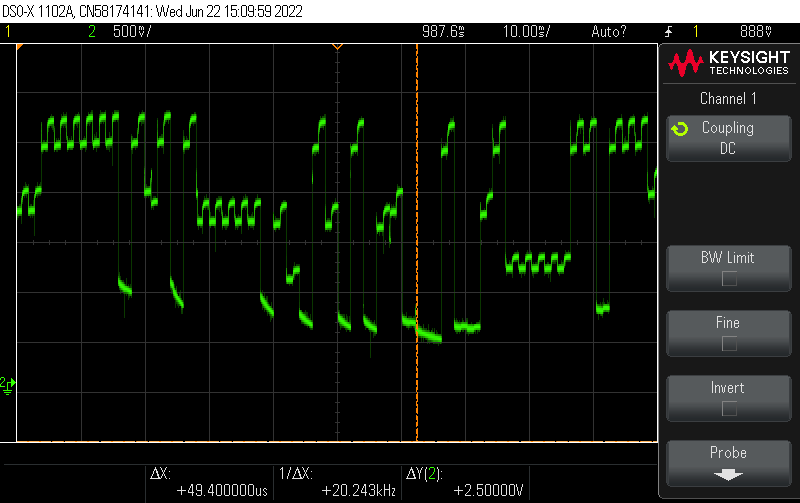

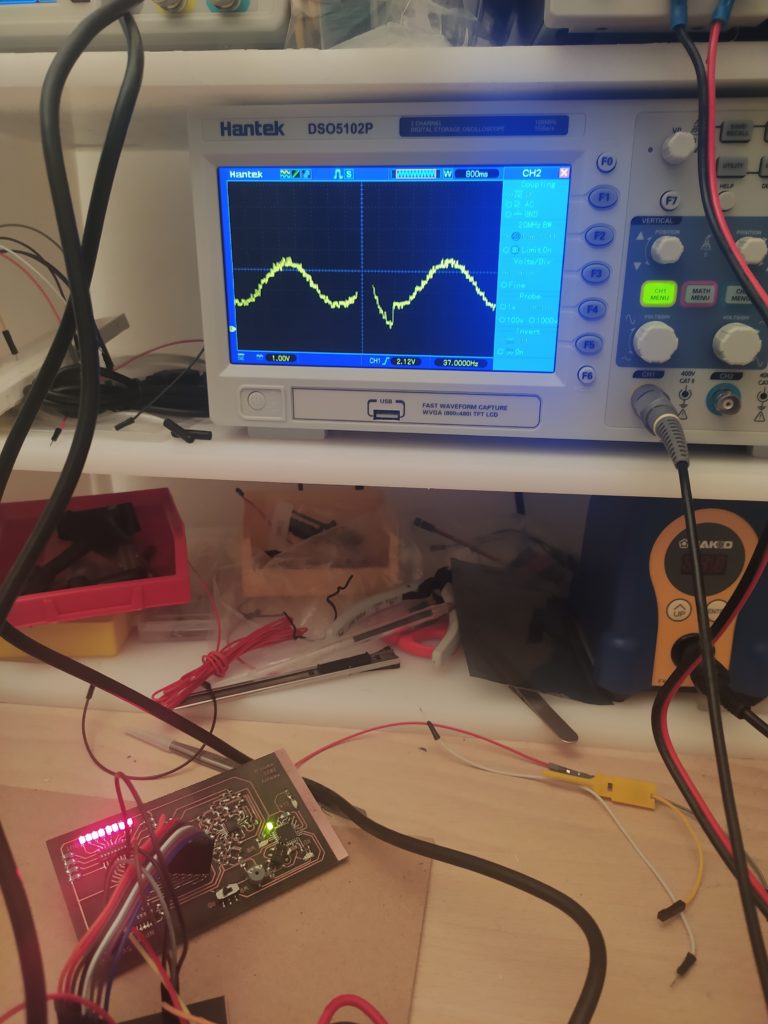

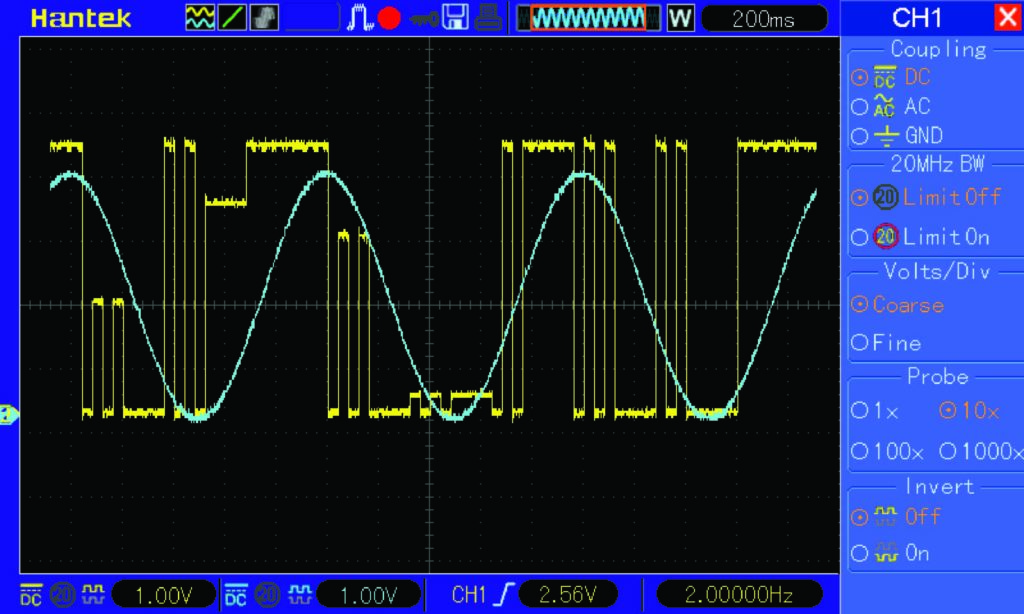

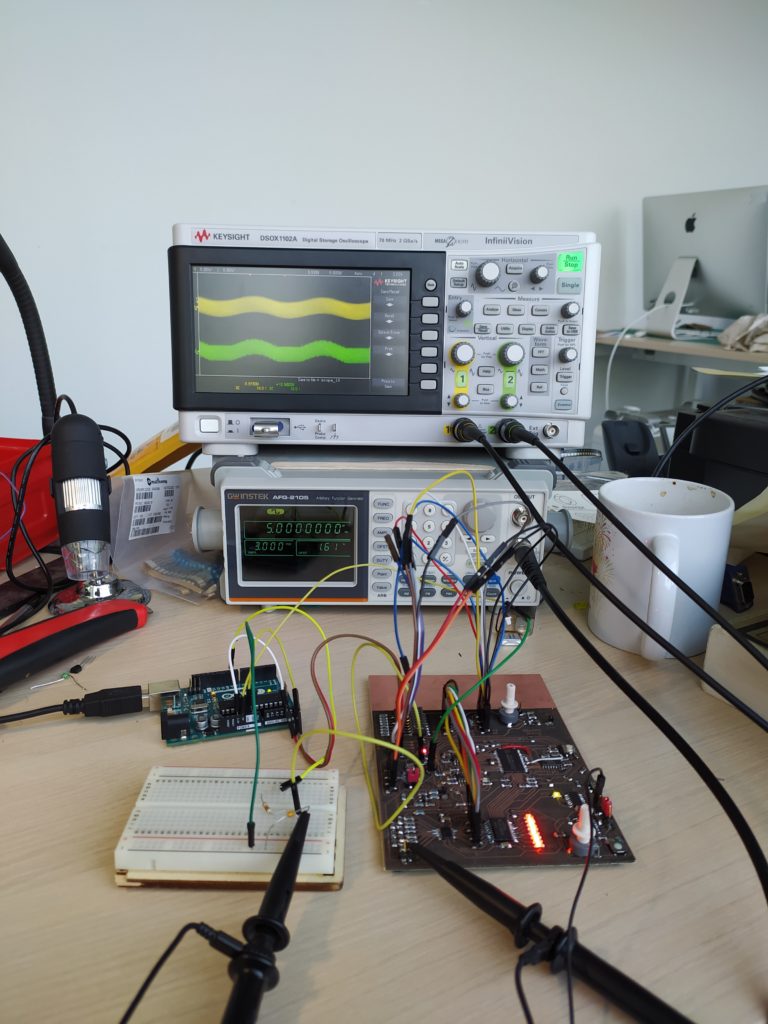

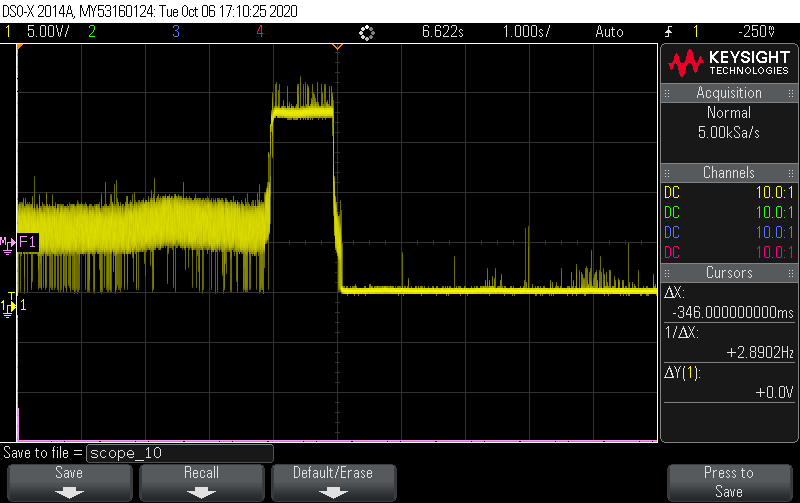

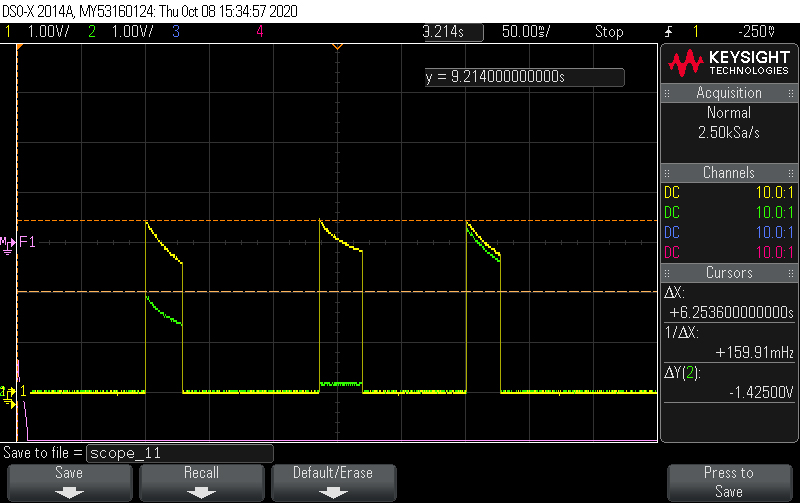

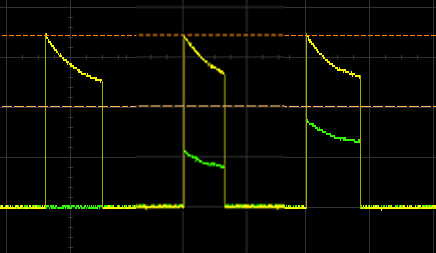

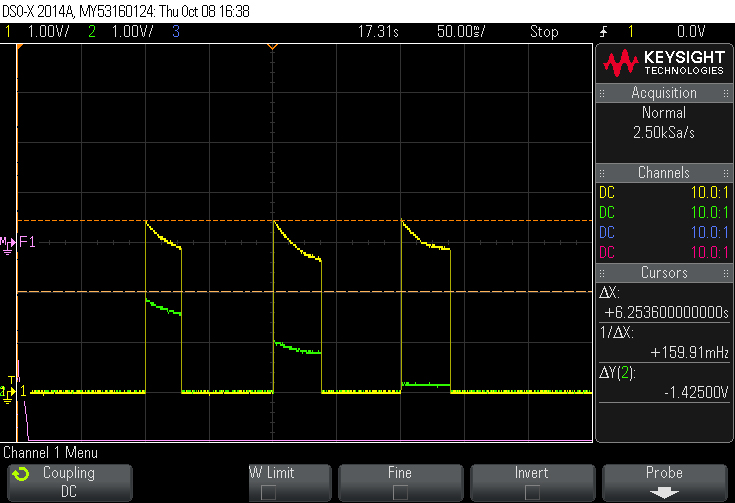

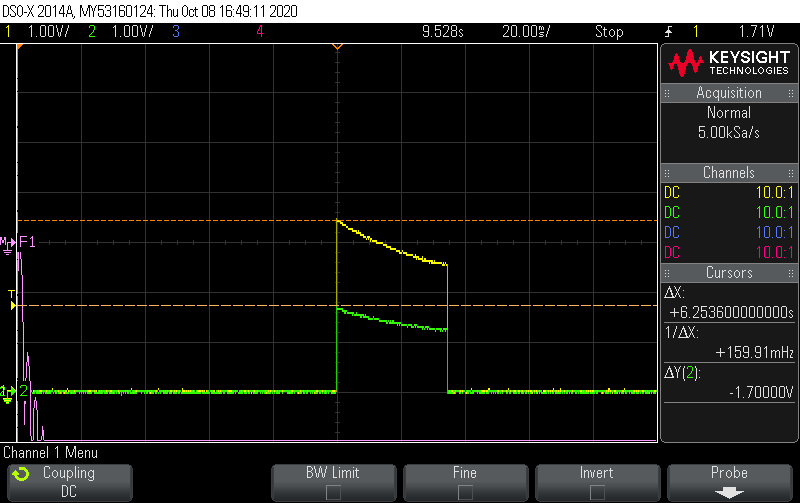

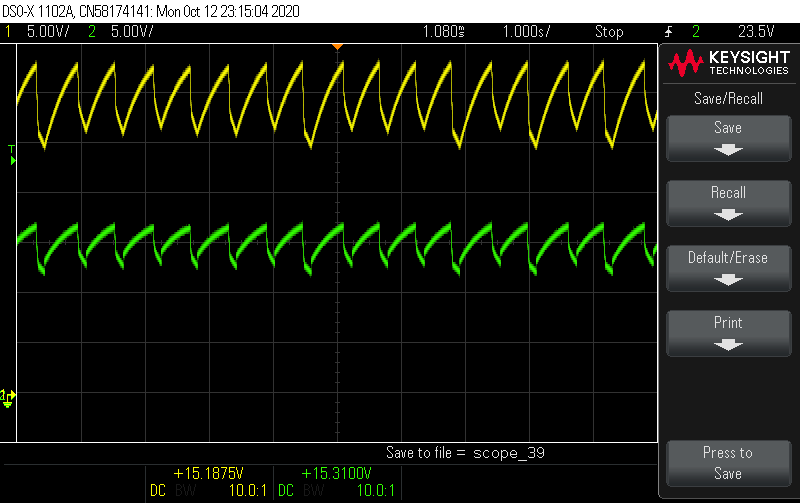

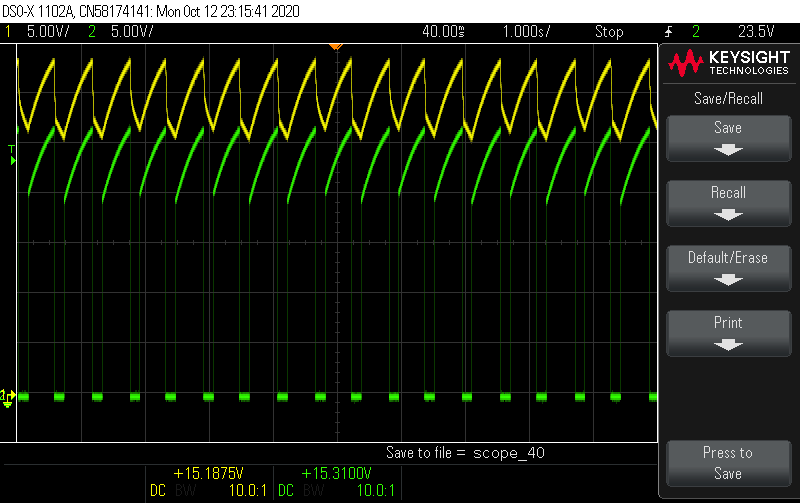

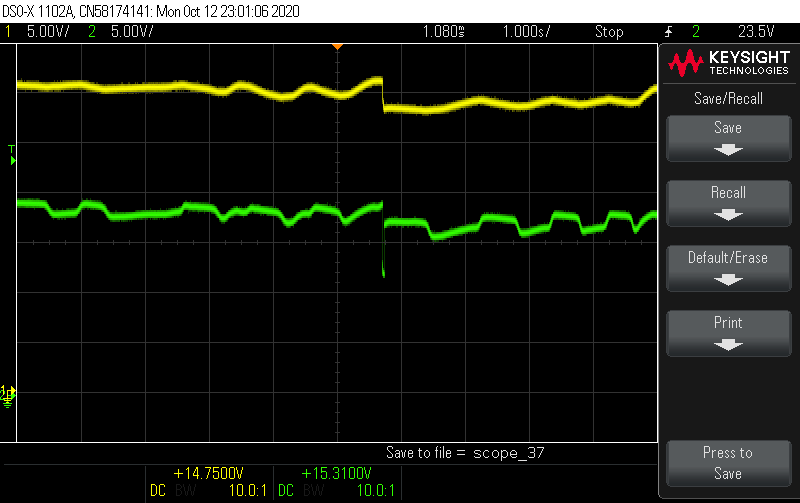

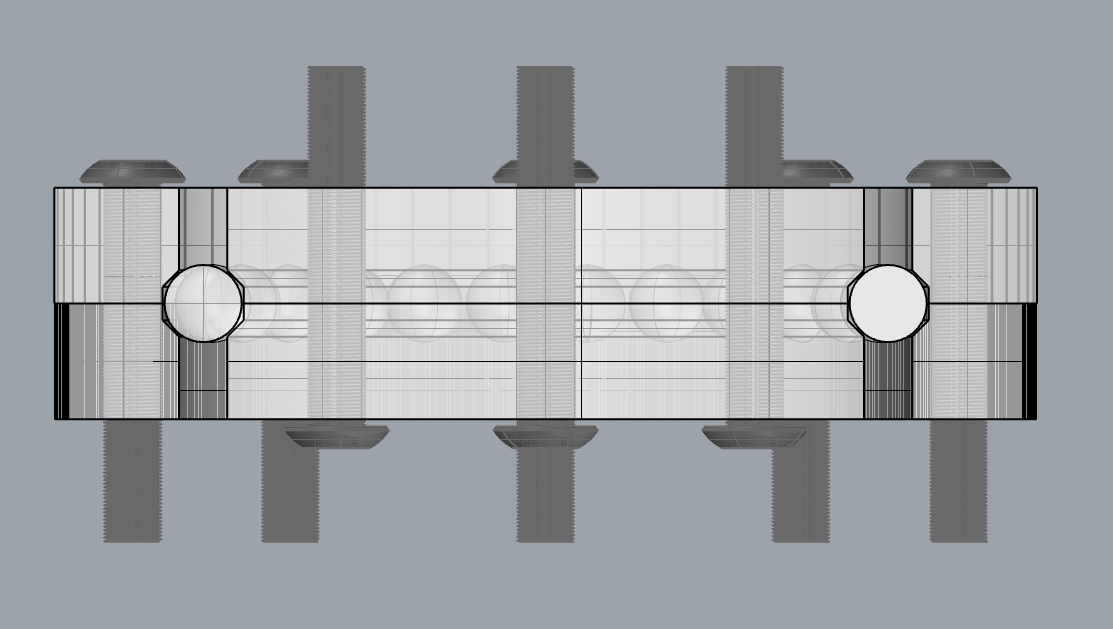

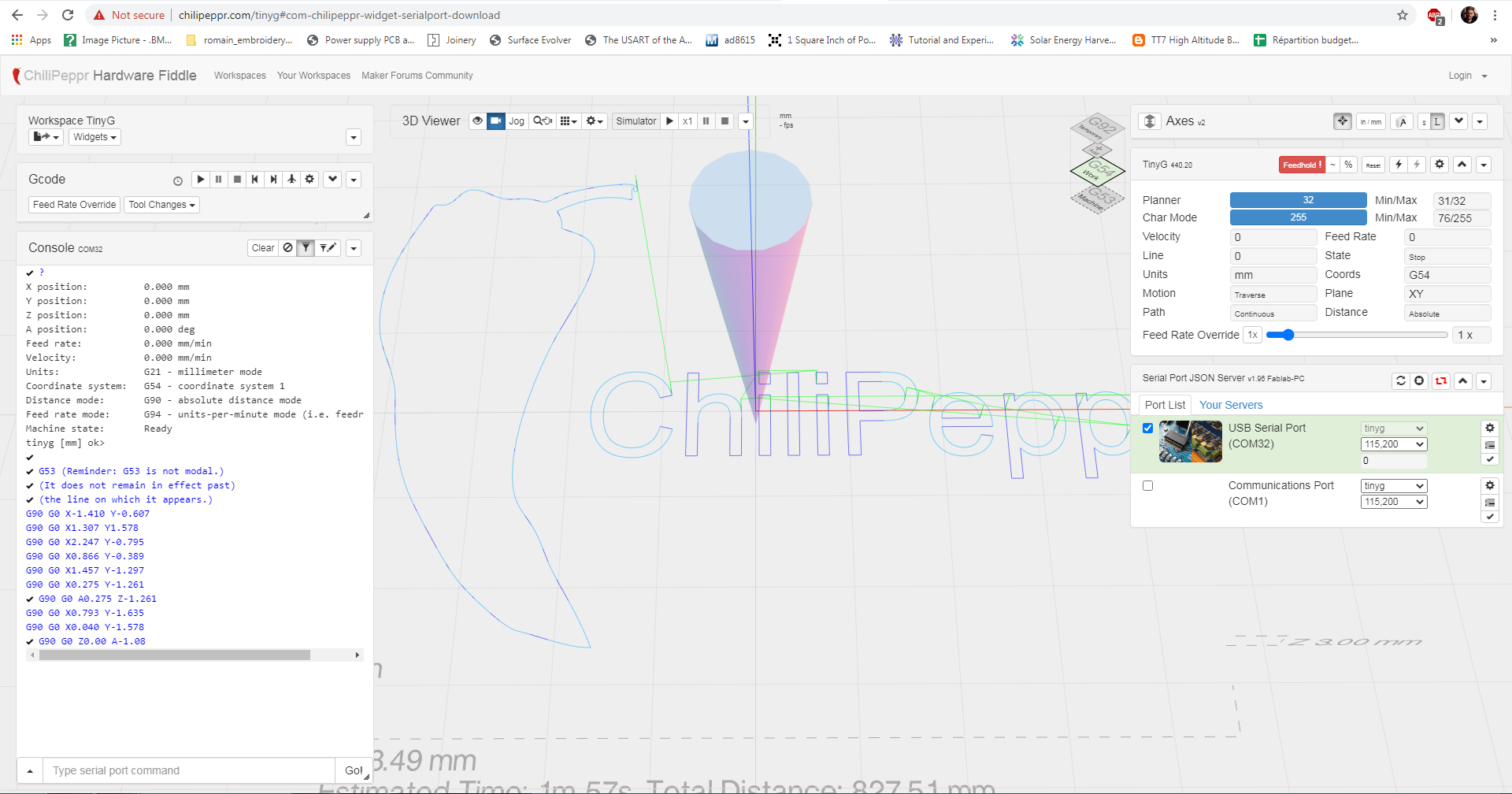

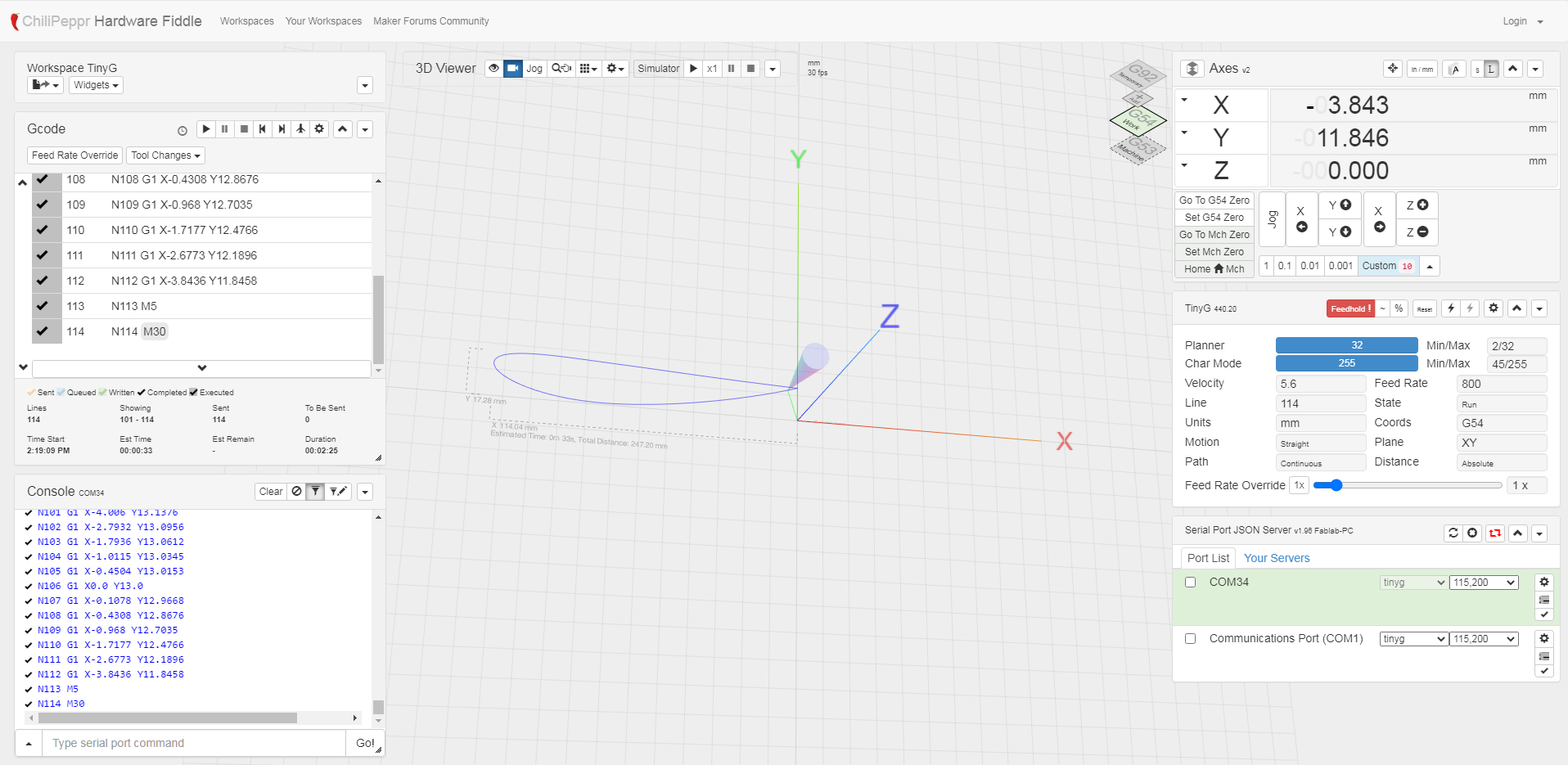

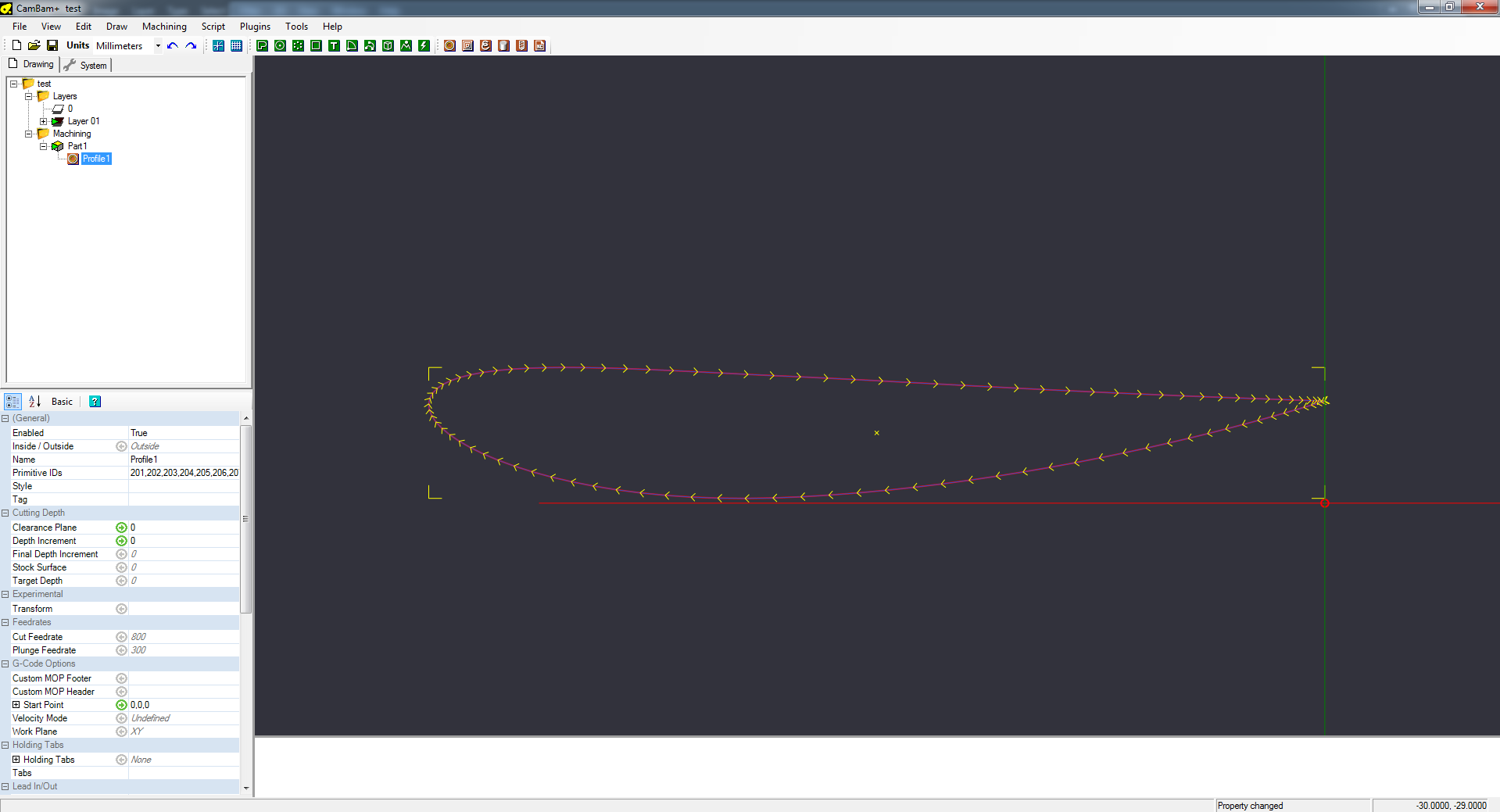

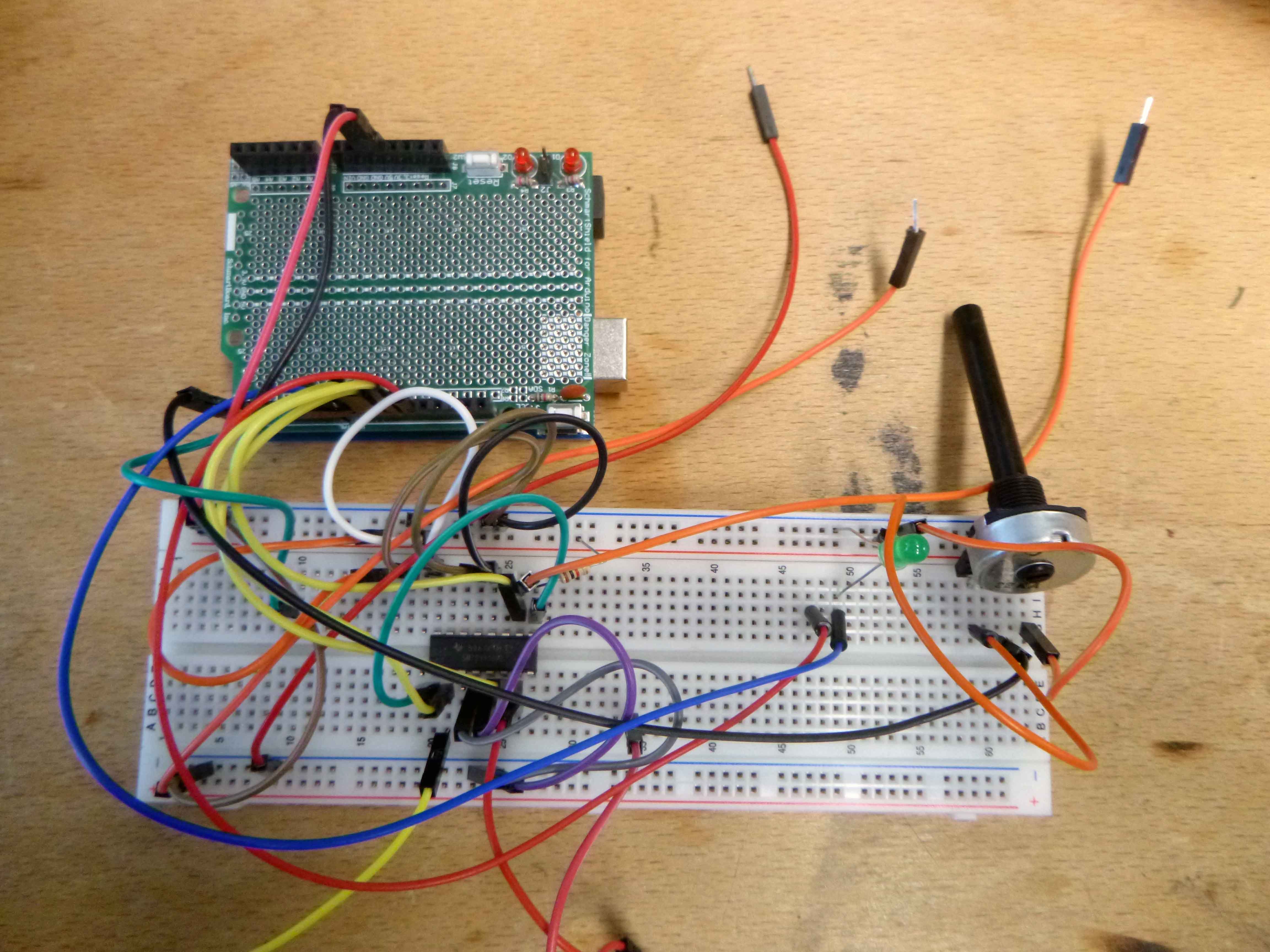

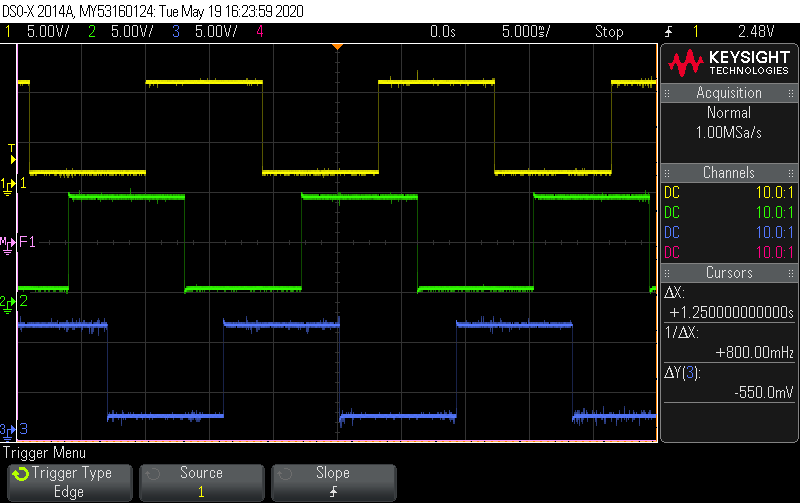

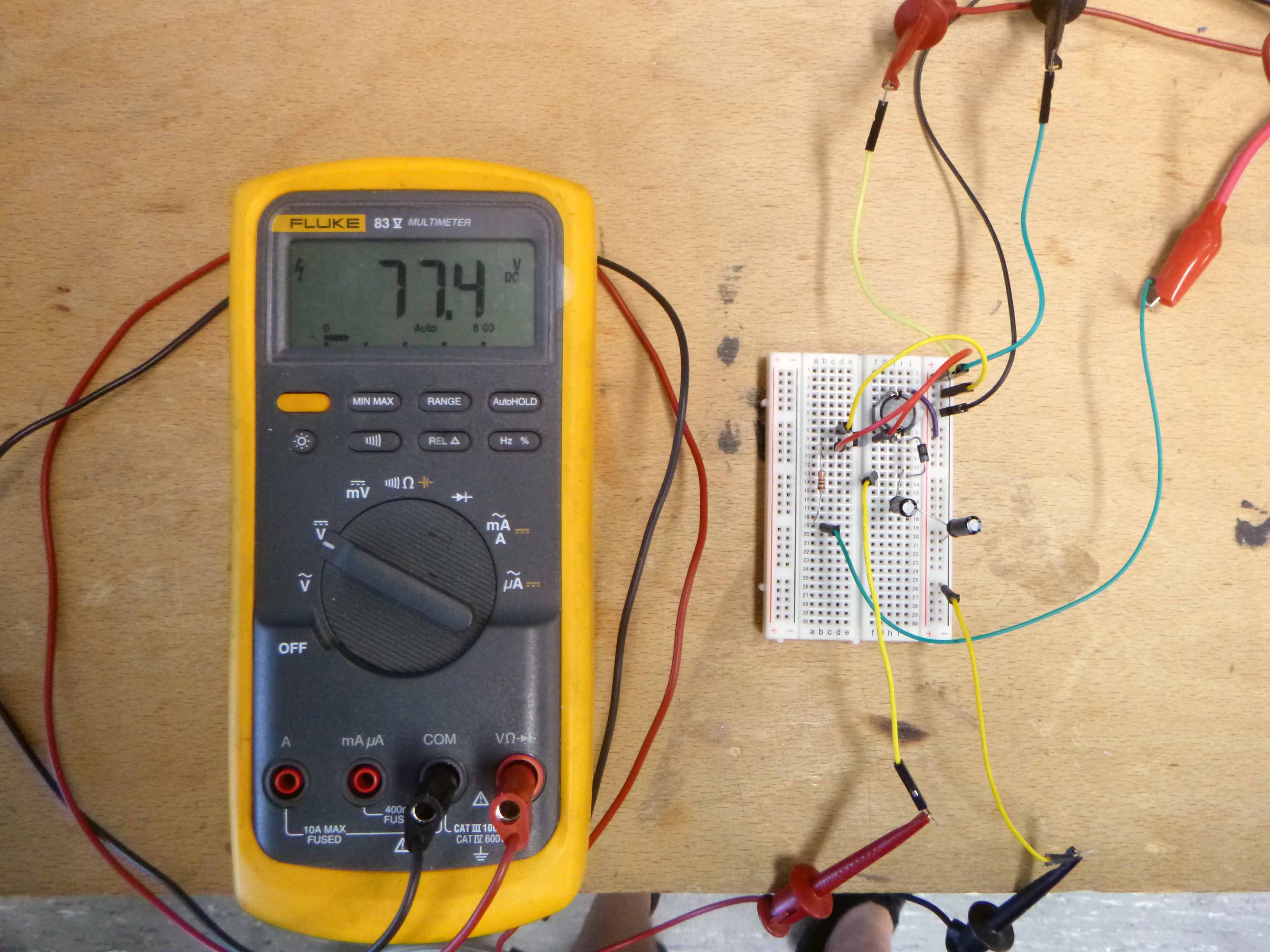

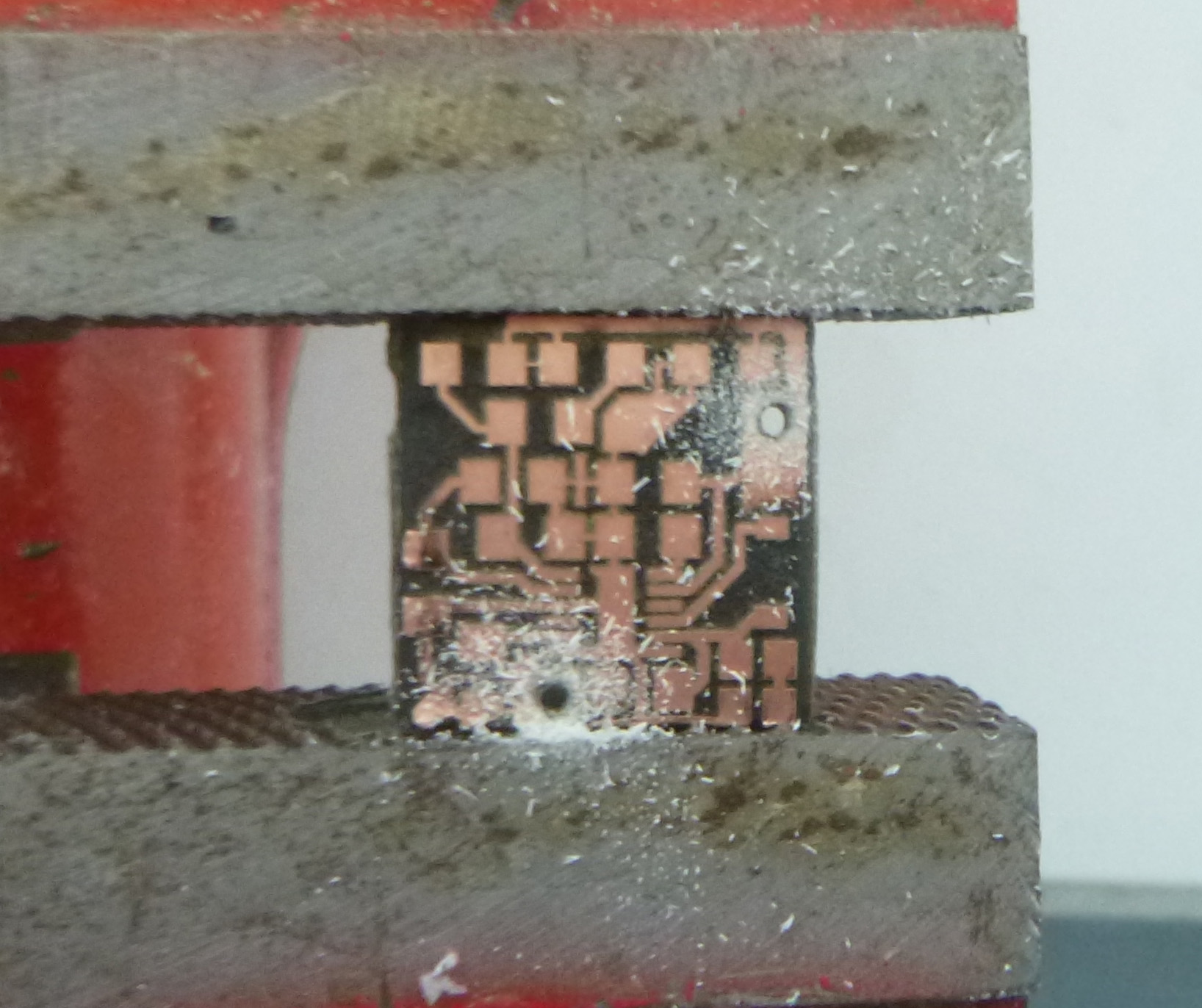

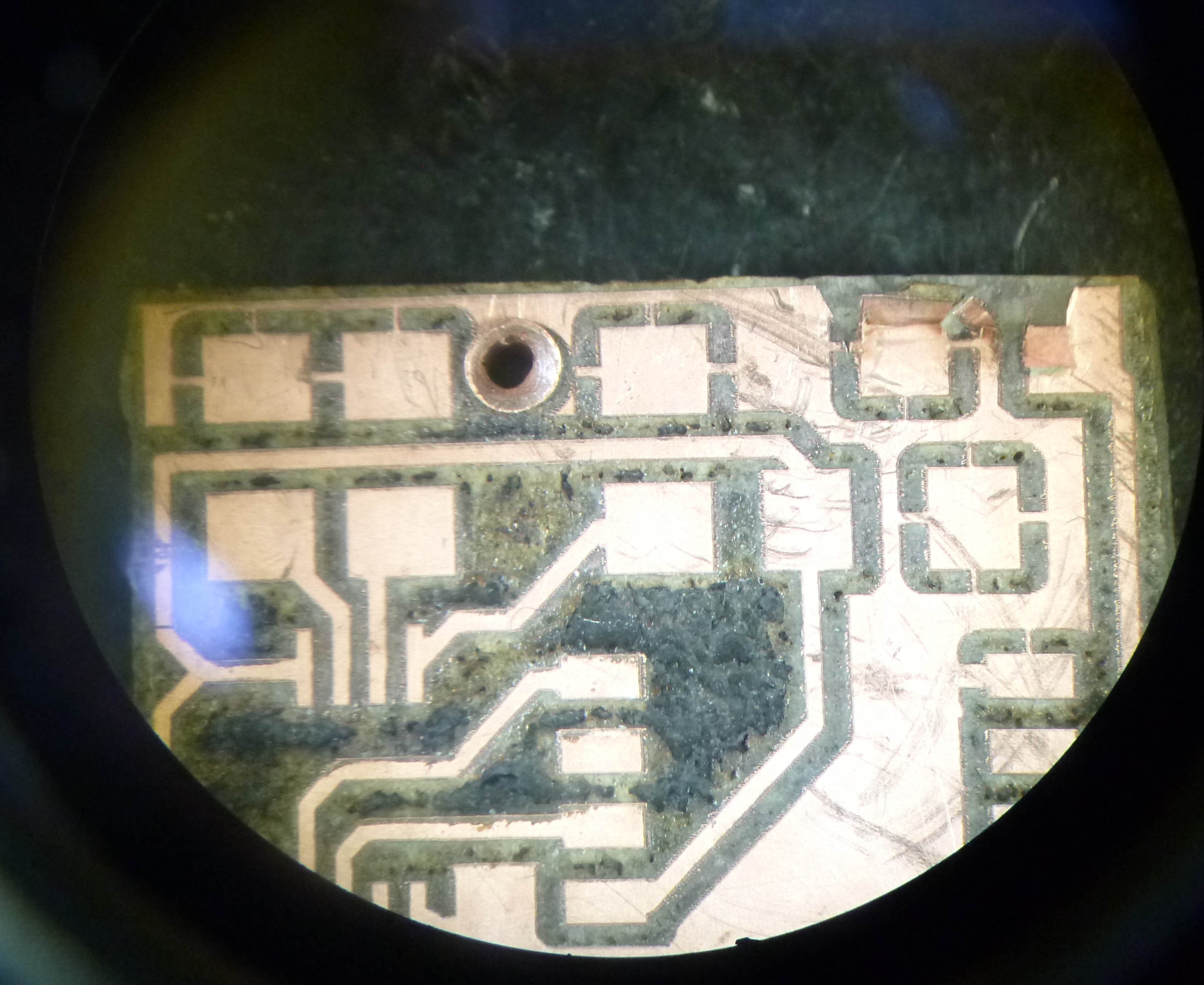

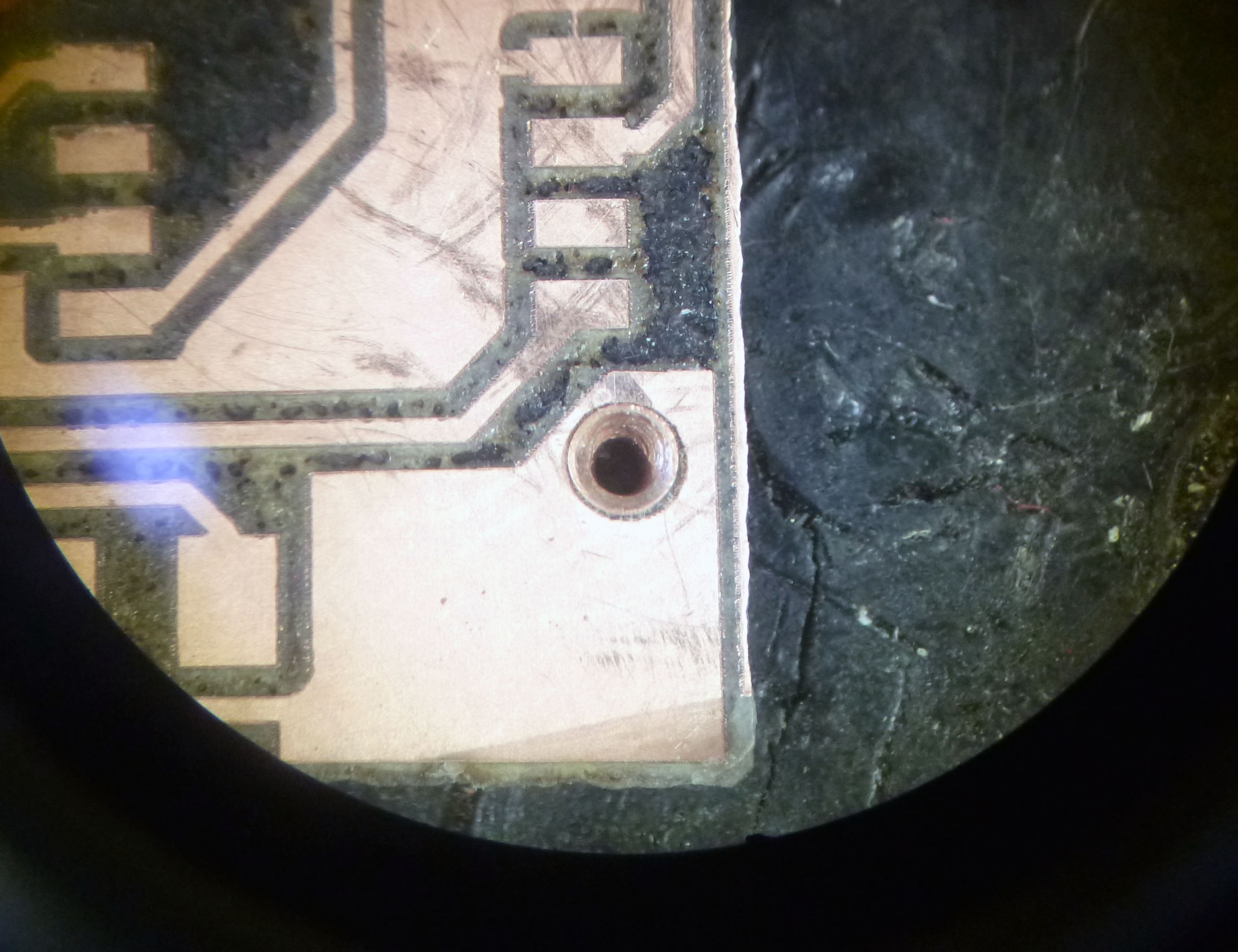

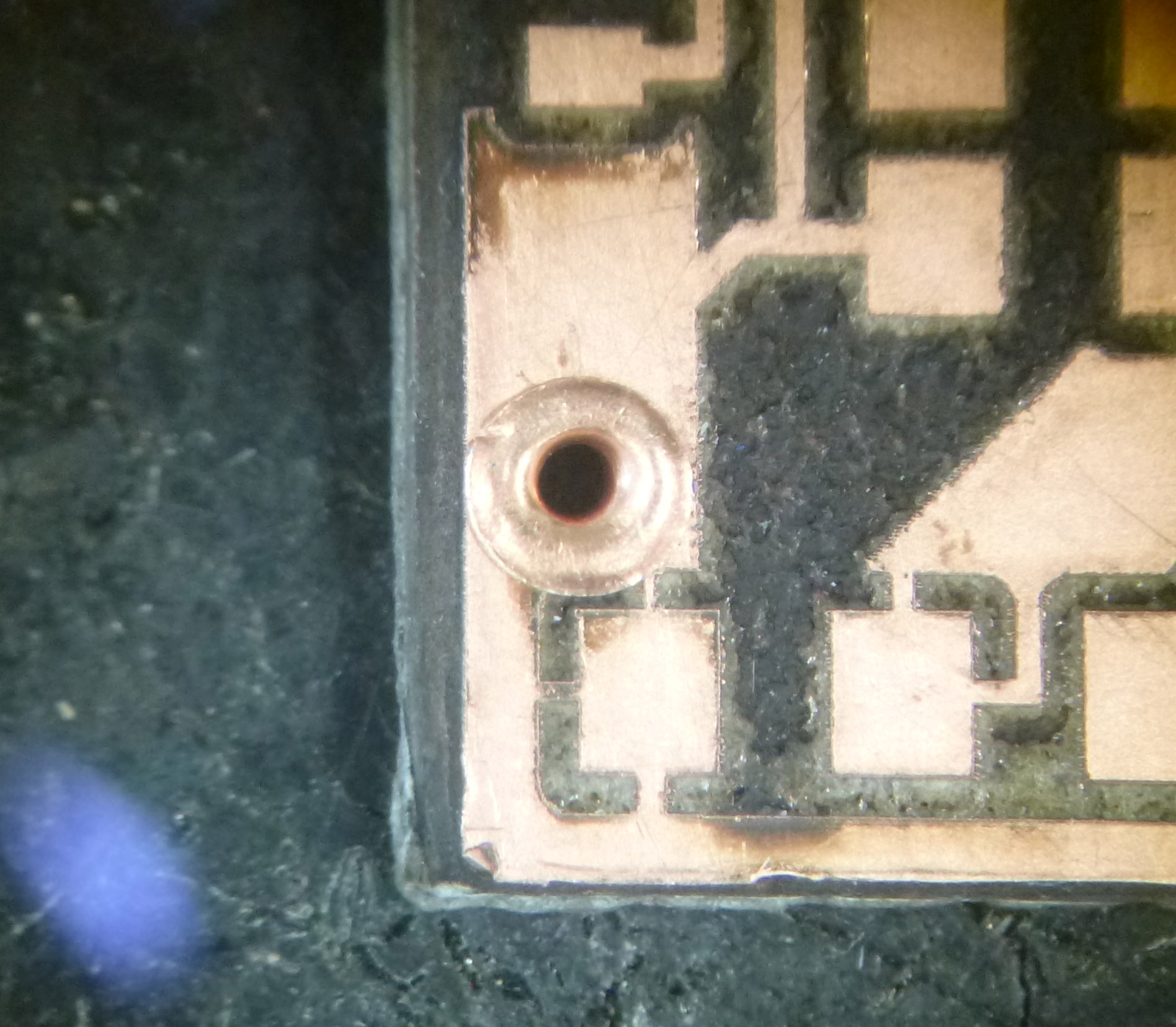

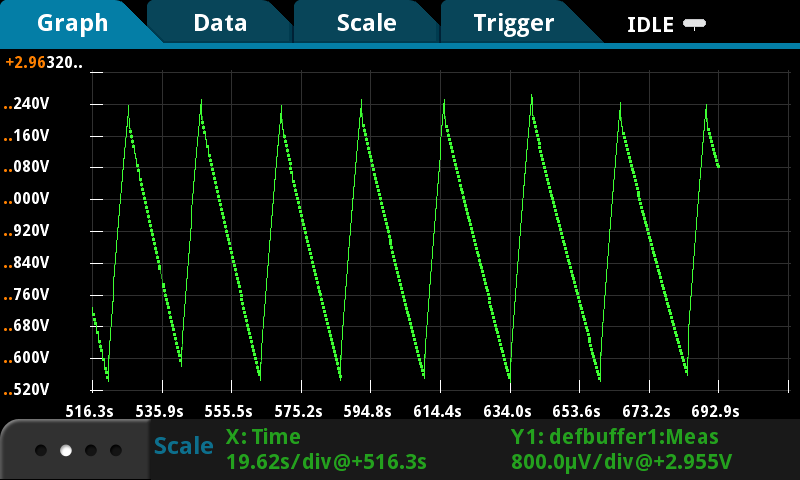

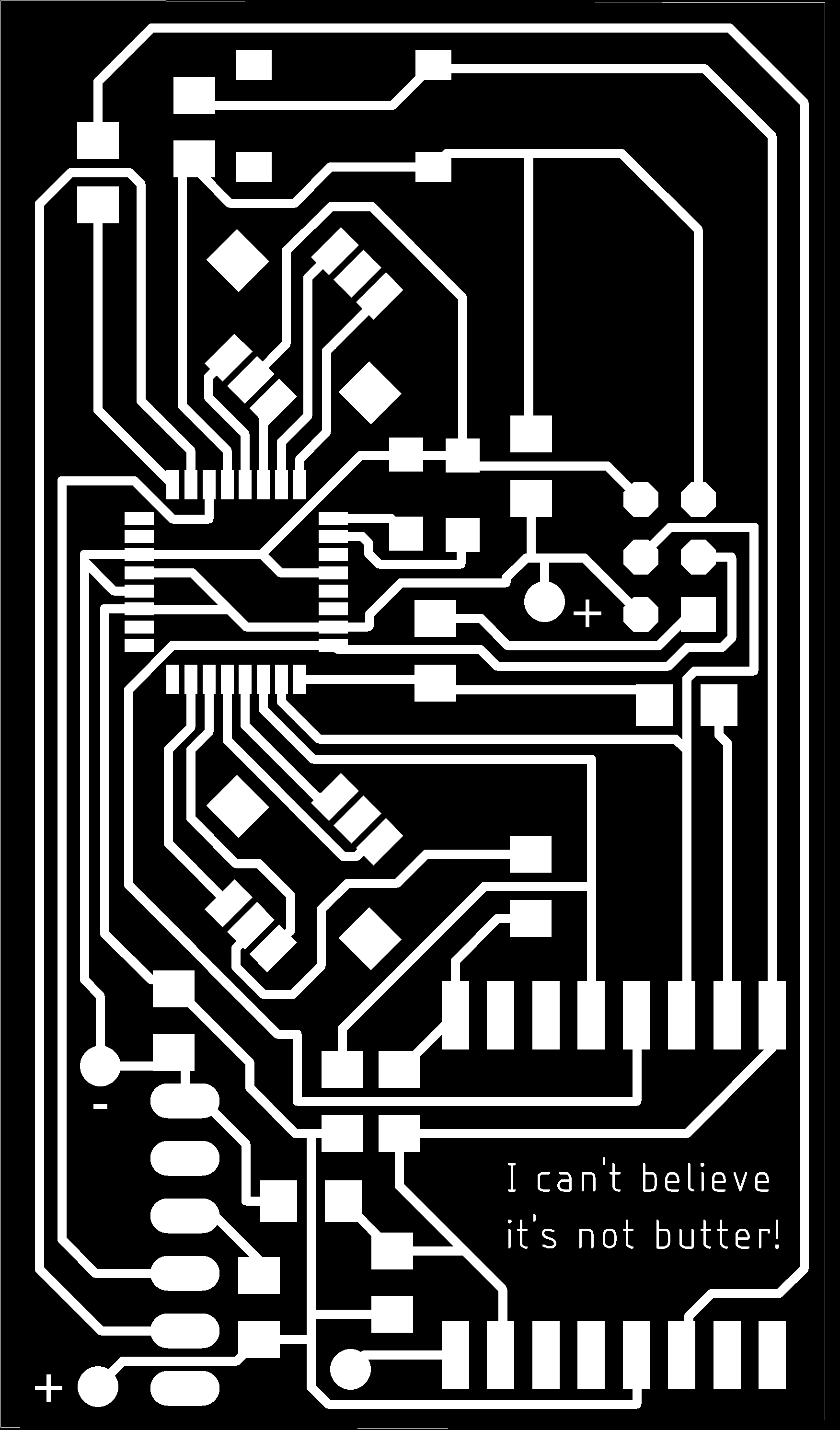

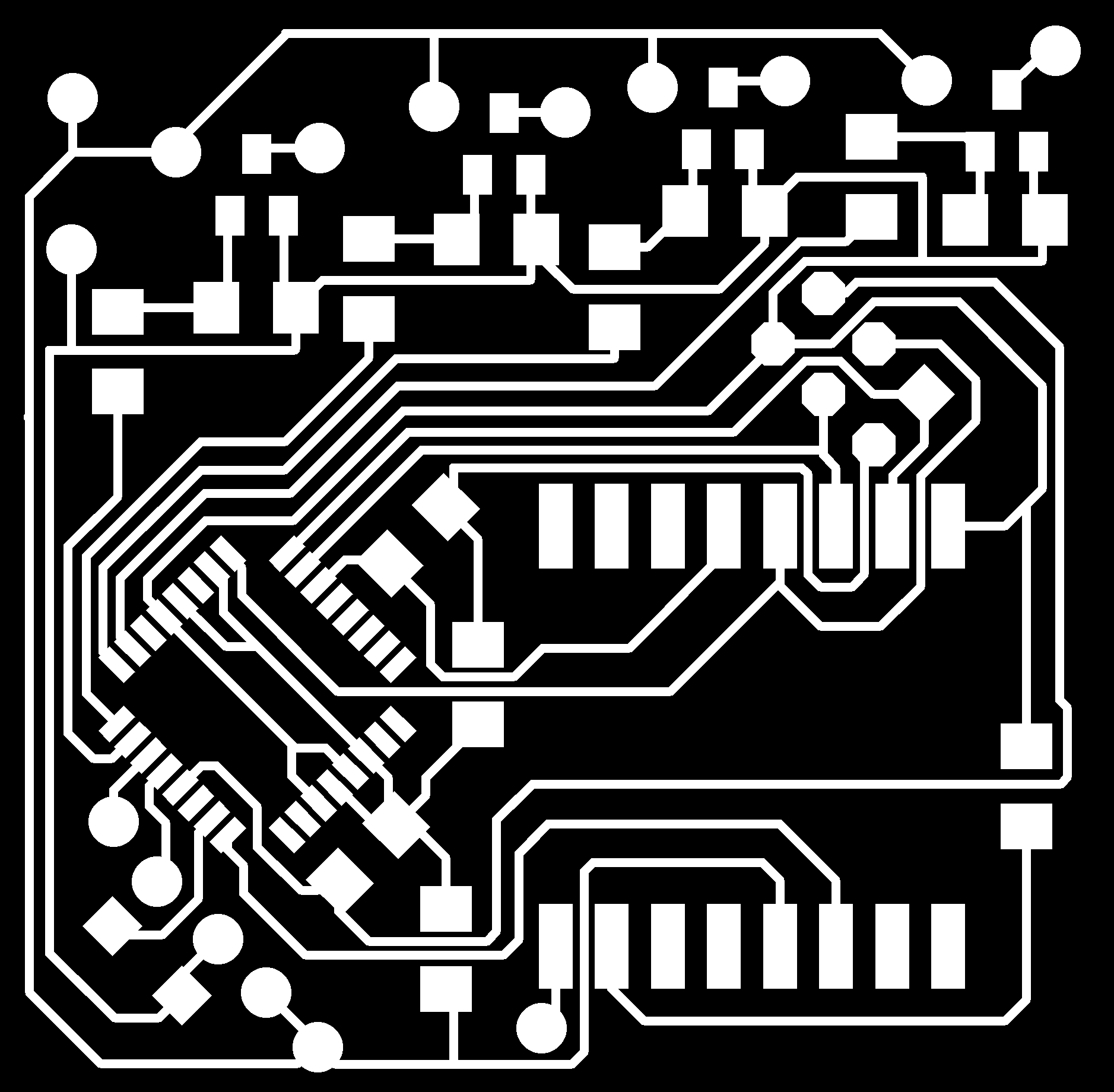

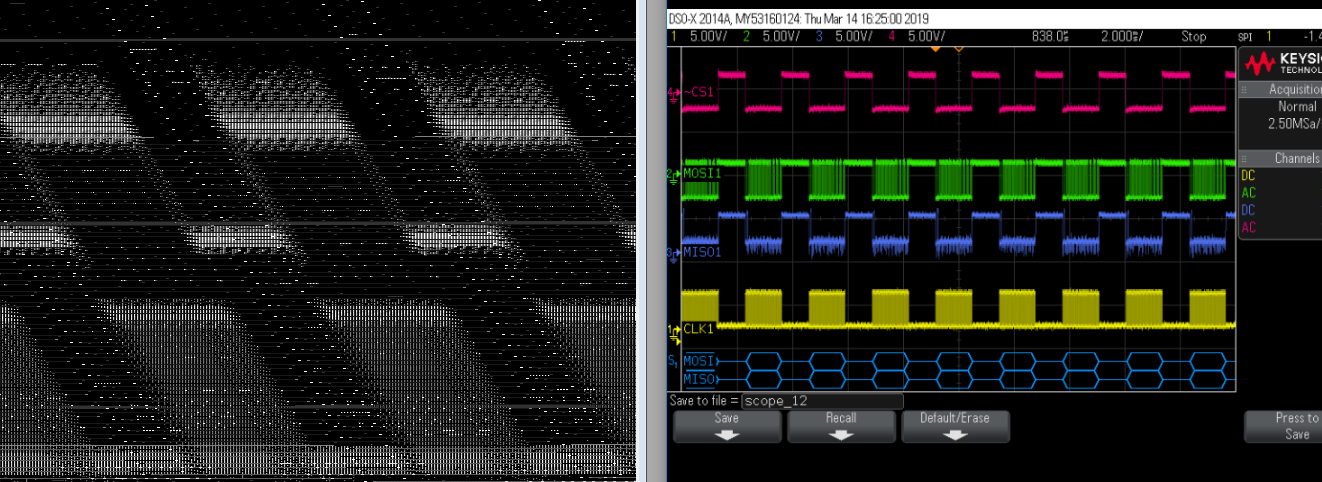

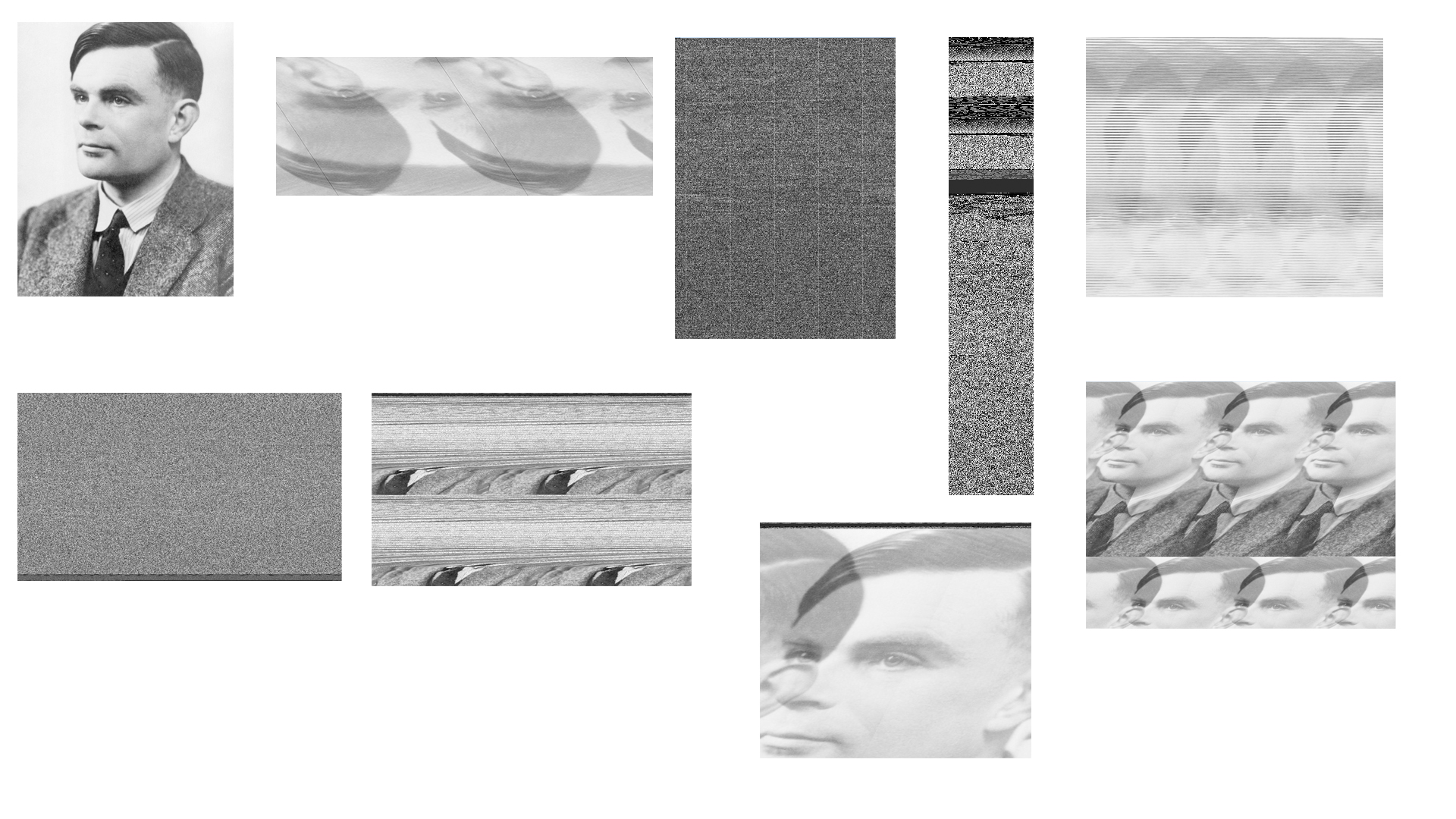

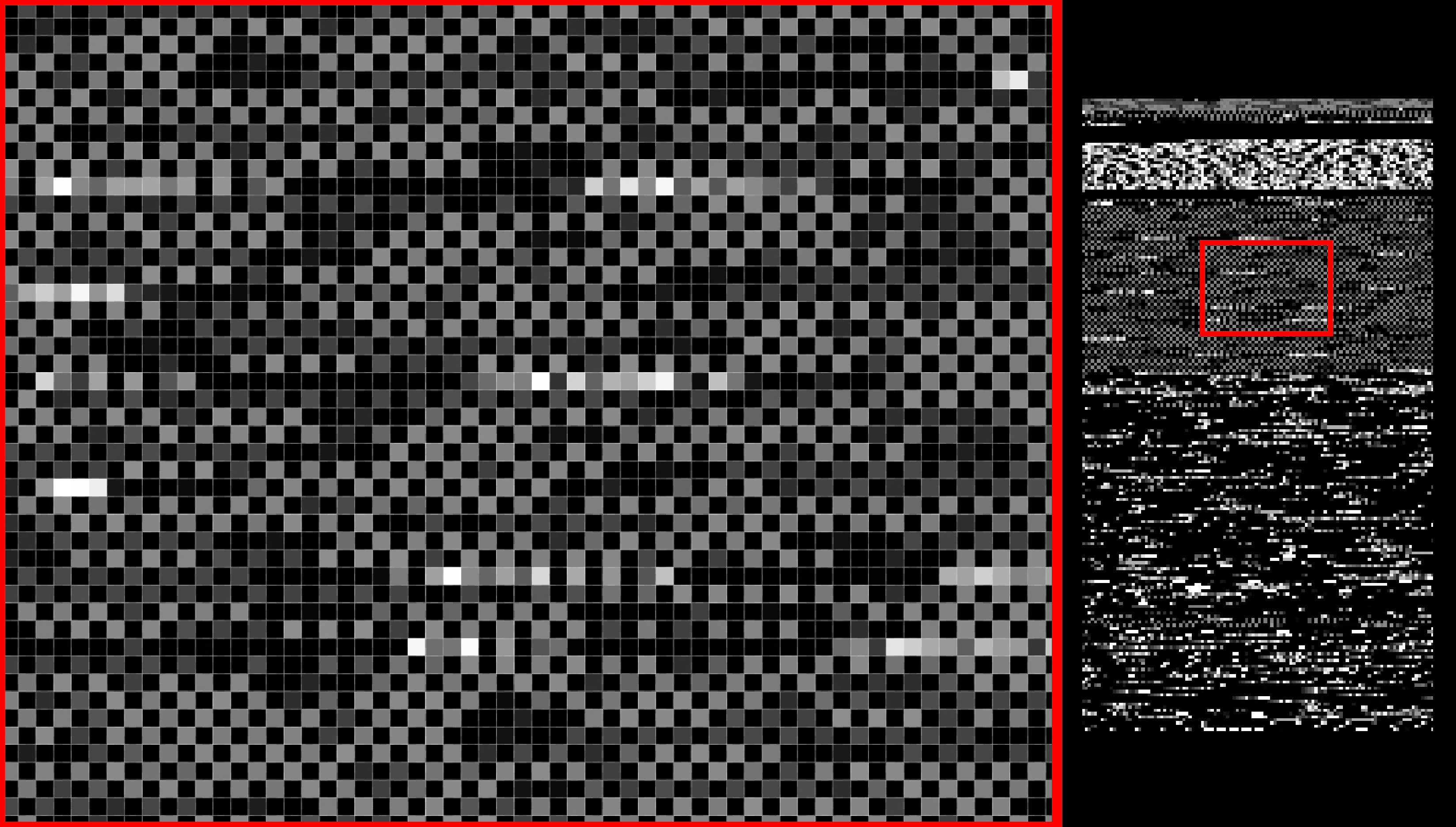

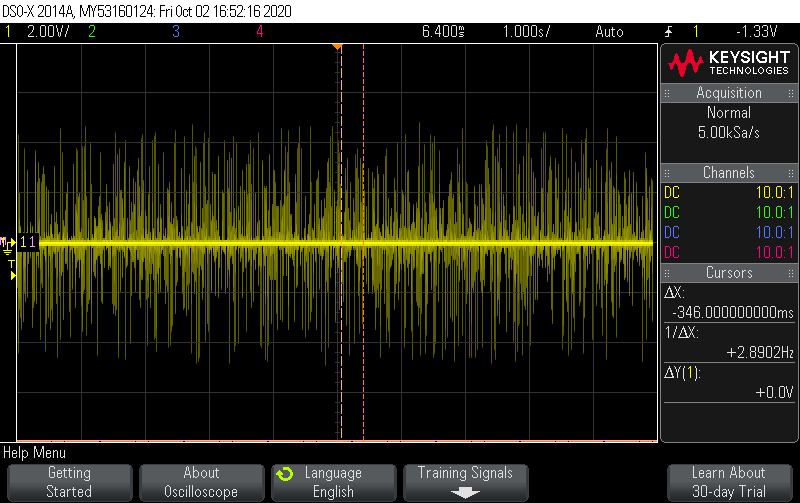

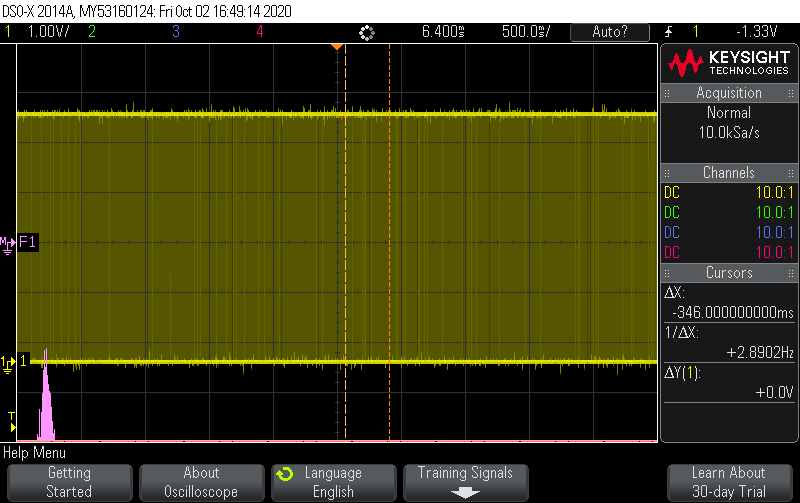

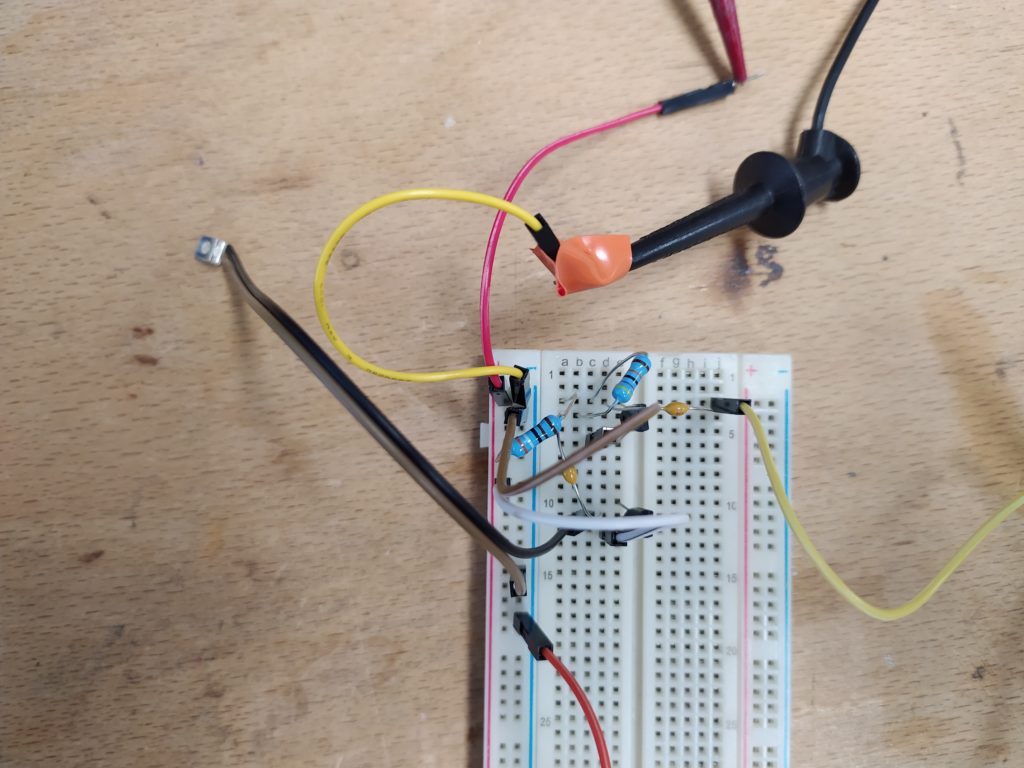

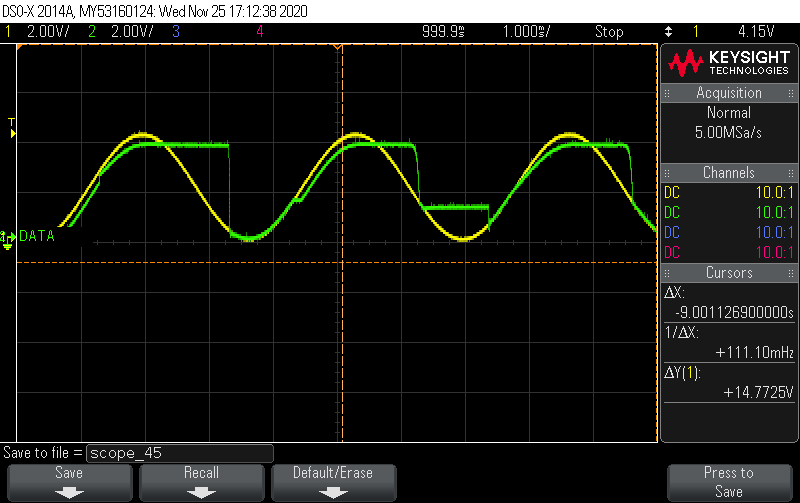

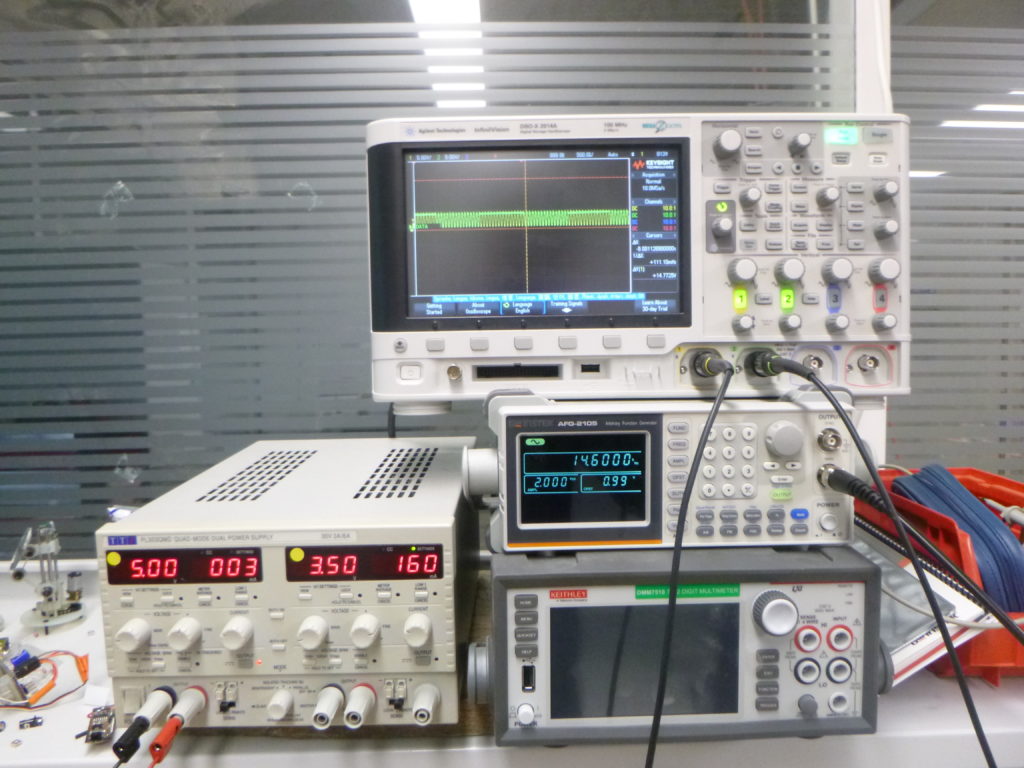

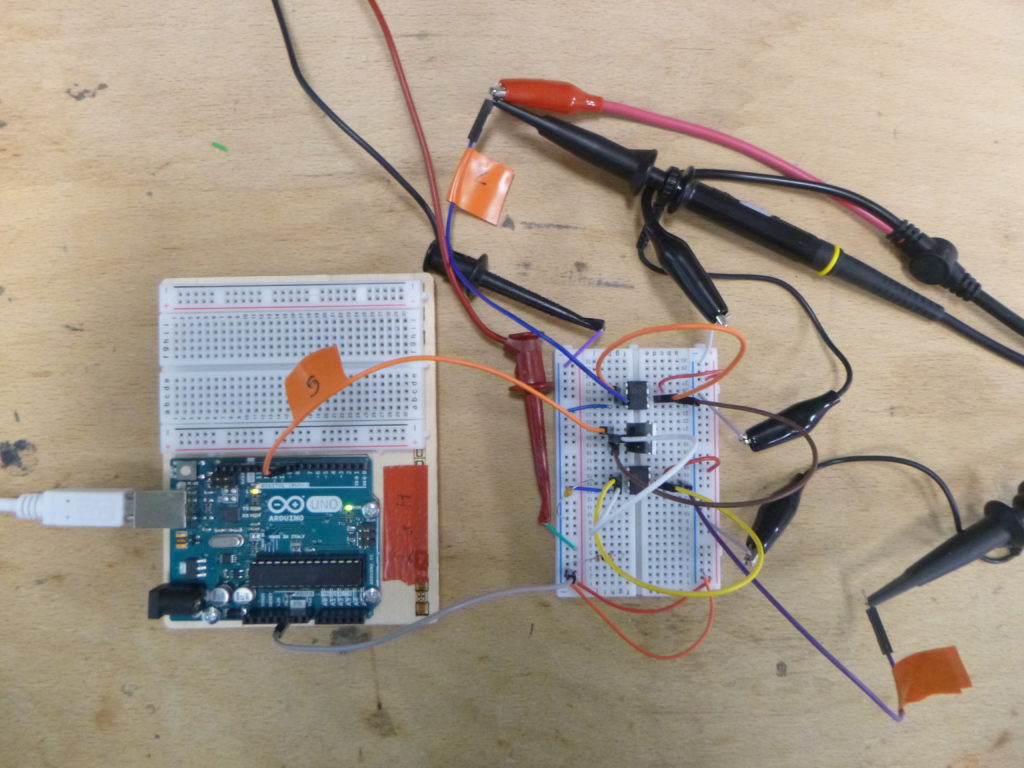

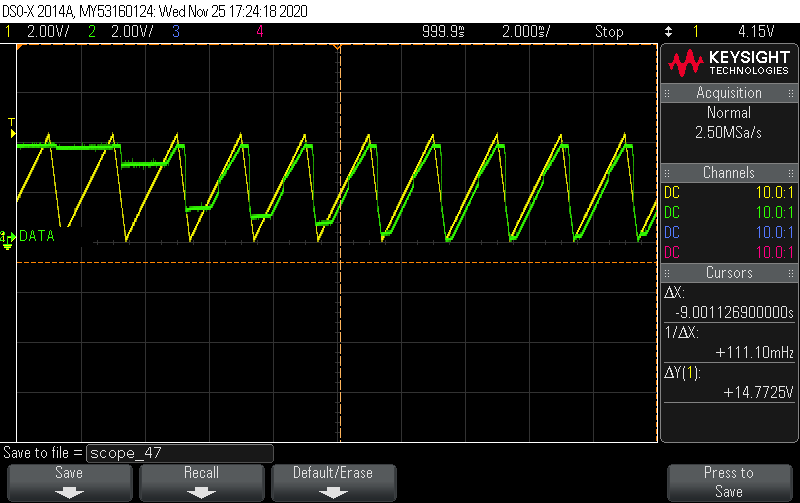

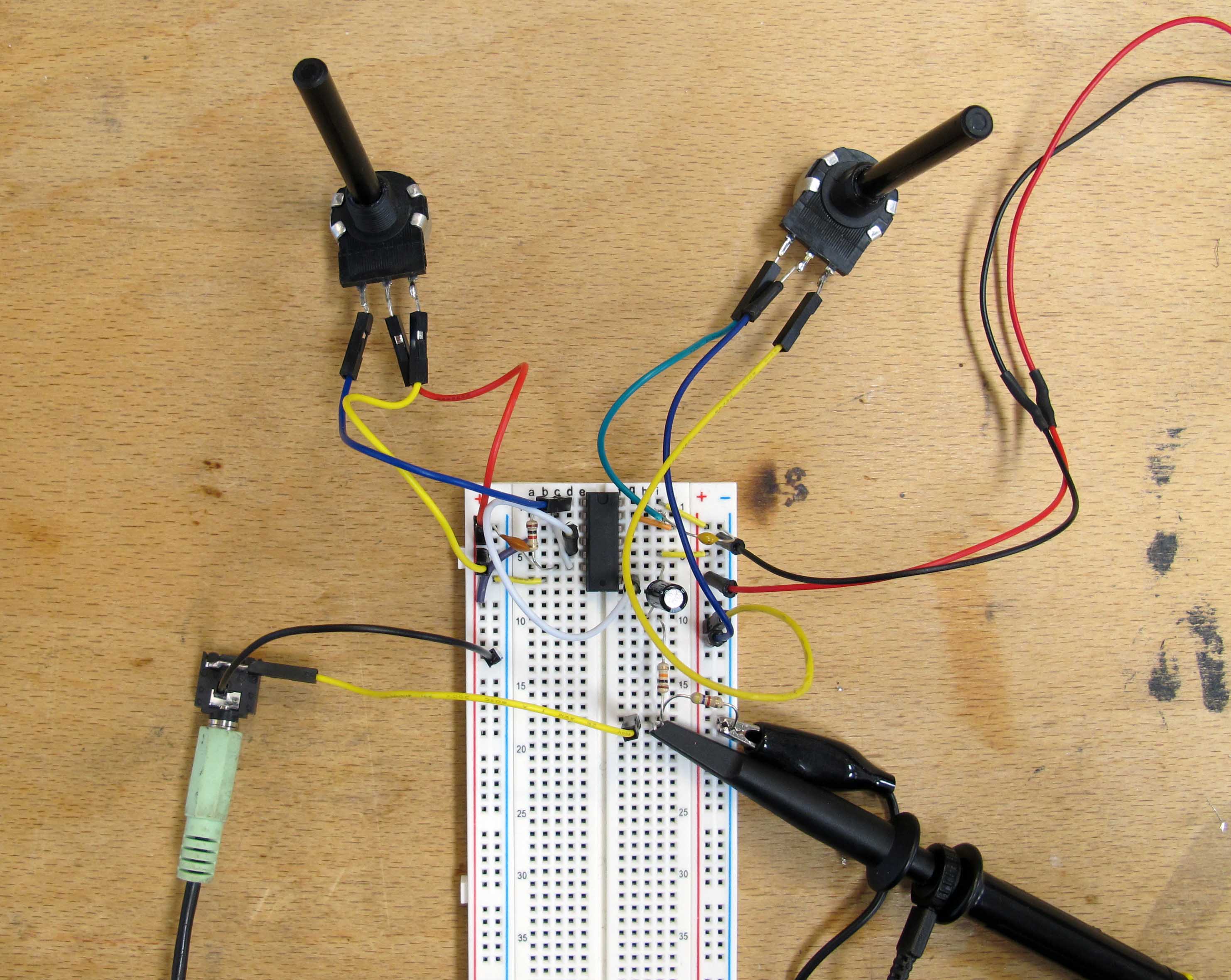

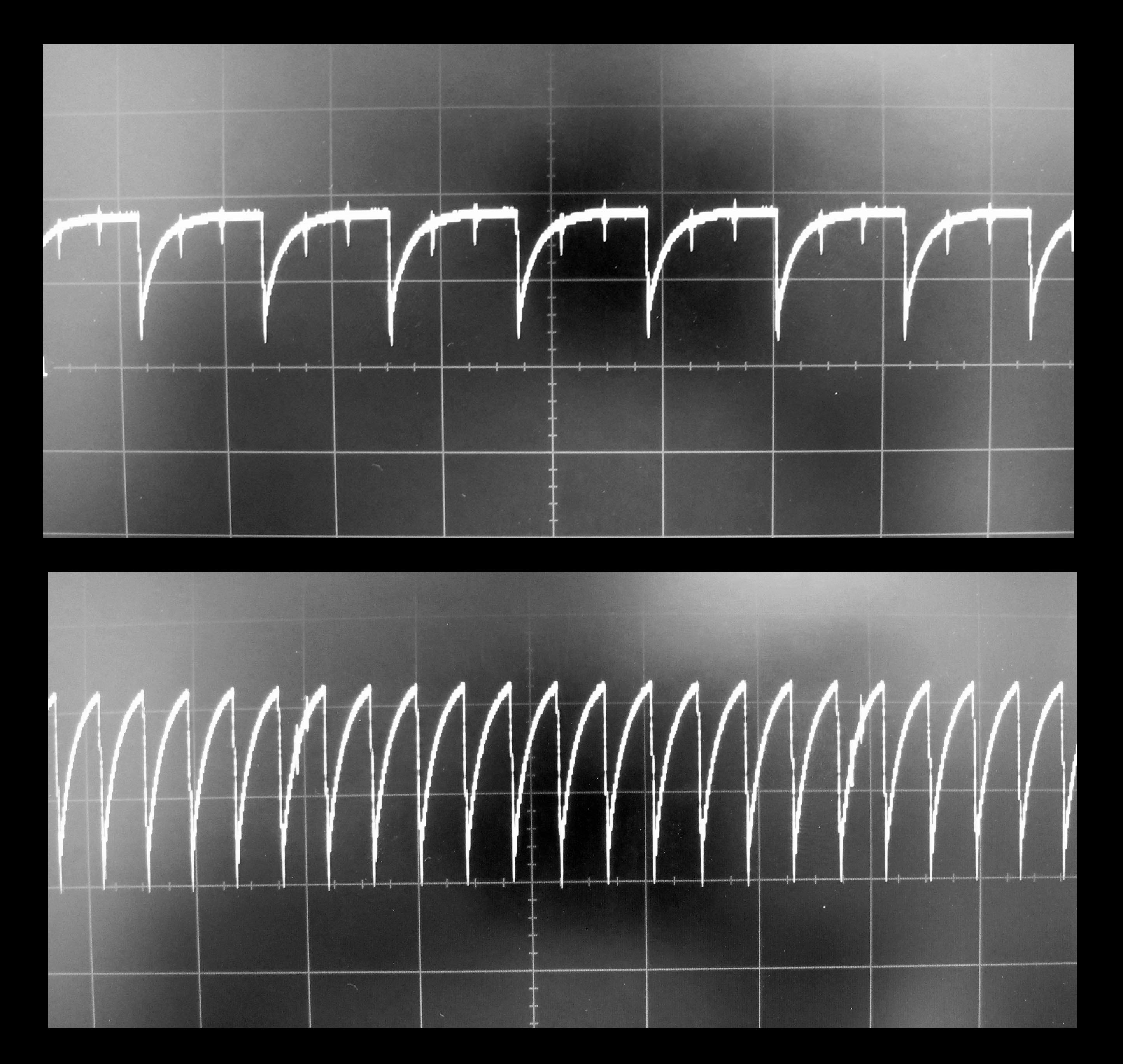

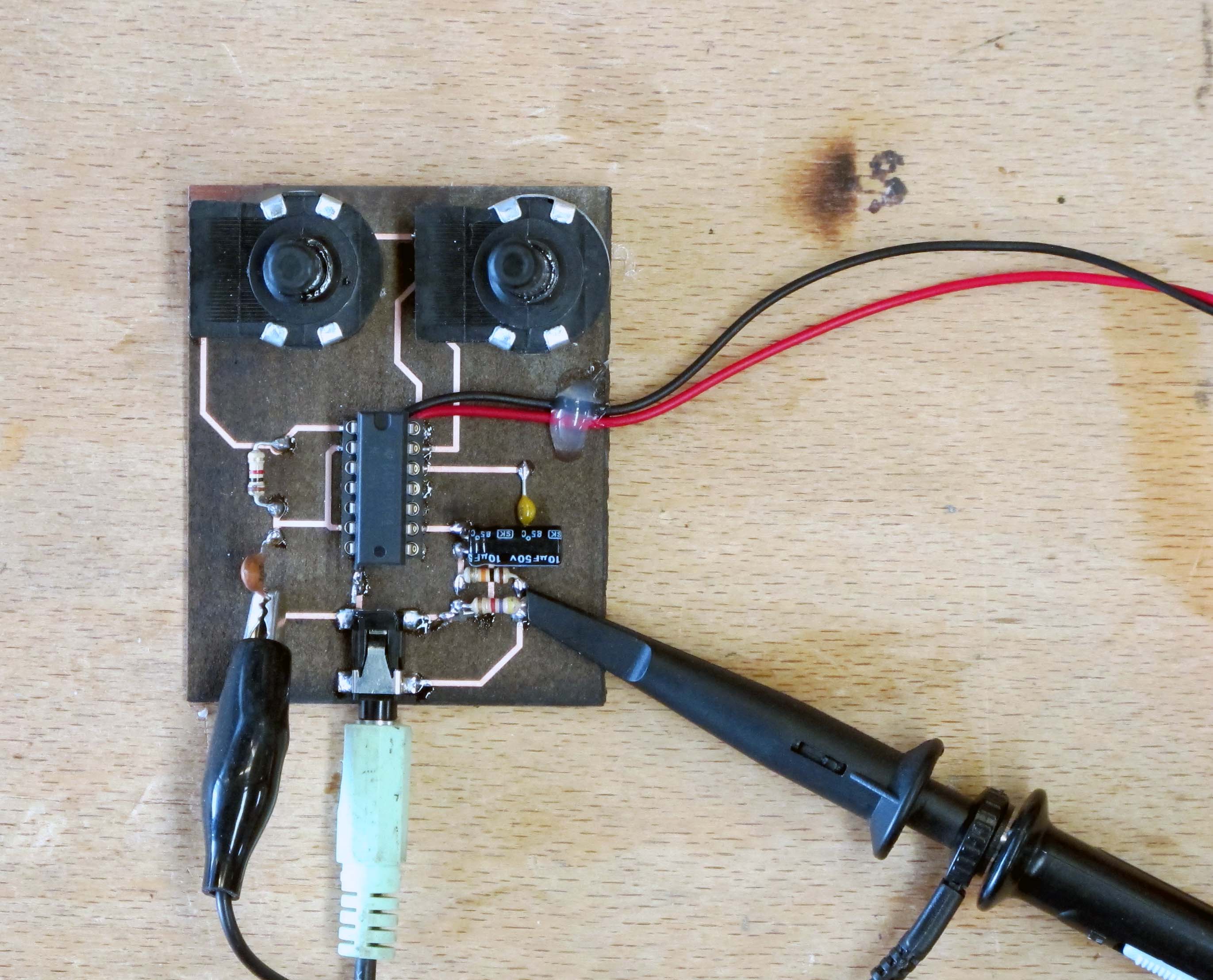

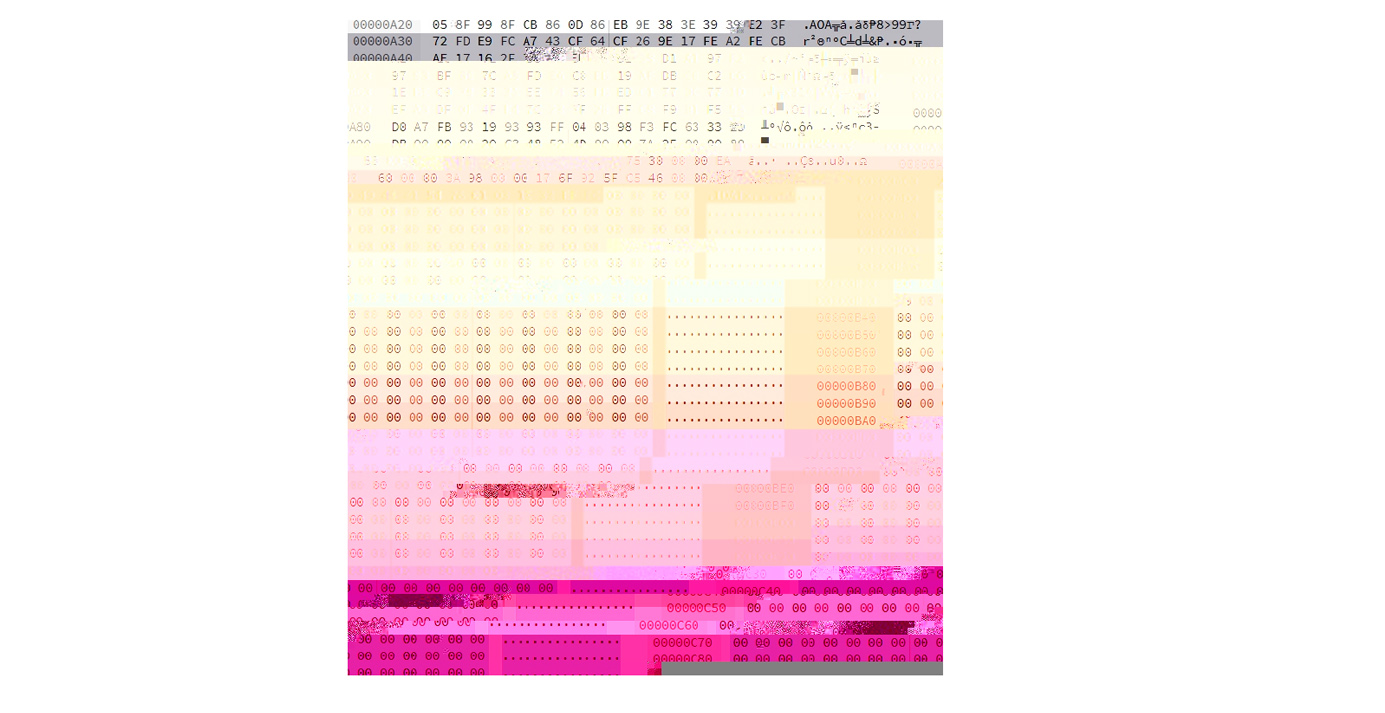

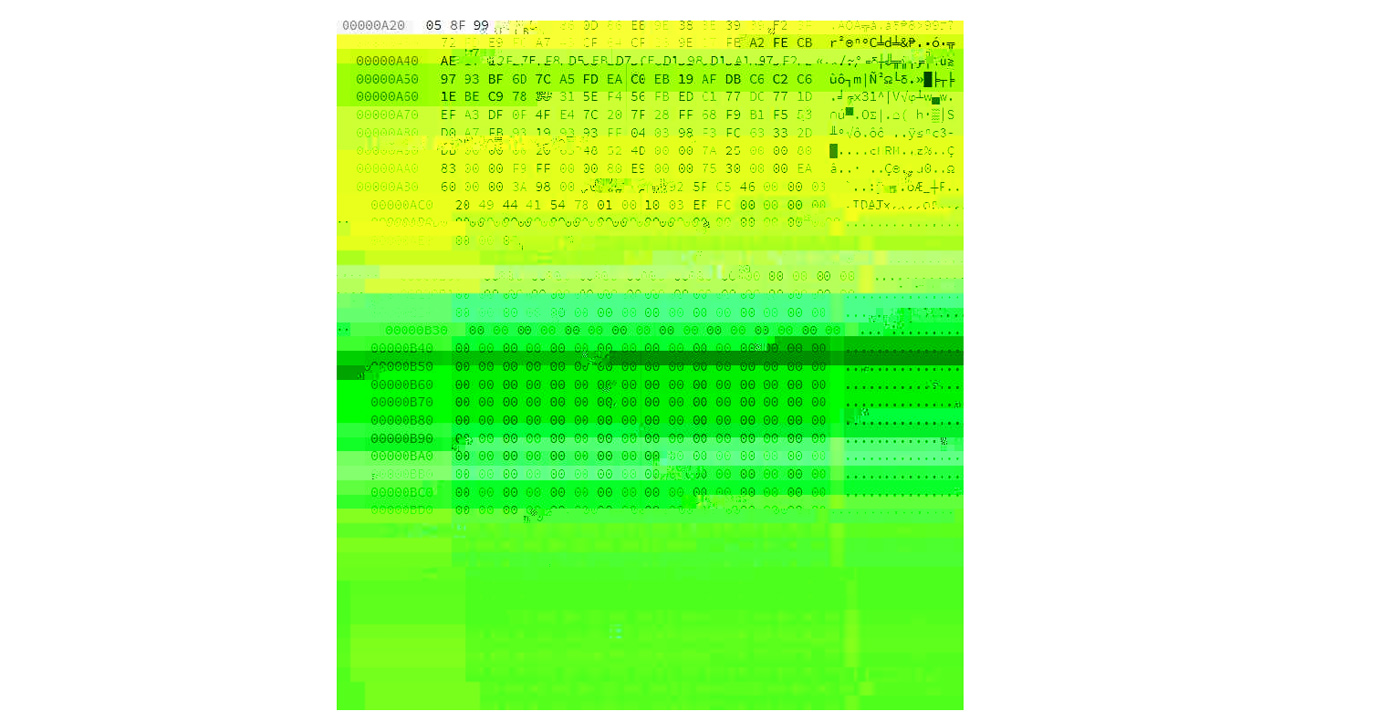

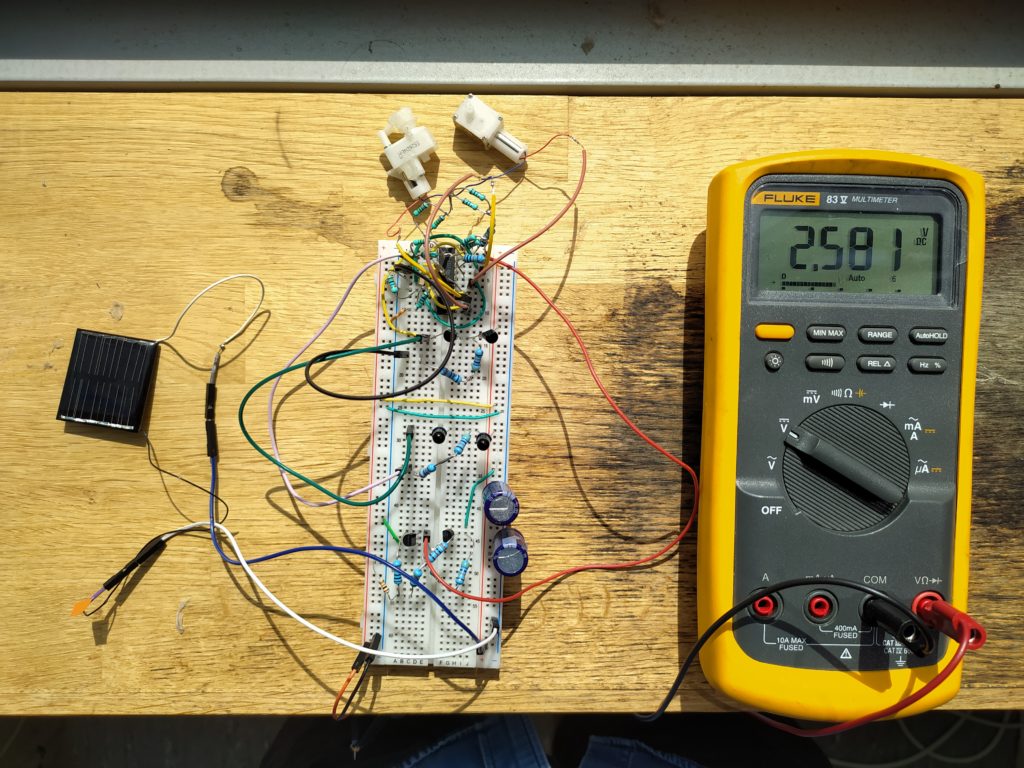

endmoduleHere is what it looks like on the scope with just one exchange :

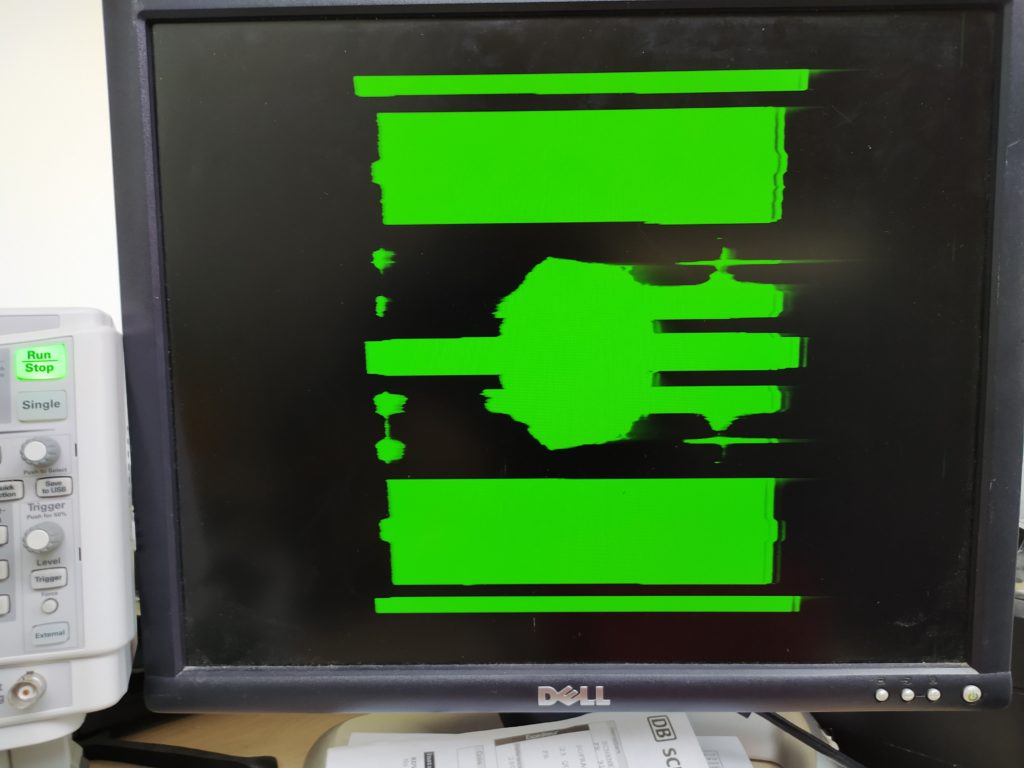

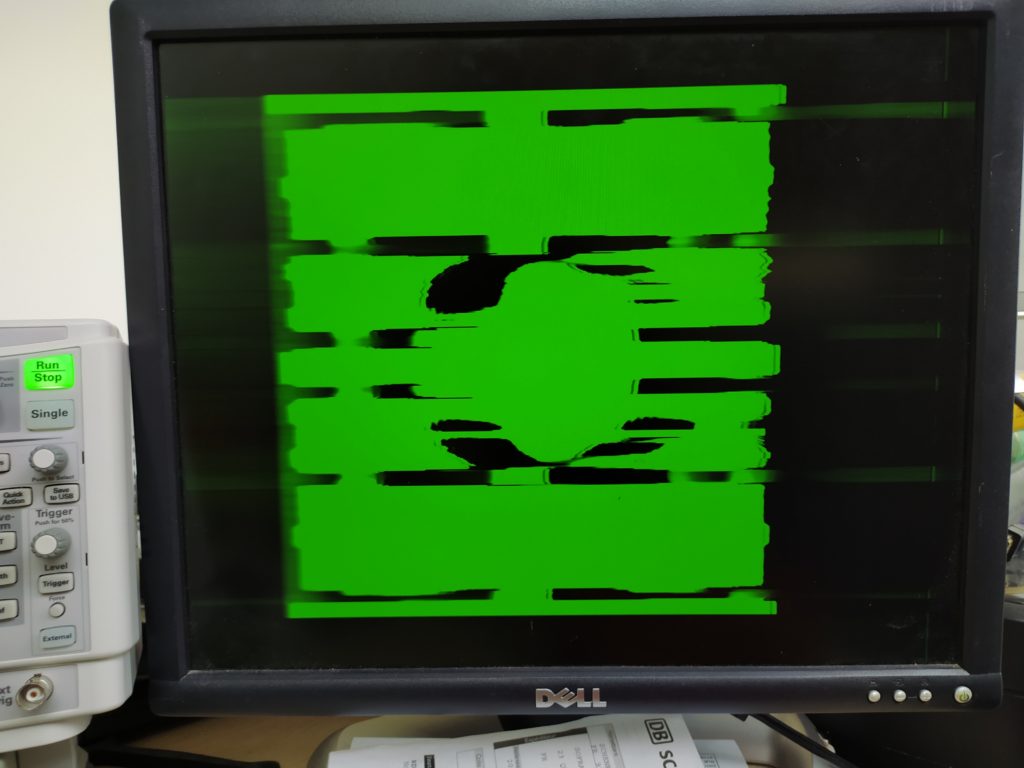

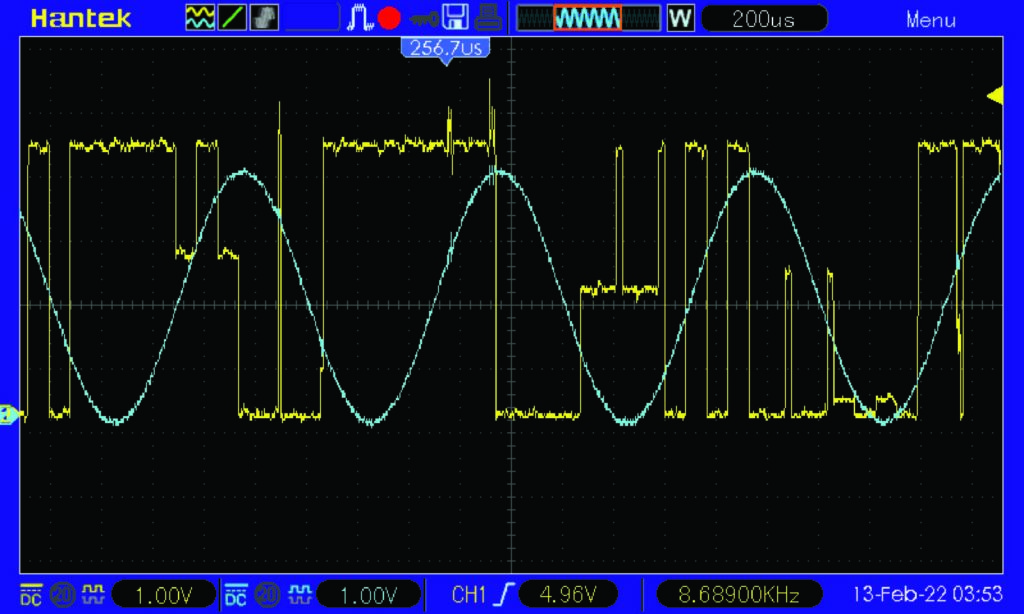

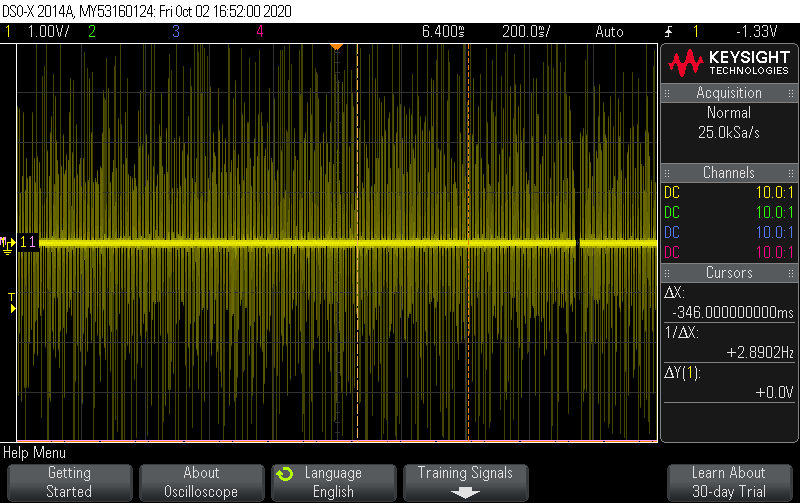

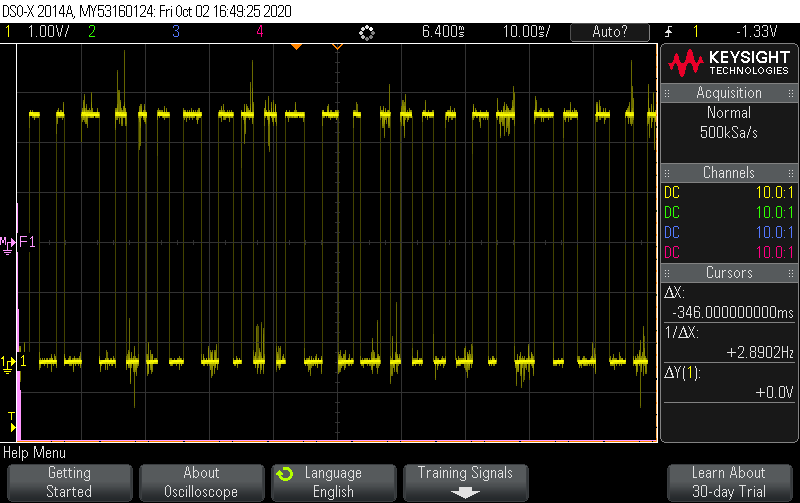

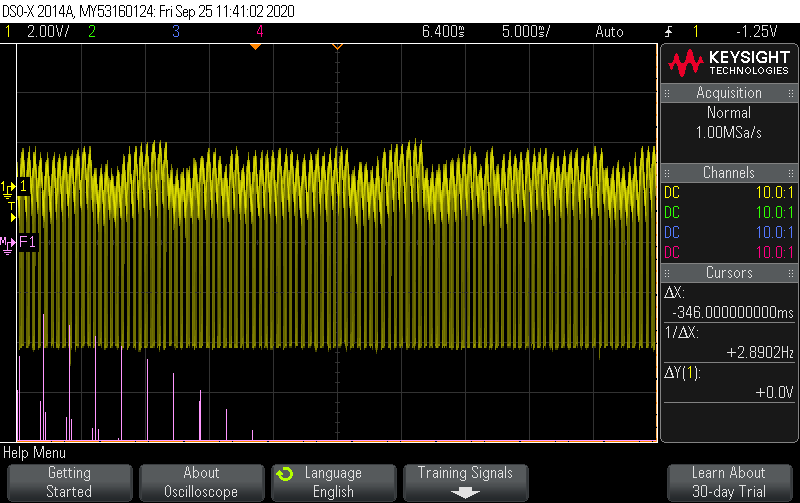

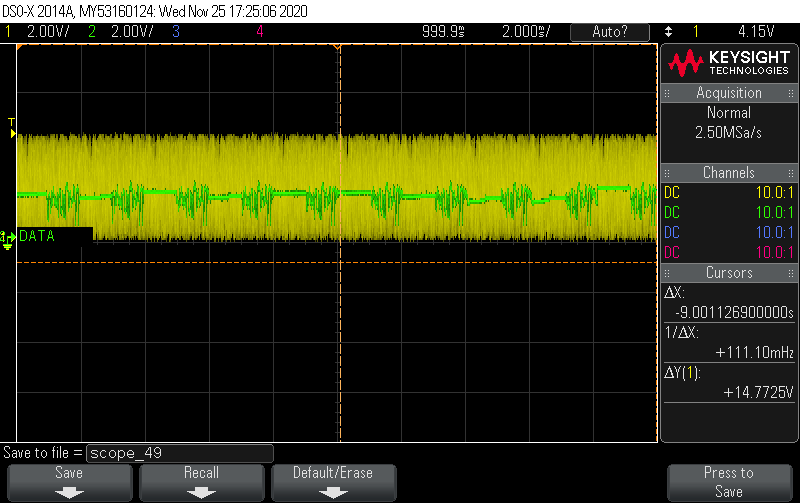

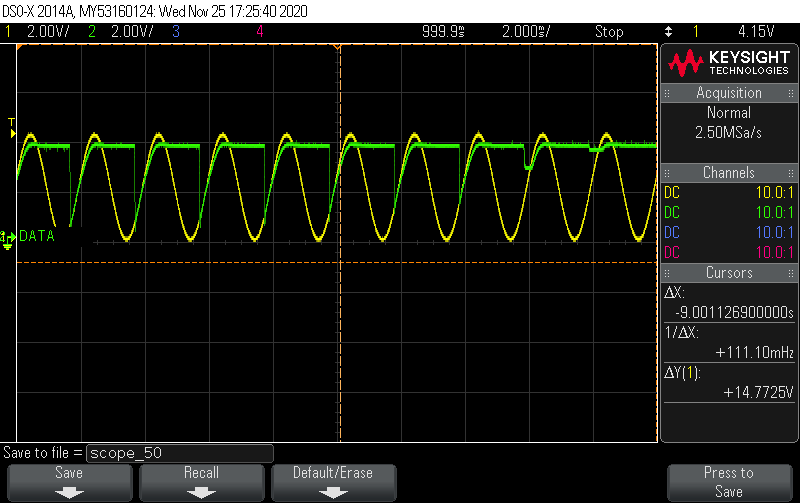

…and a series of back and forth commands :

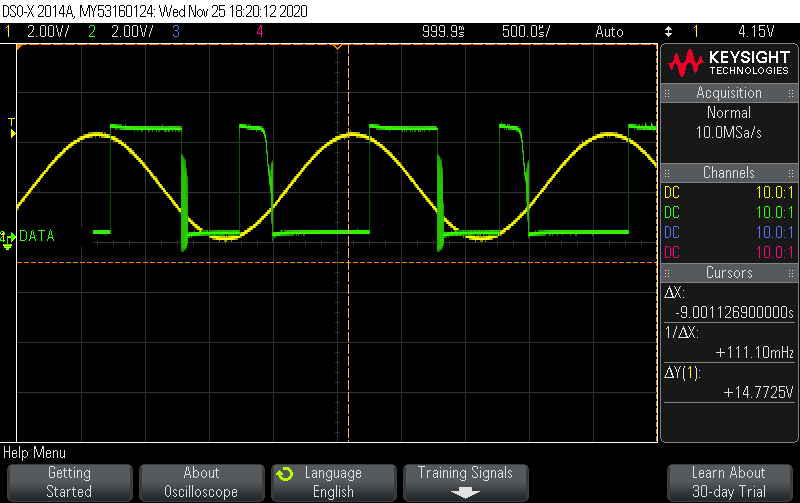

….

….

To go further I would need to switch the logic analyzer.

*******

*******

*

*

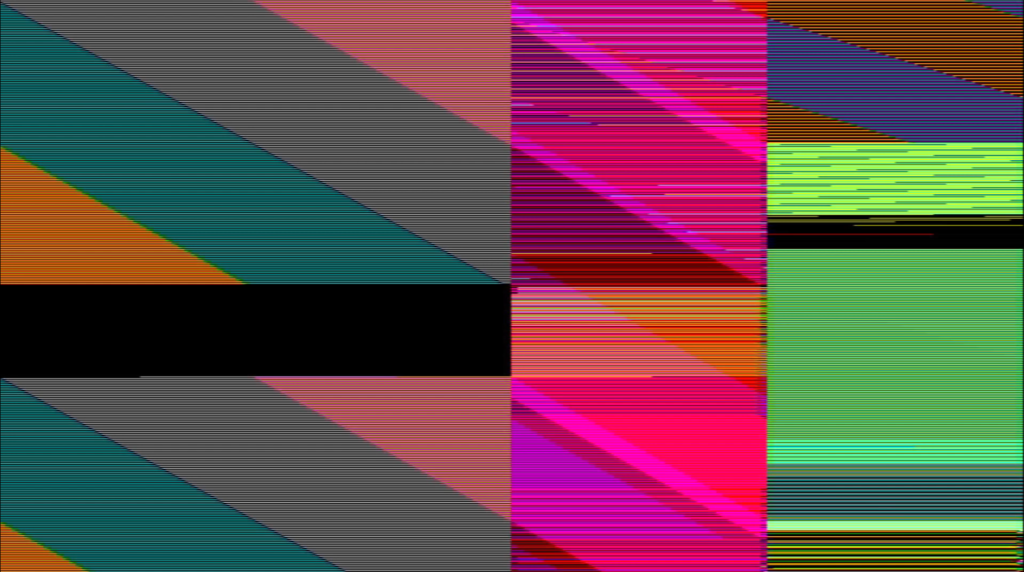

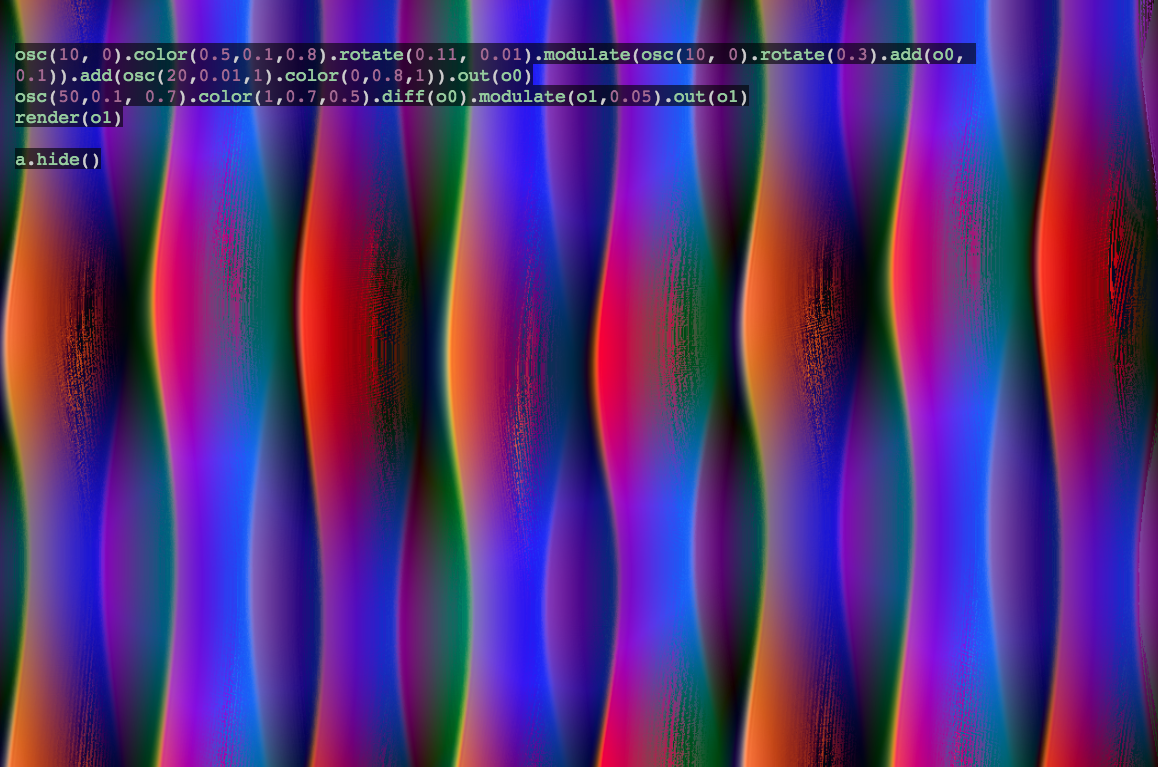

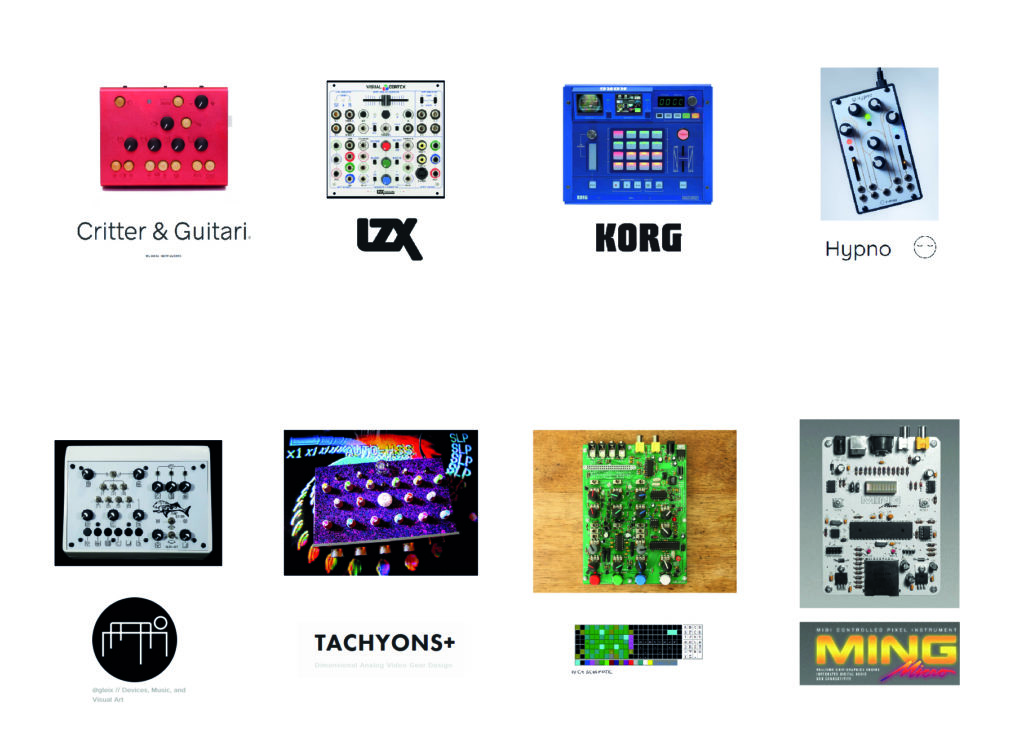

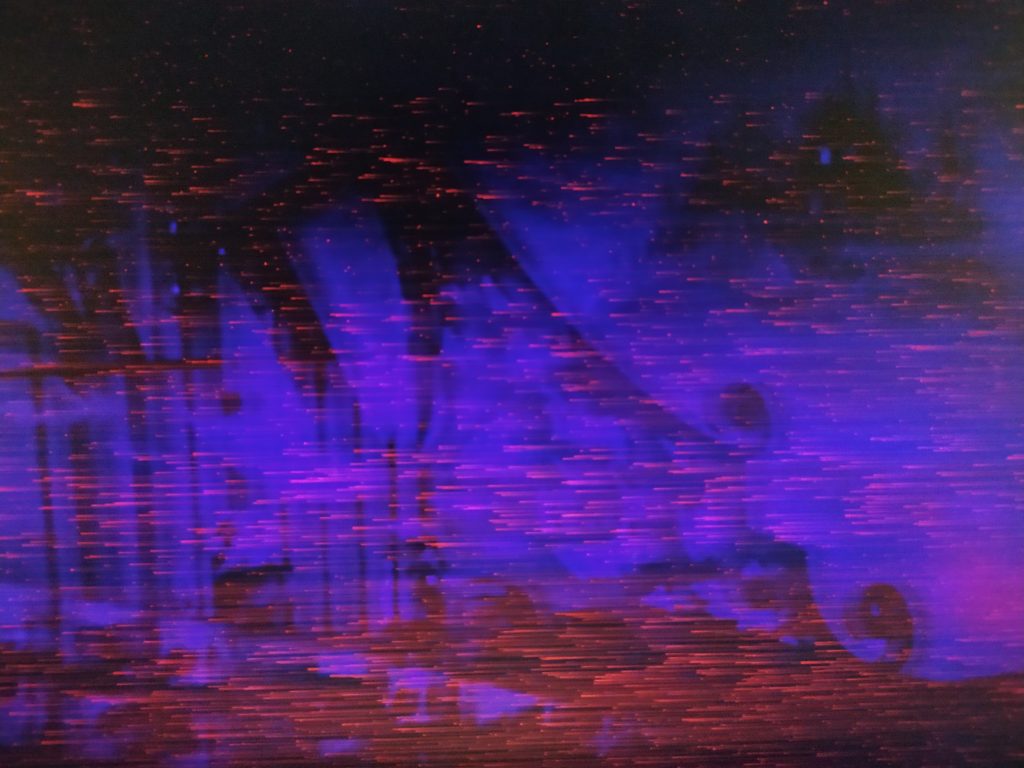

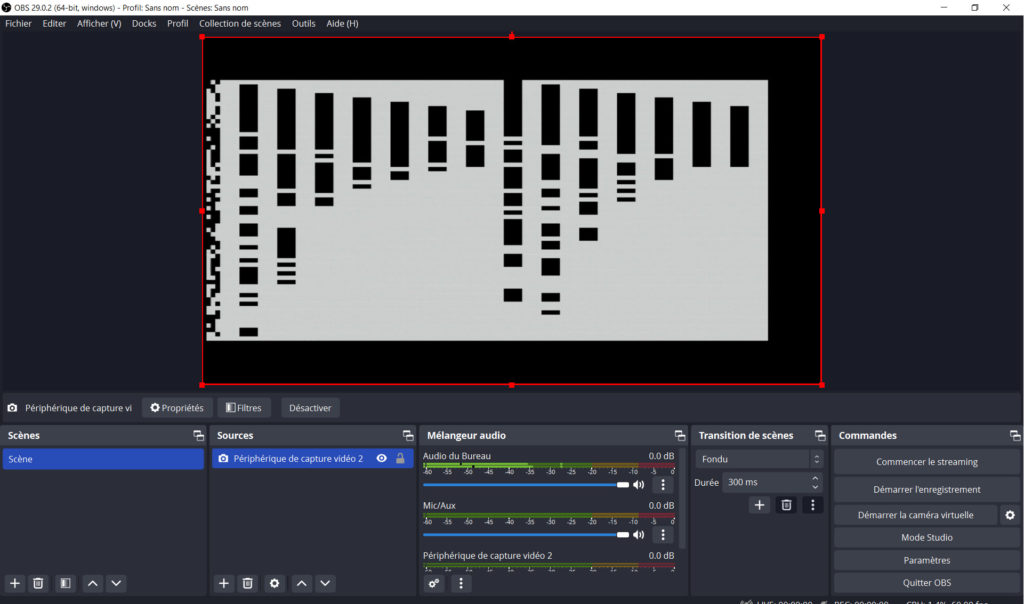

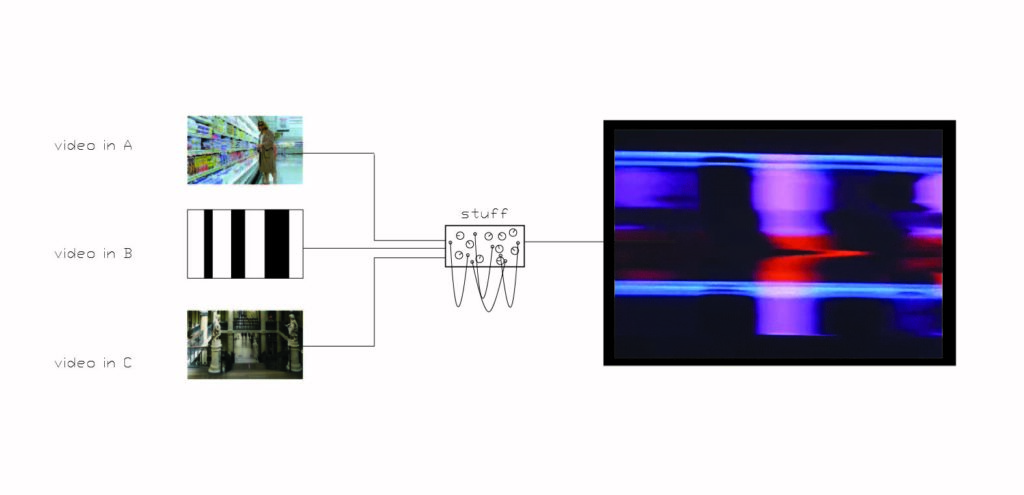

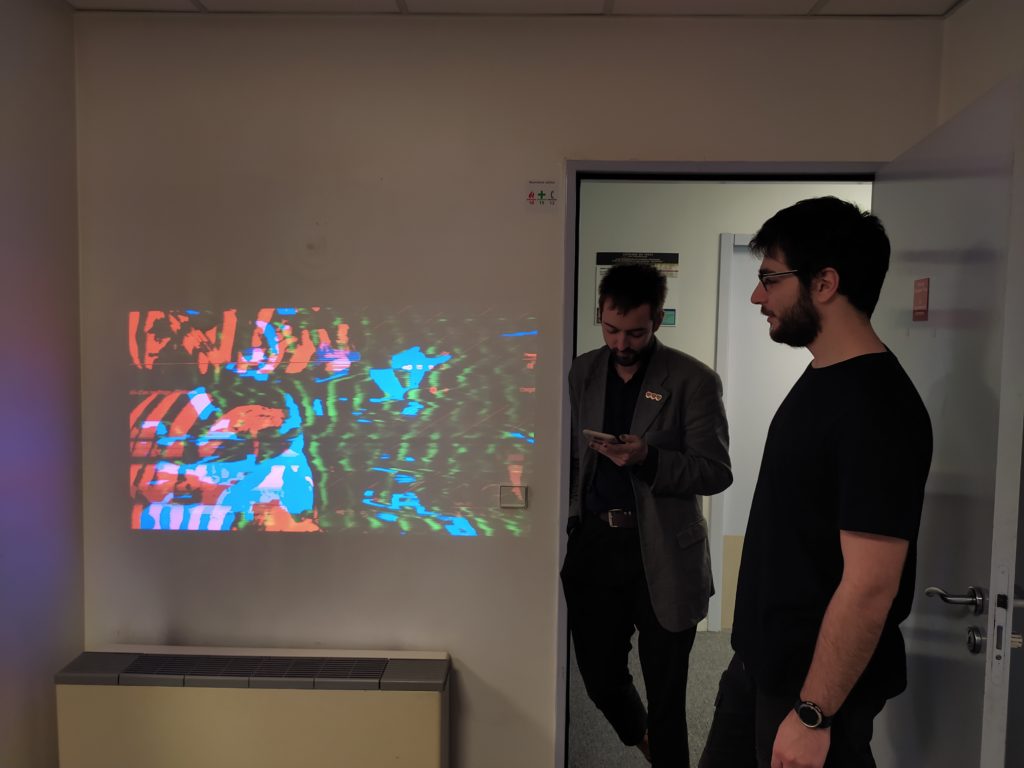

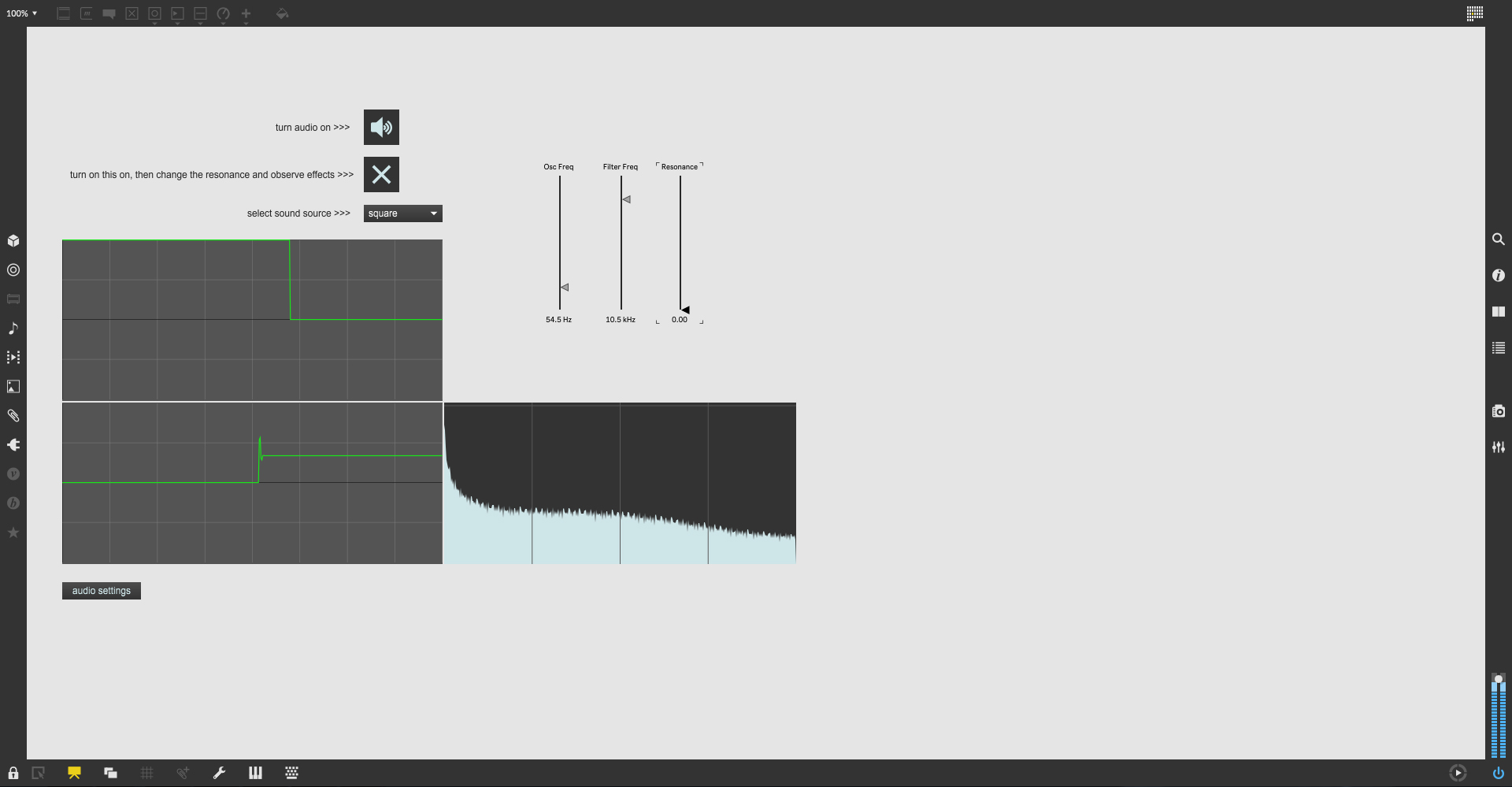

I will be VJing this month, we’ll see what that experience is like. Perhaps it will help me design boards that VJs could use. Here’s what I learned :

I will be VJing this month, we’ll see what that experience is like. Perhaps it will help me design boards that VJs could use. Here’s what I learned :

**********

**********

An

An

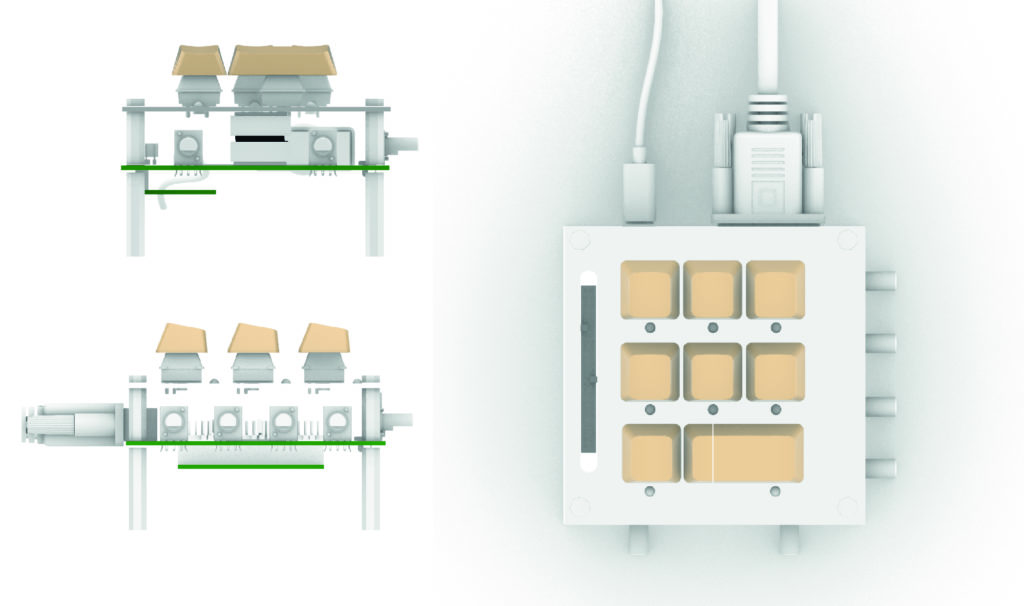

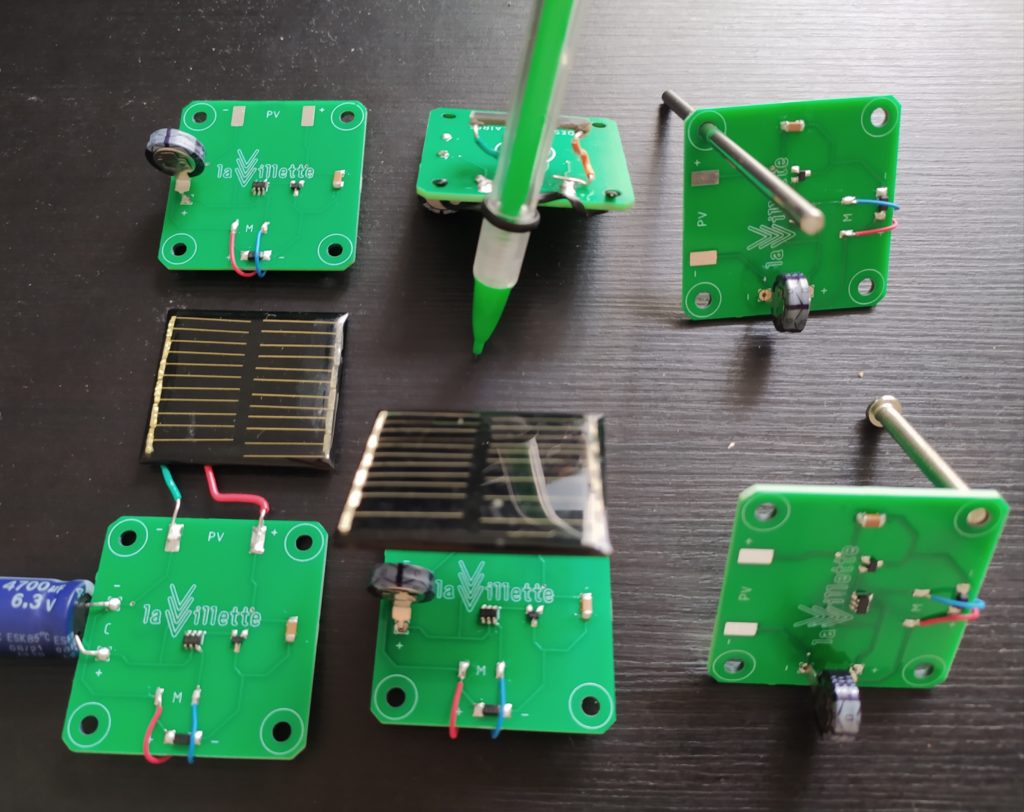

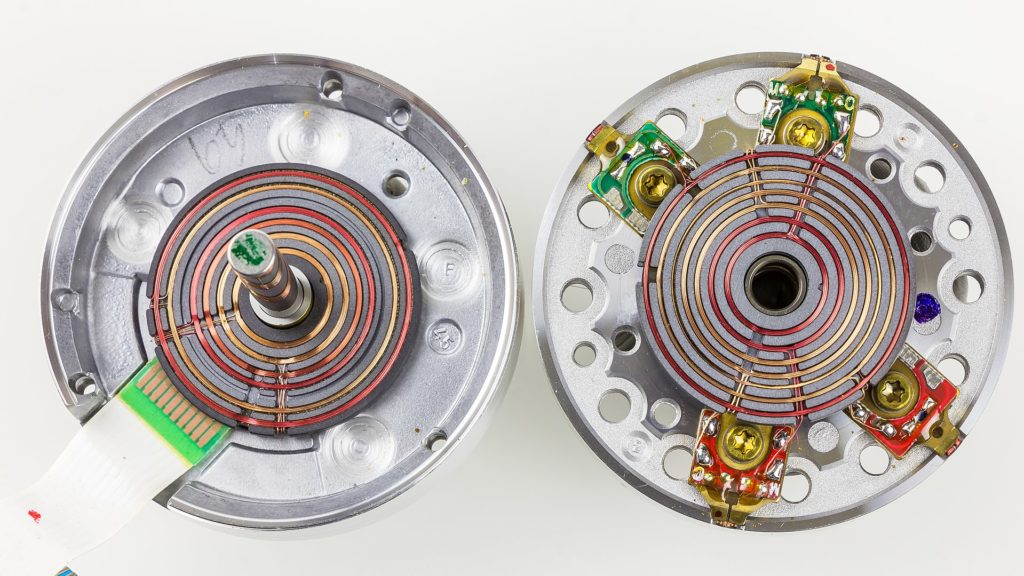

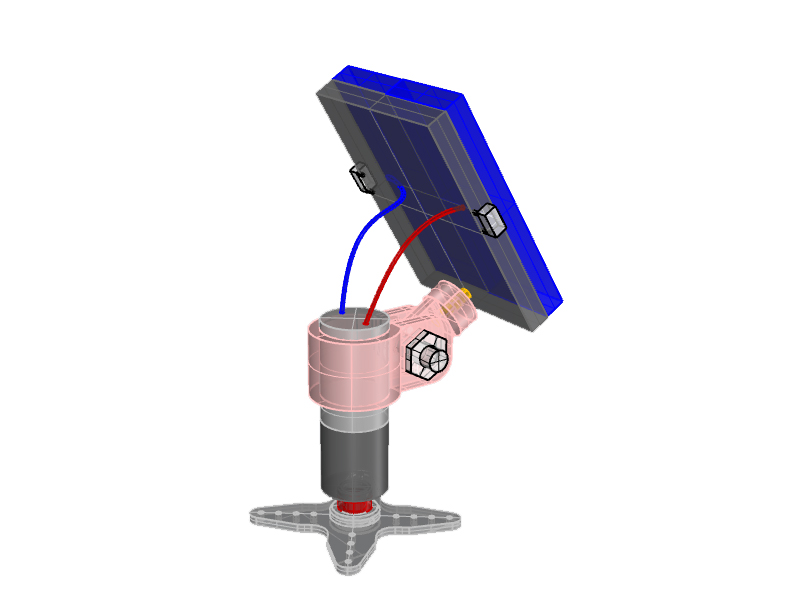

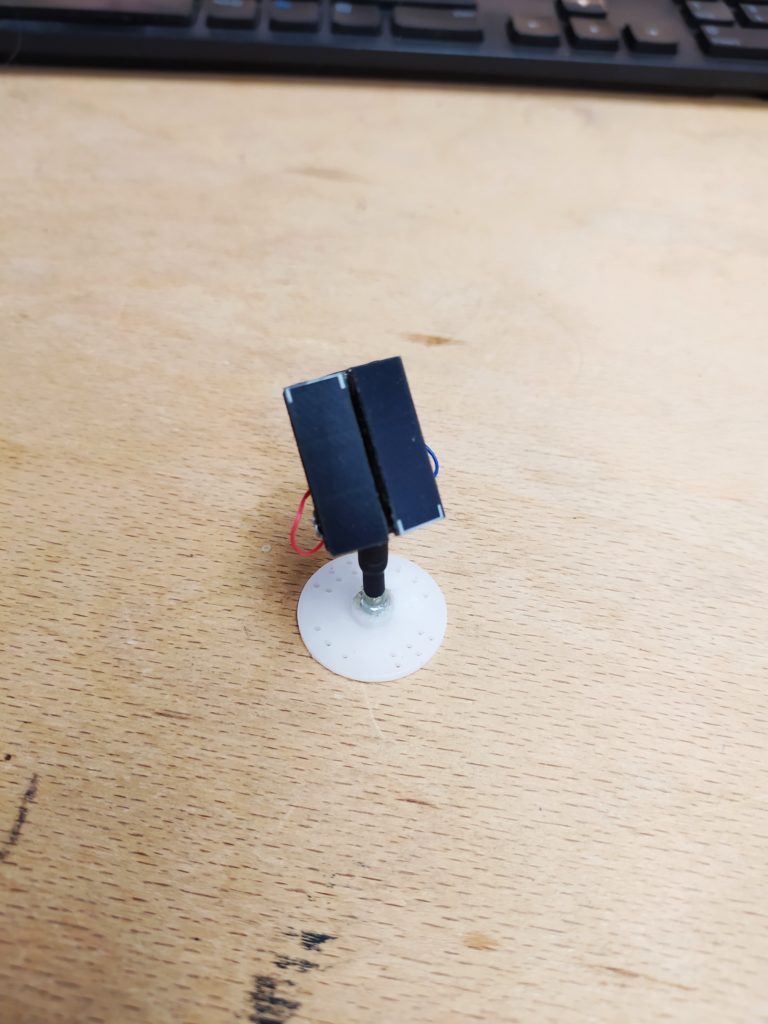

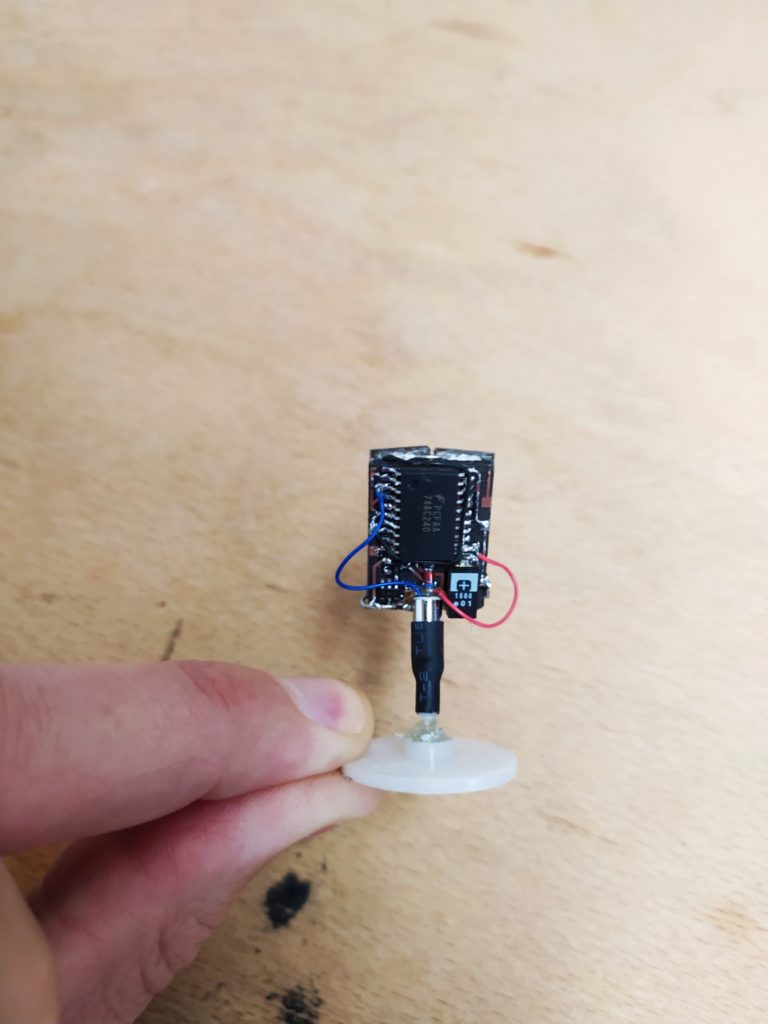

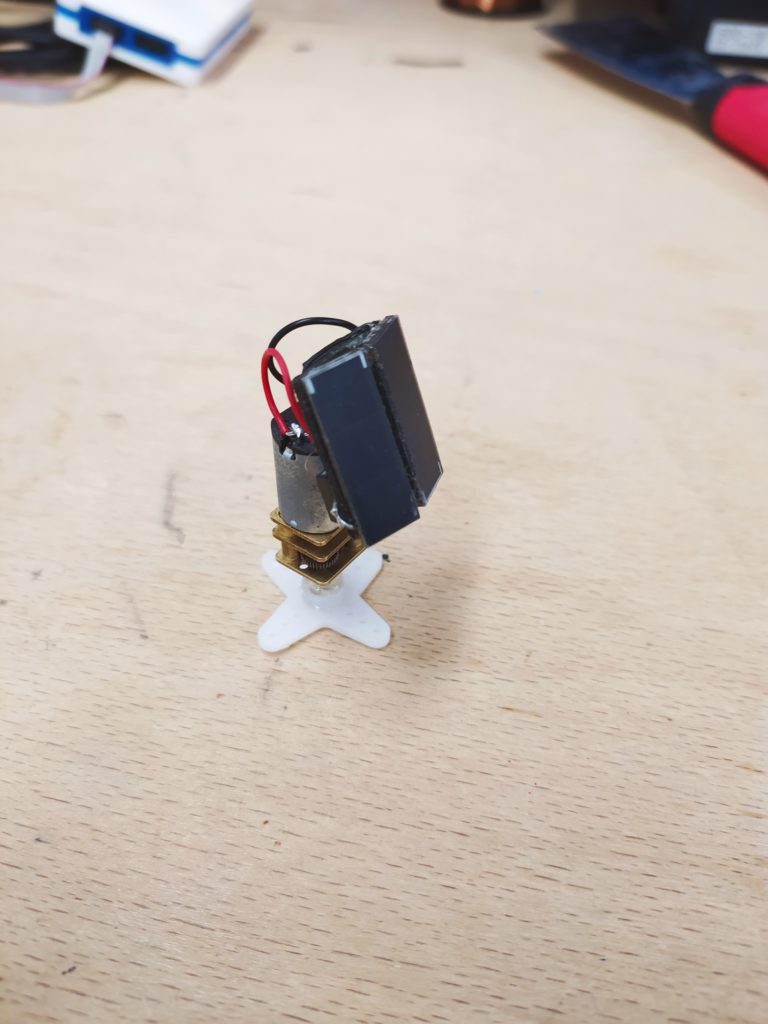

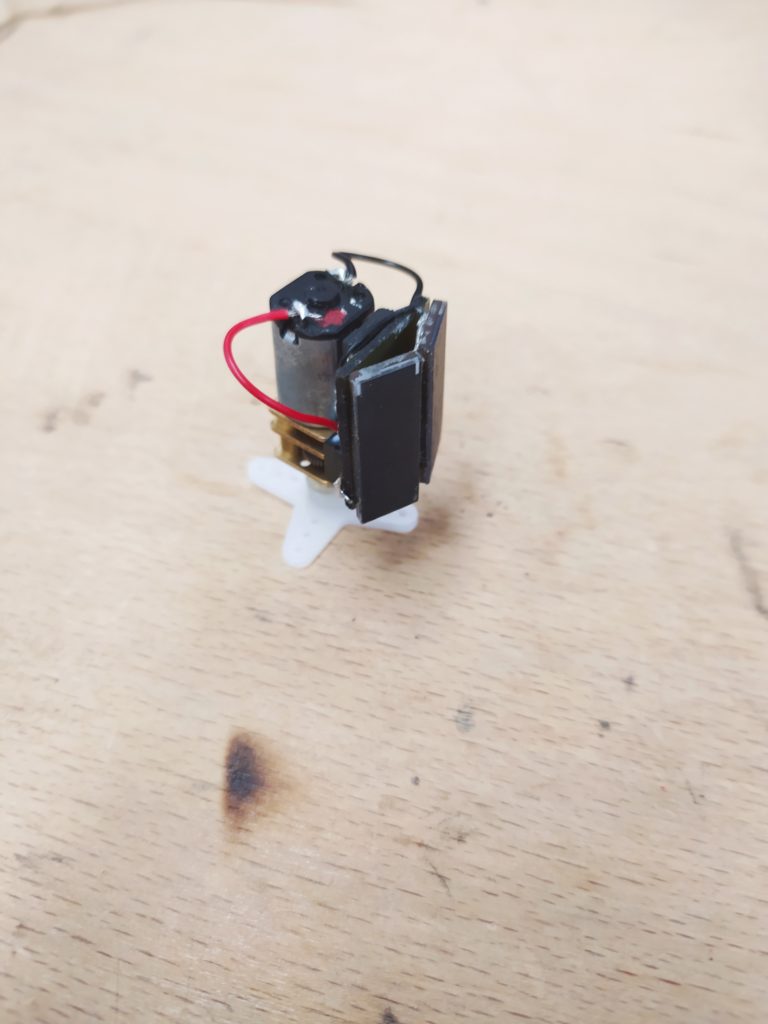

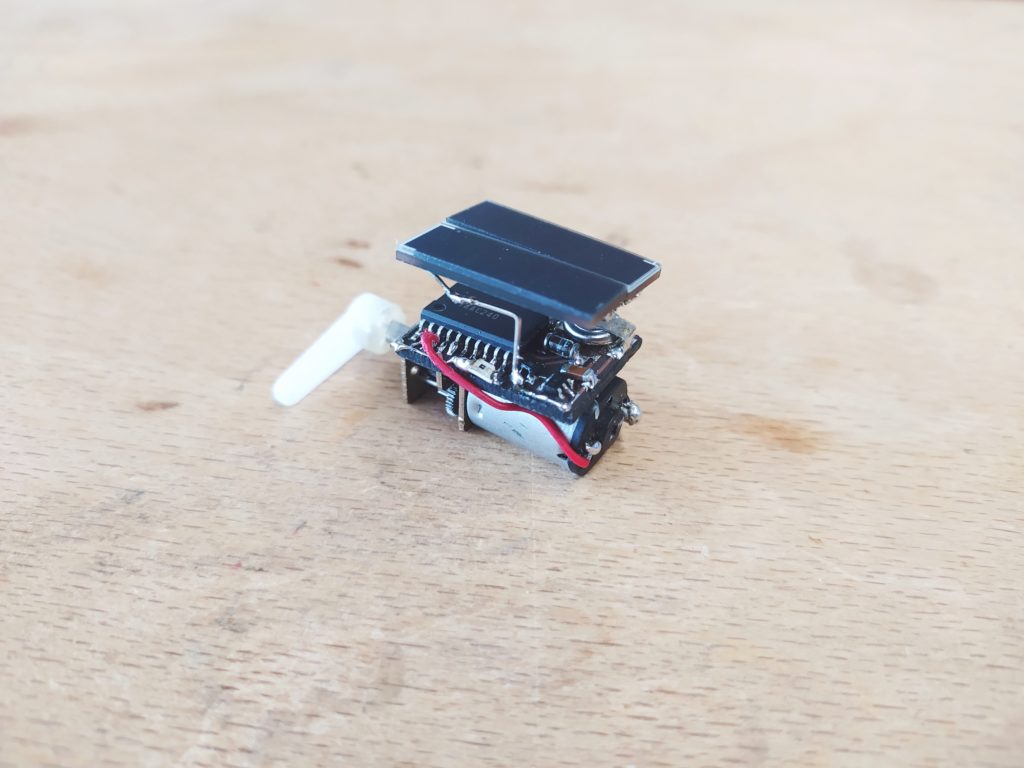

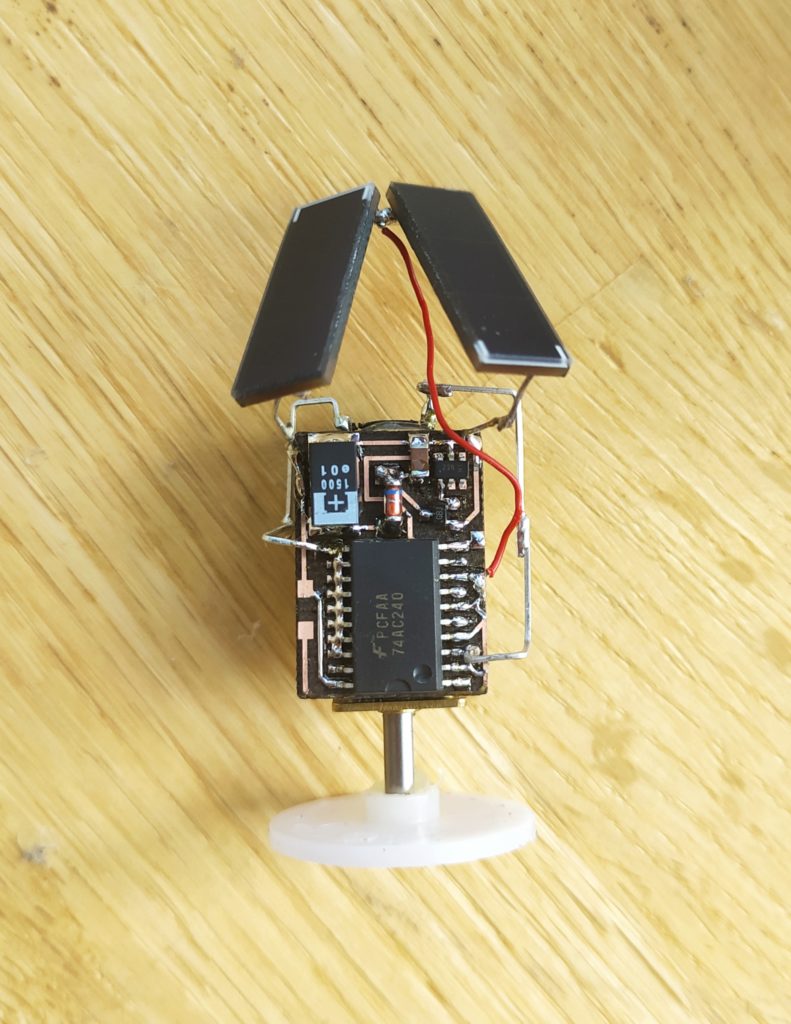

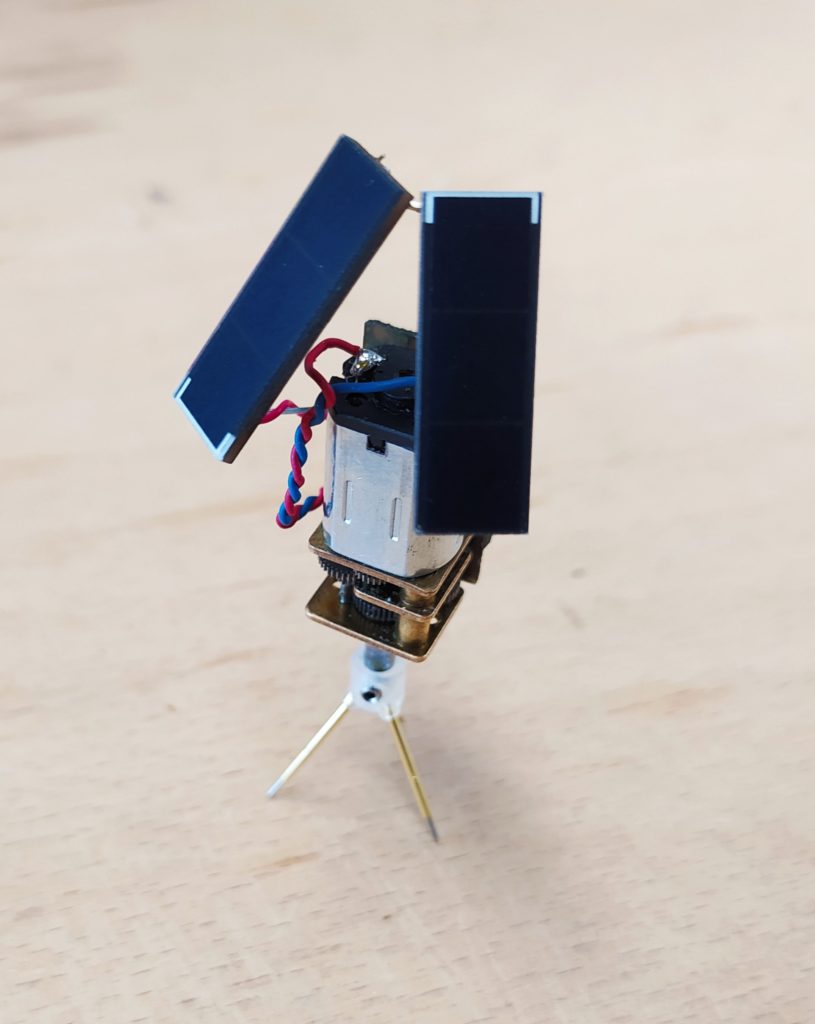

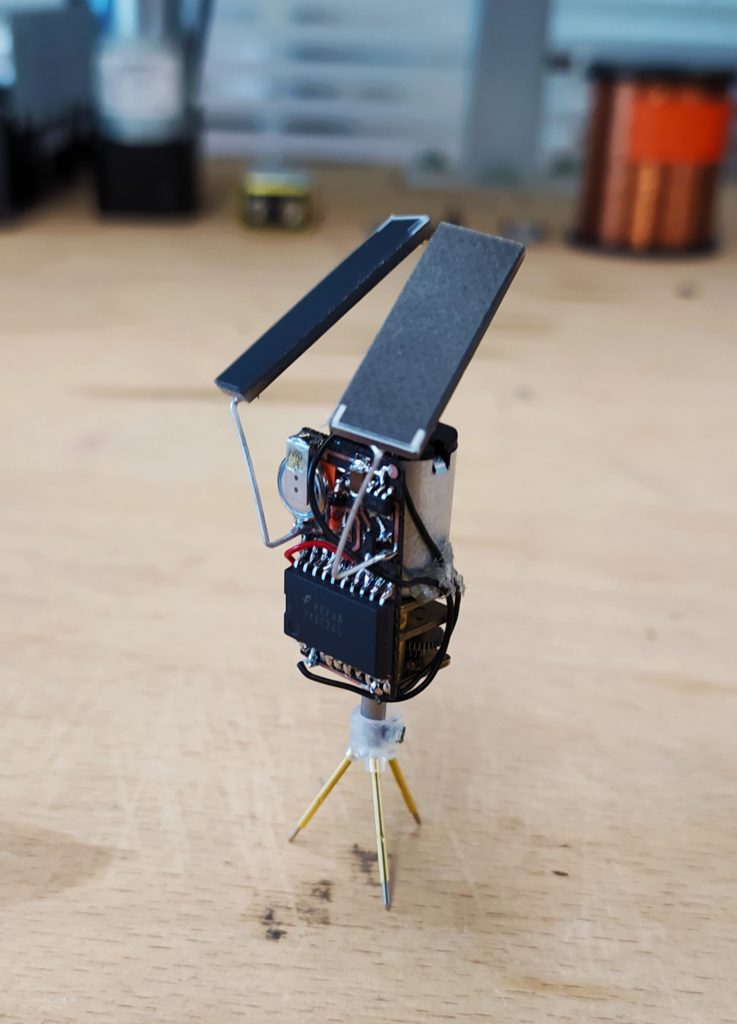

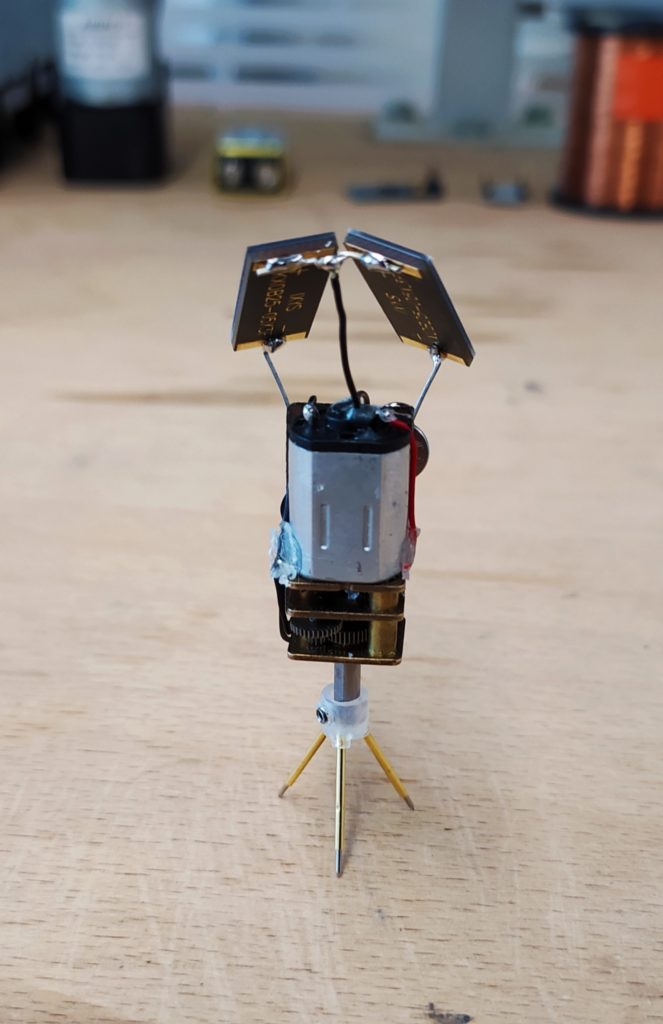

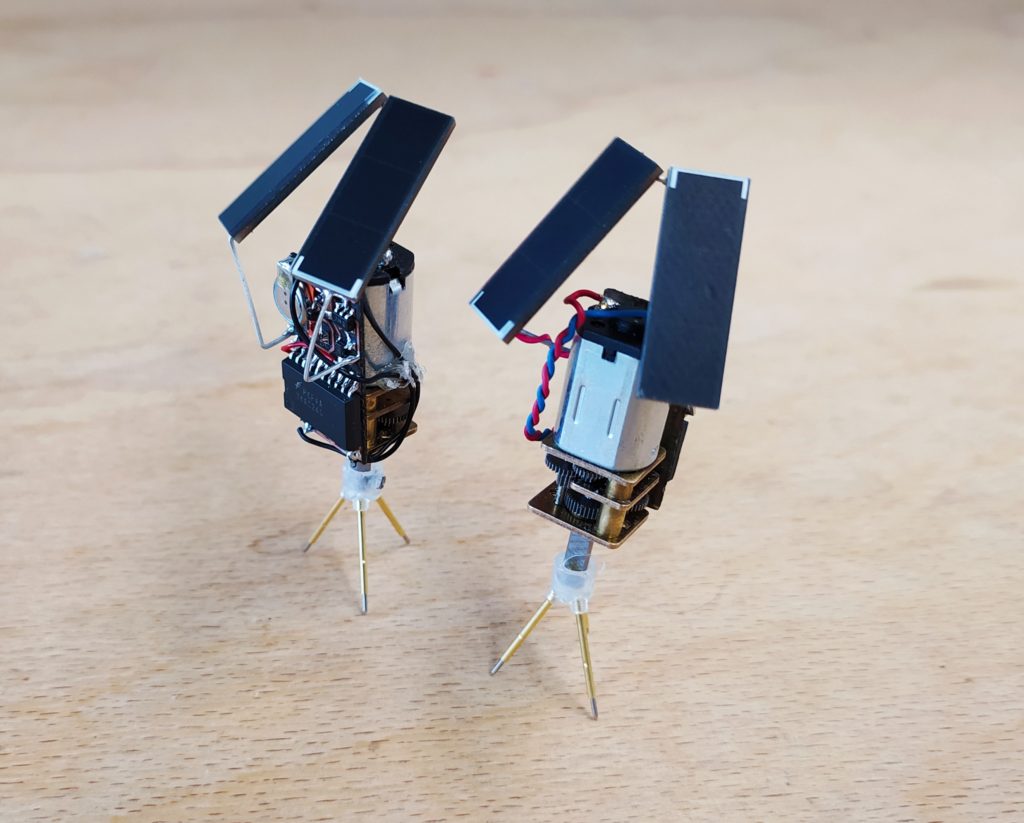

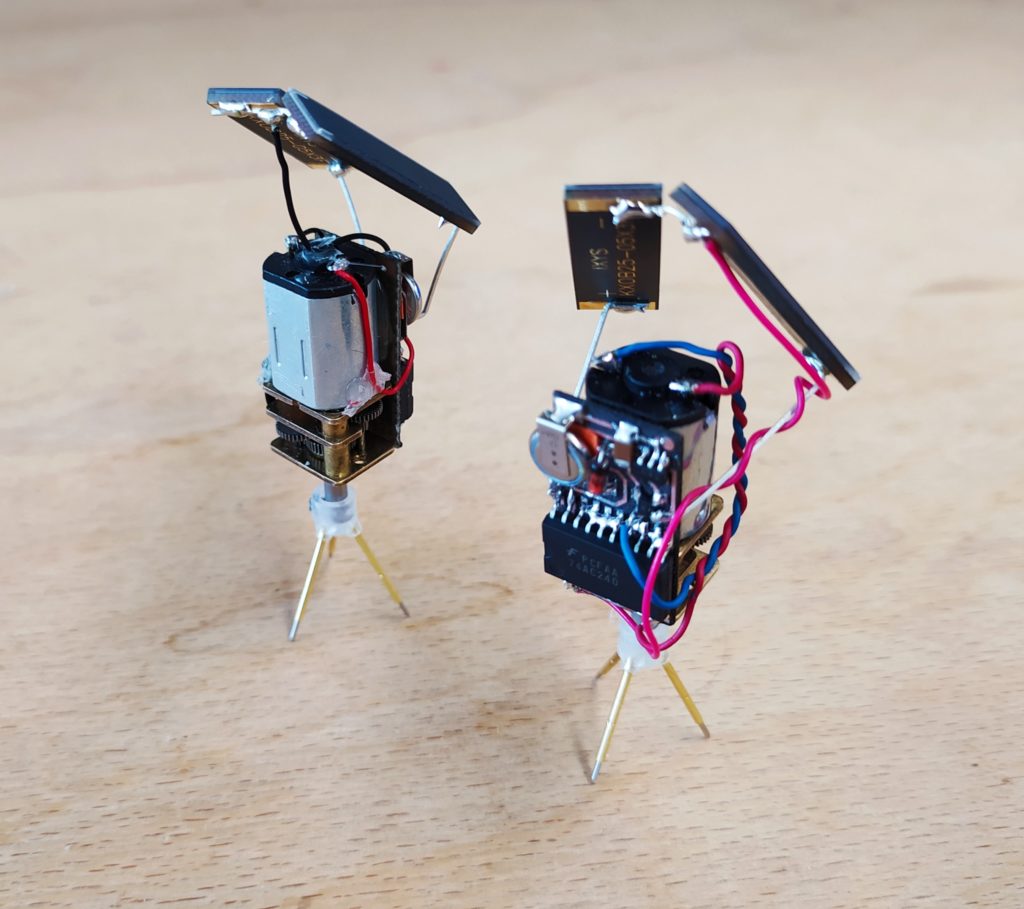

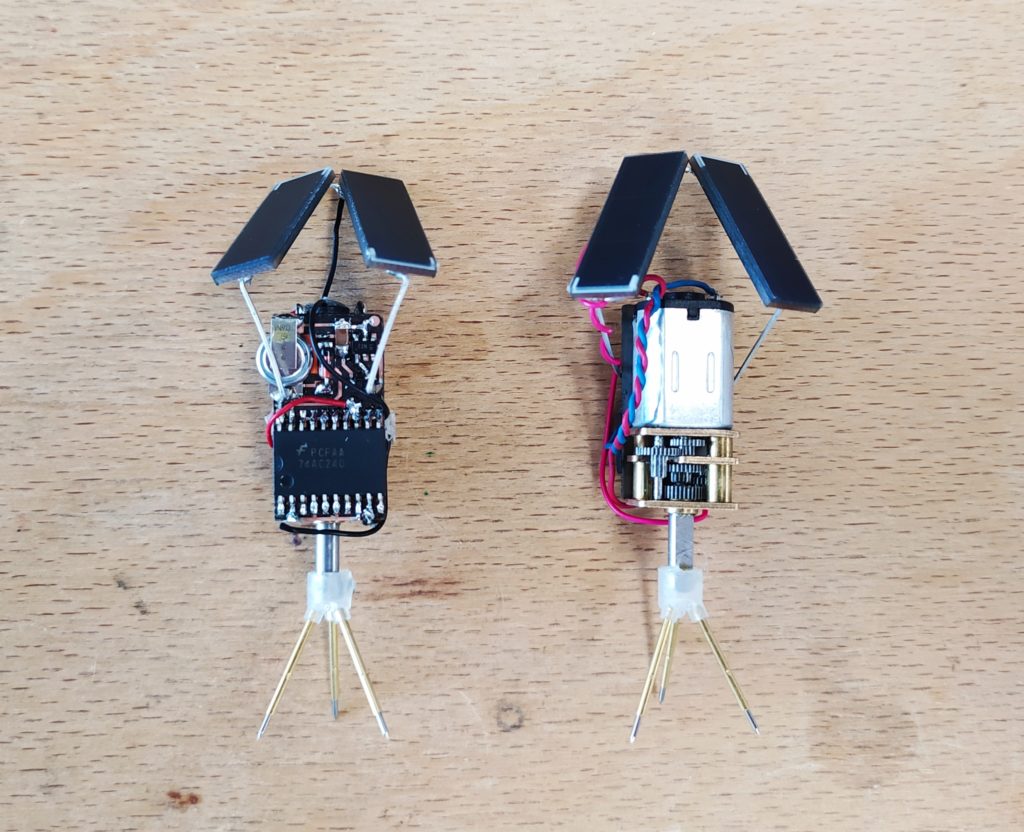

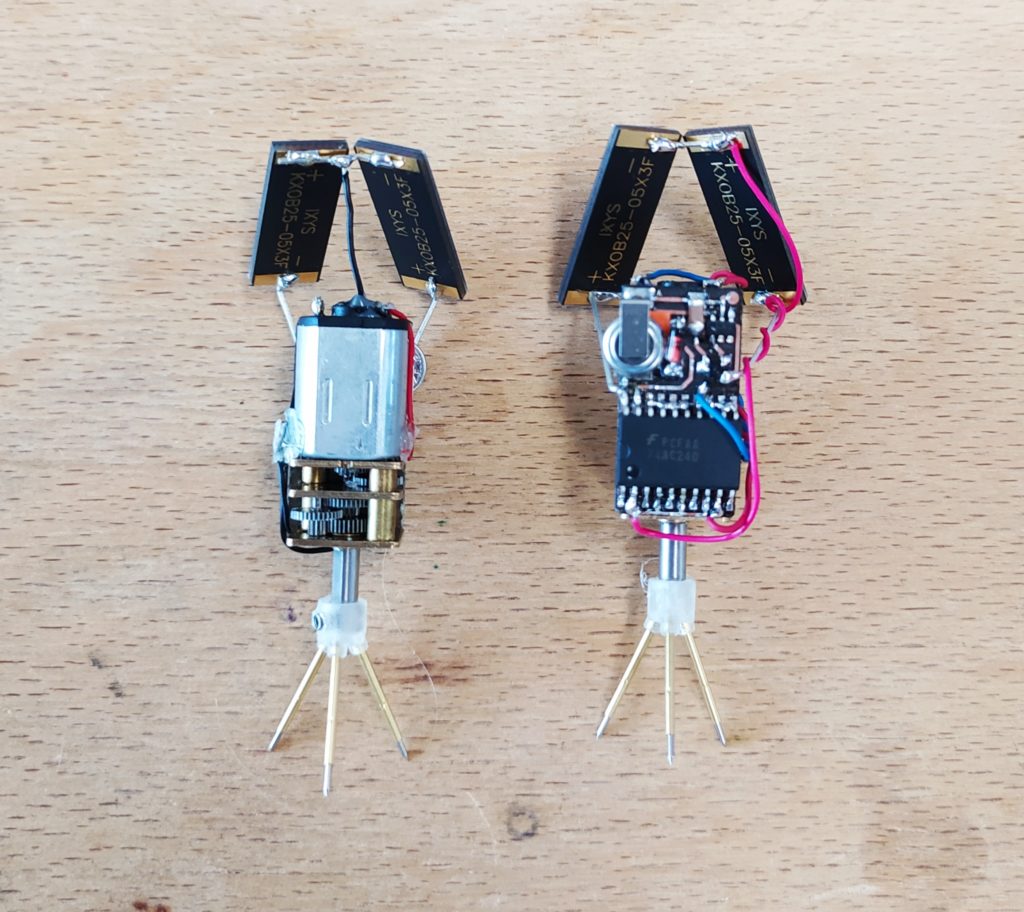

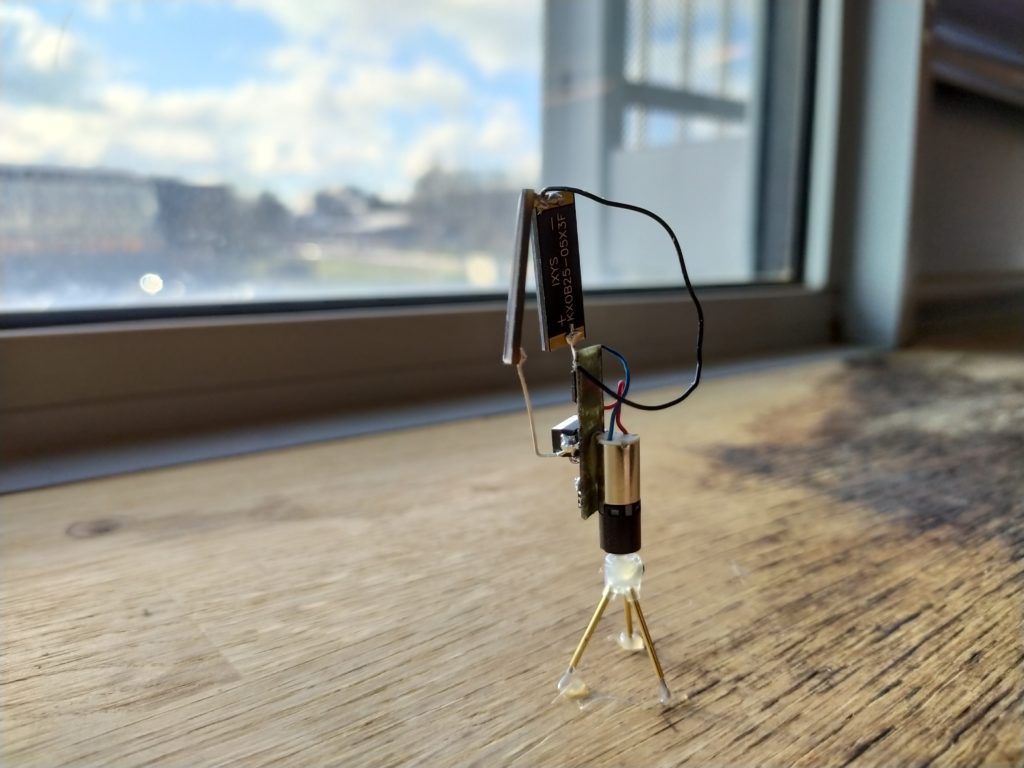

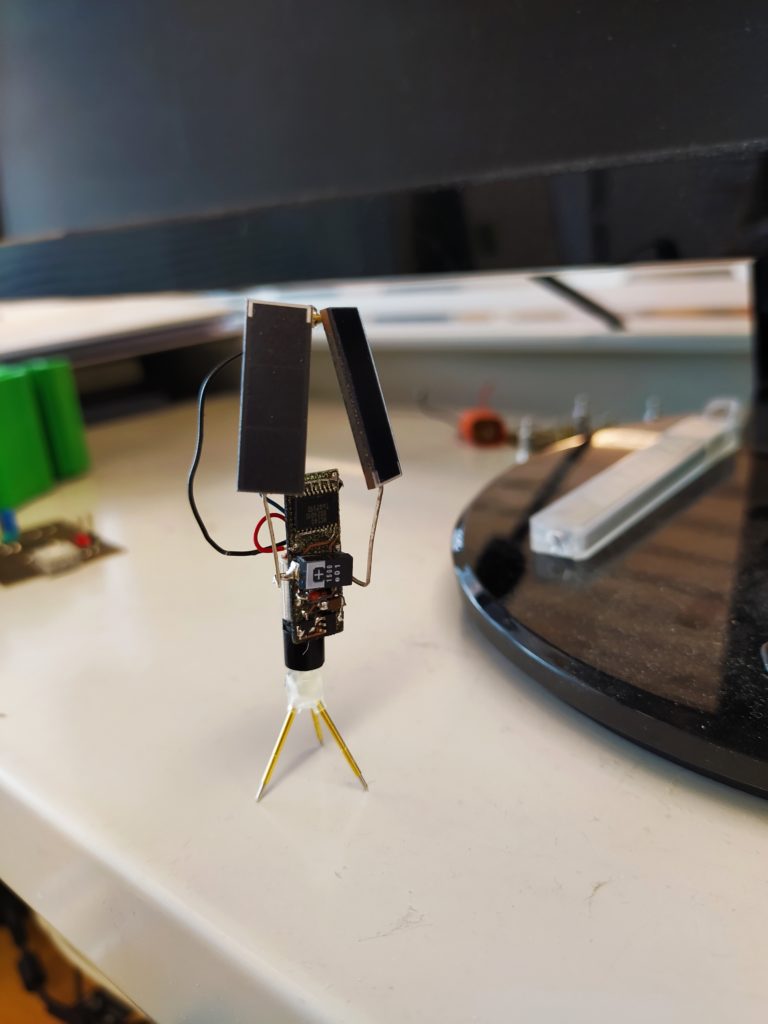

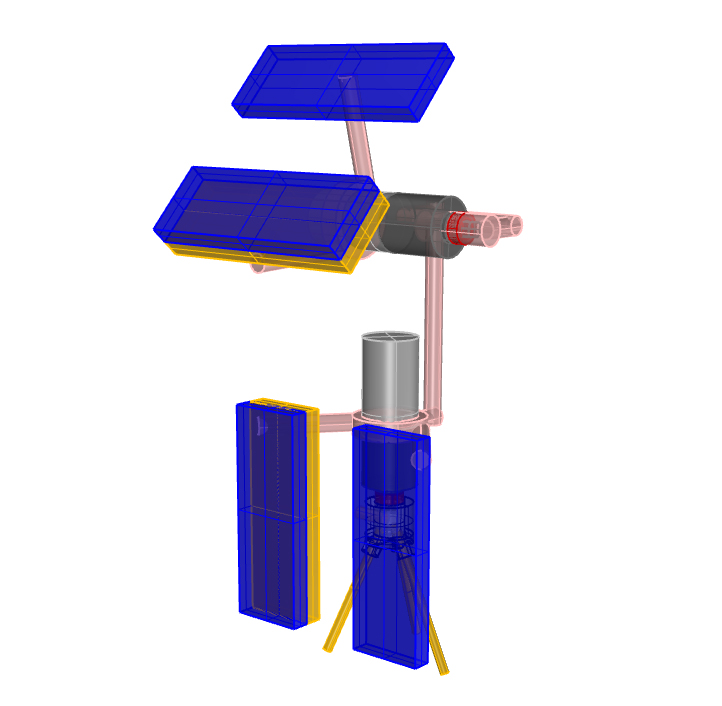

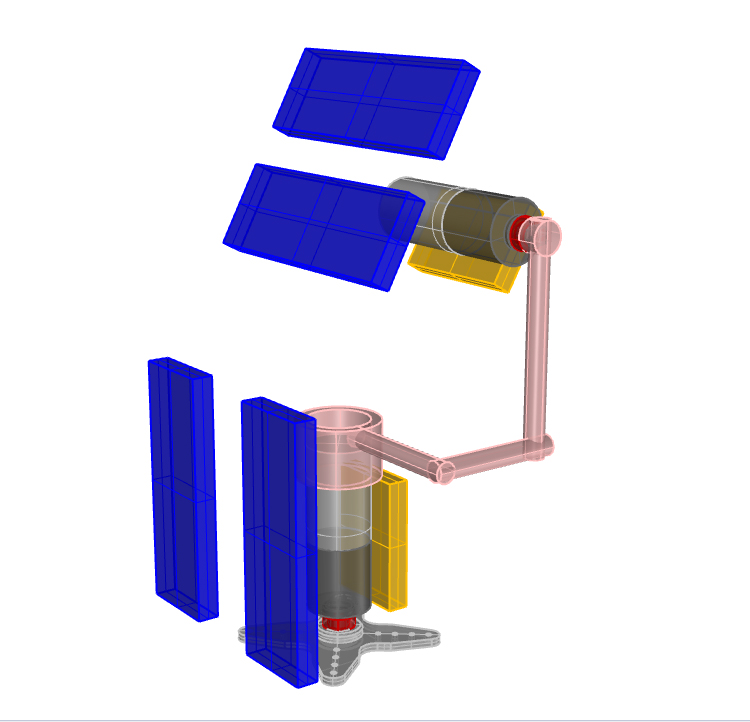

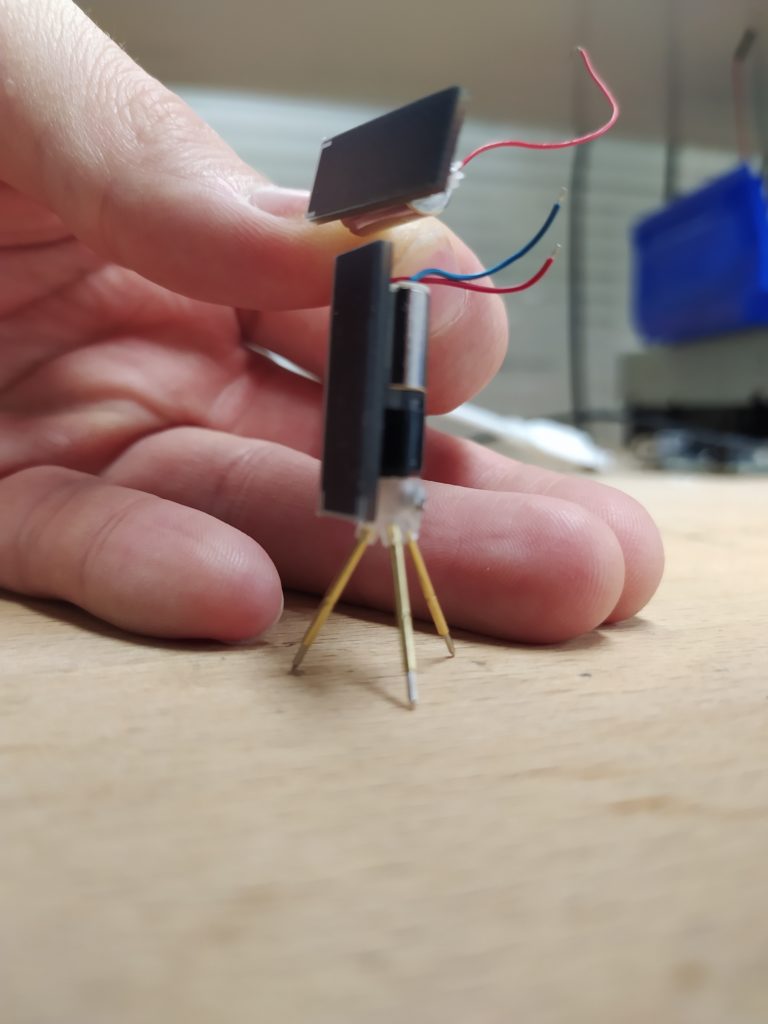

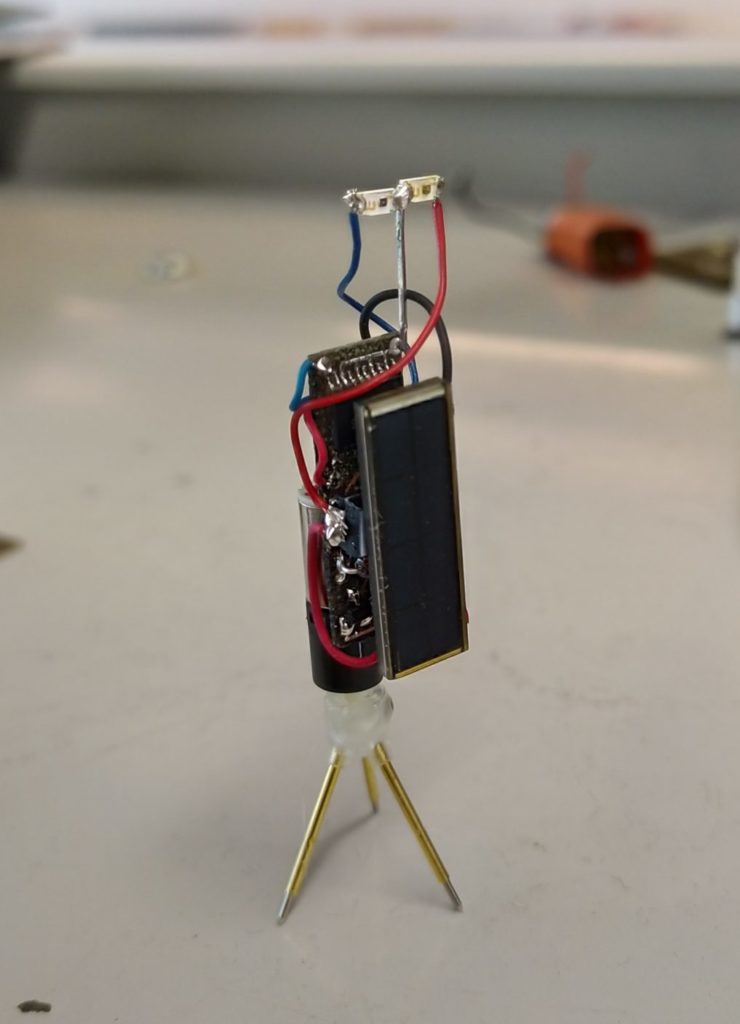

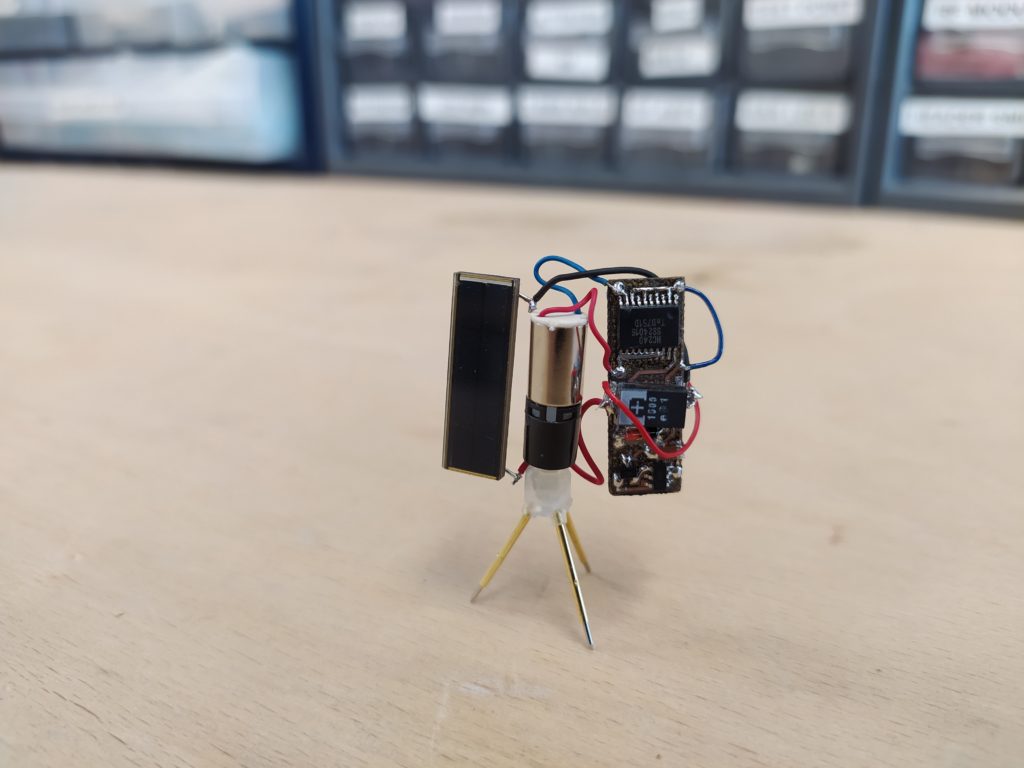

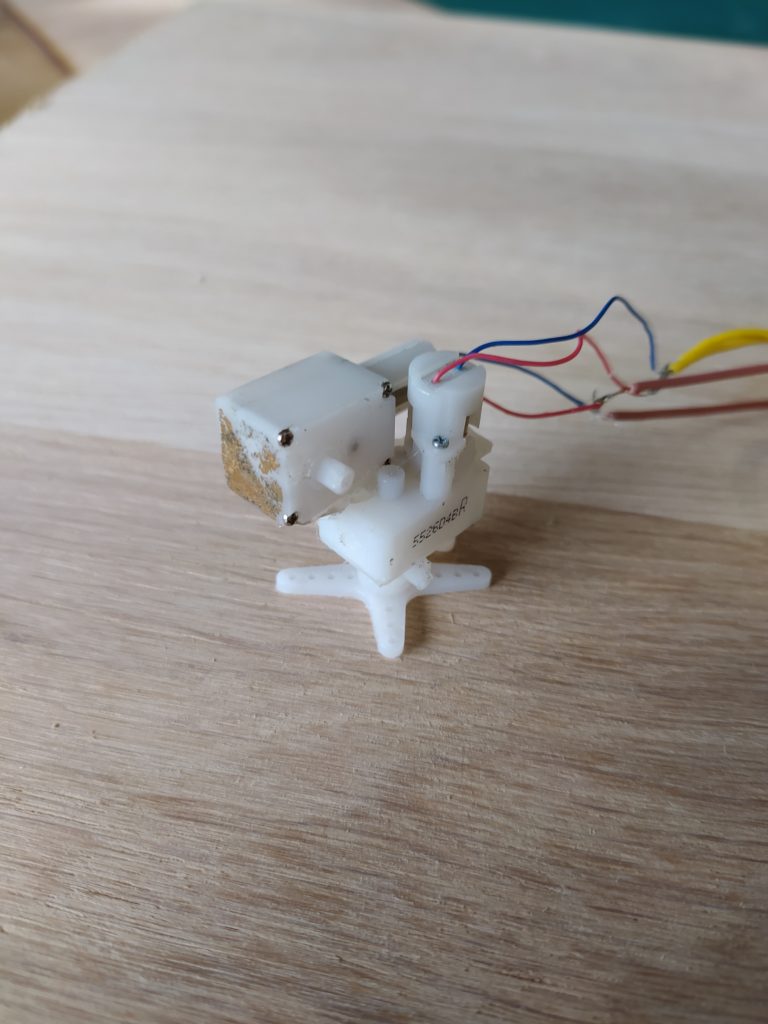

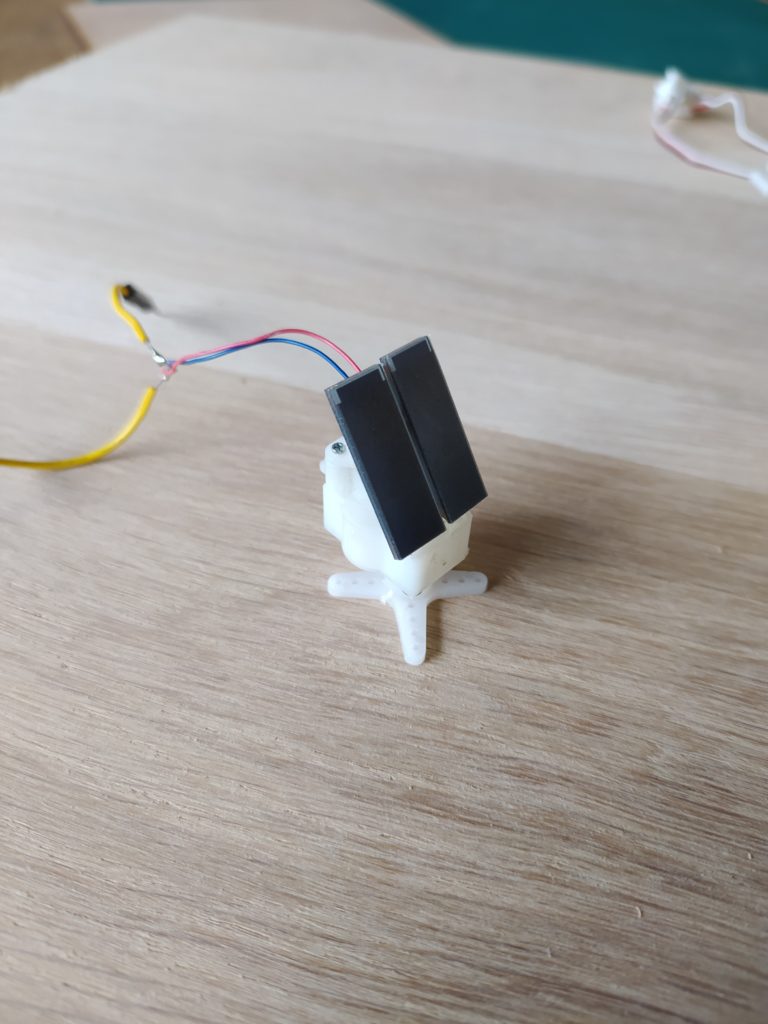

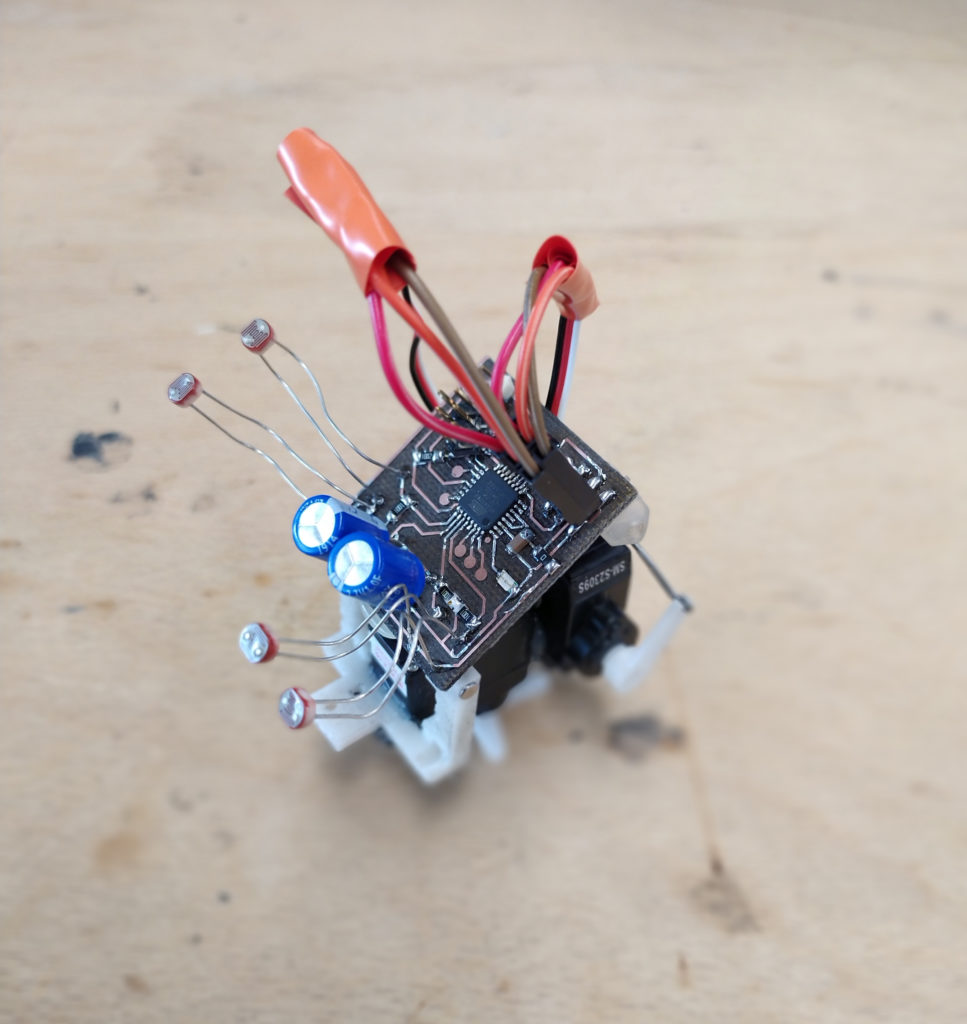

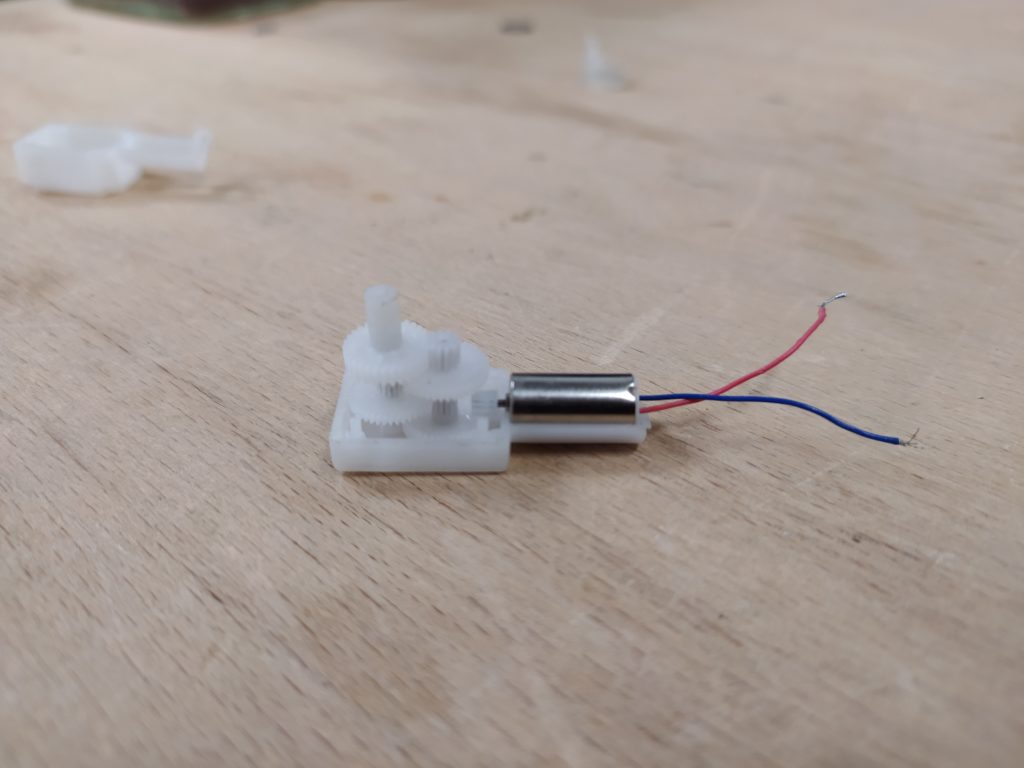

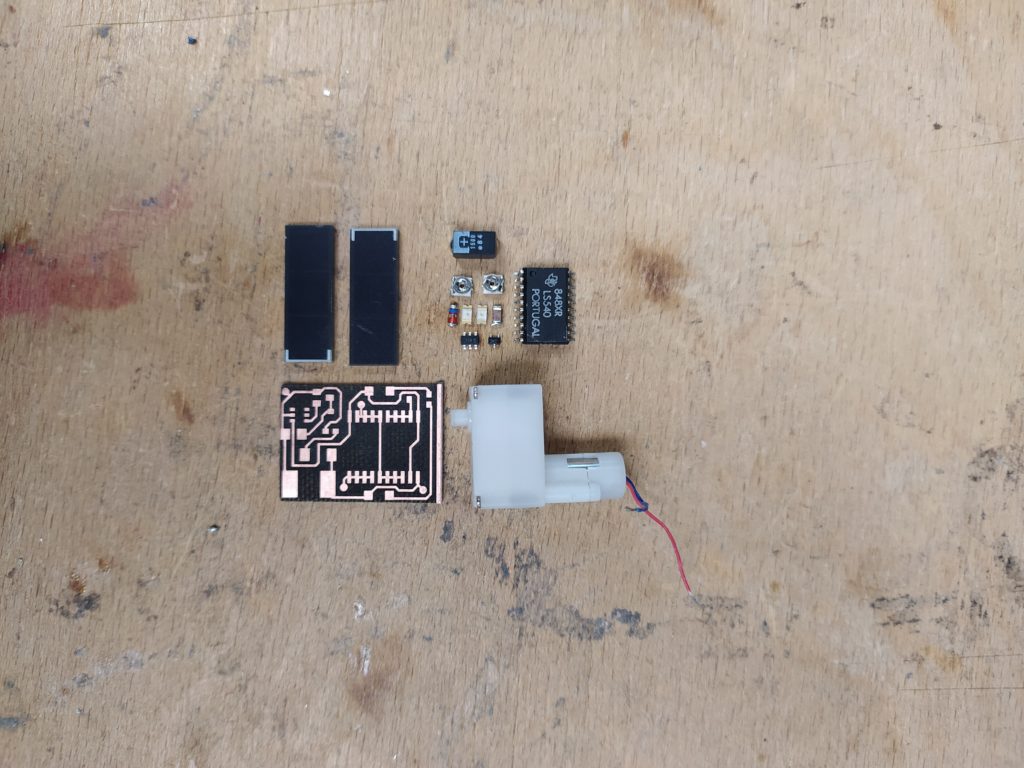

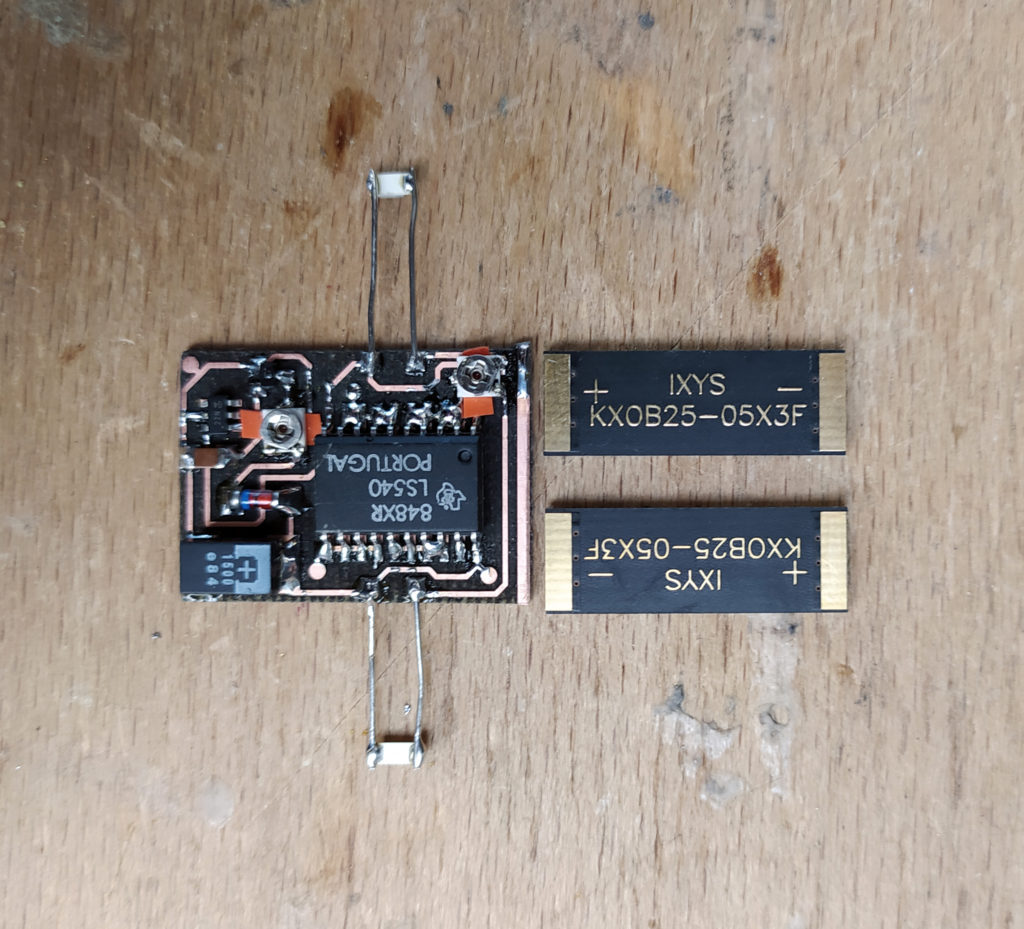

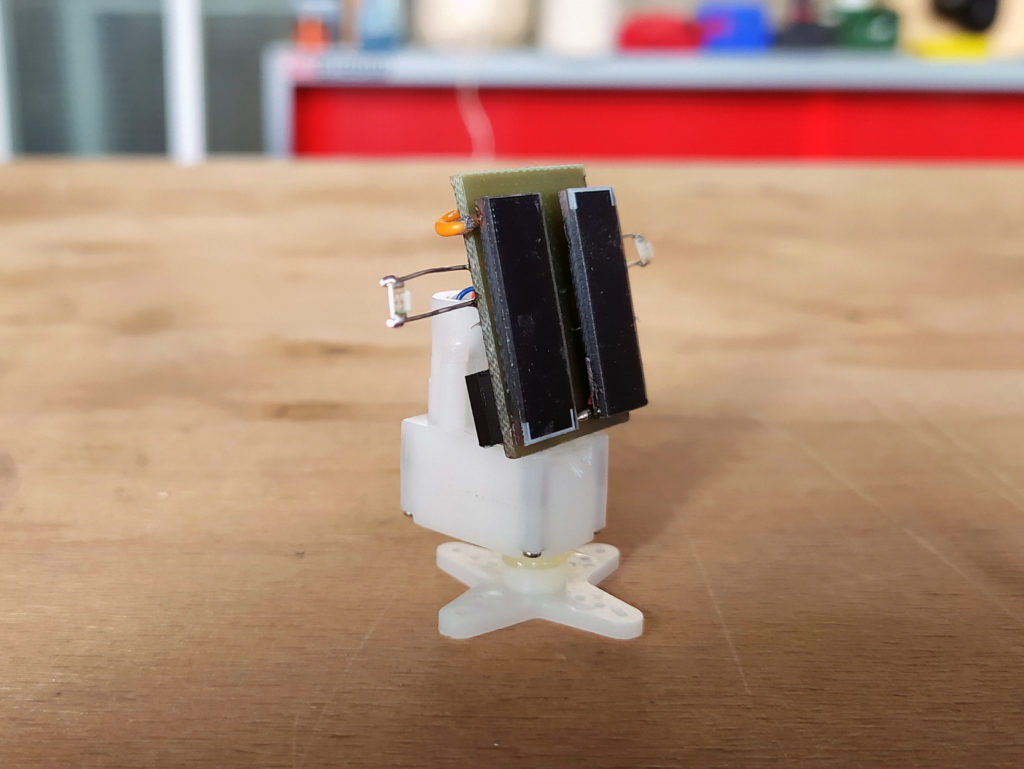

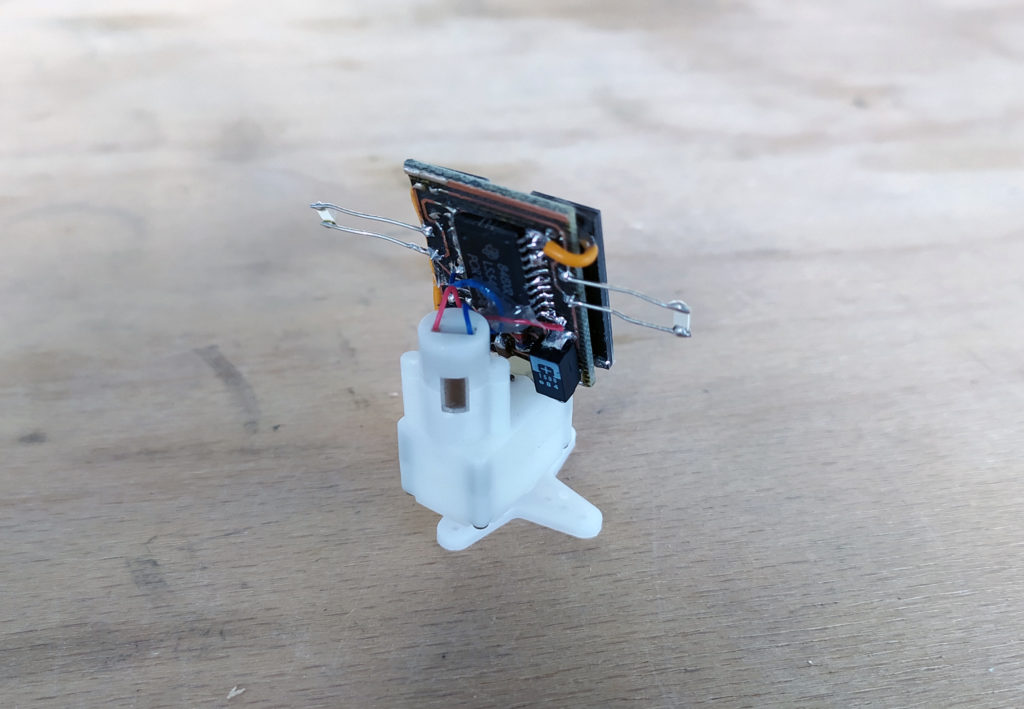

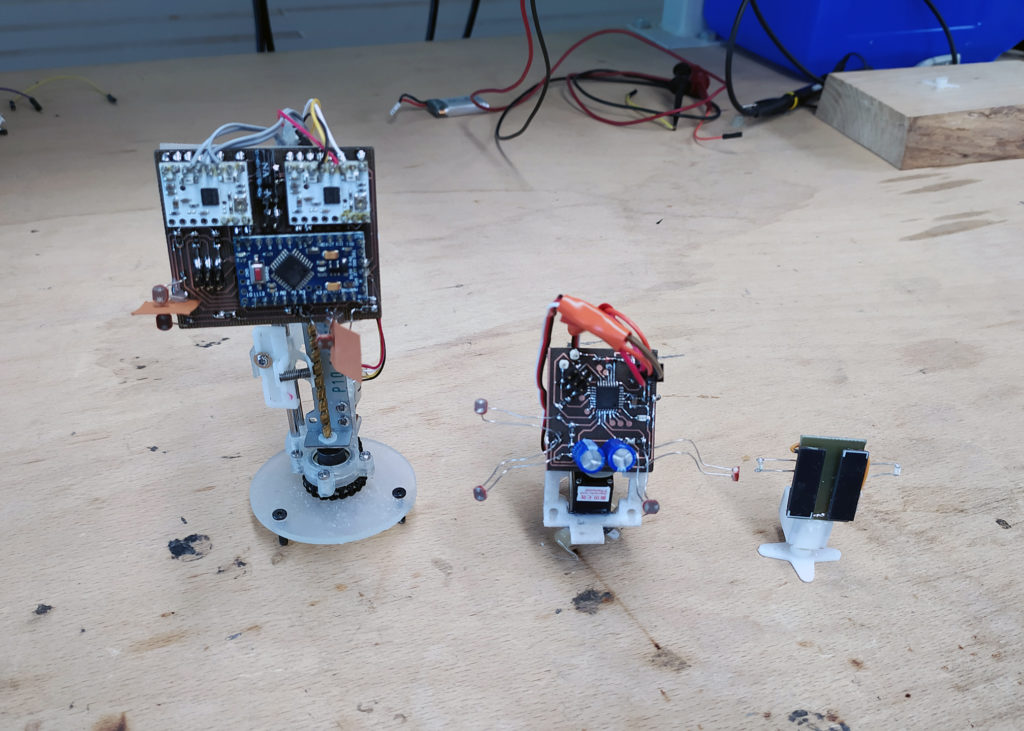

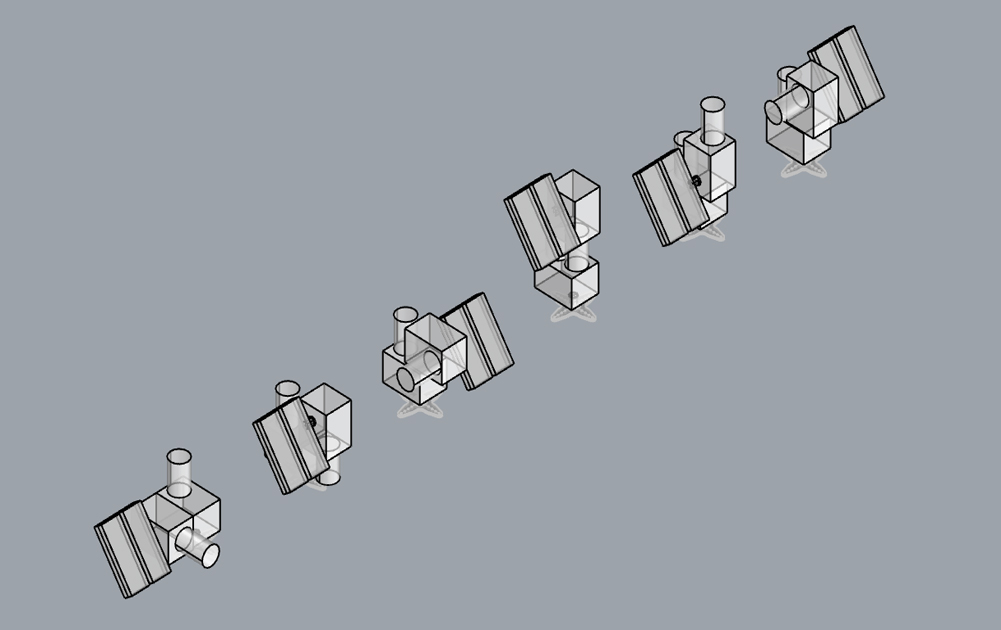

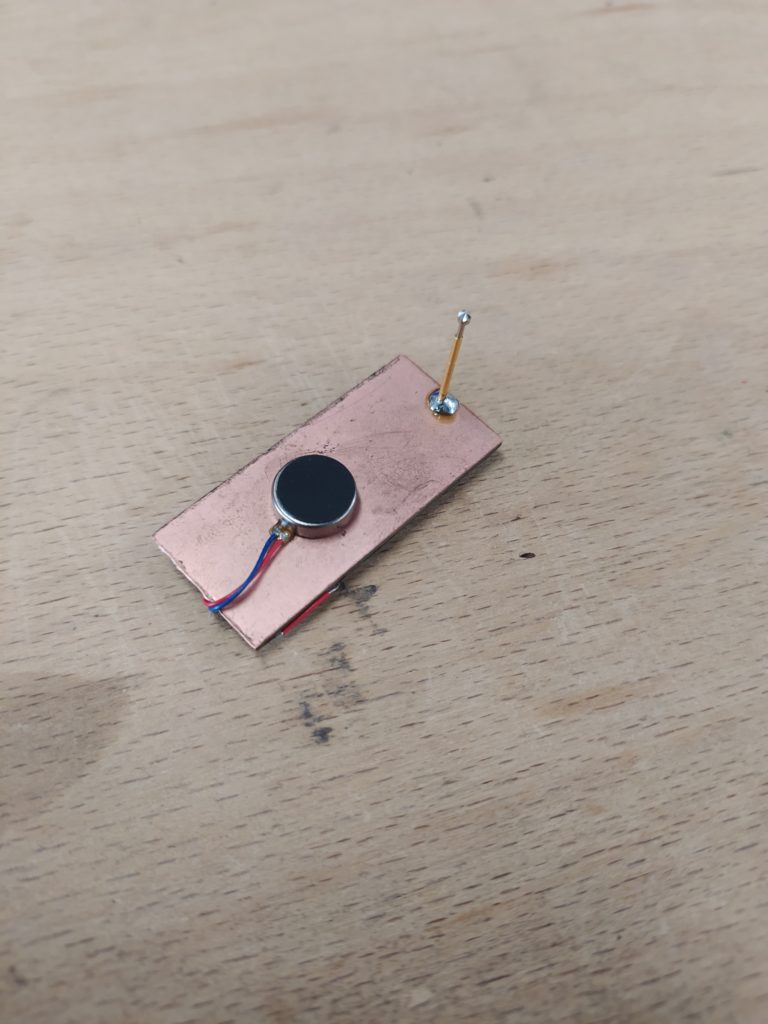

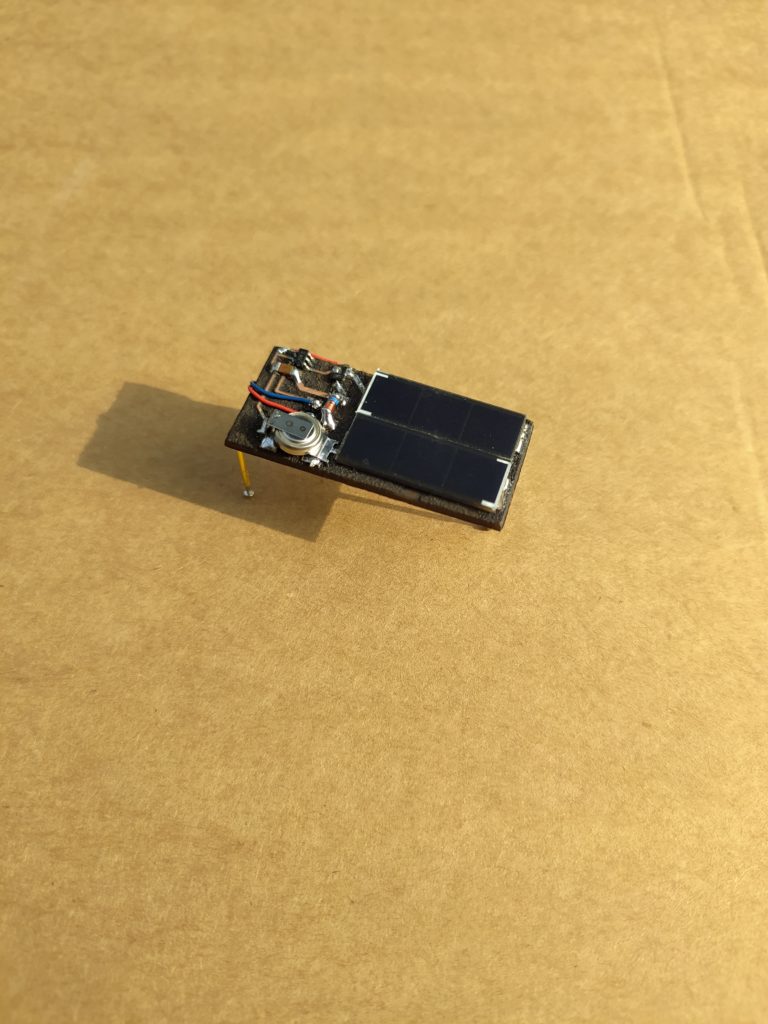

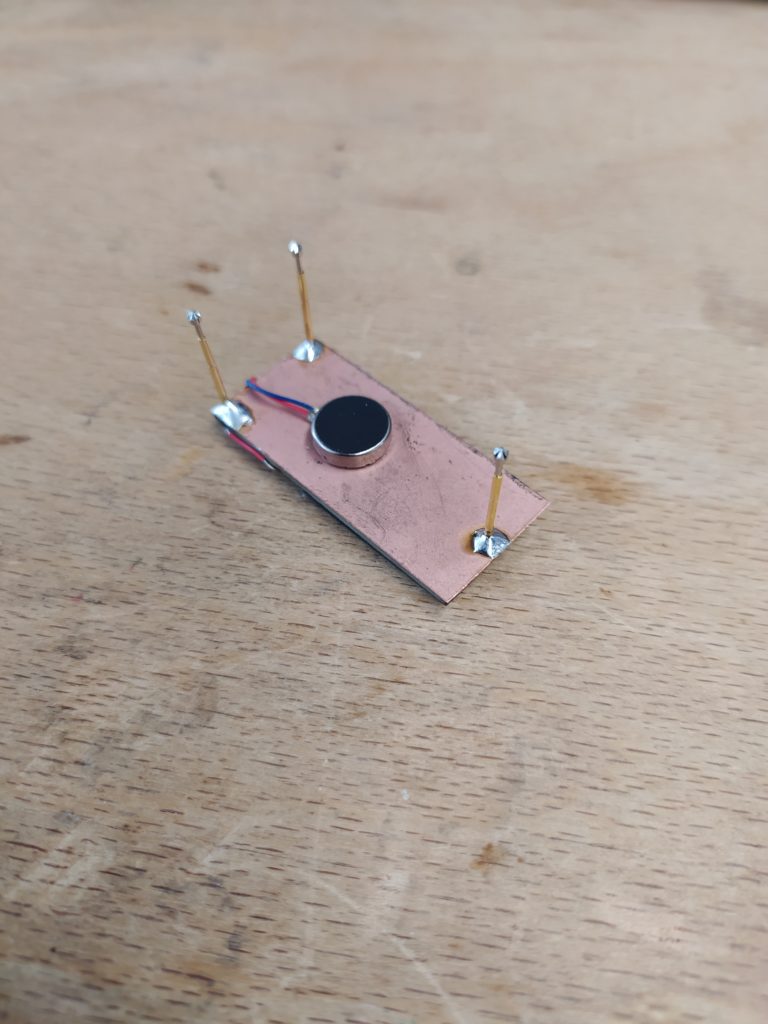

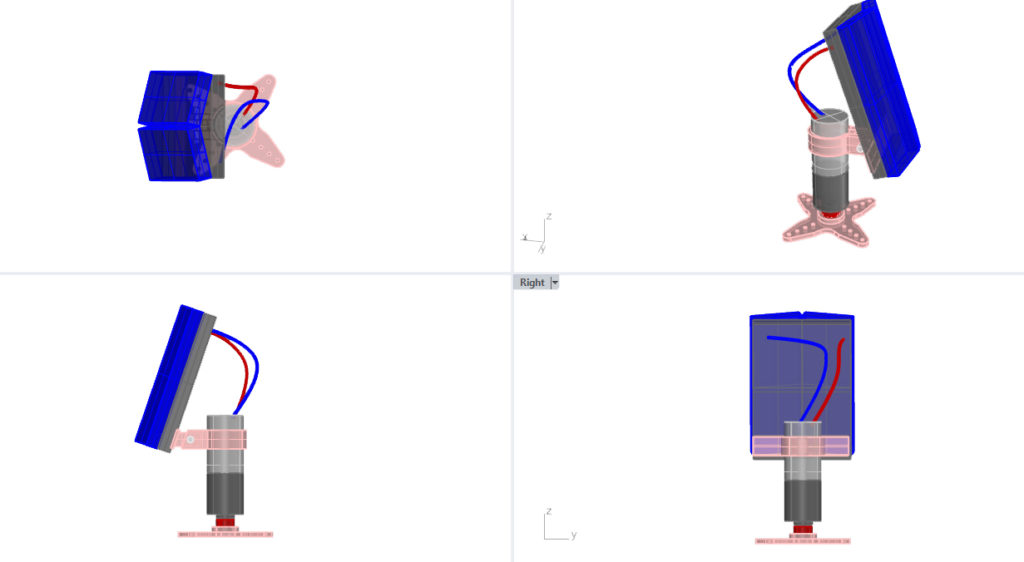

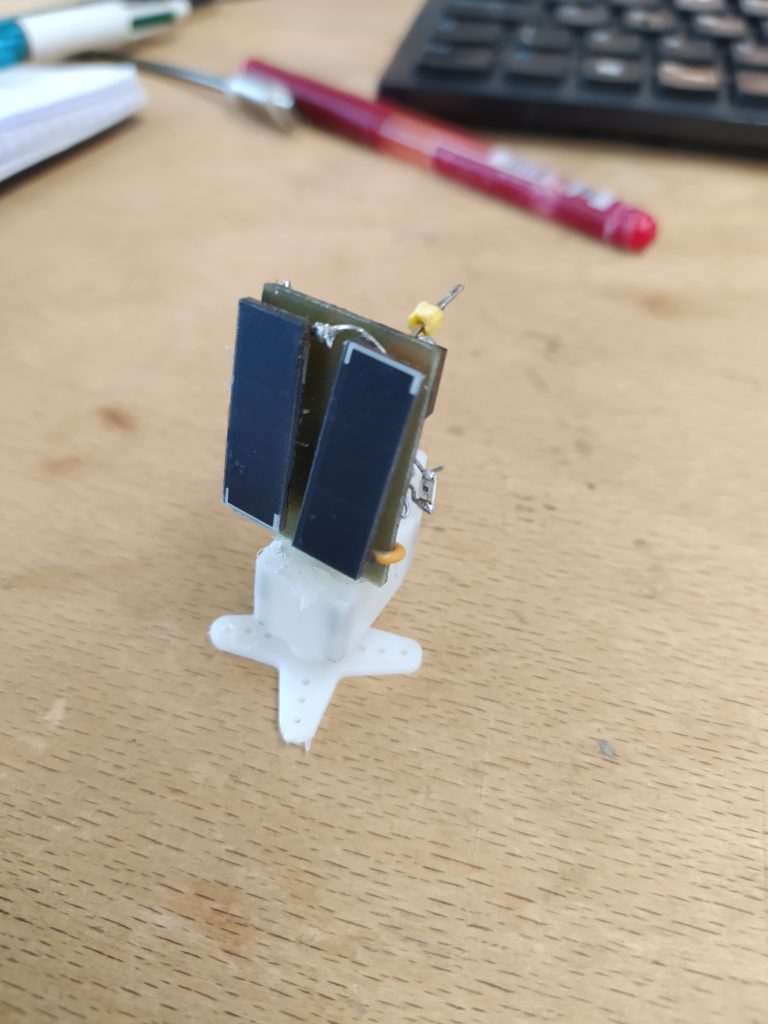

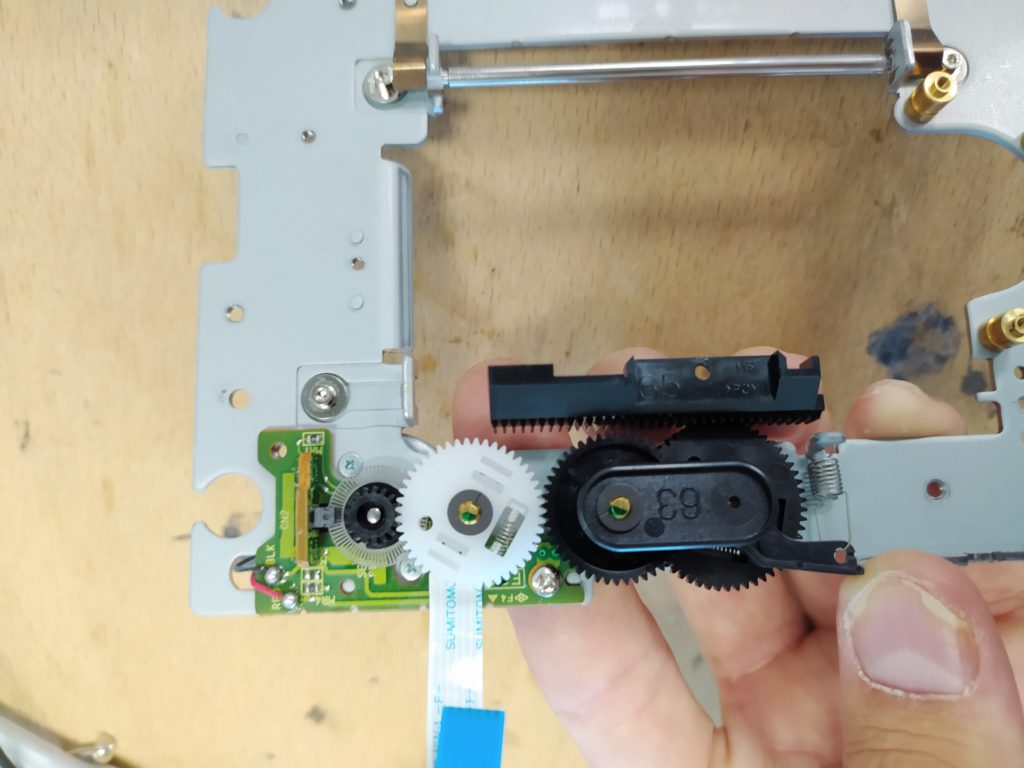

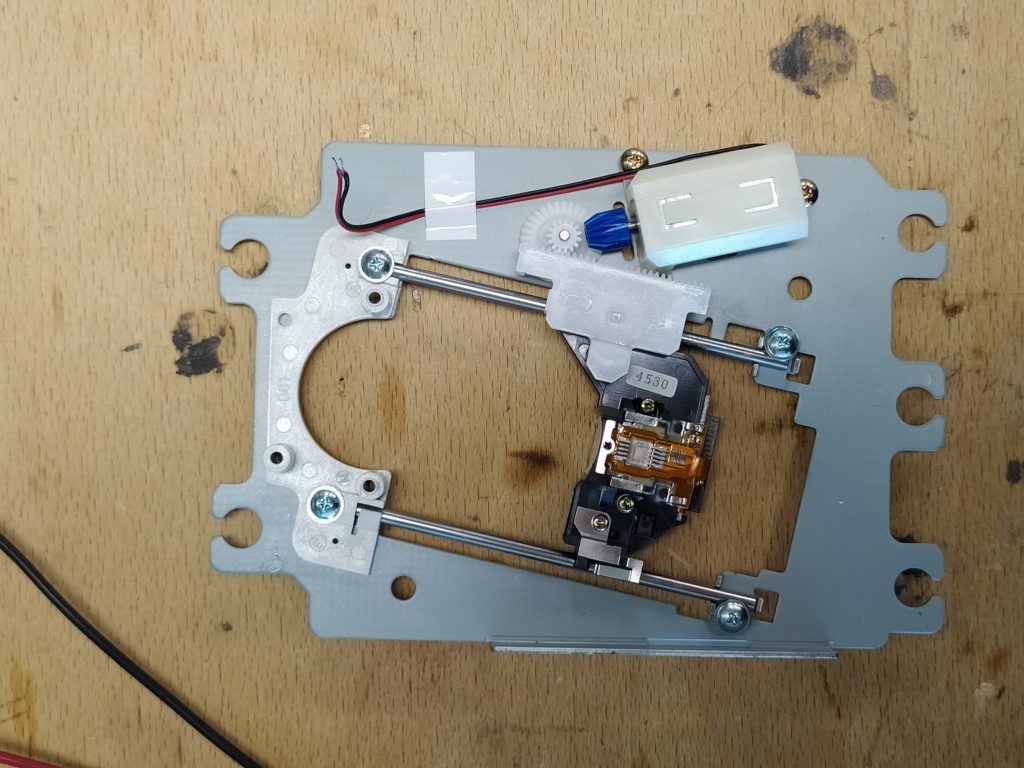

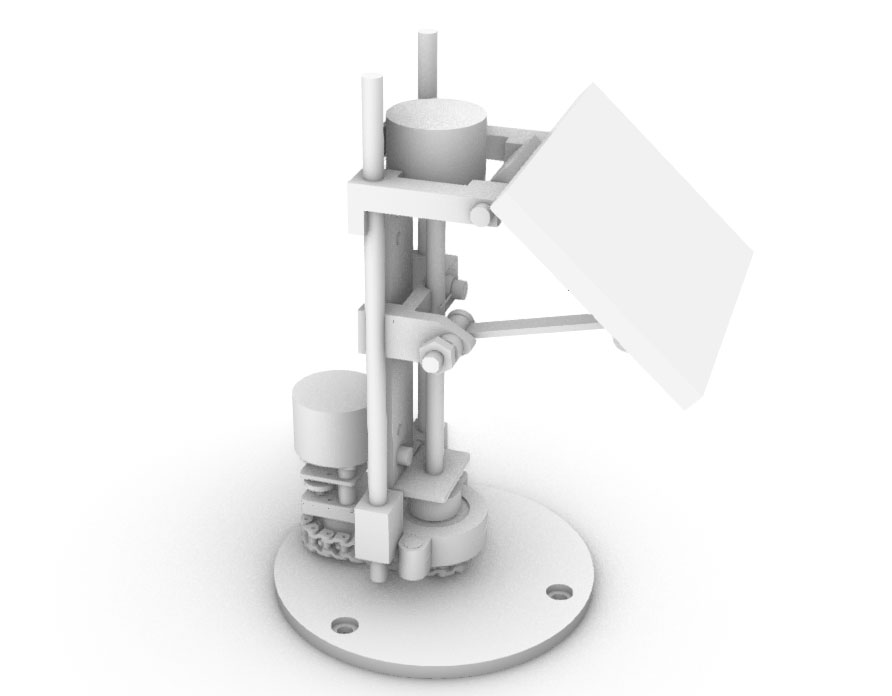

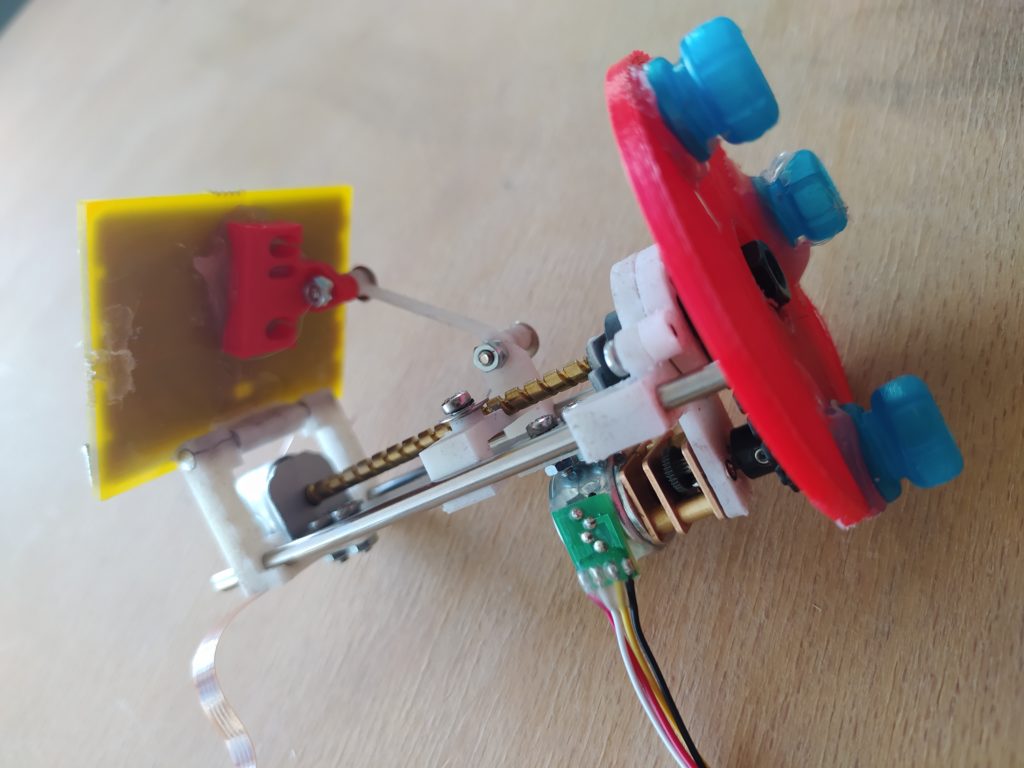

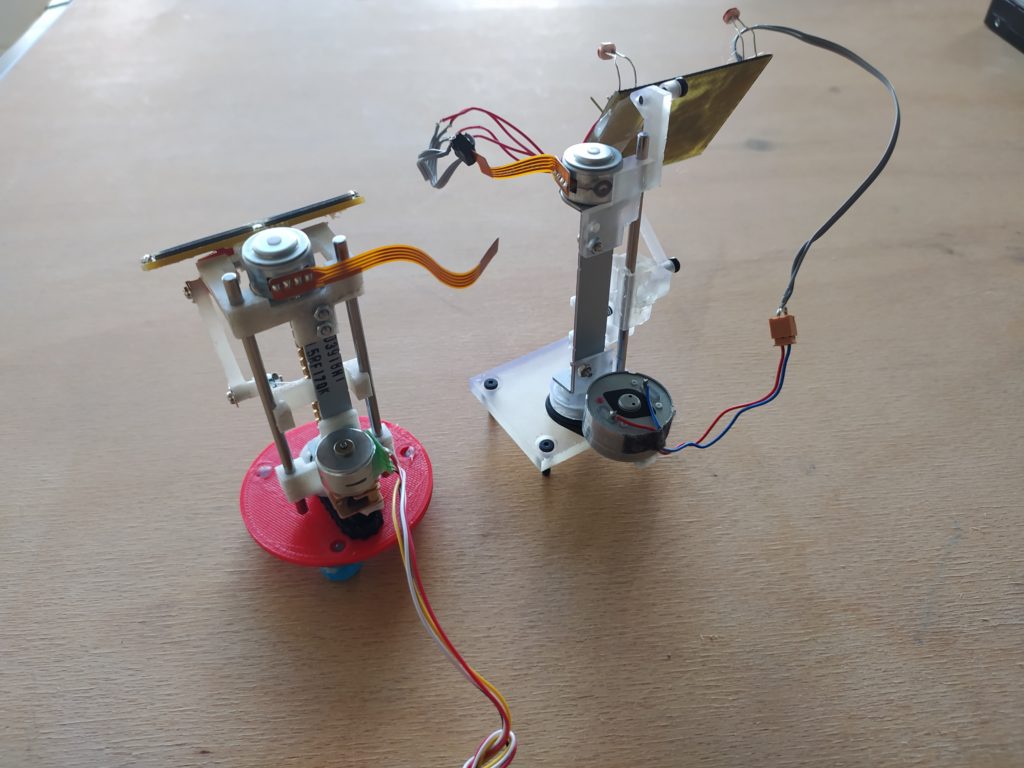

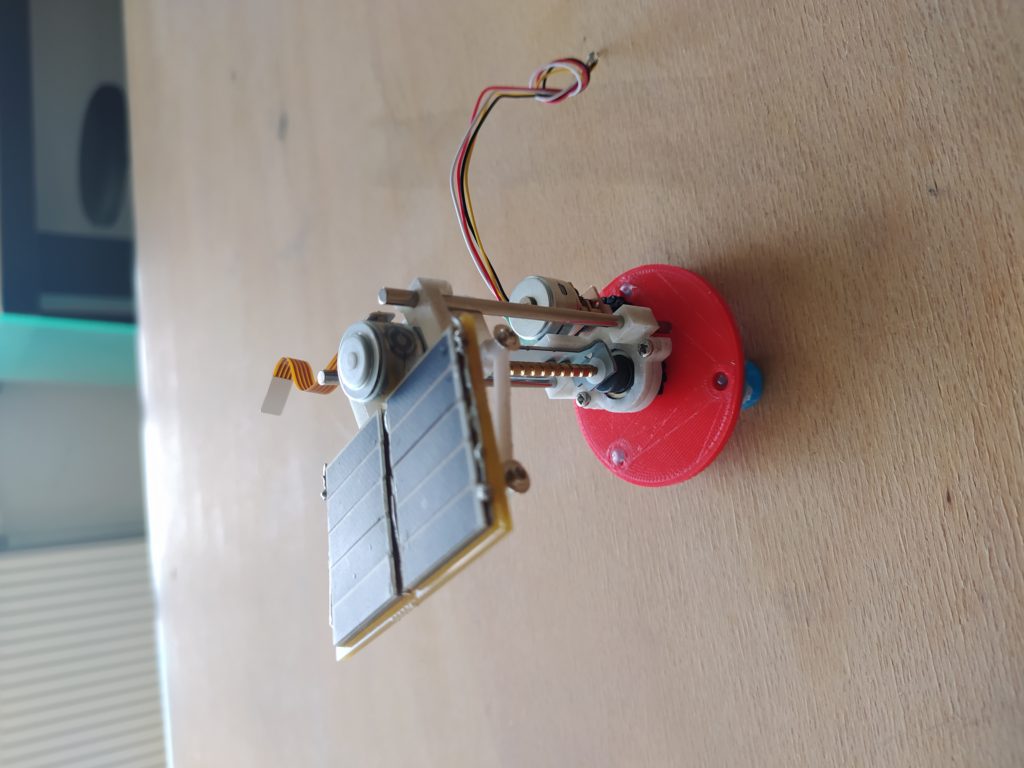

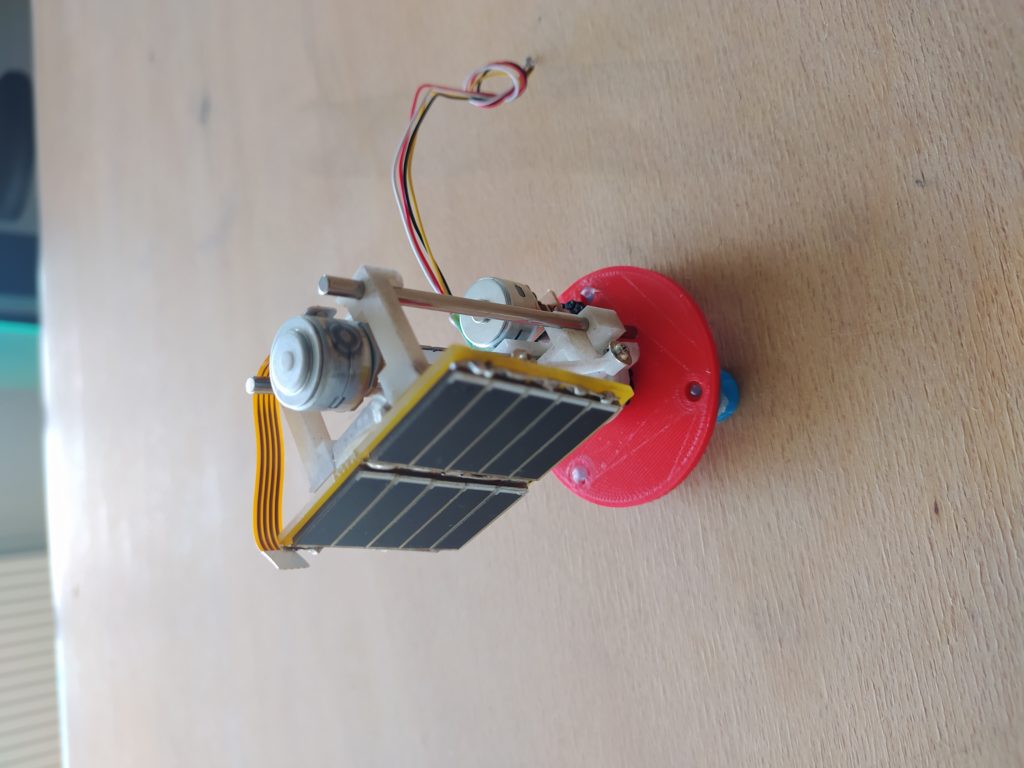

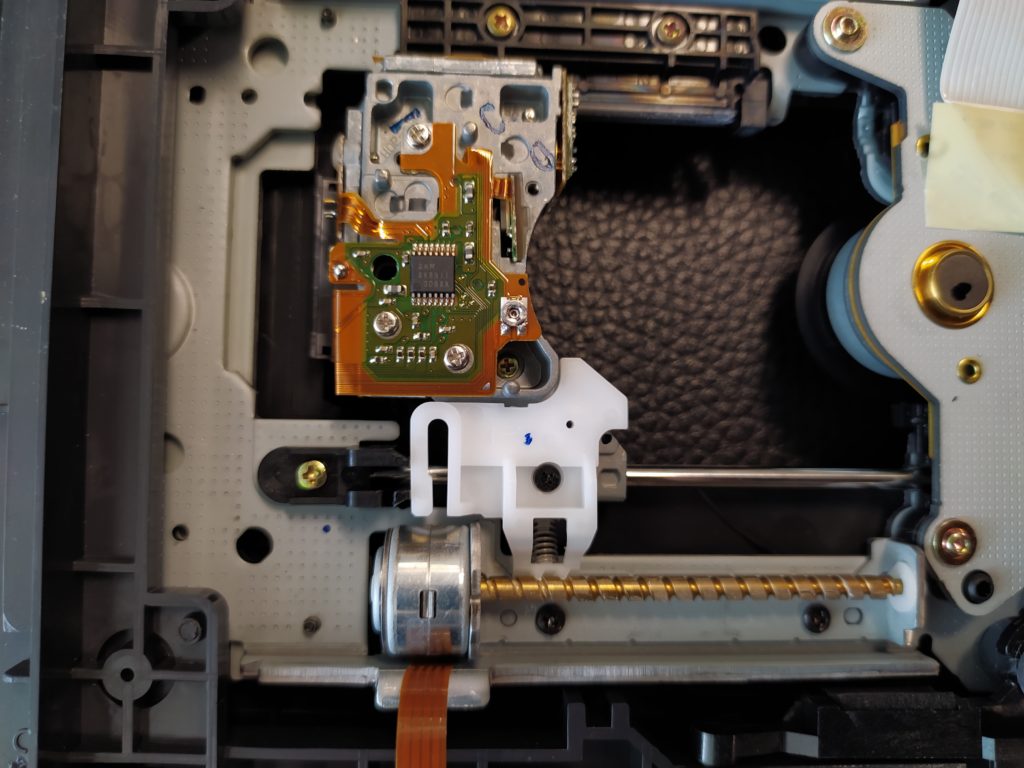

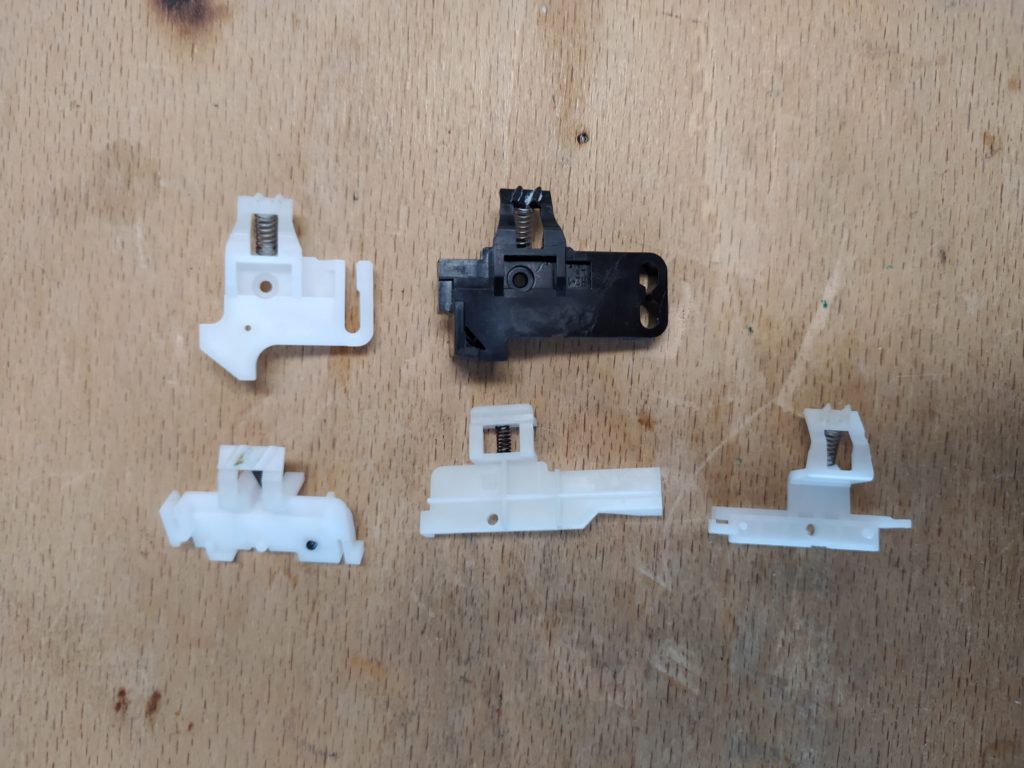

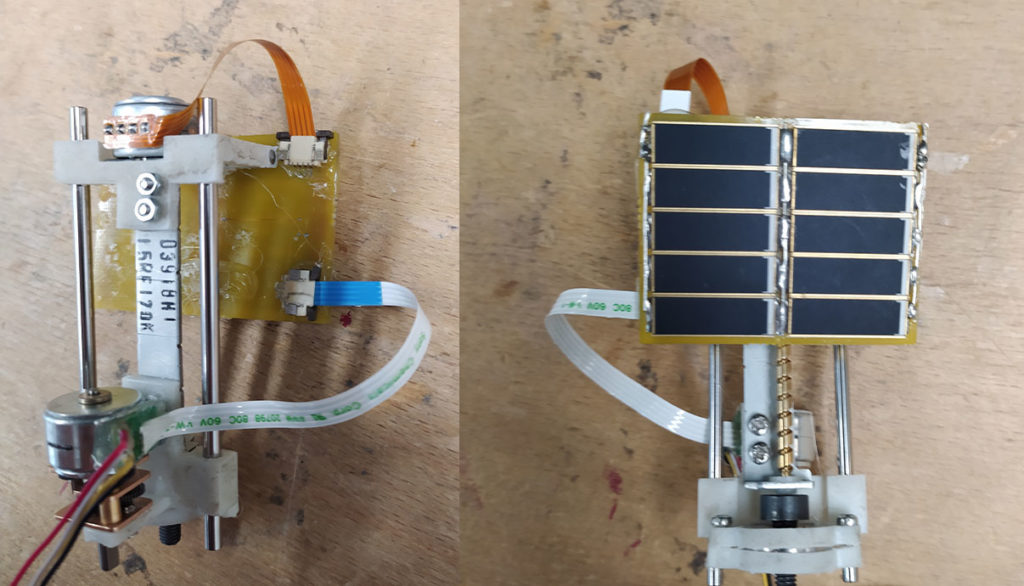

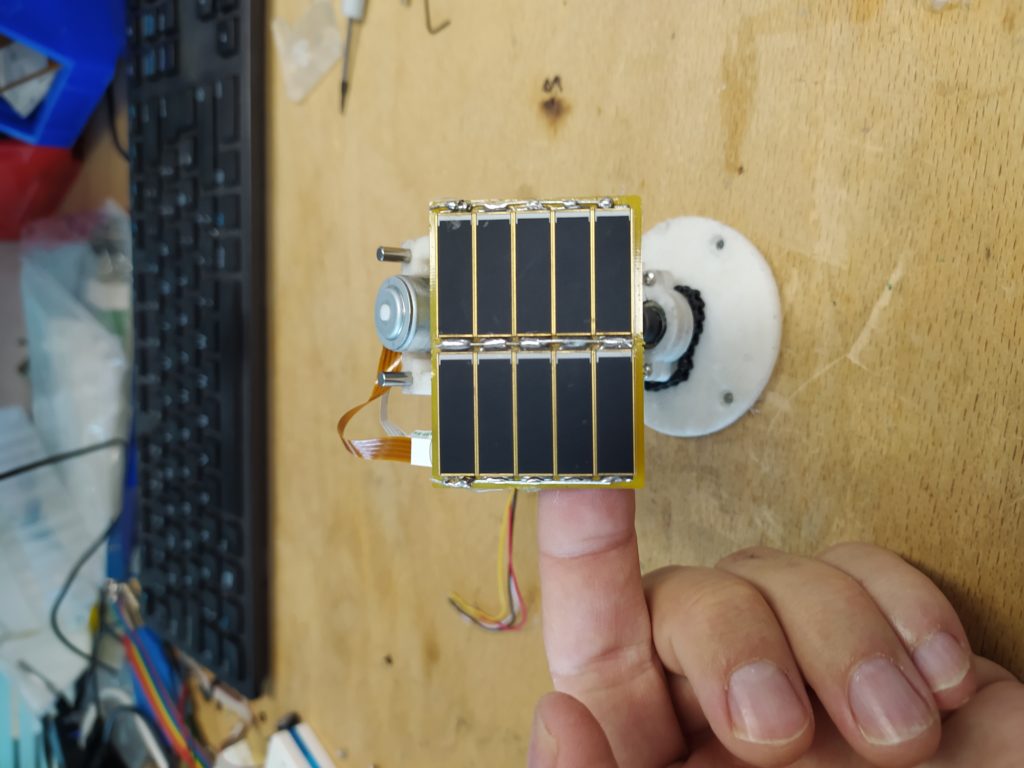

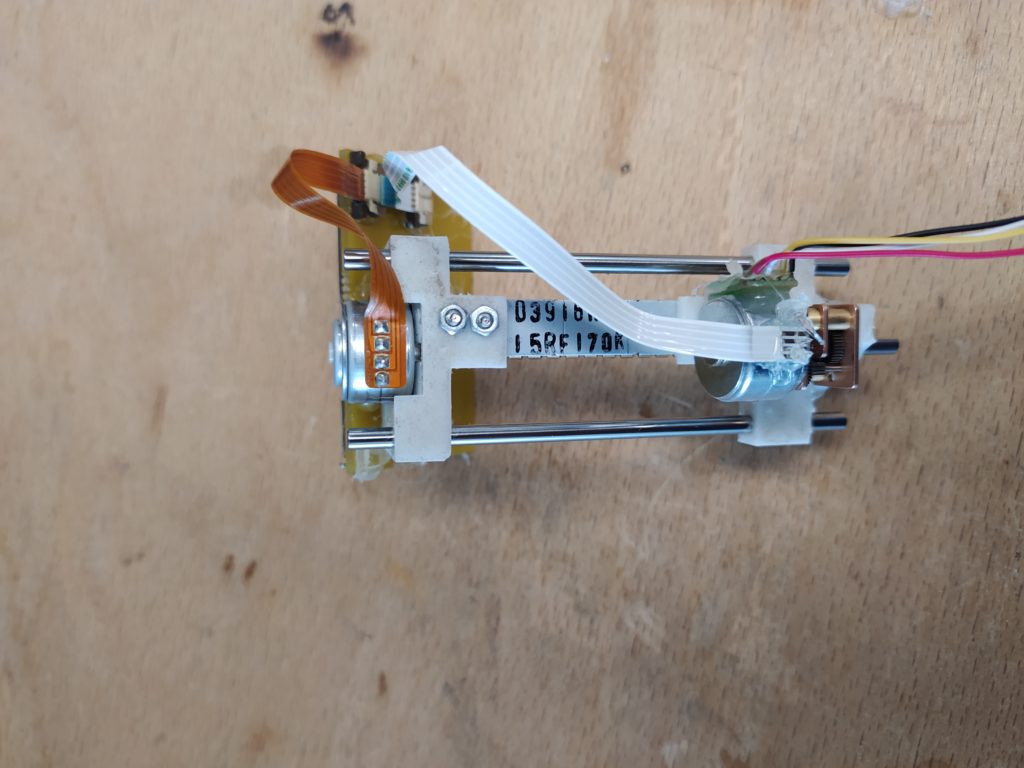

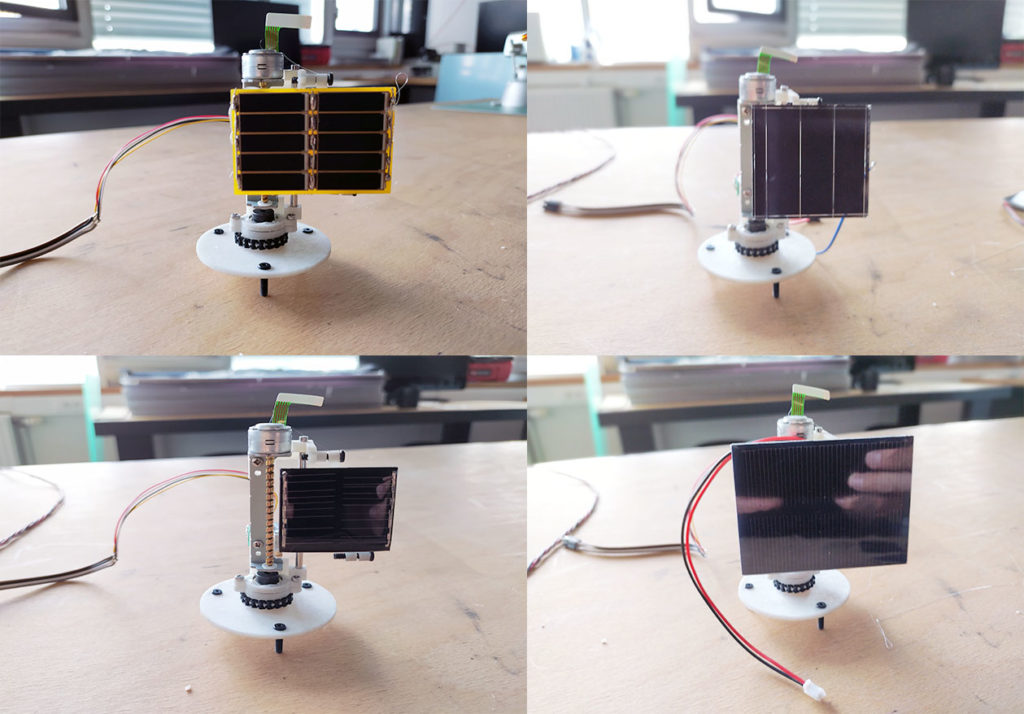

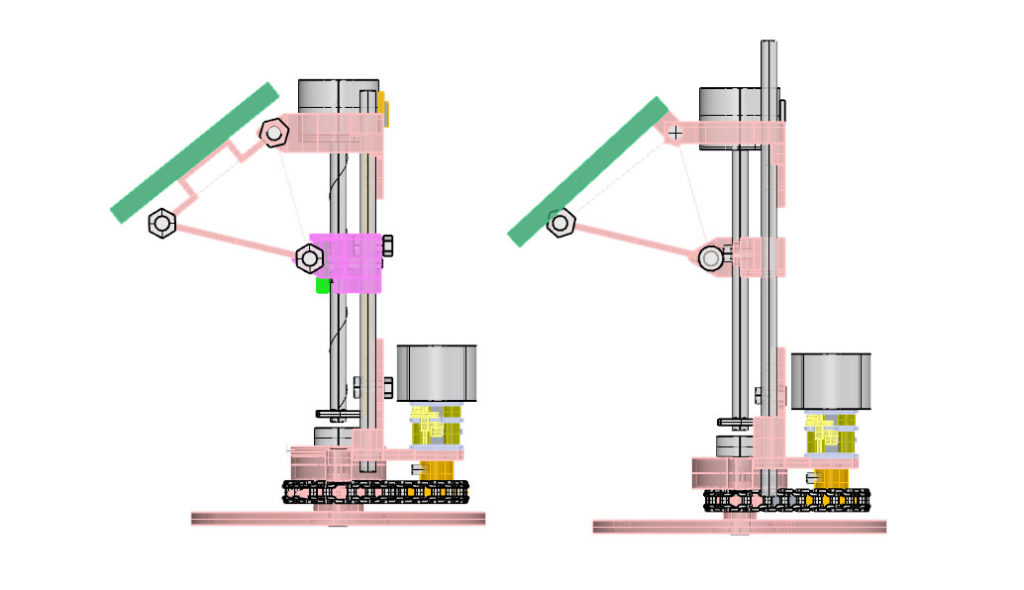

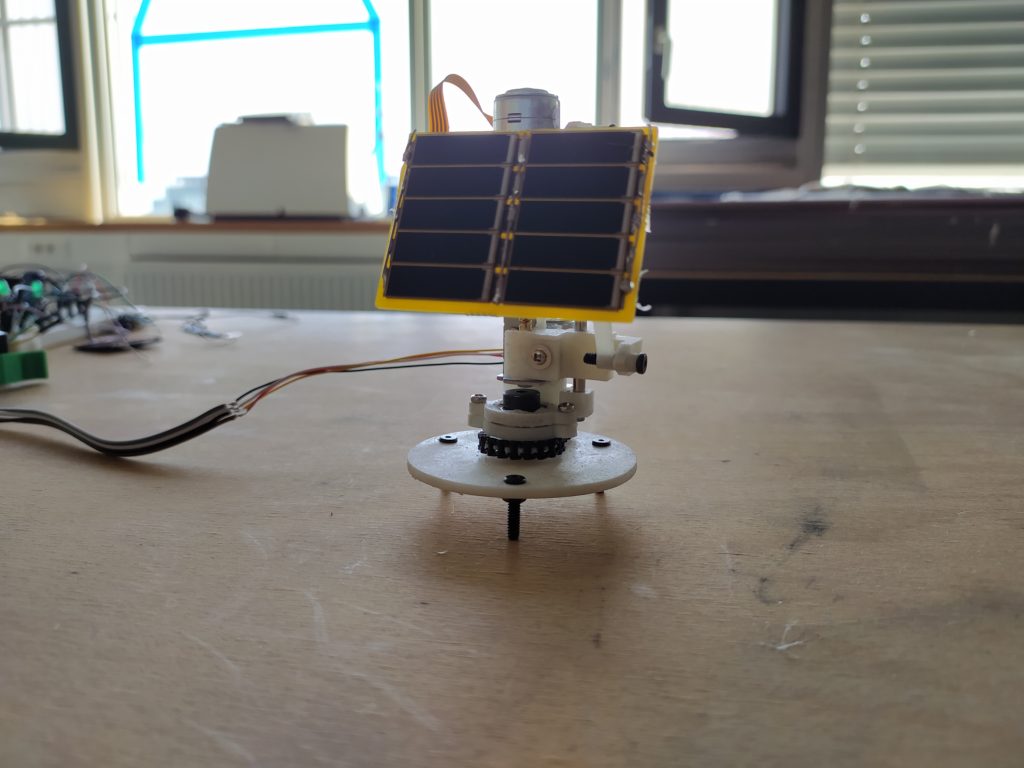

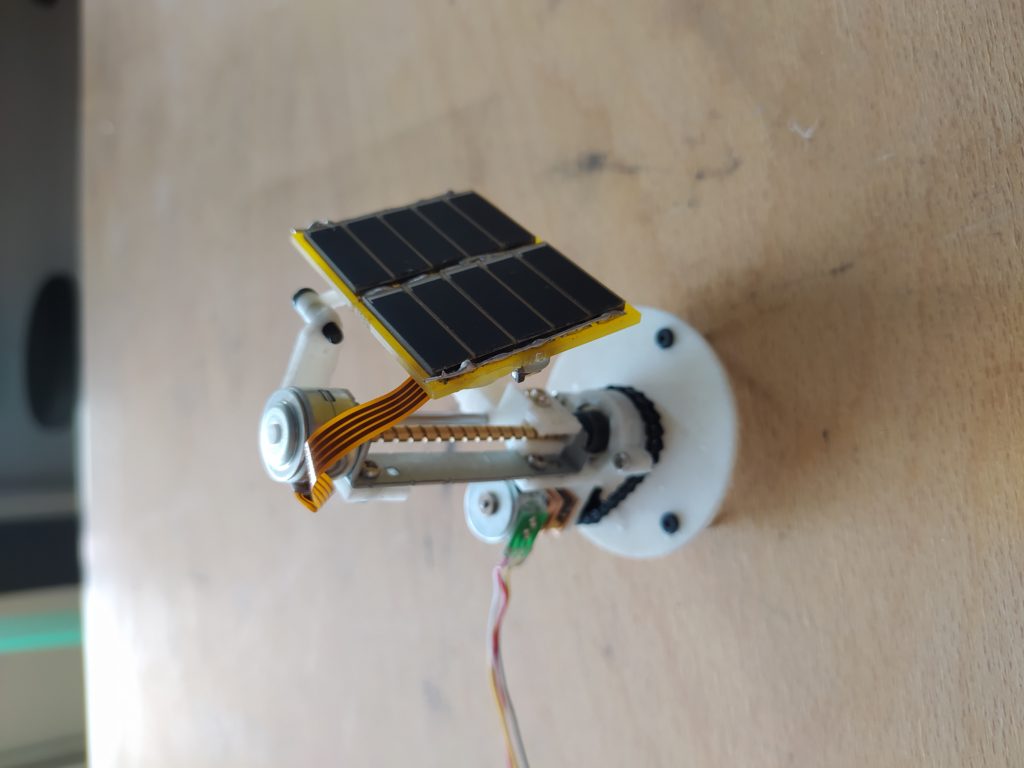

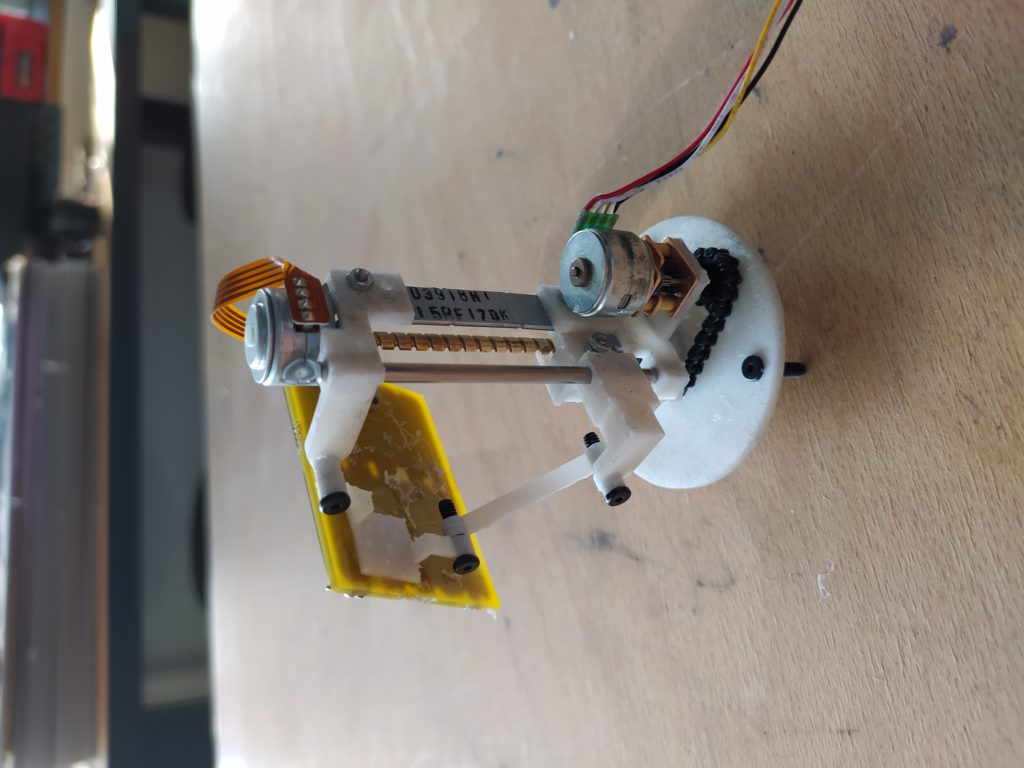

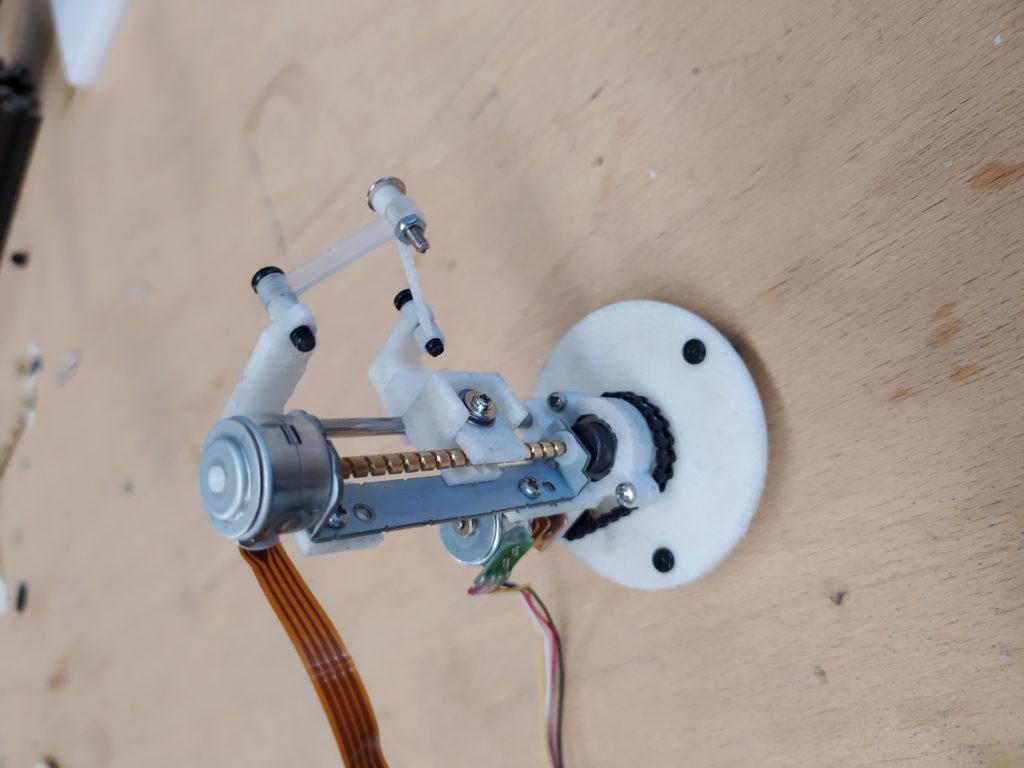

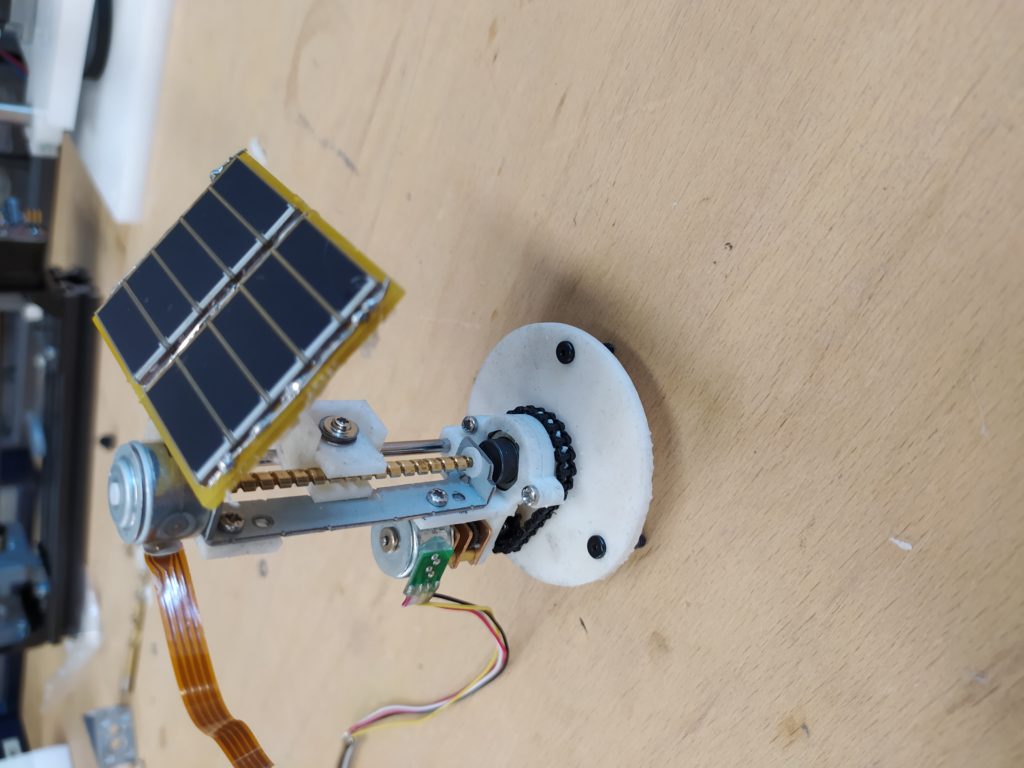

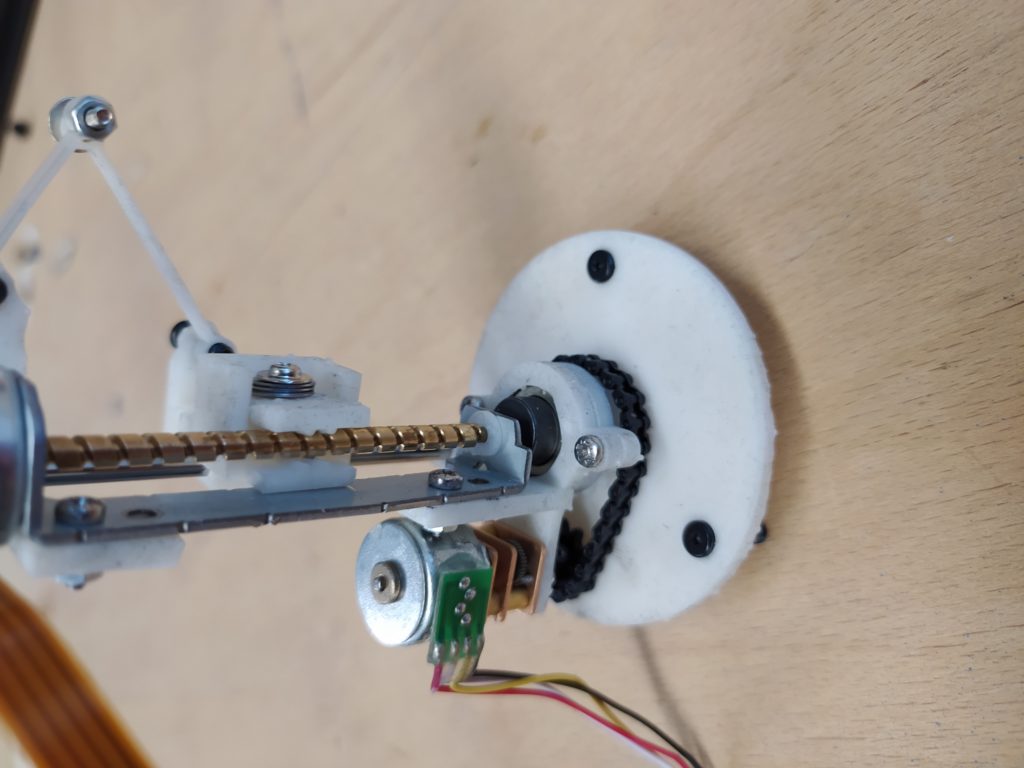

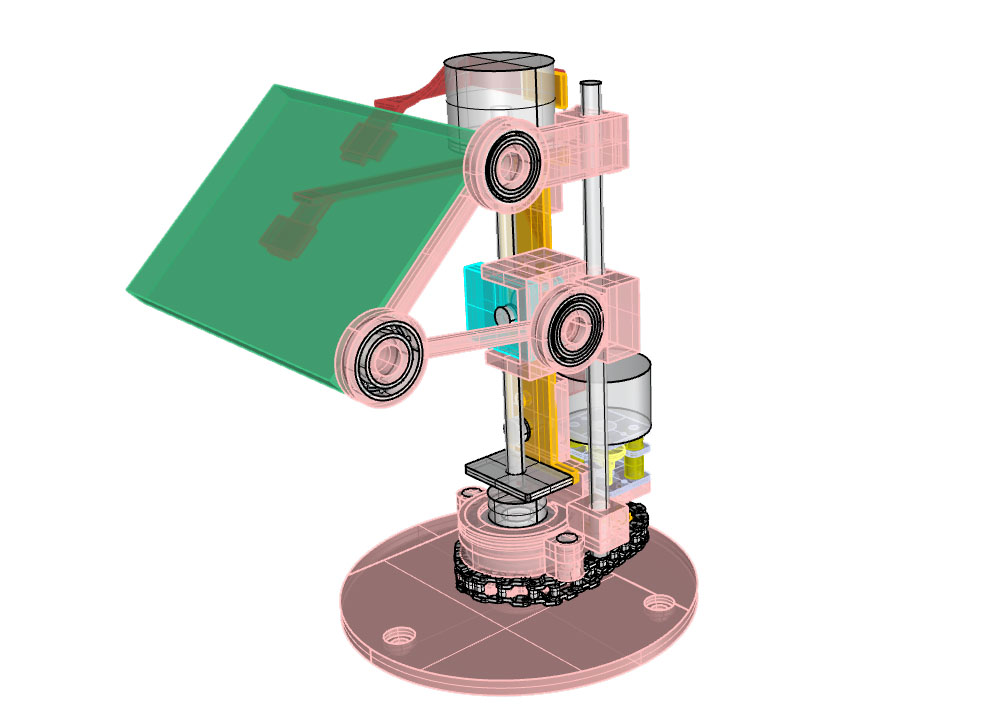

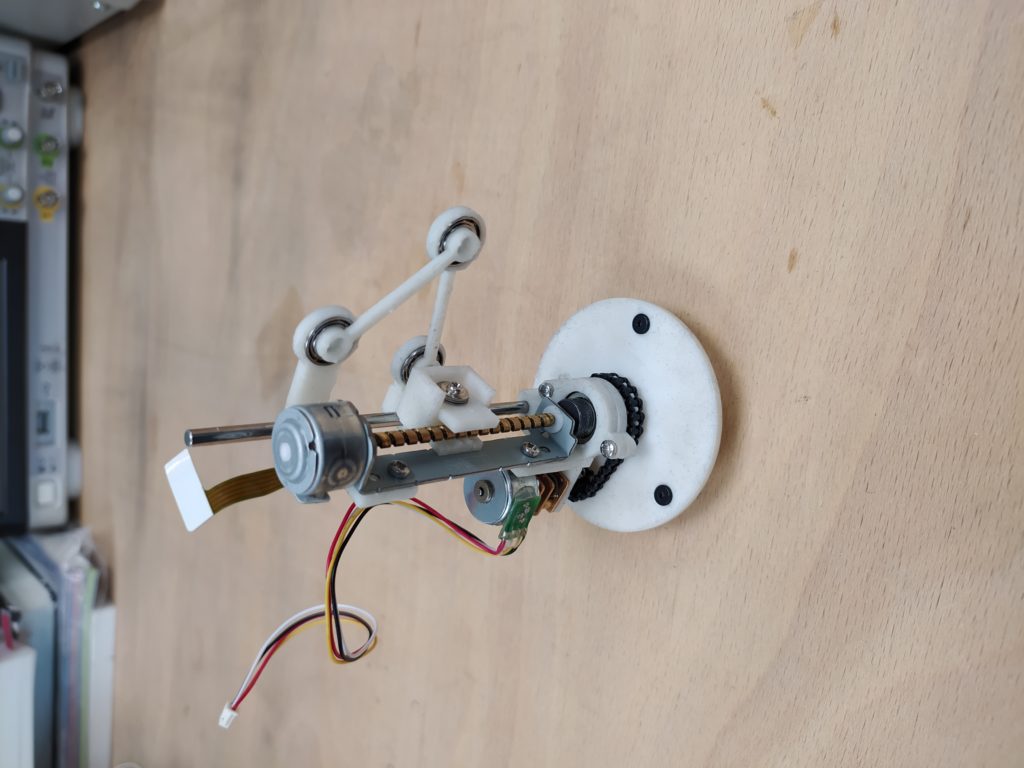

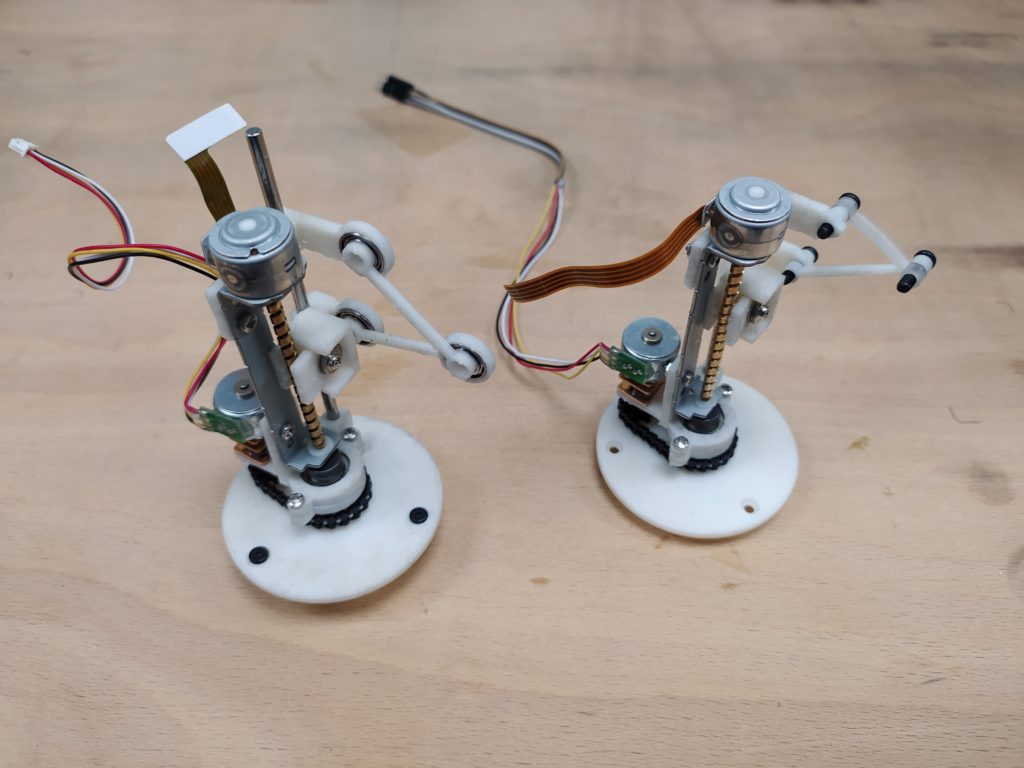

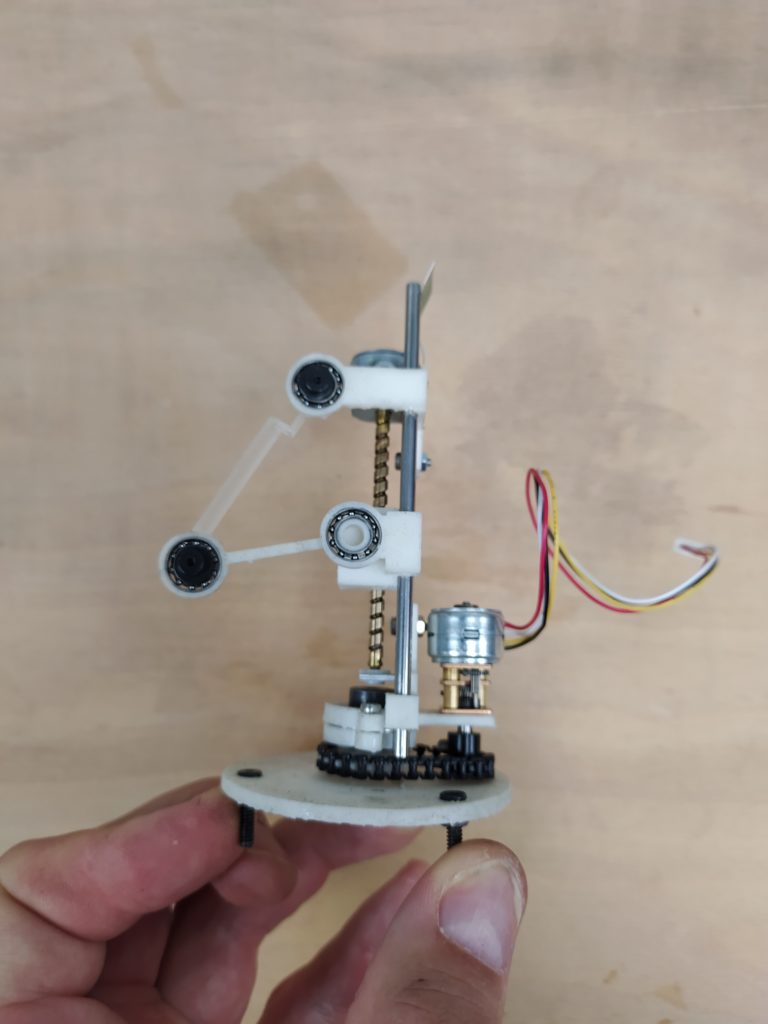

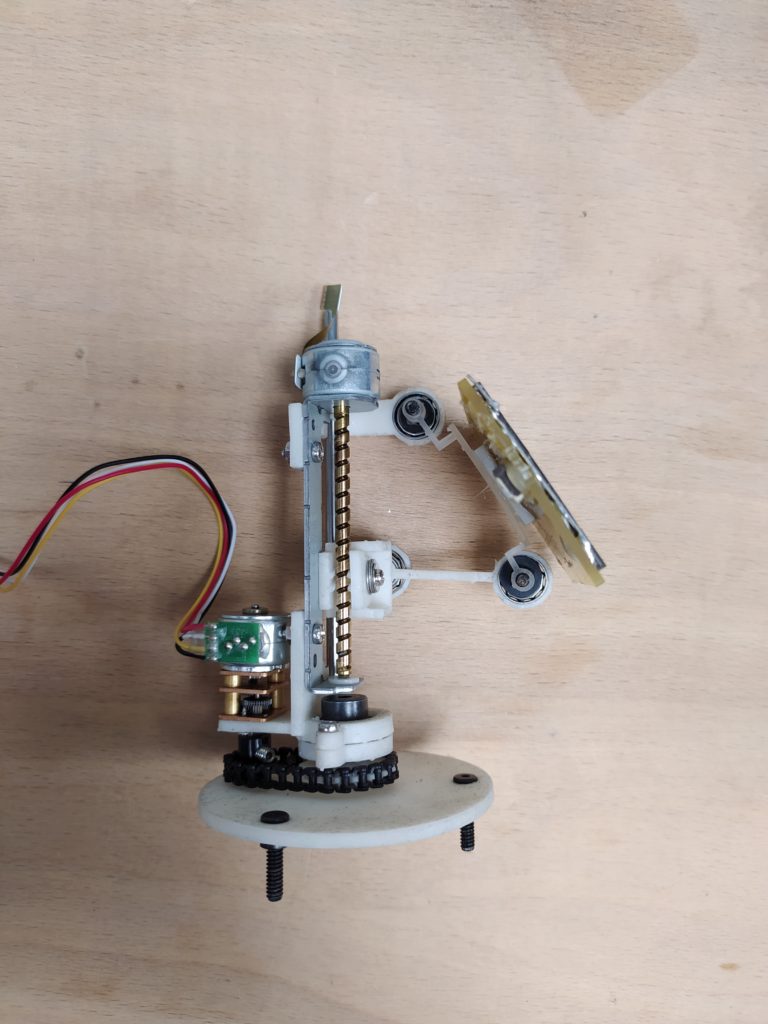

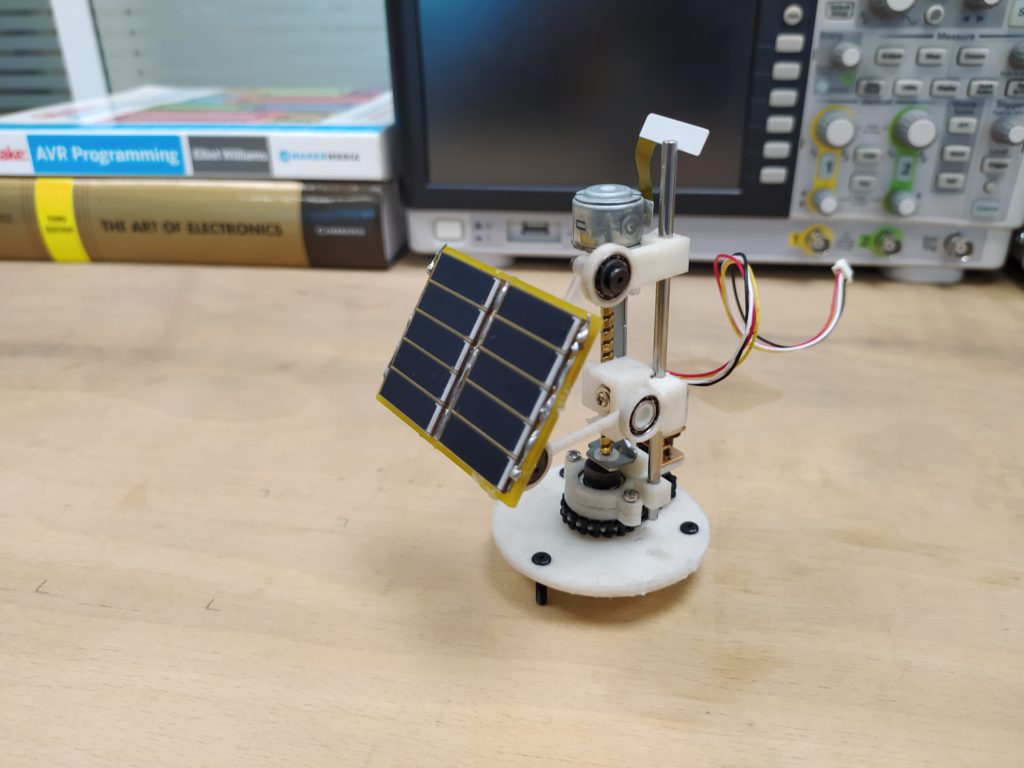

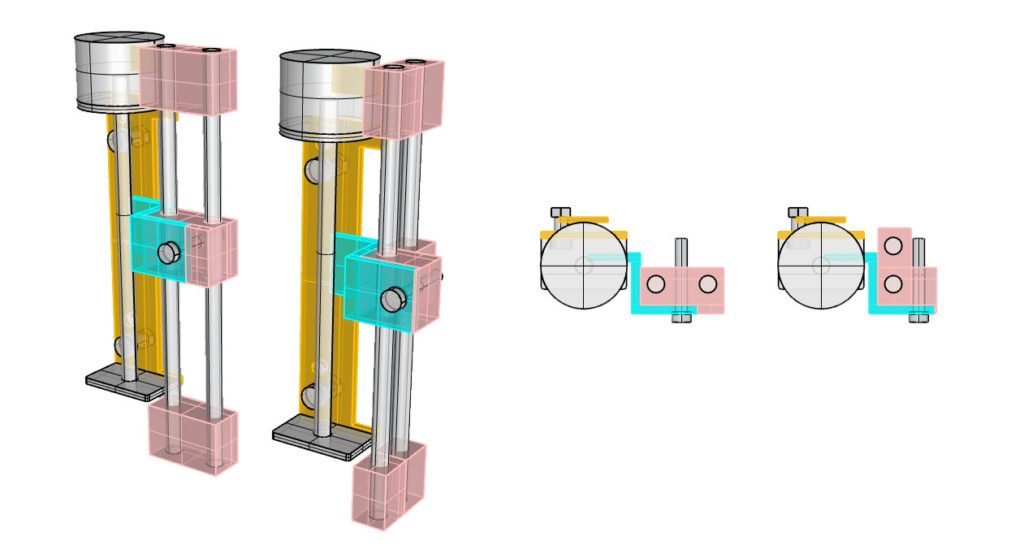

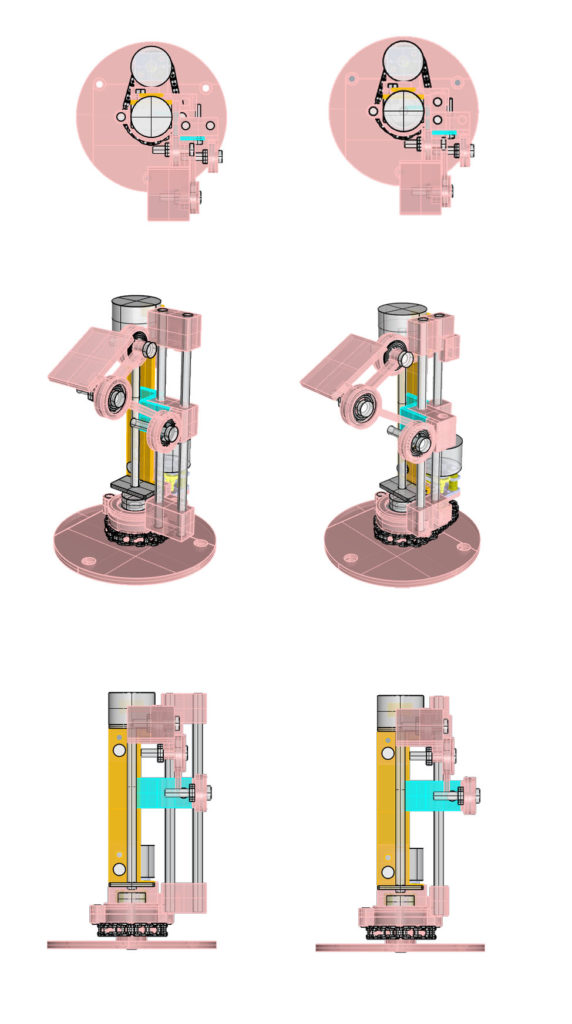

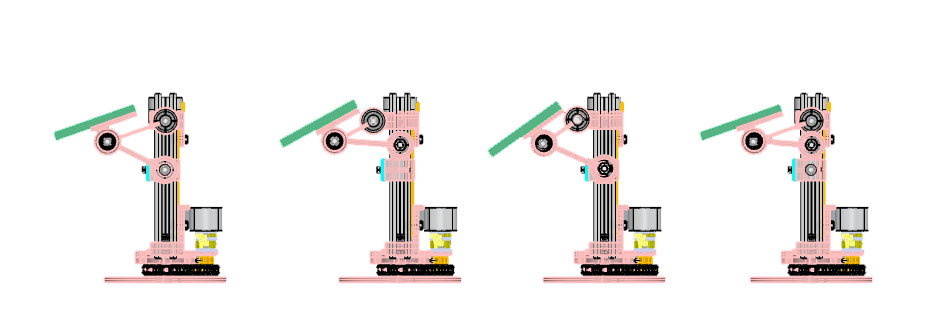

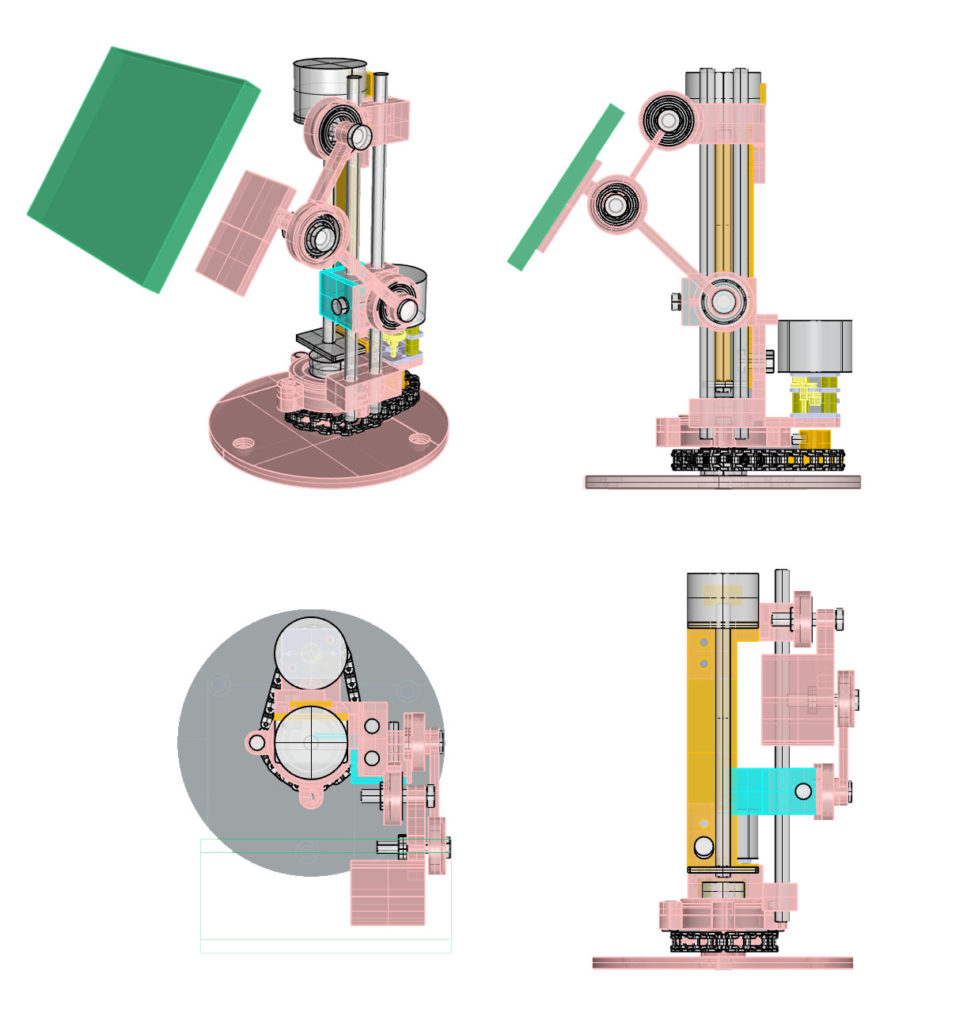

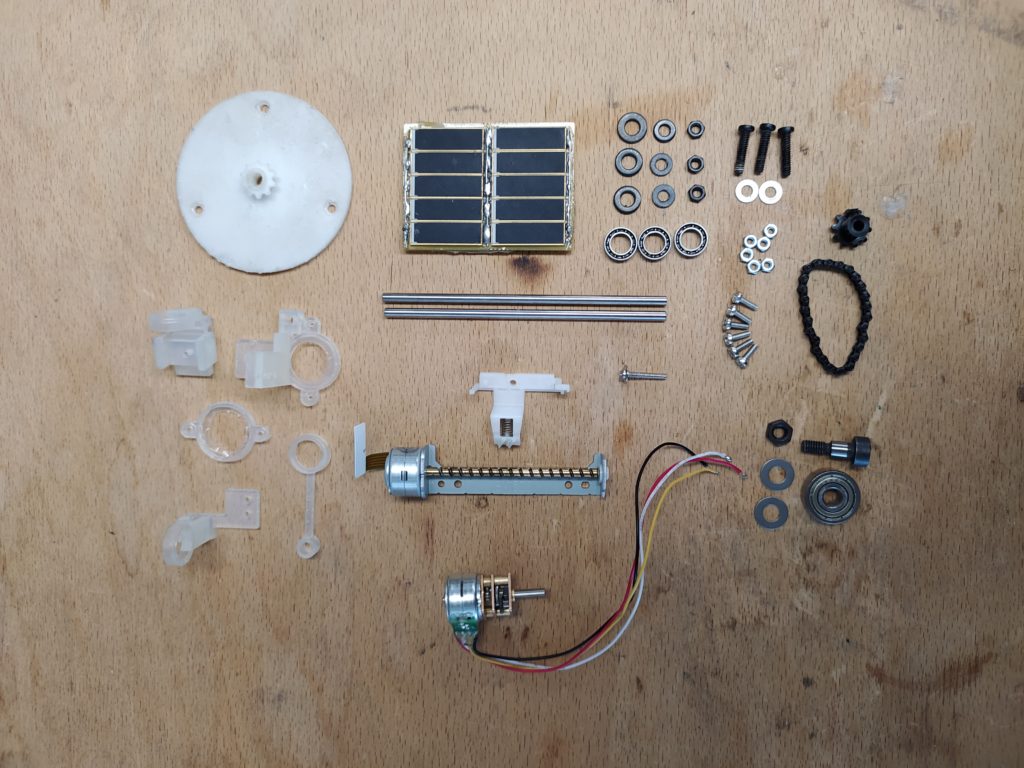

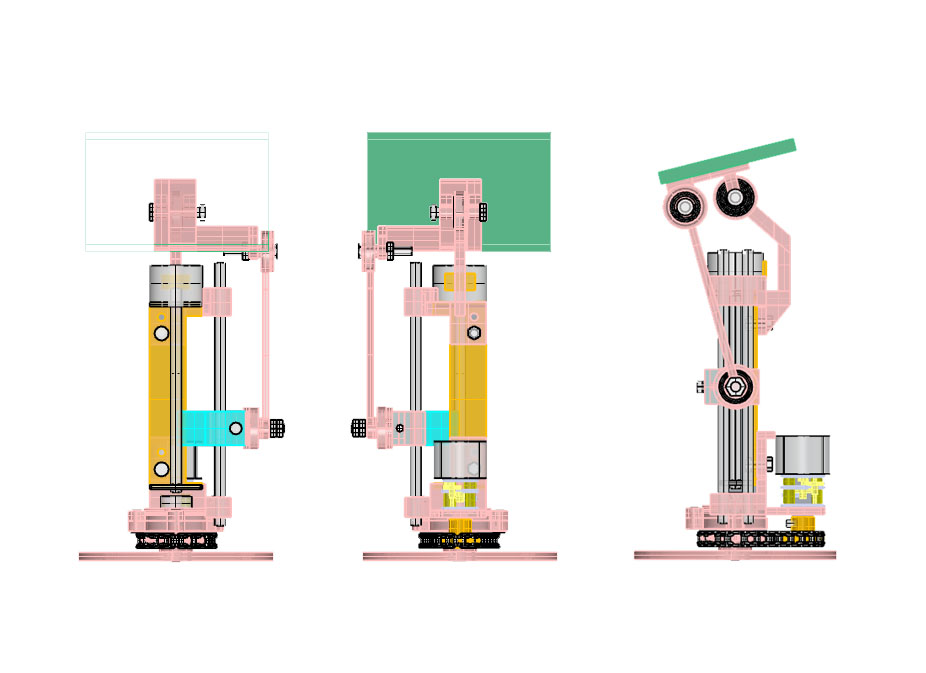

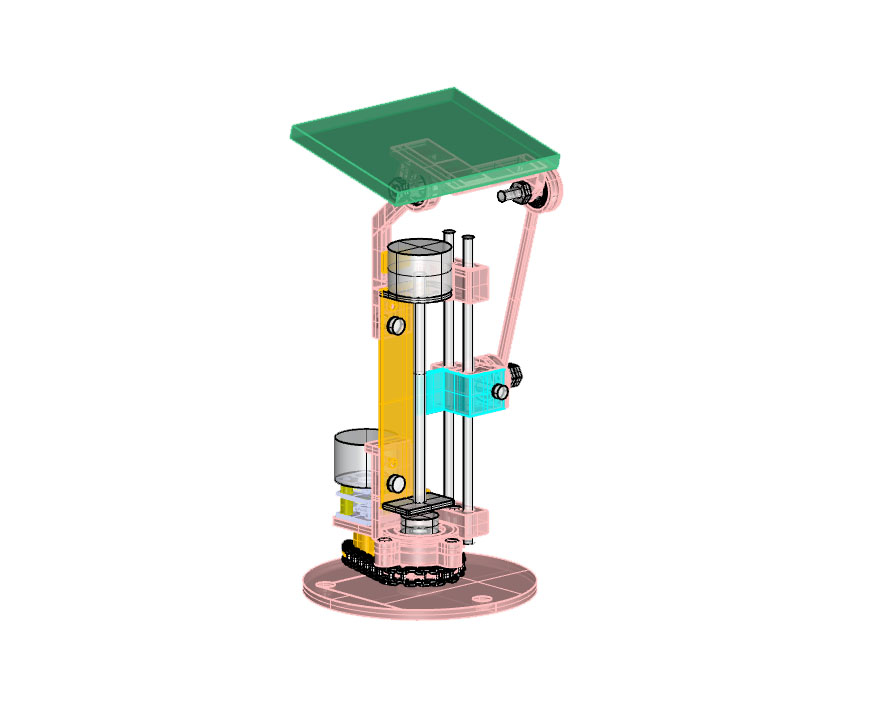

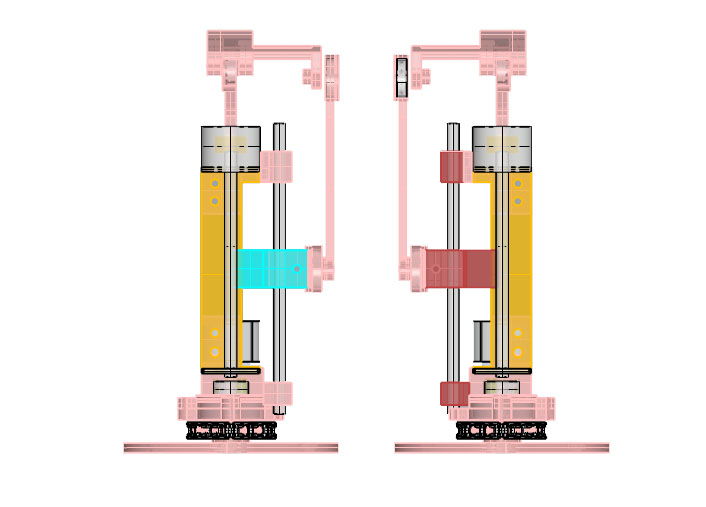

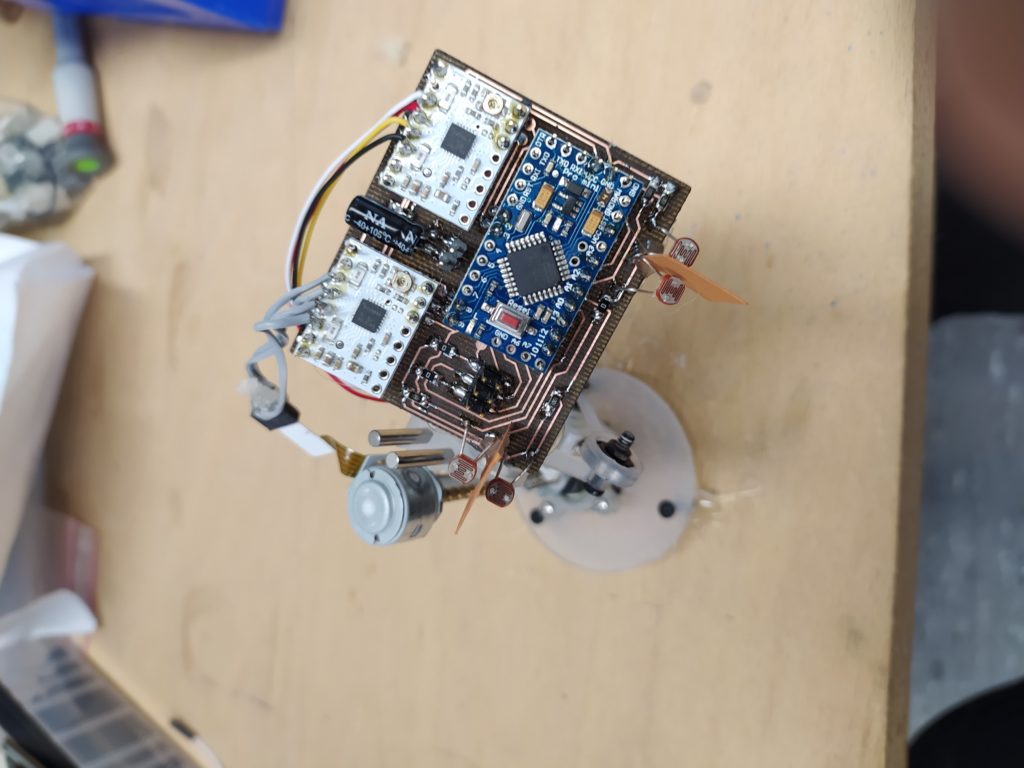

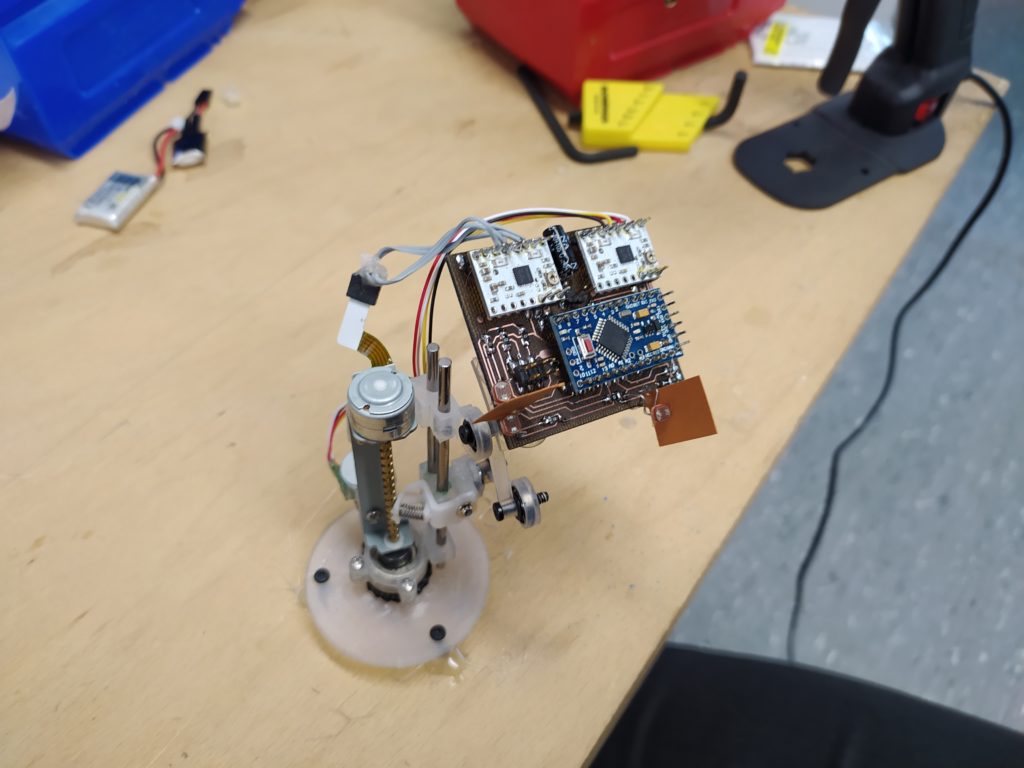

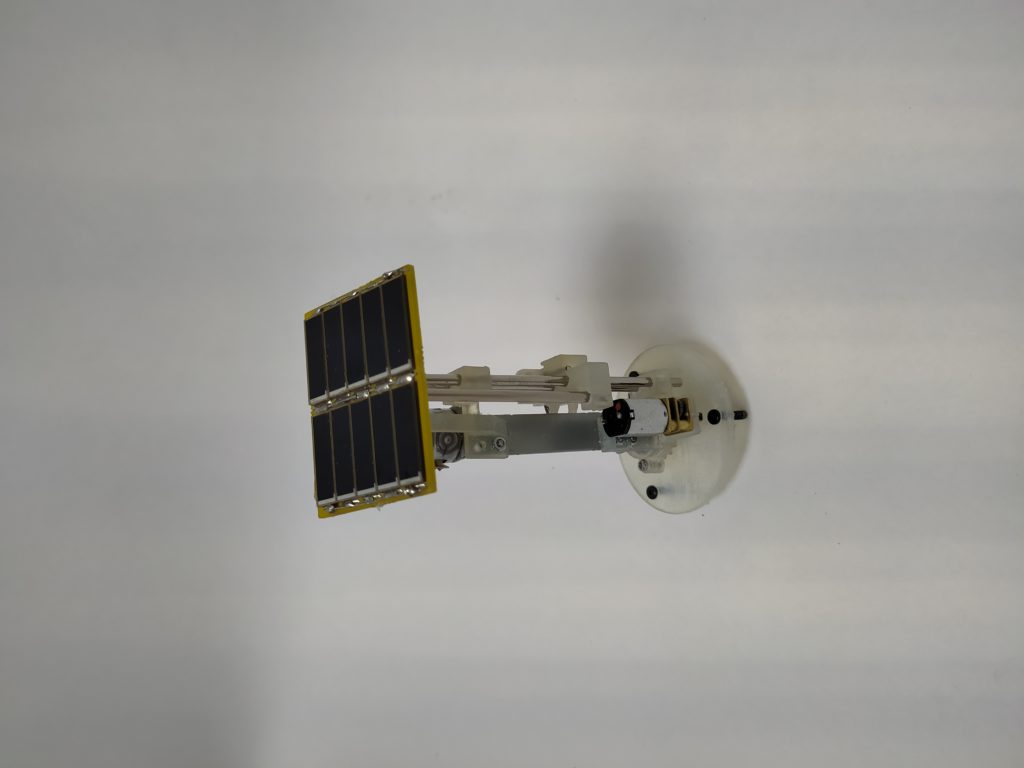

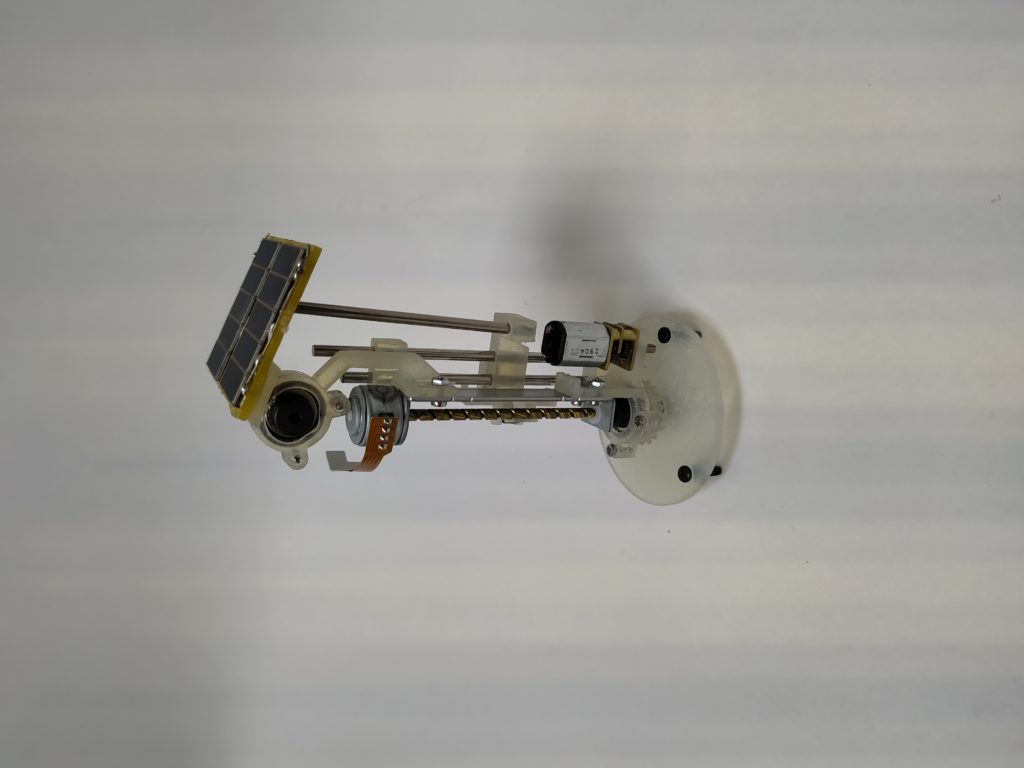

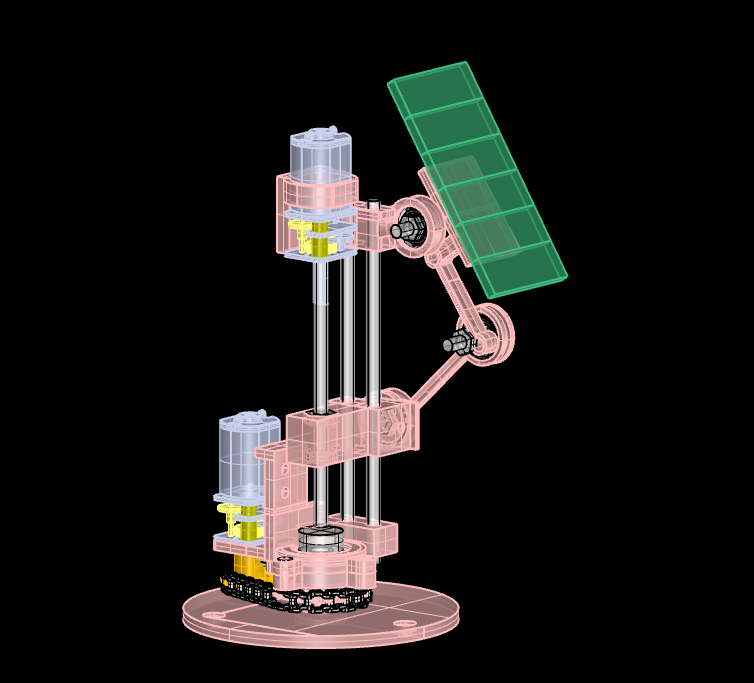

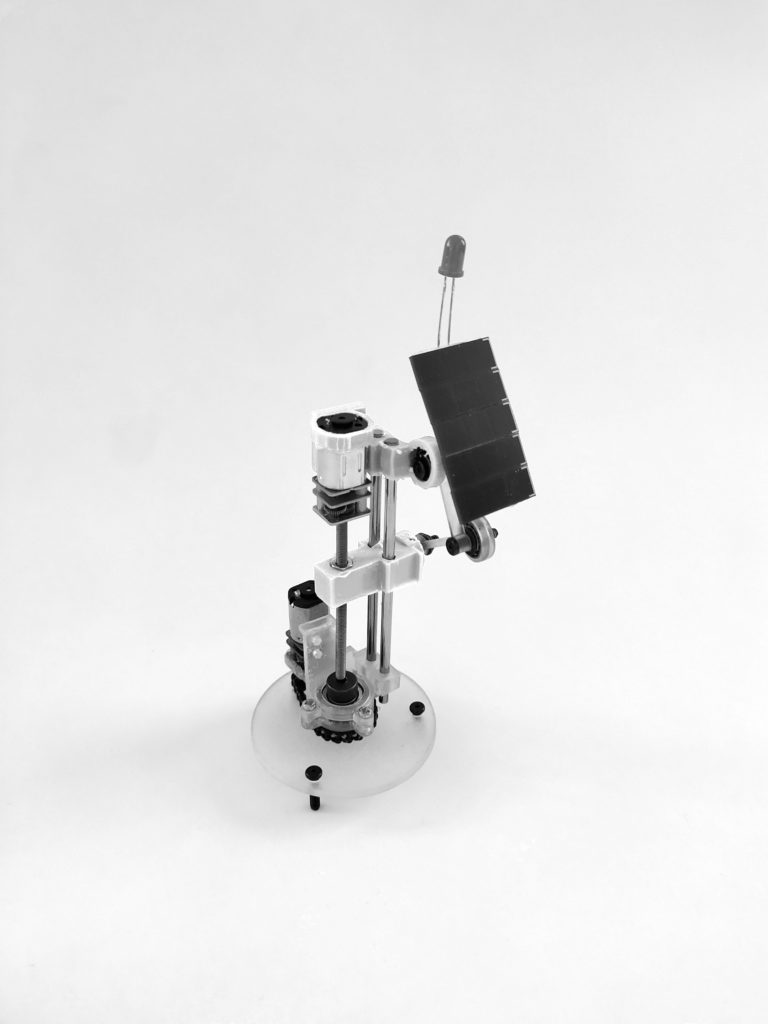

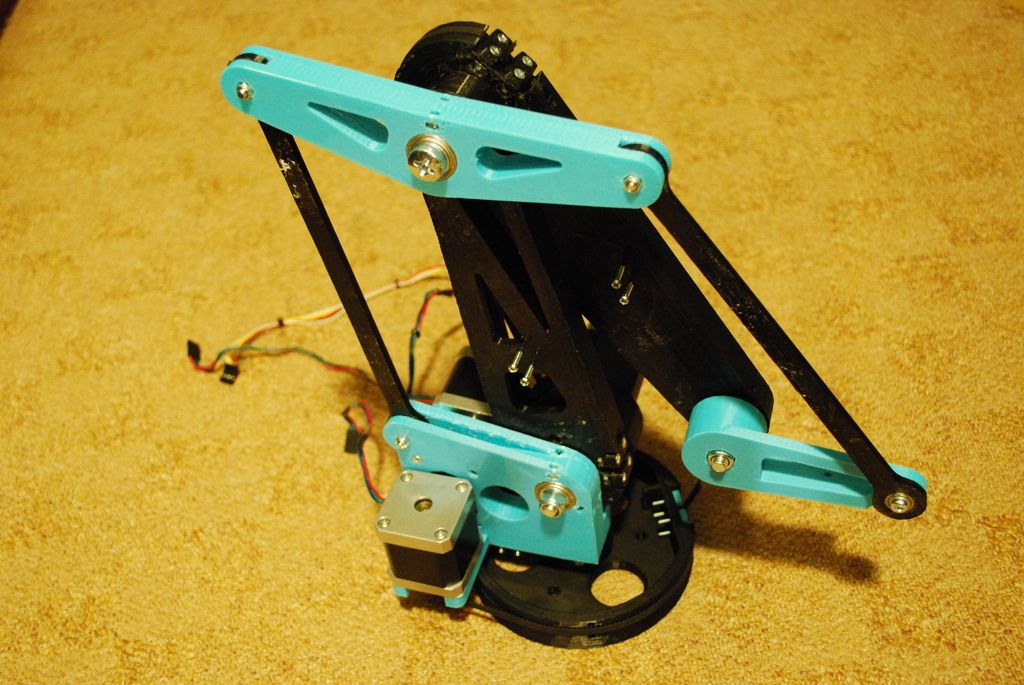

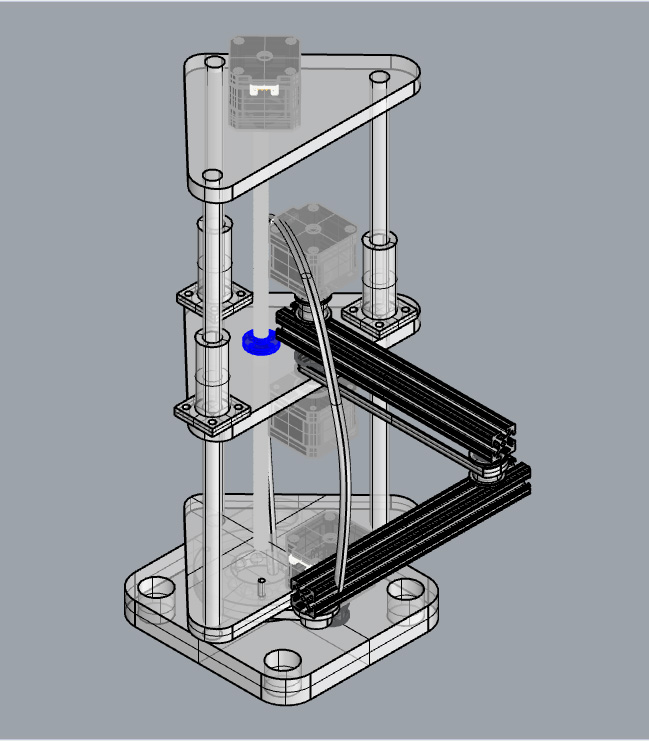

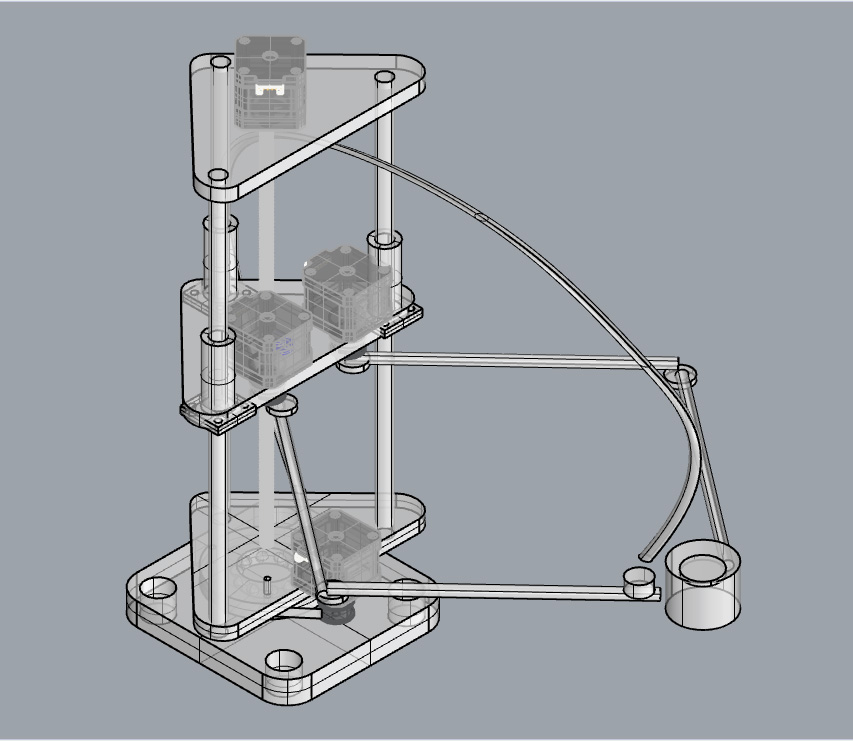

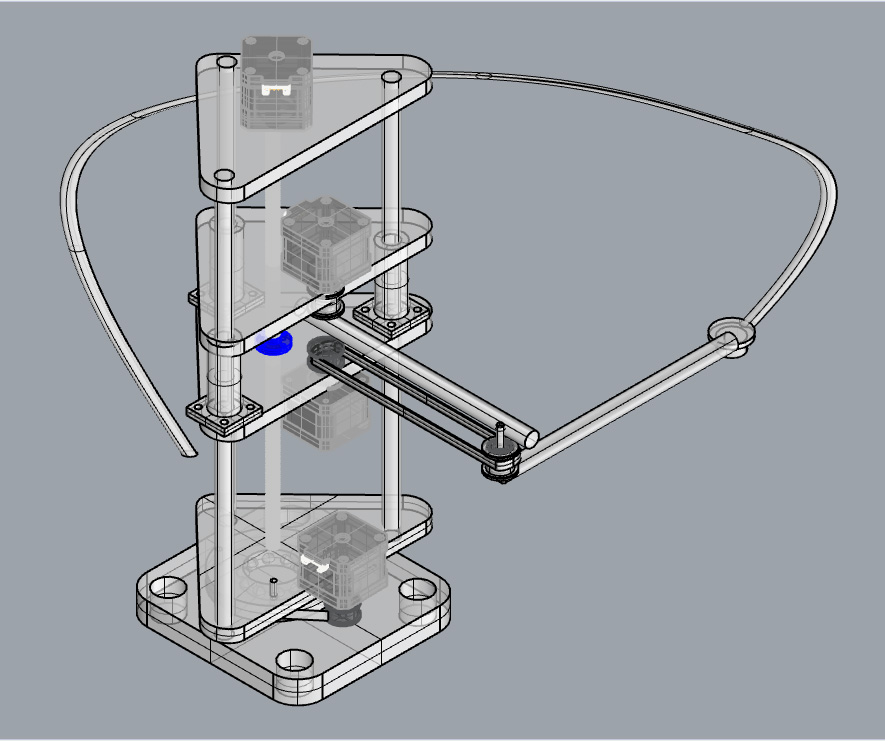

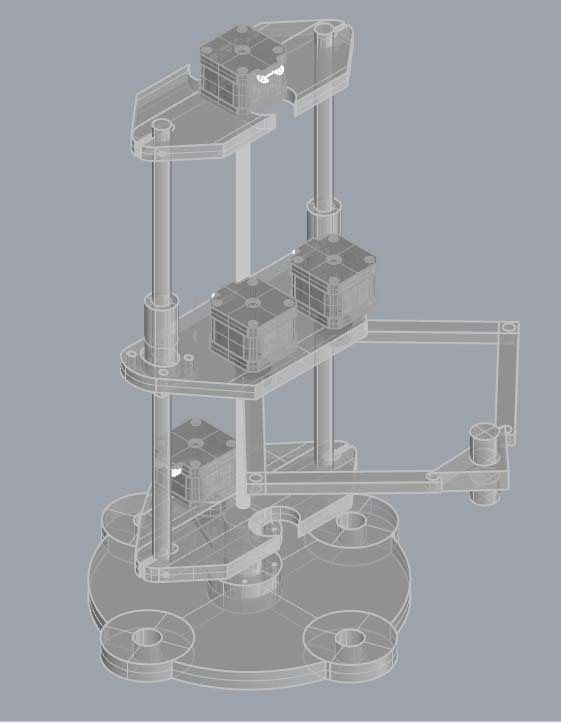

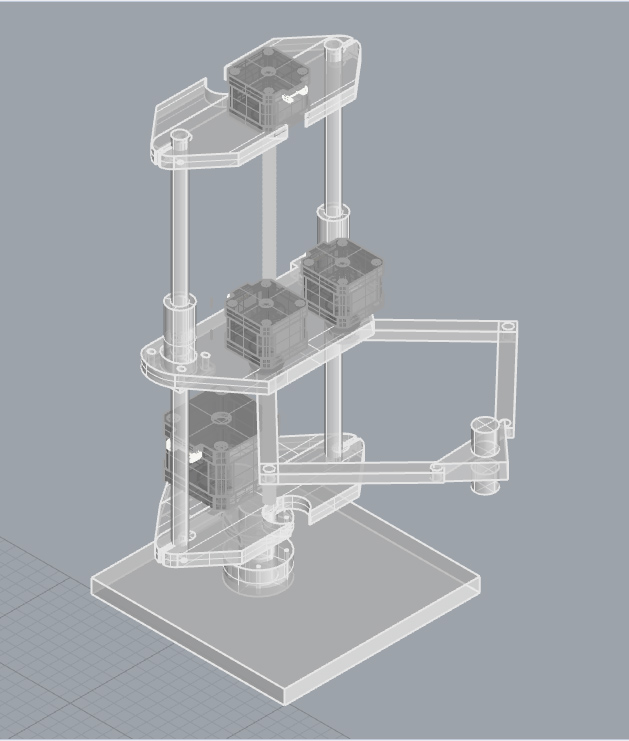

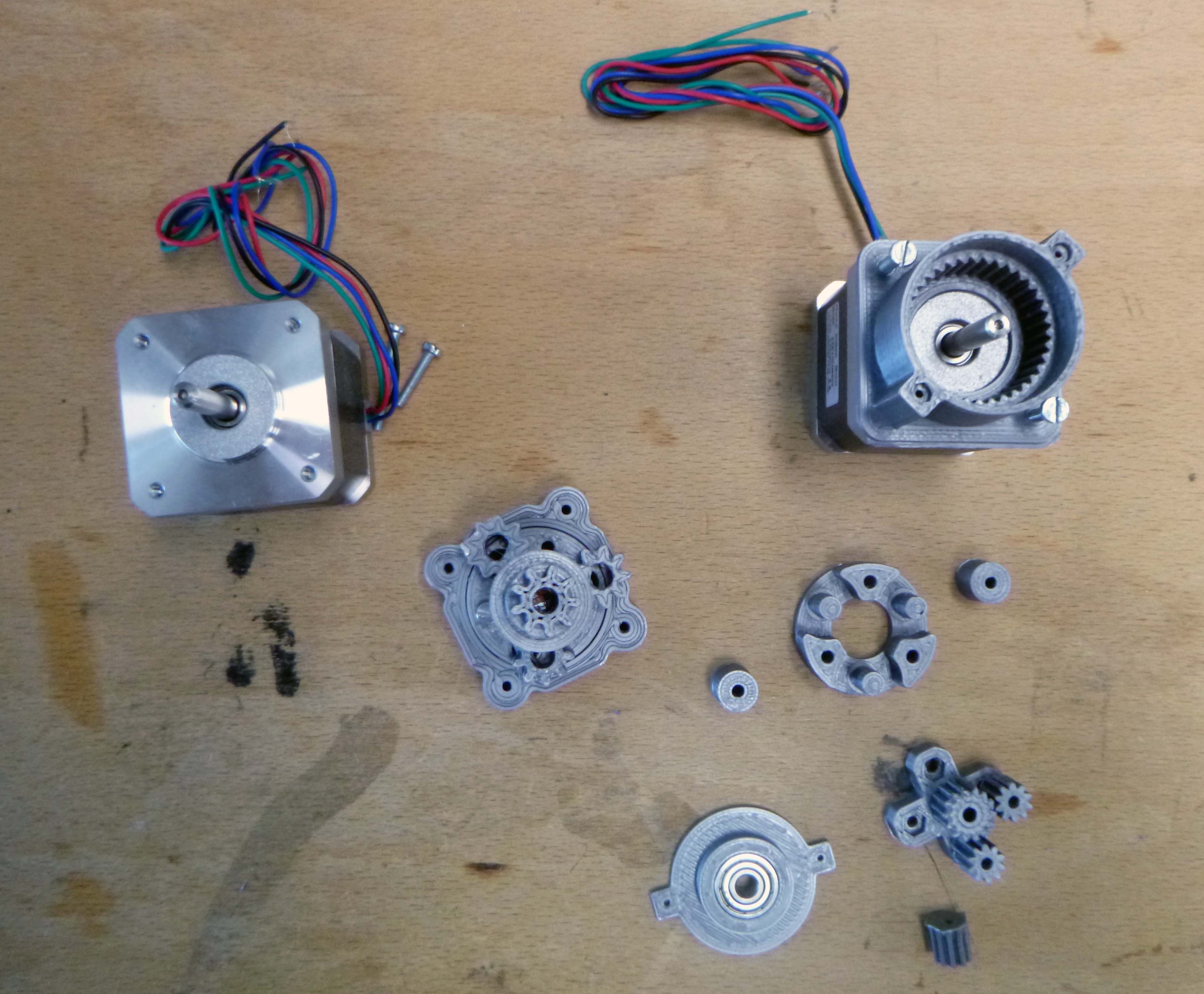

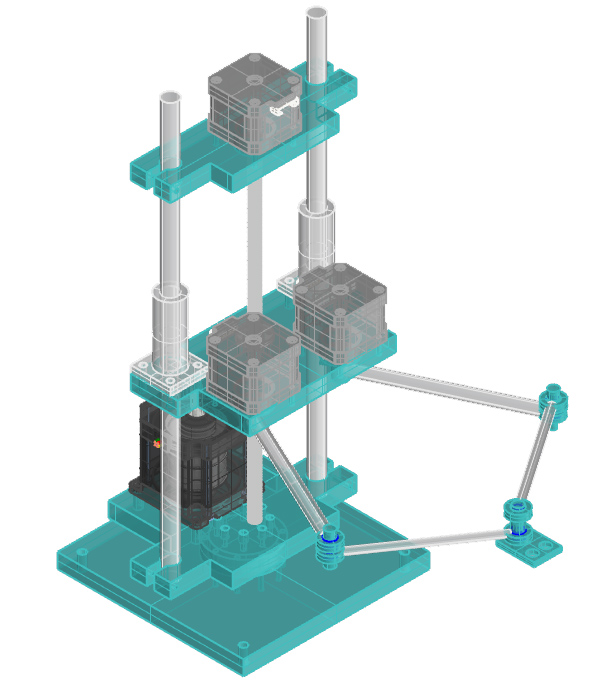

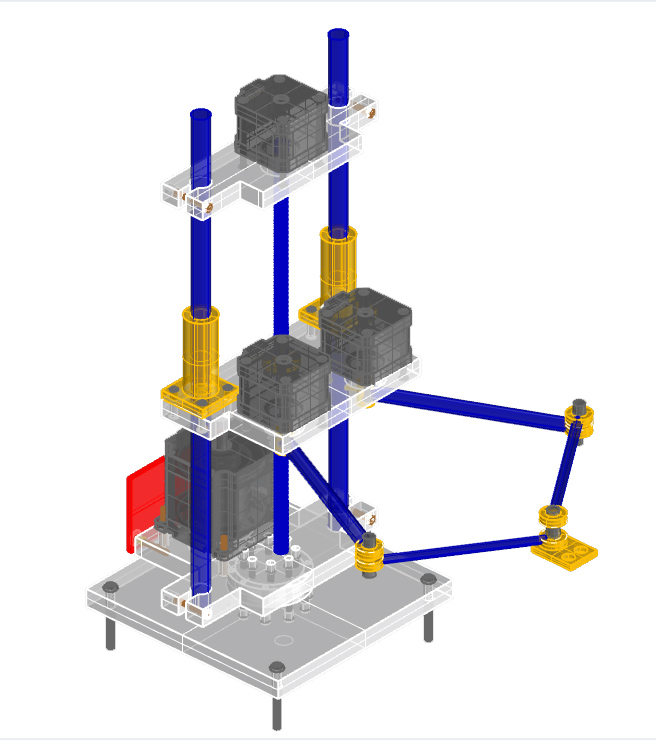

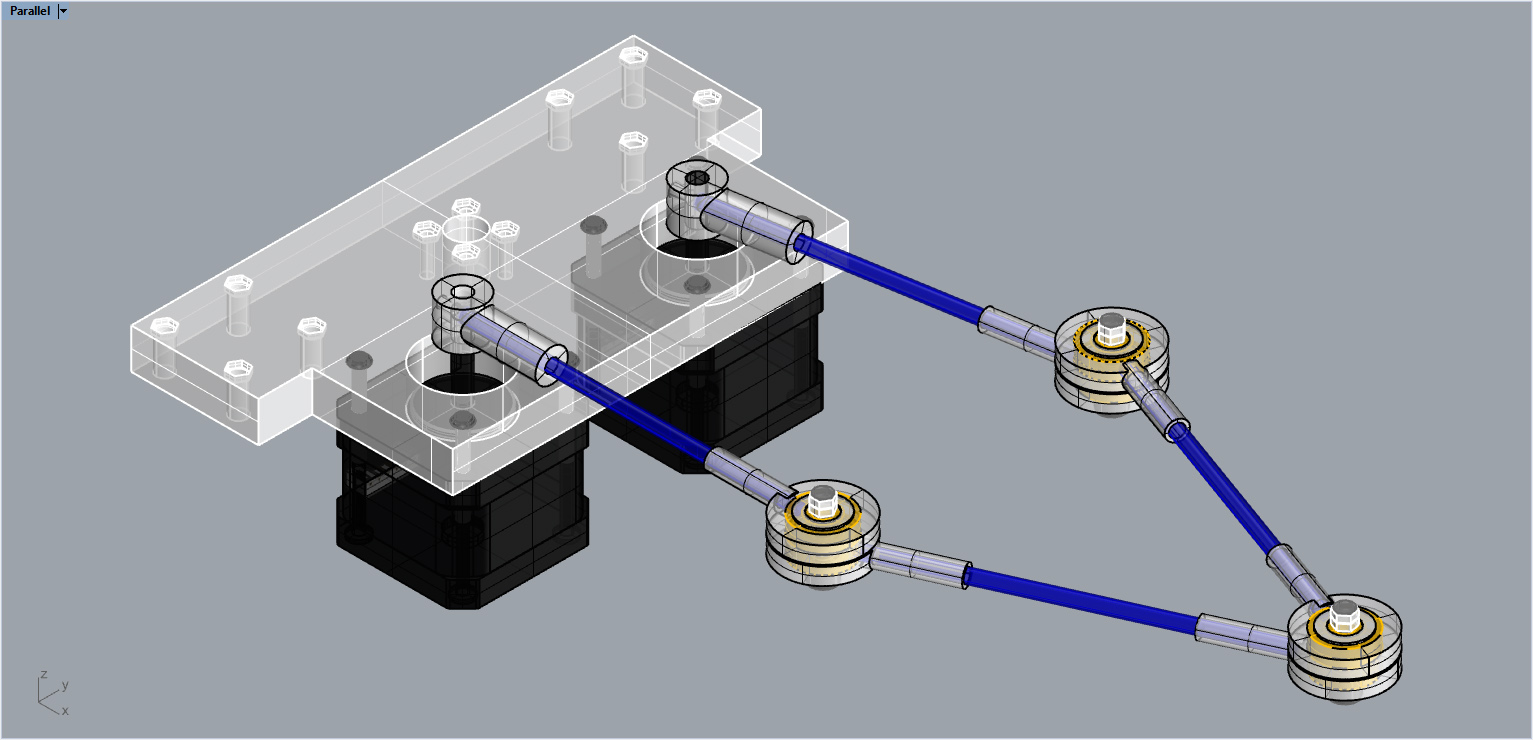

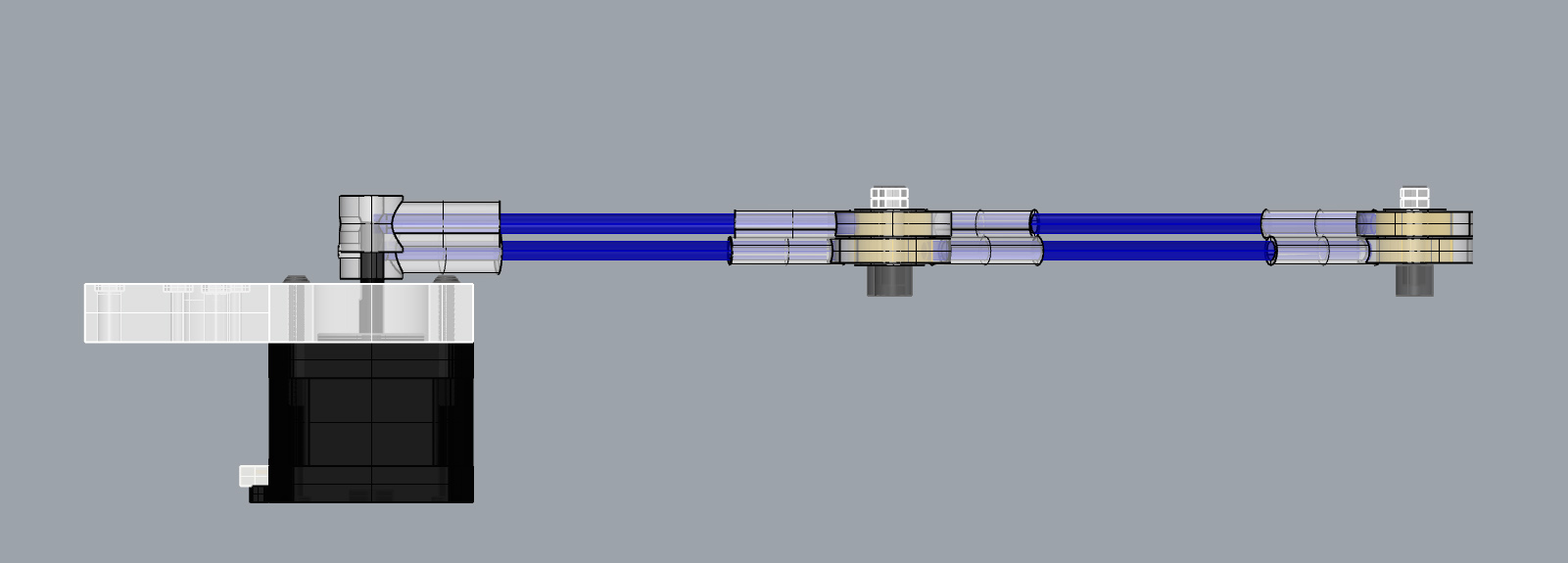

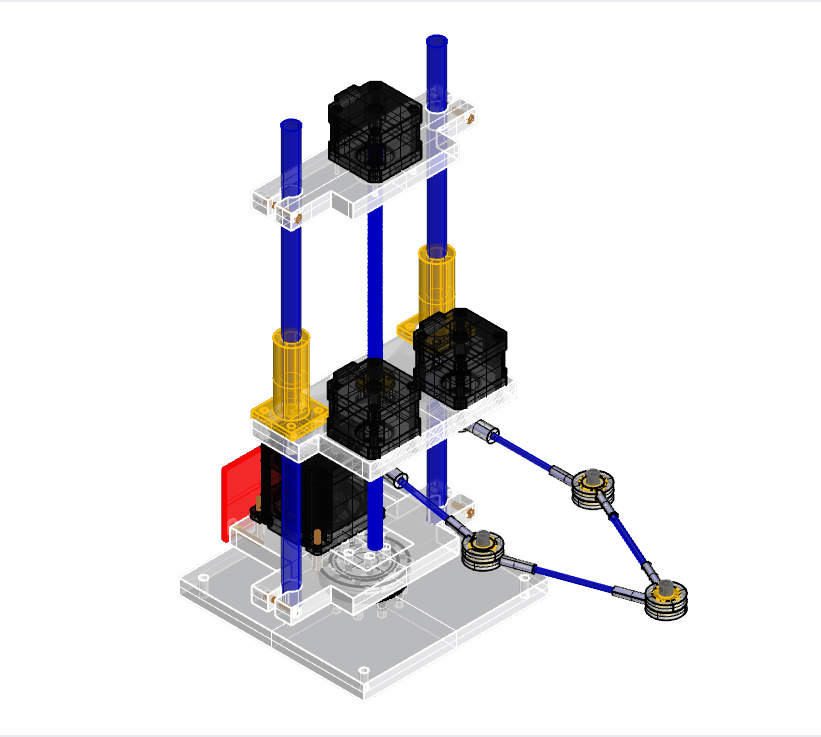

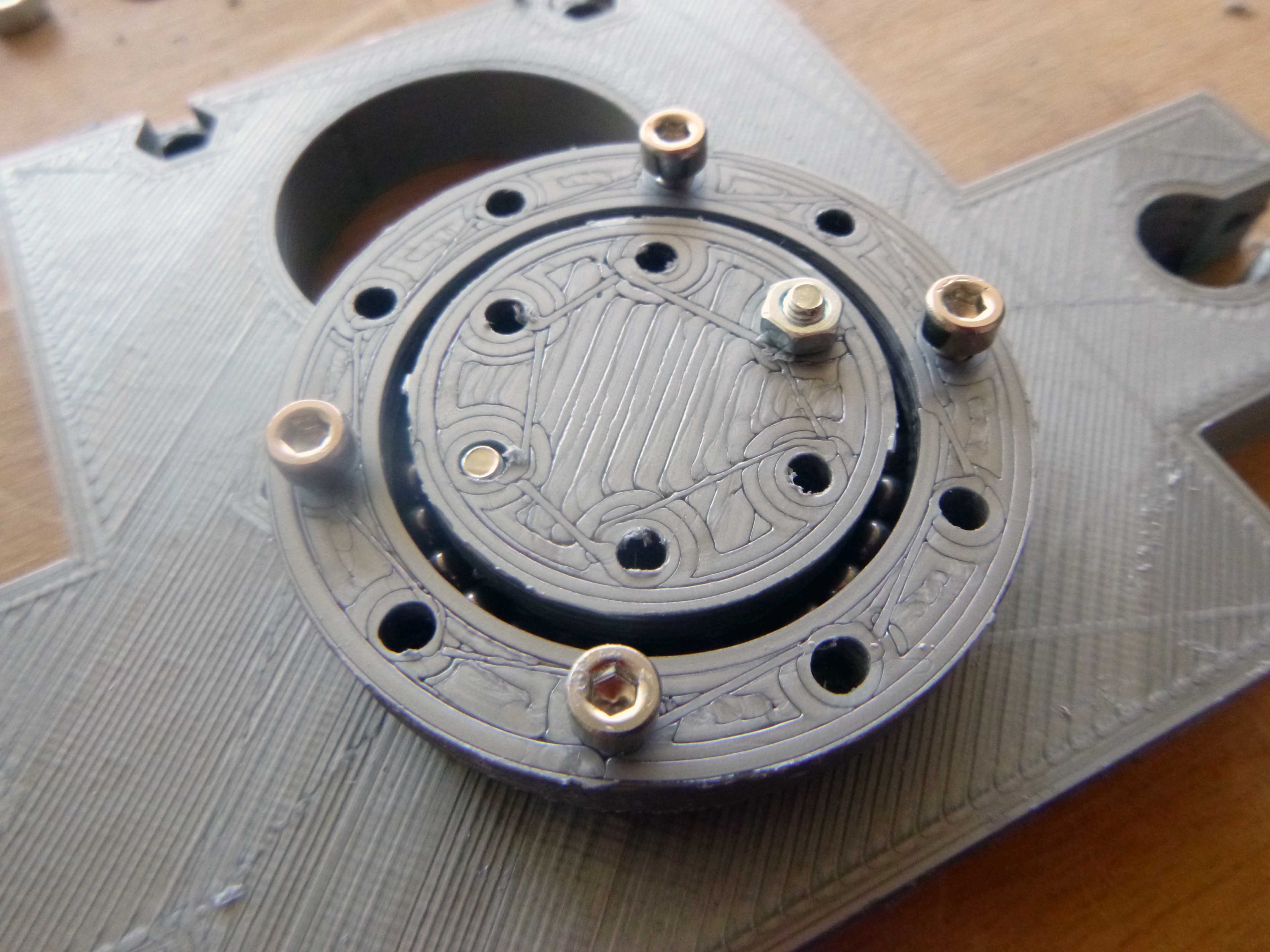

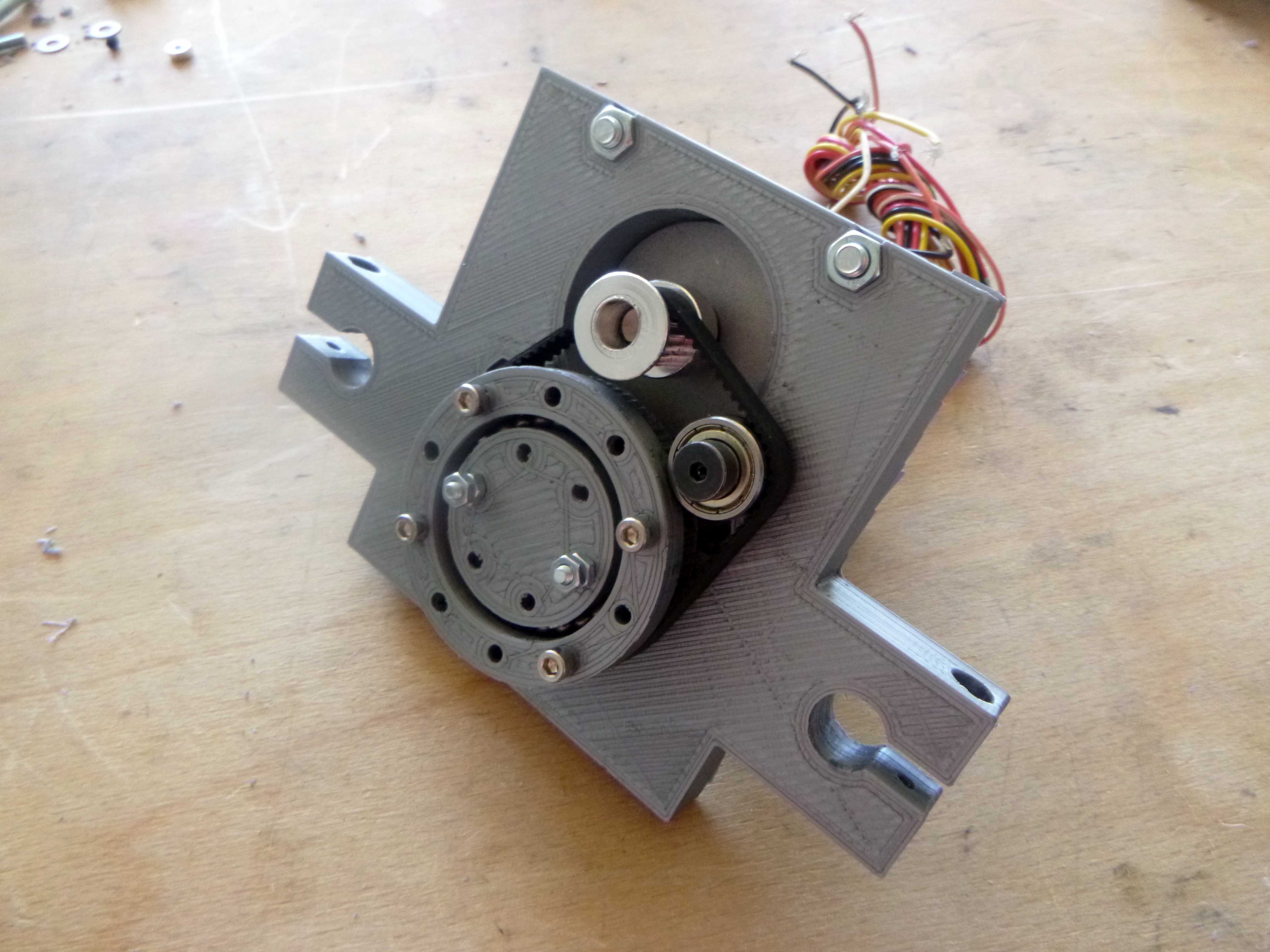

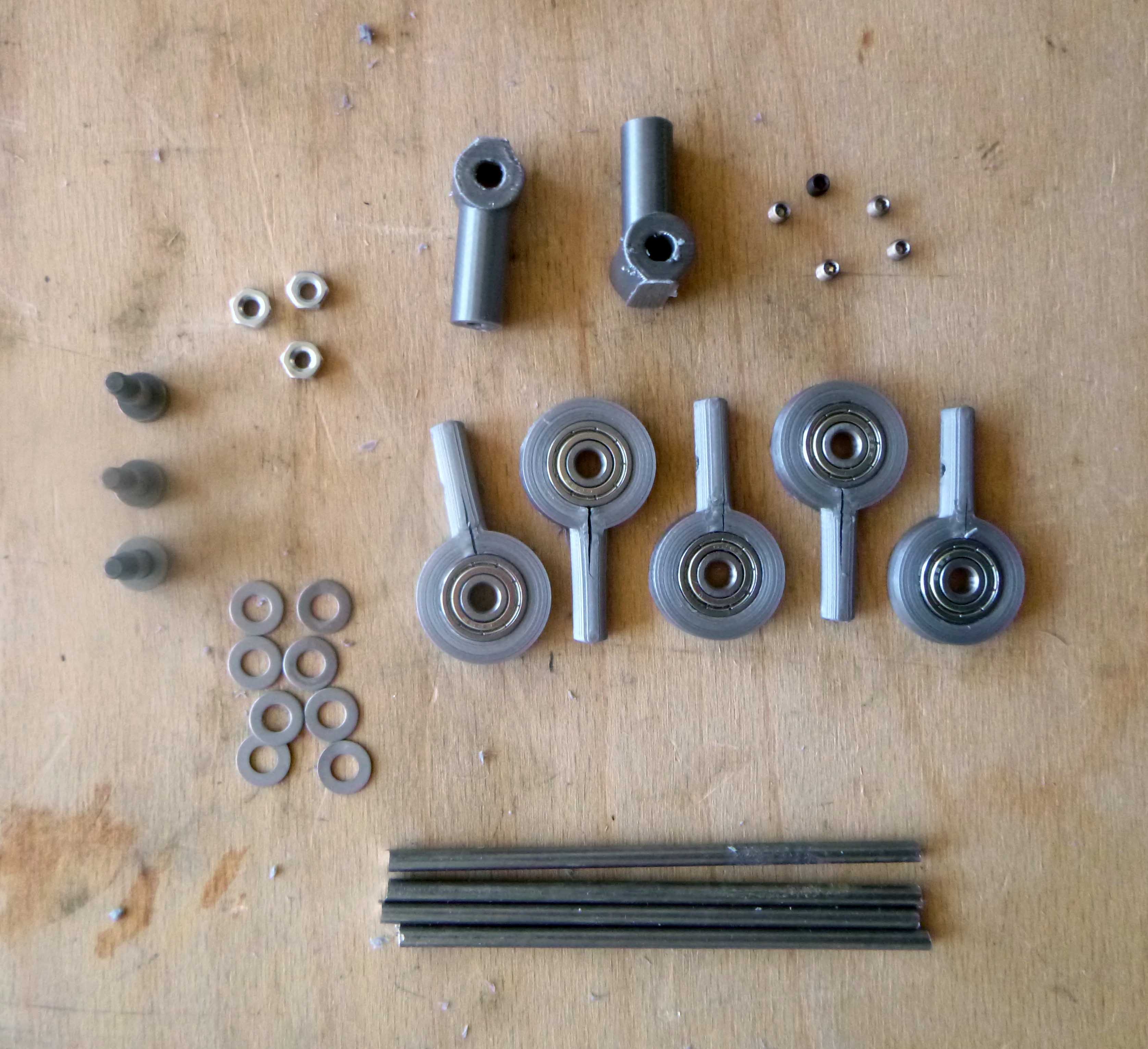

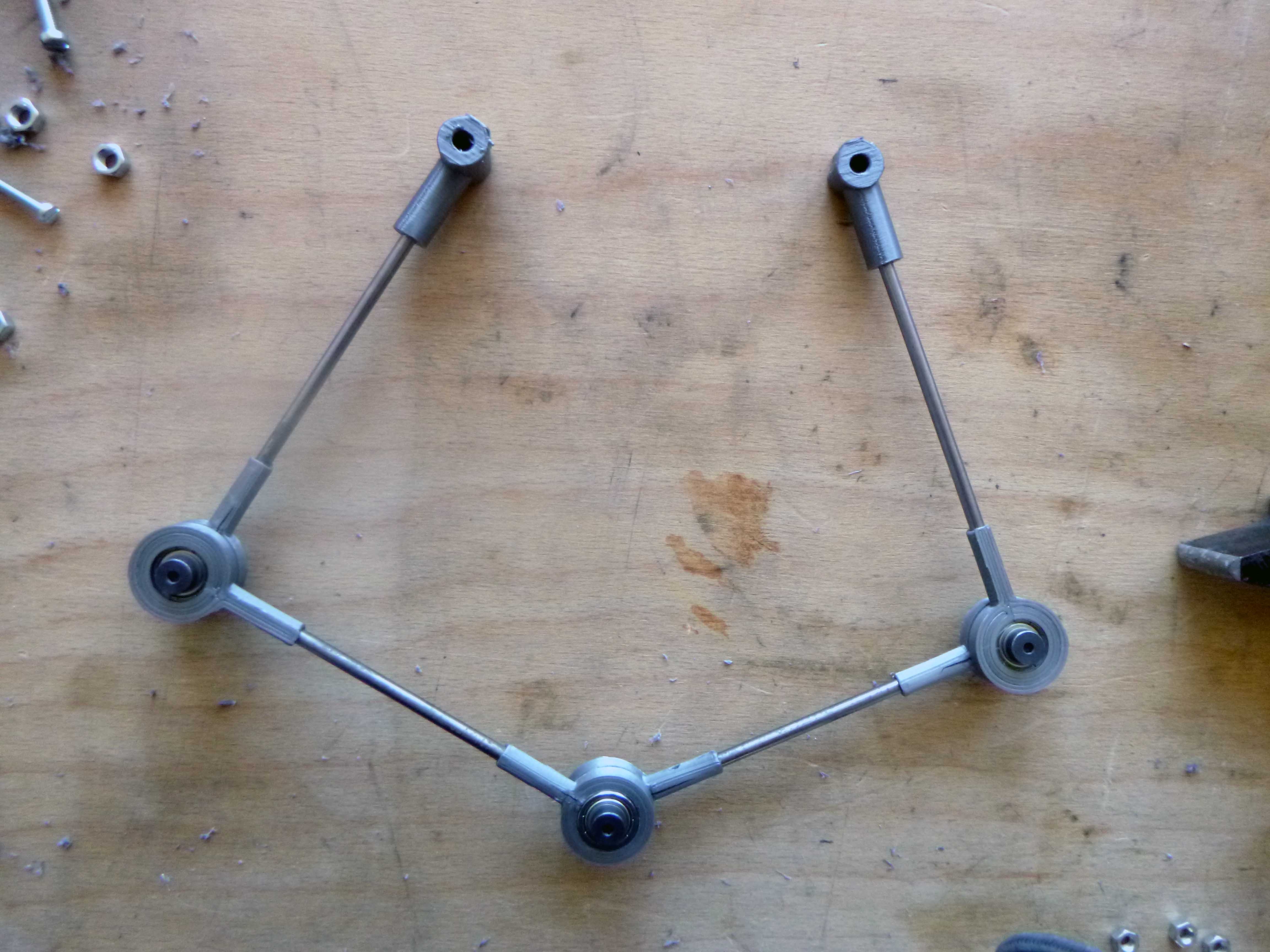

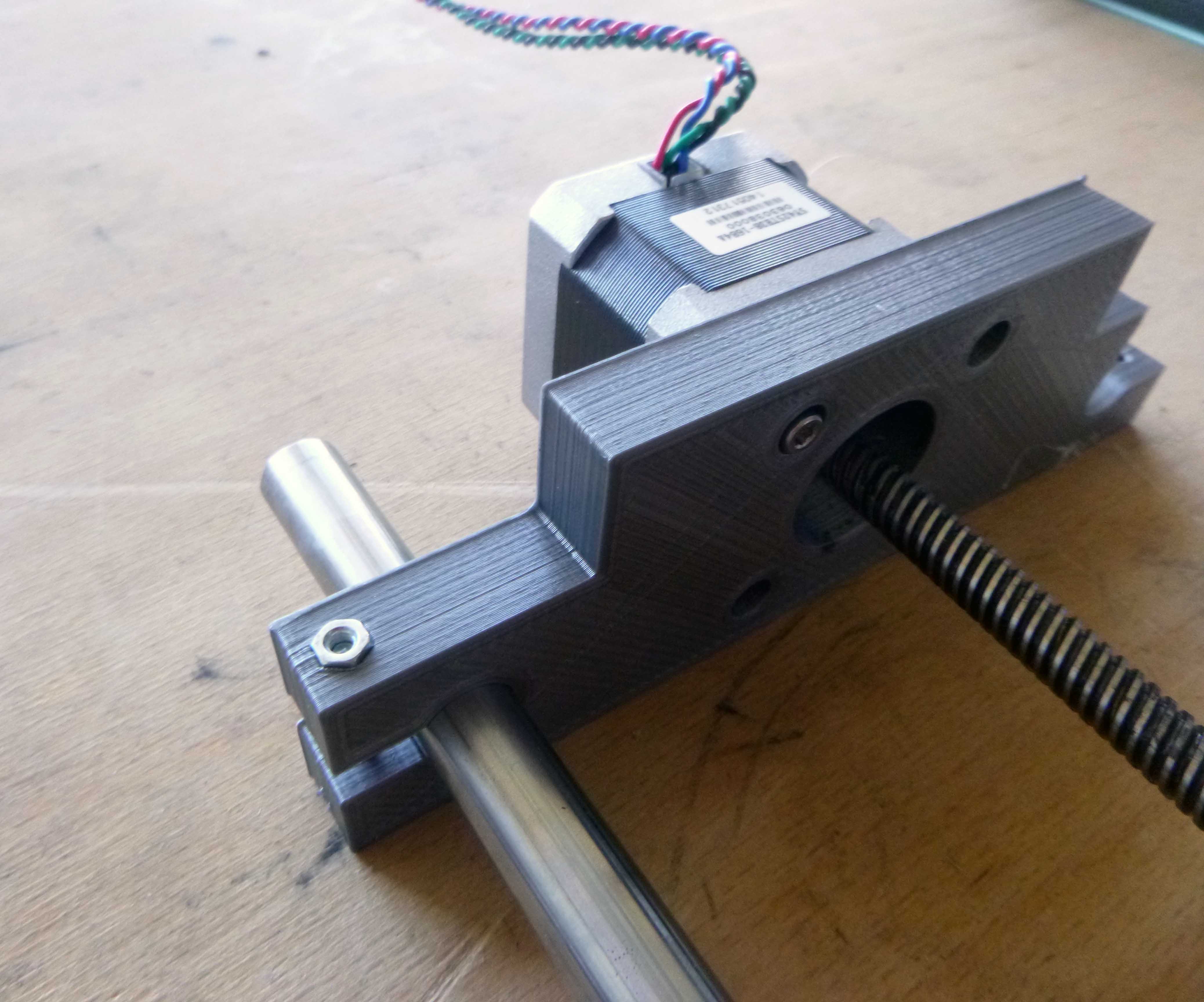

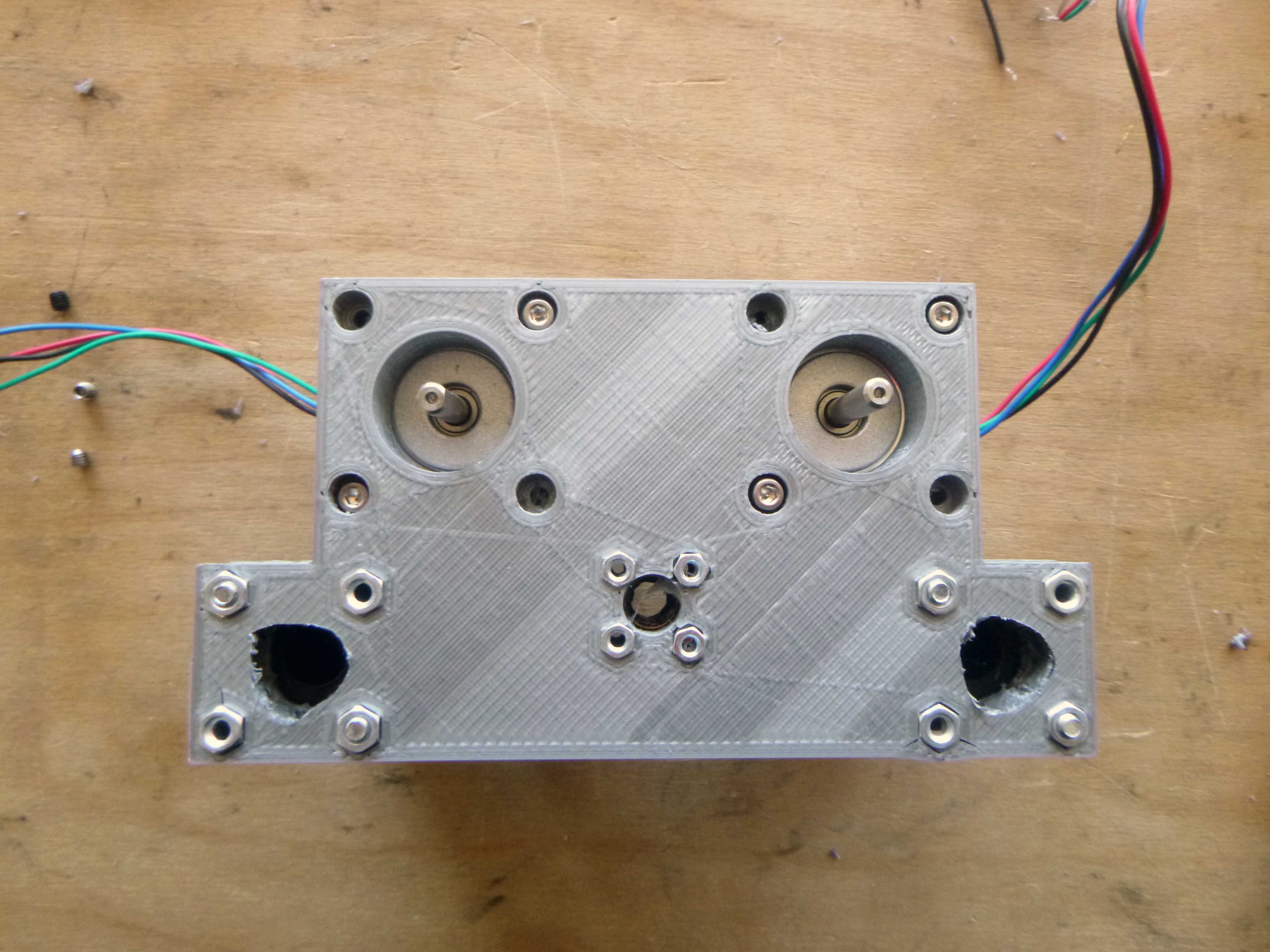

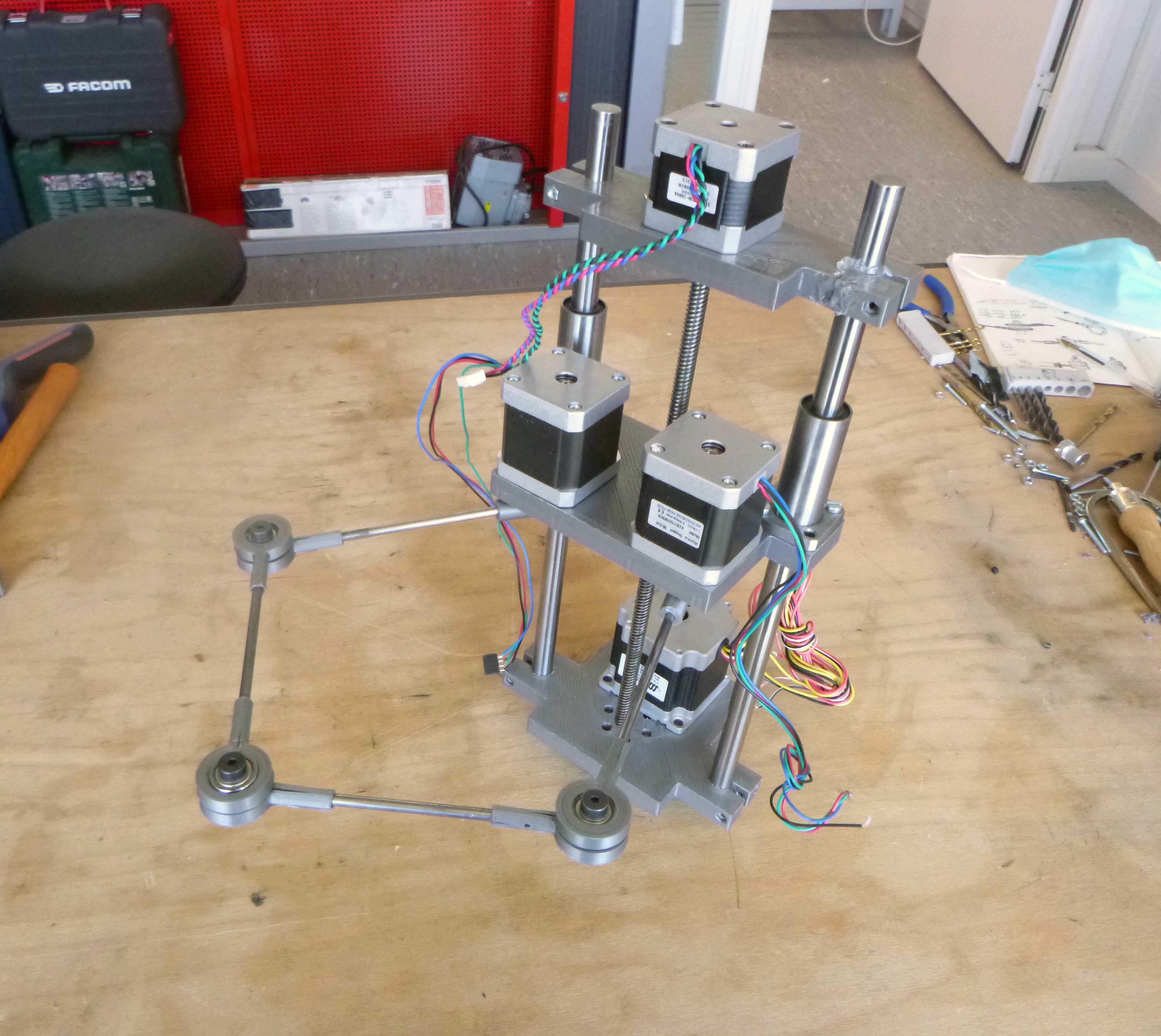

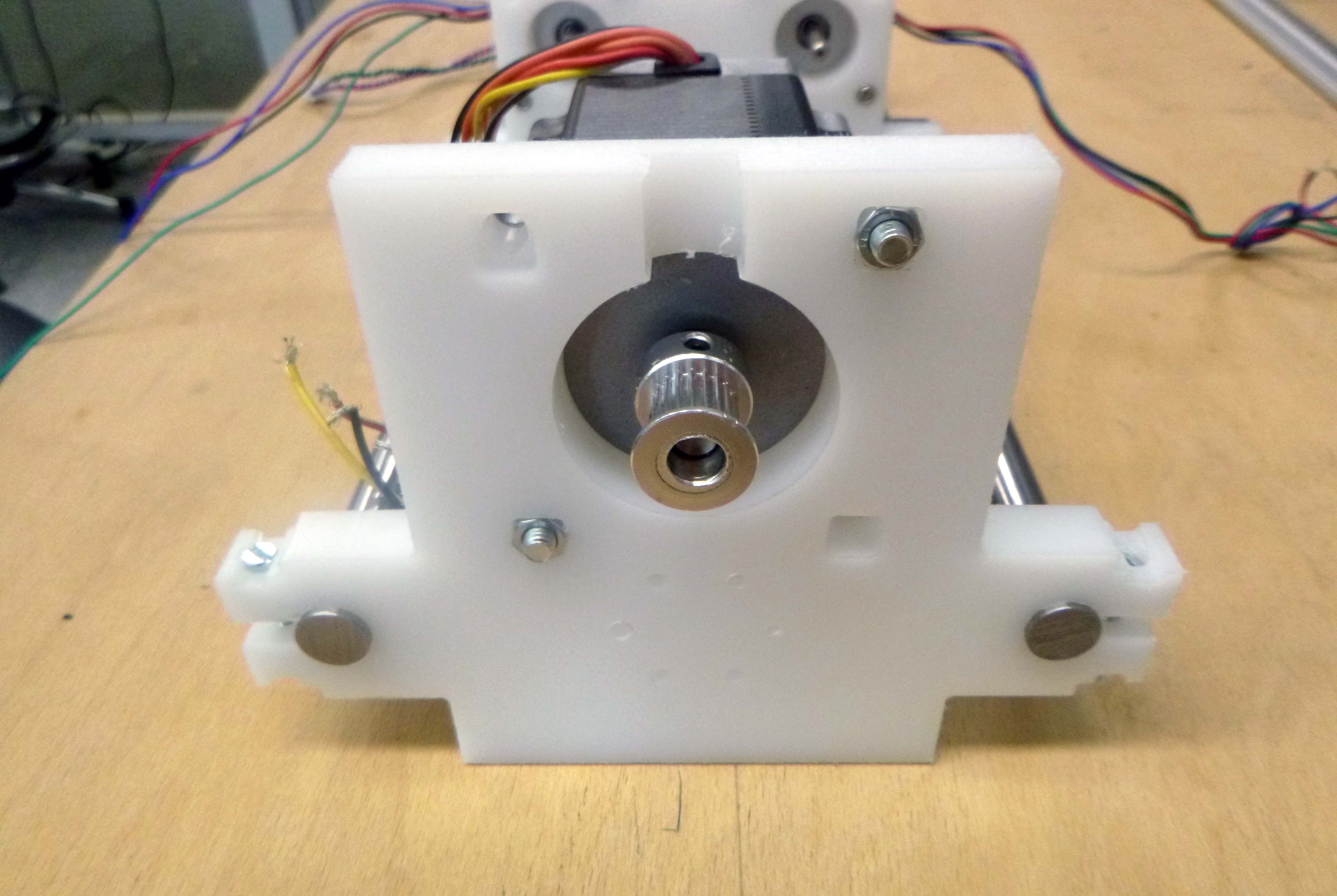

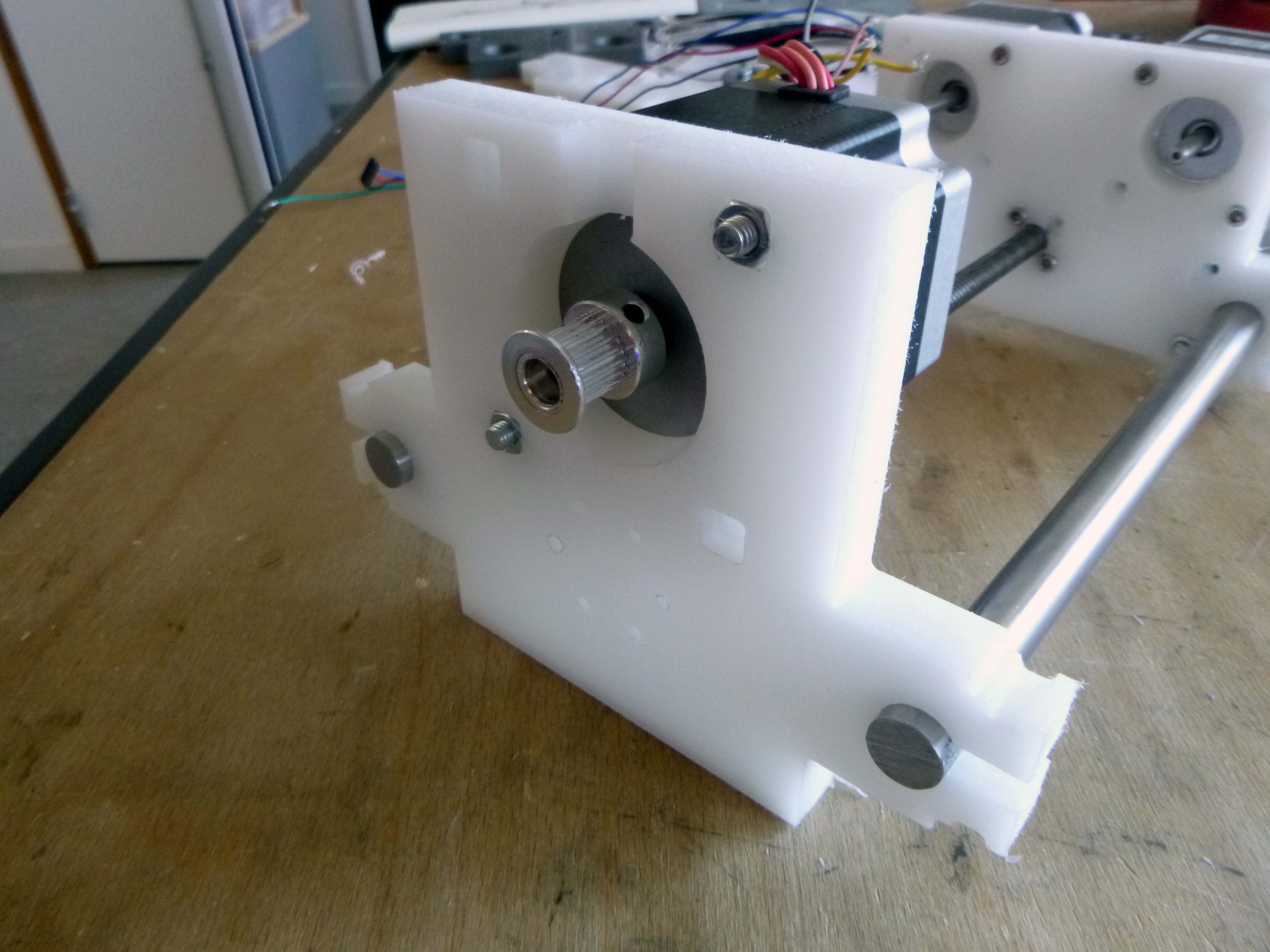

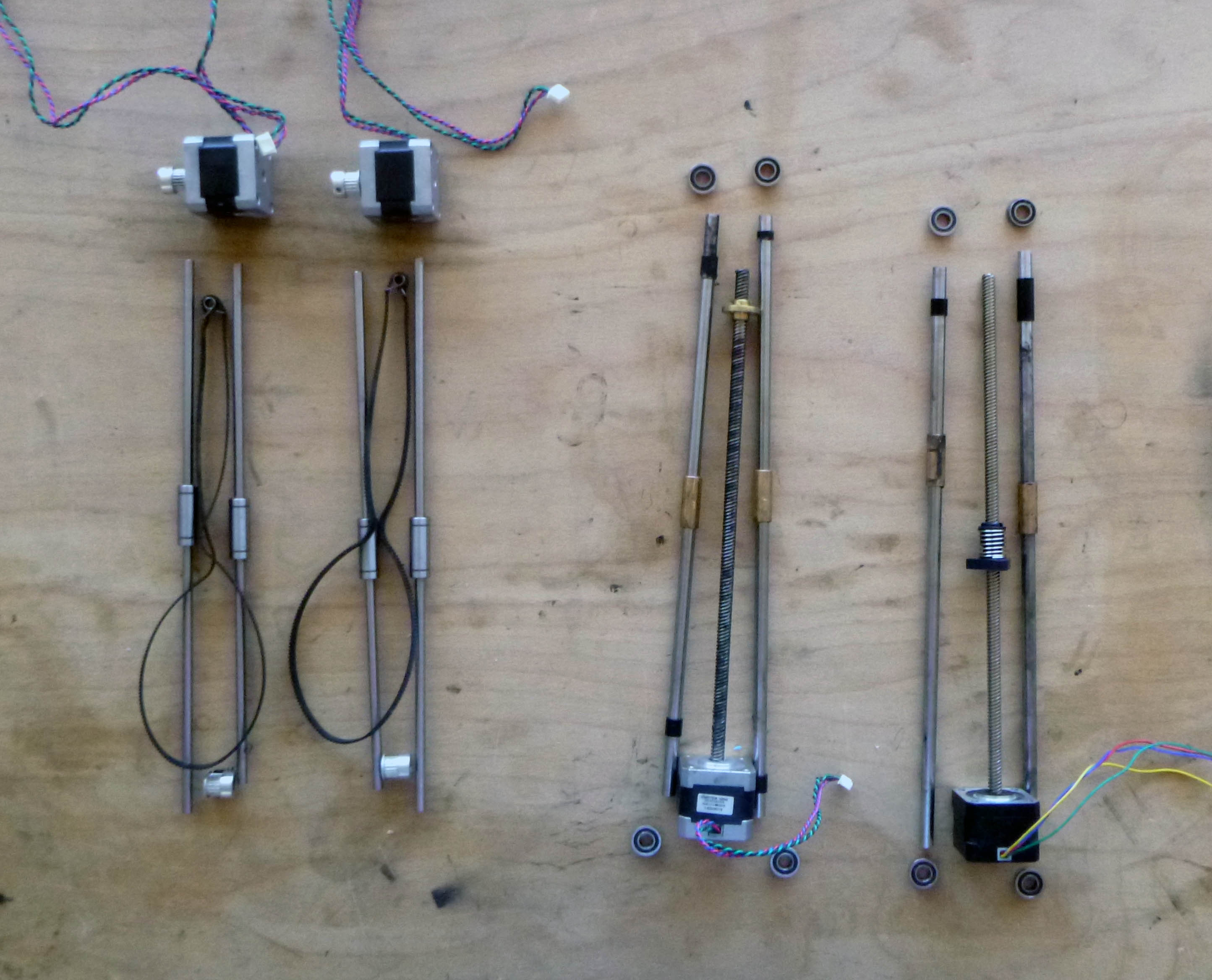

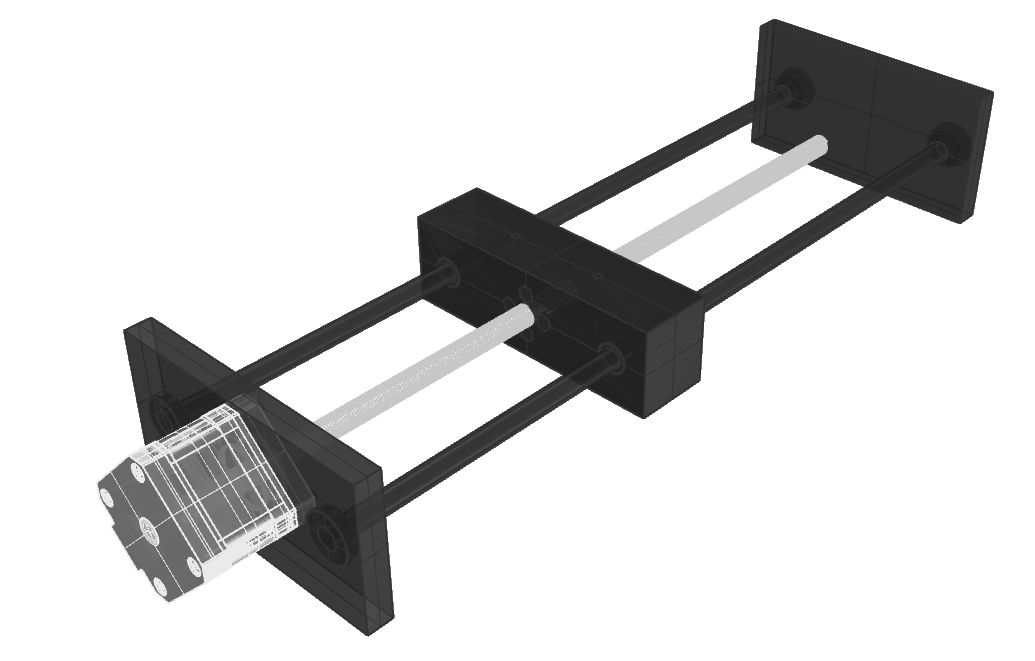

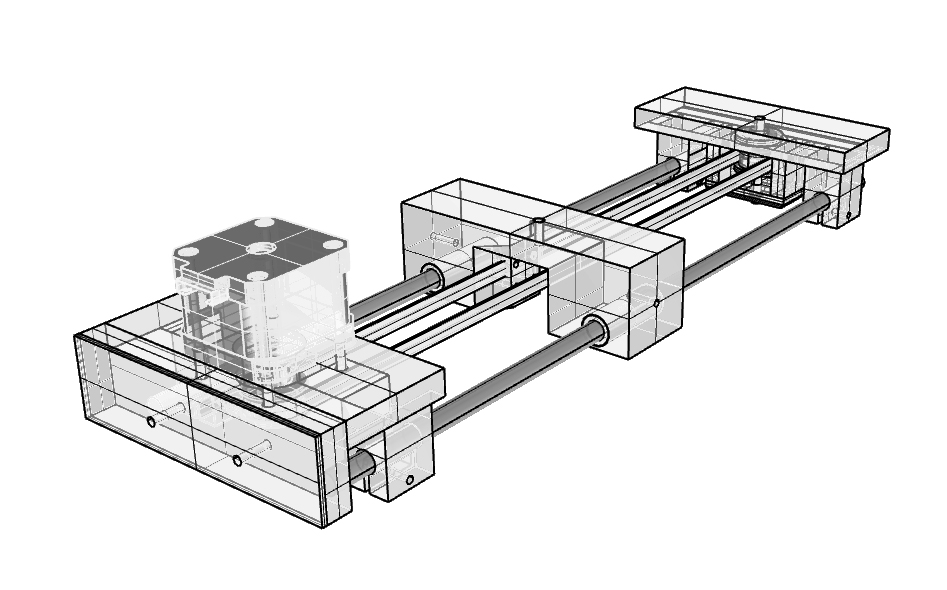

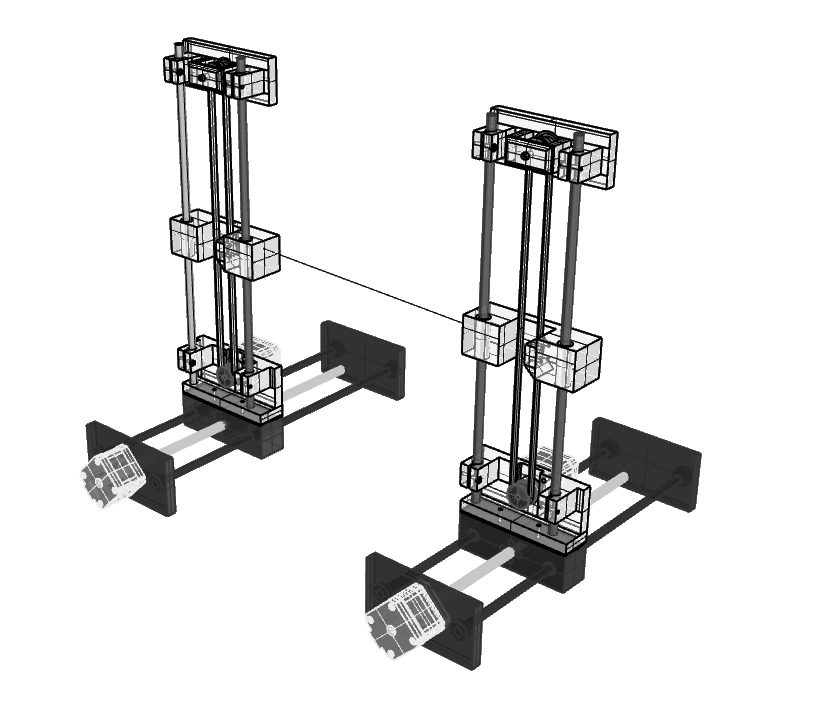

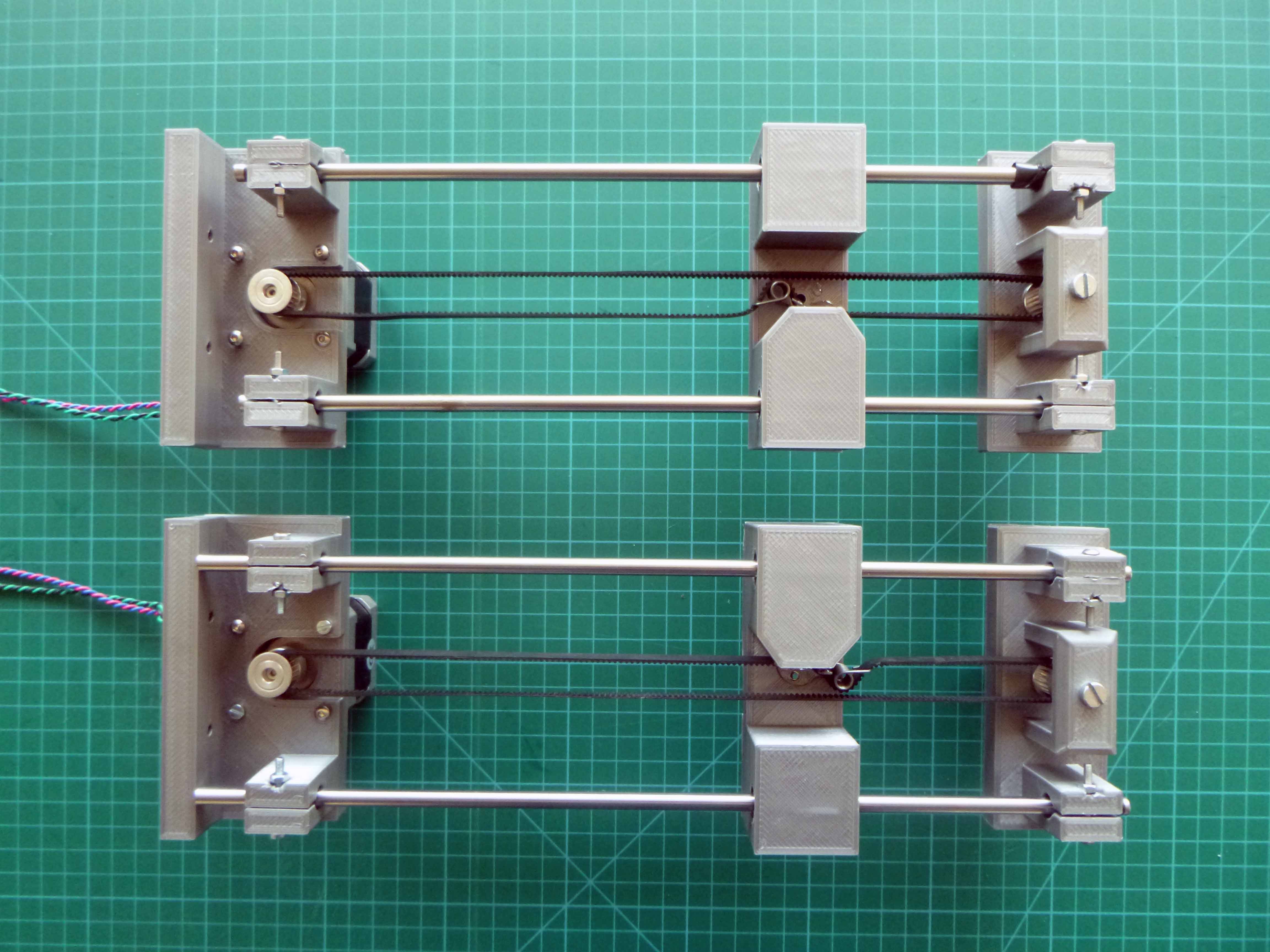

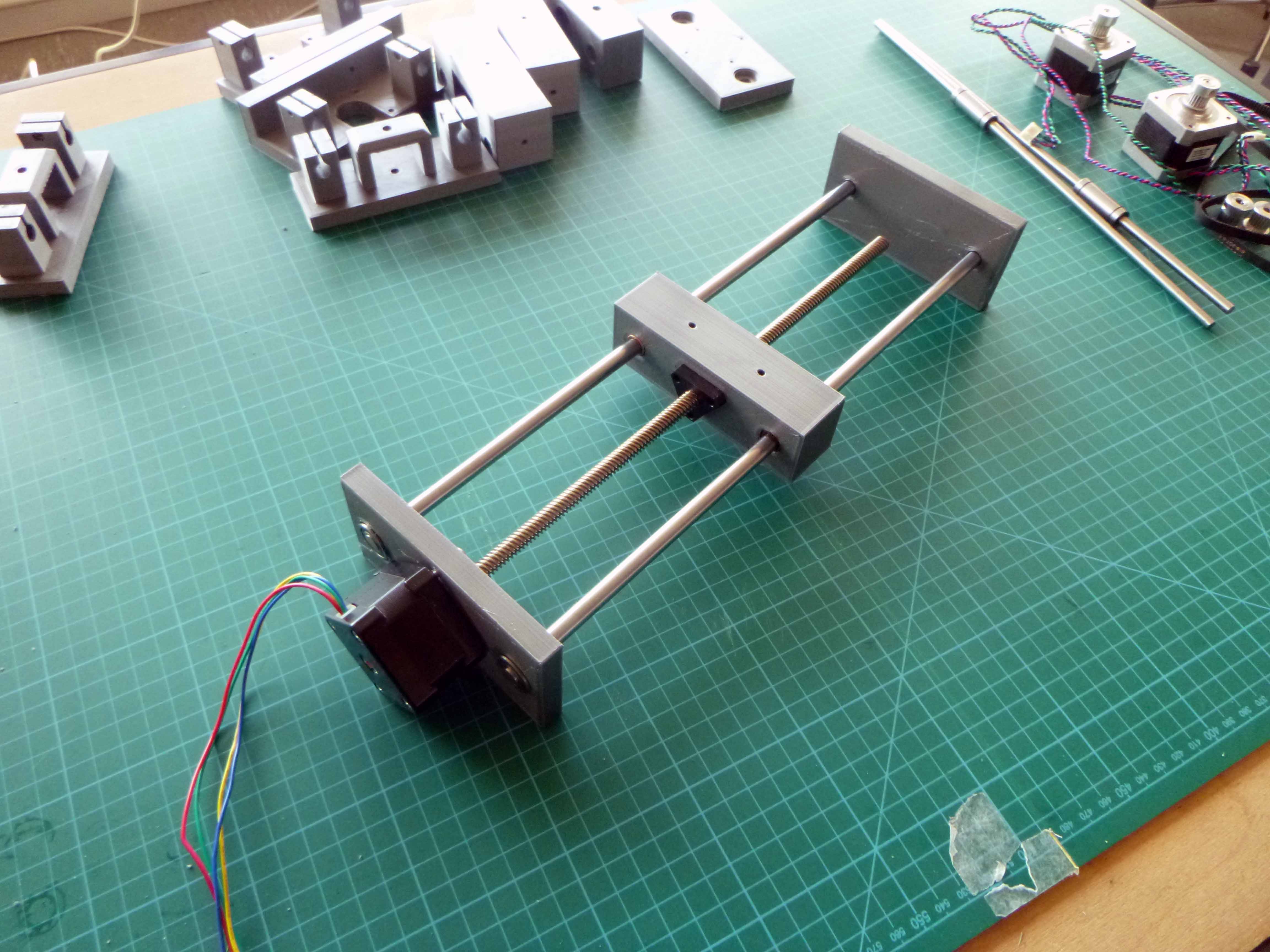

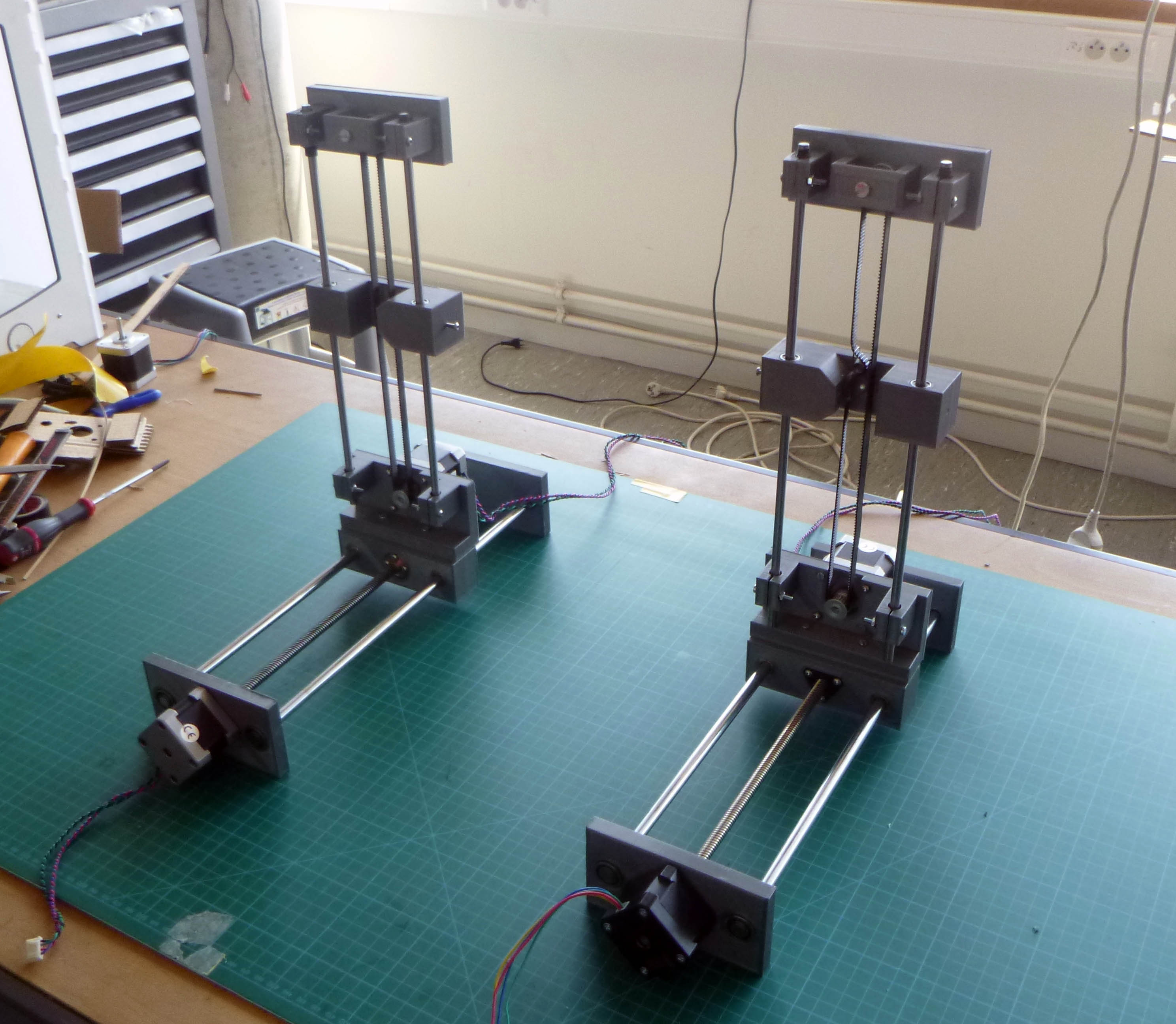

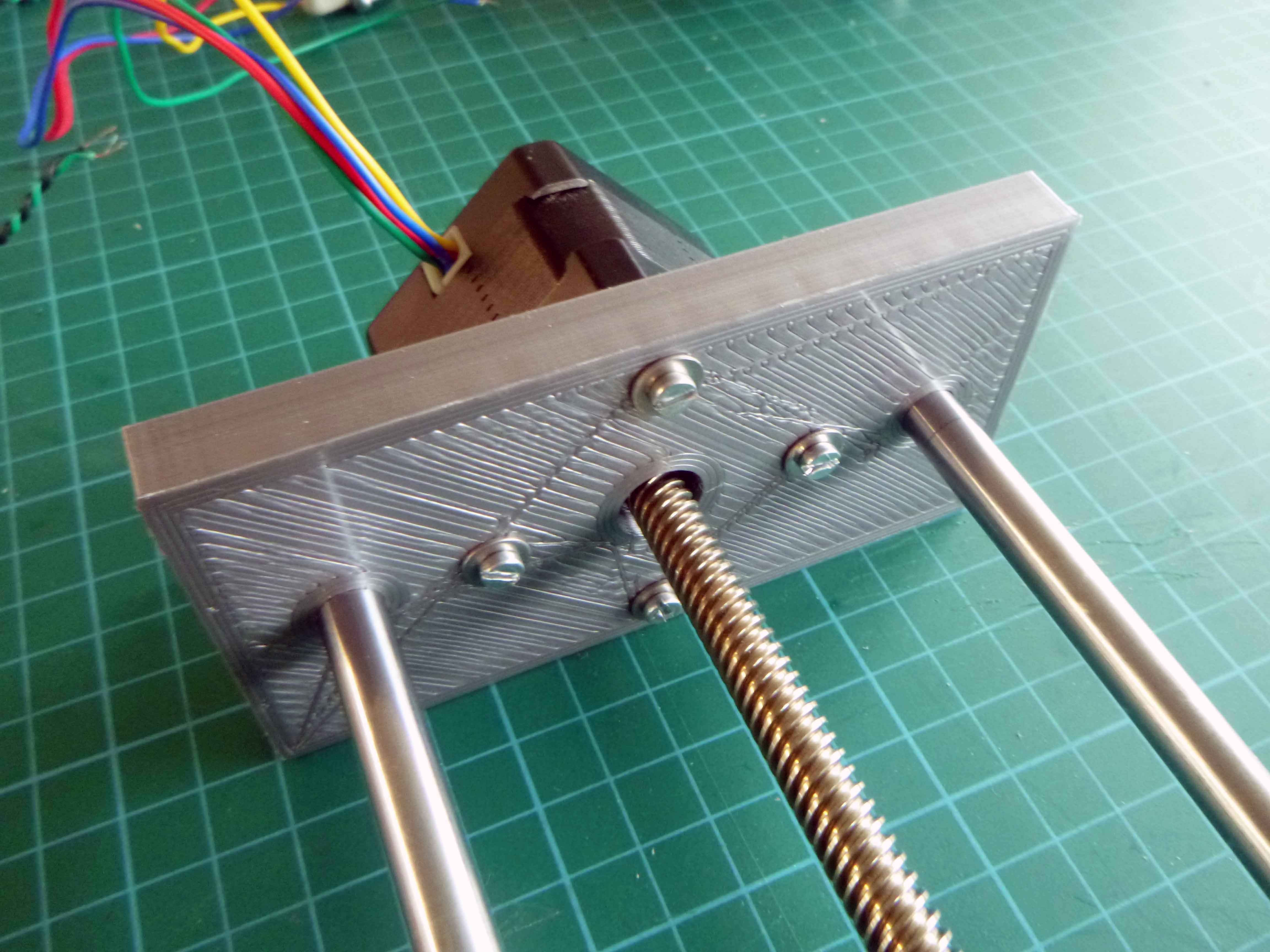

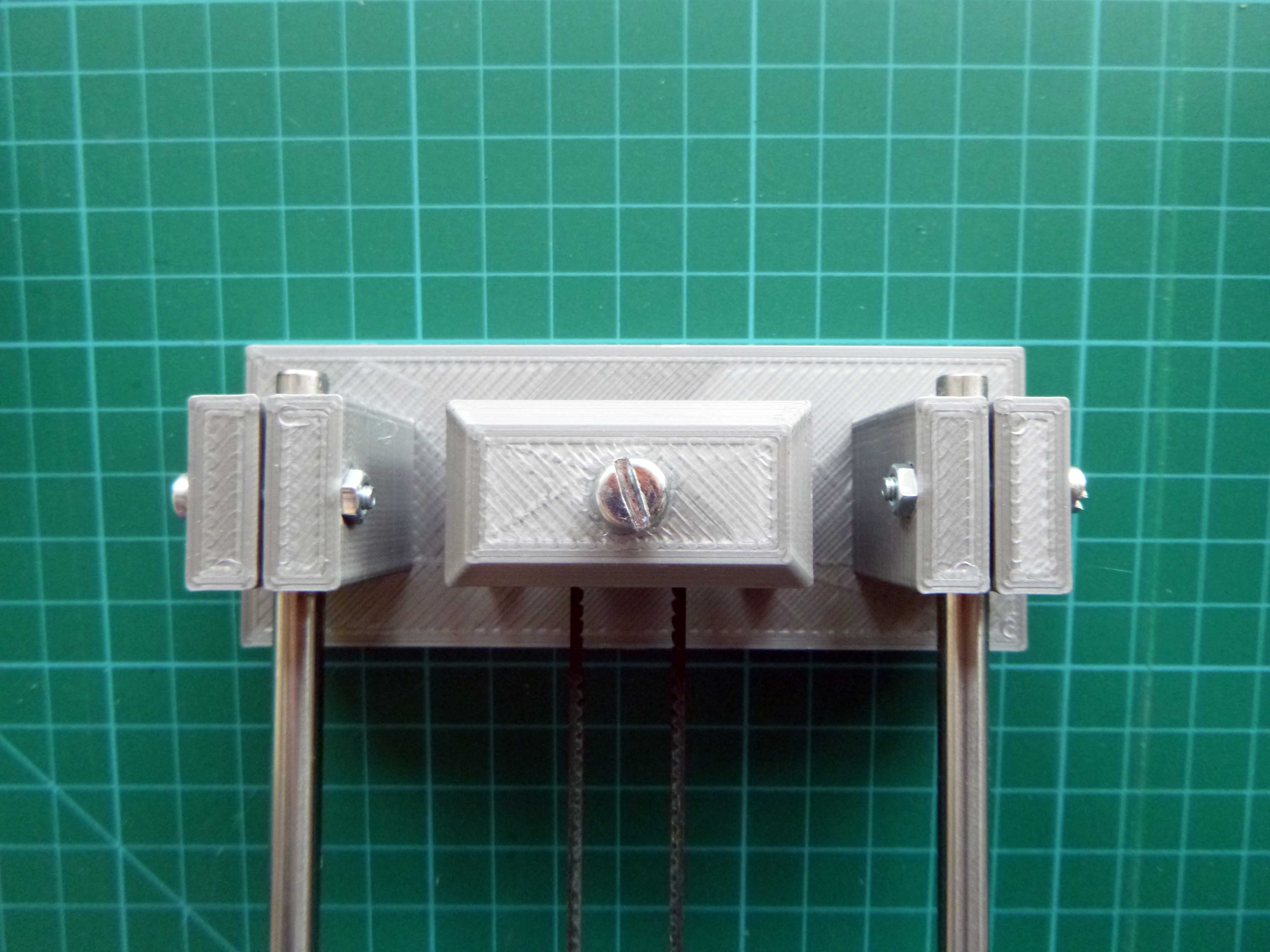

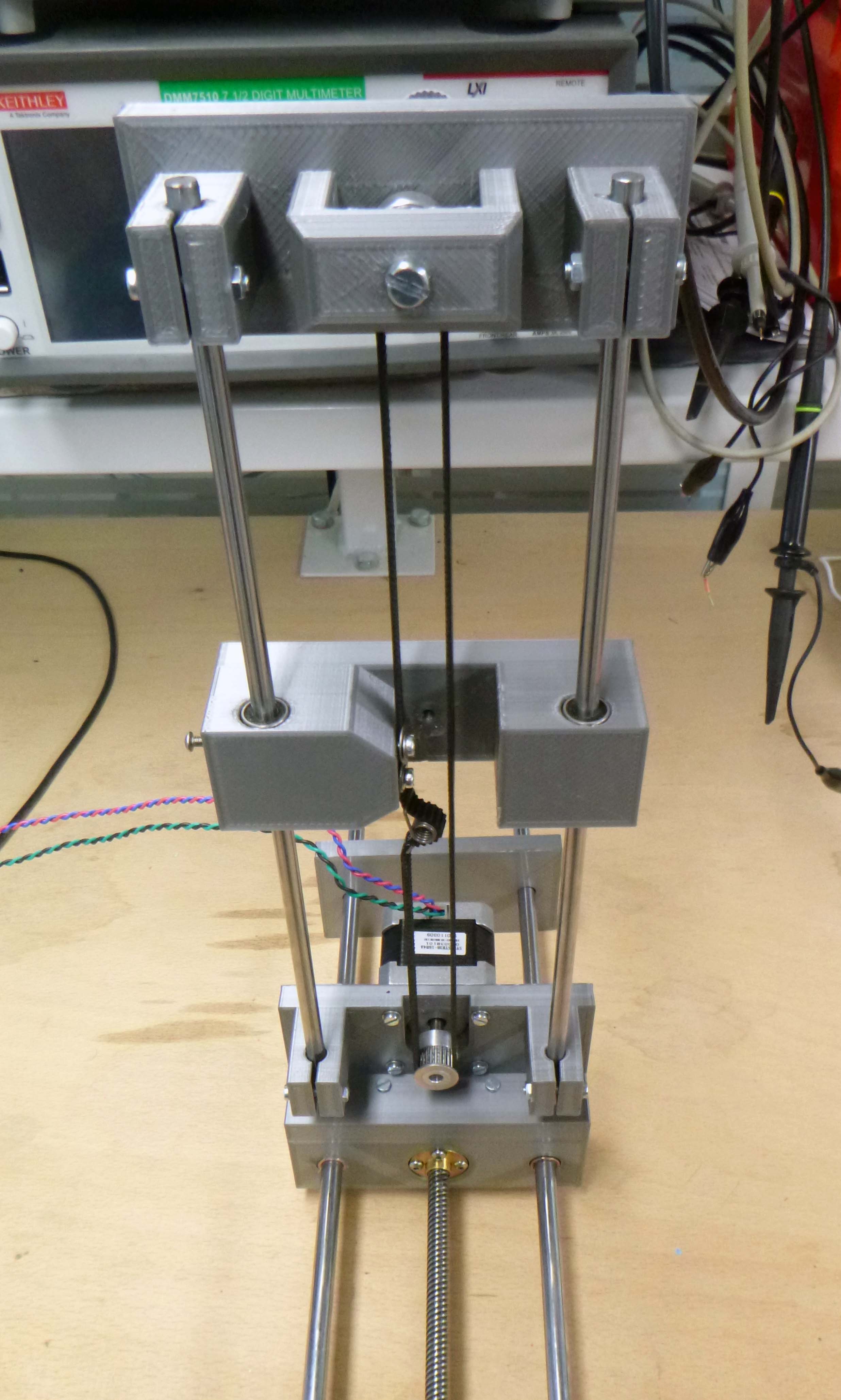

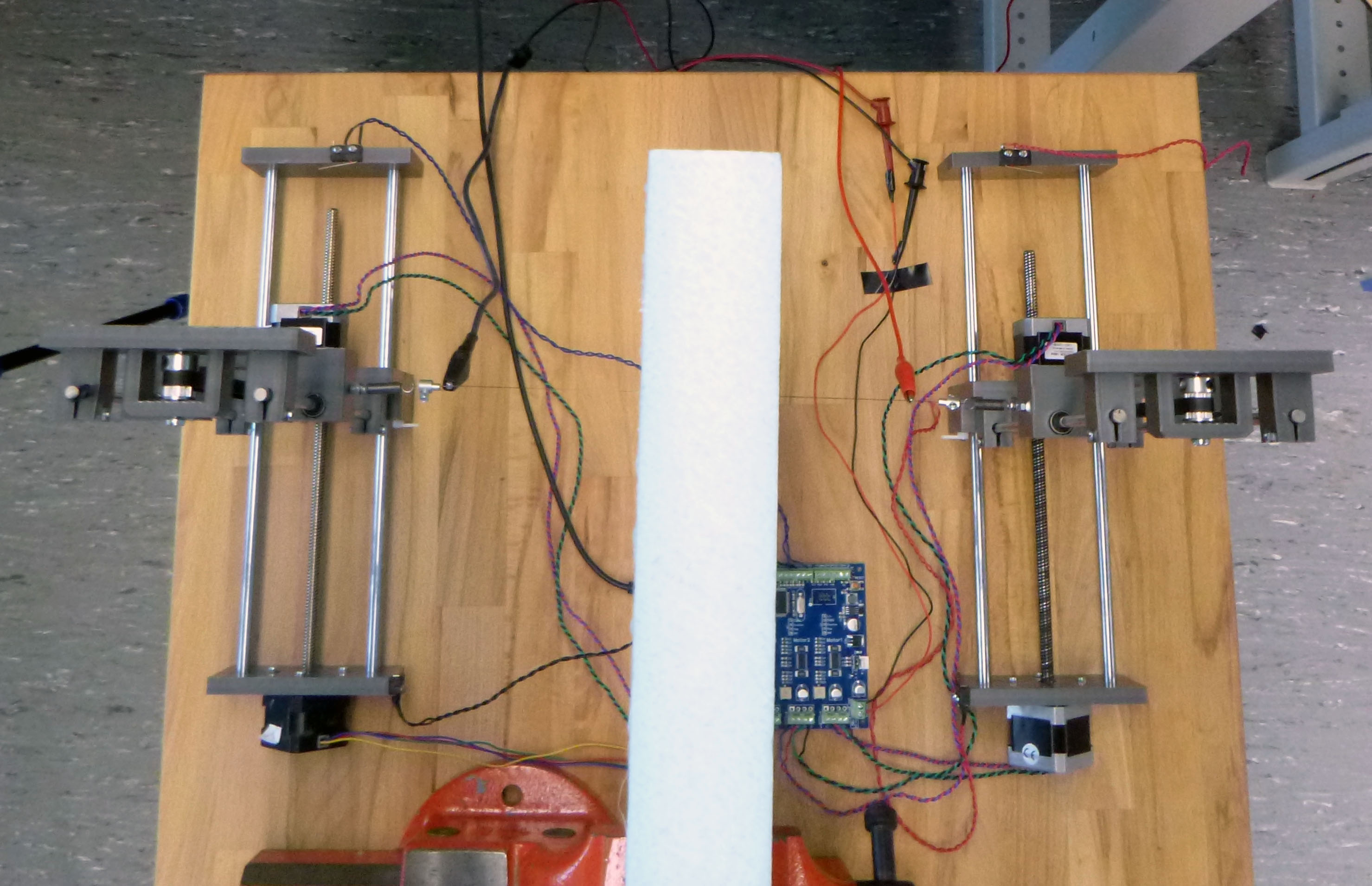

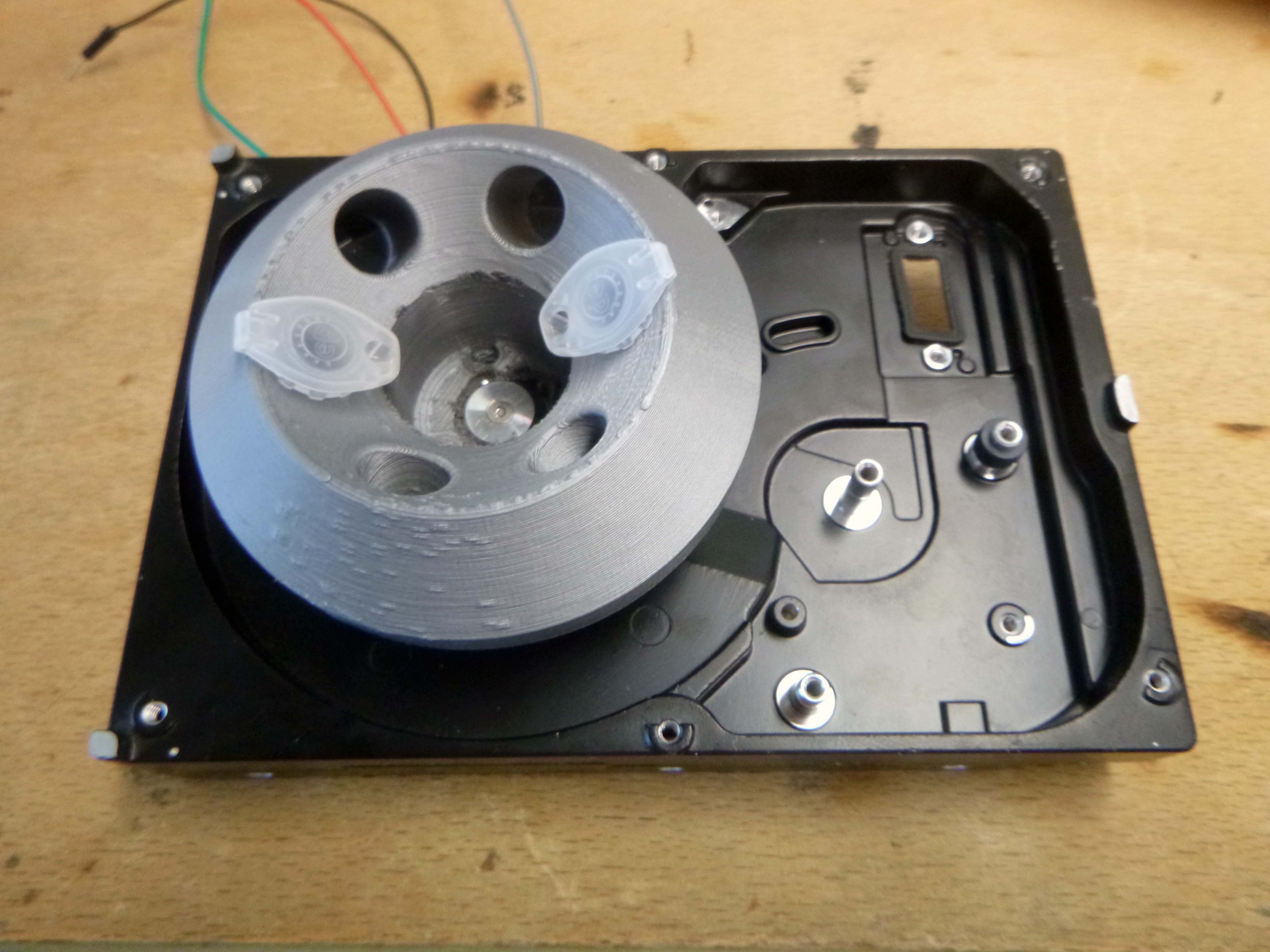

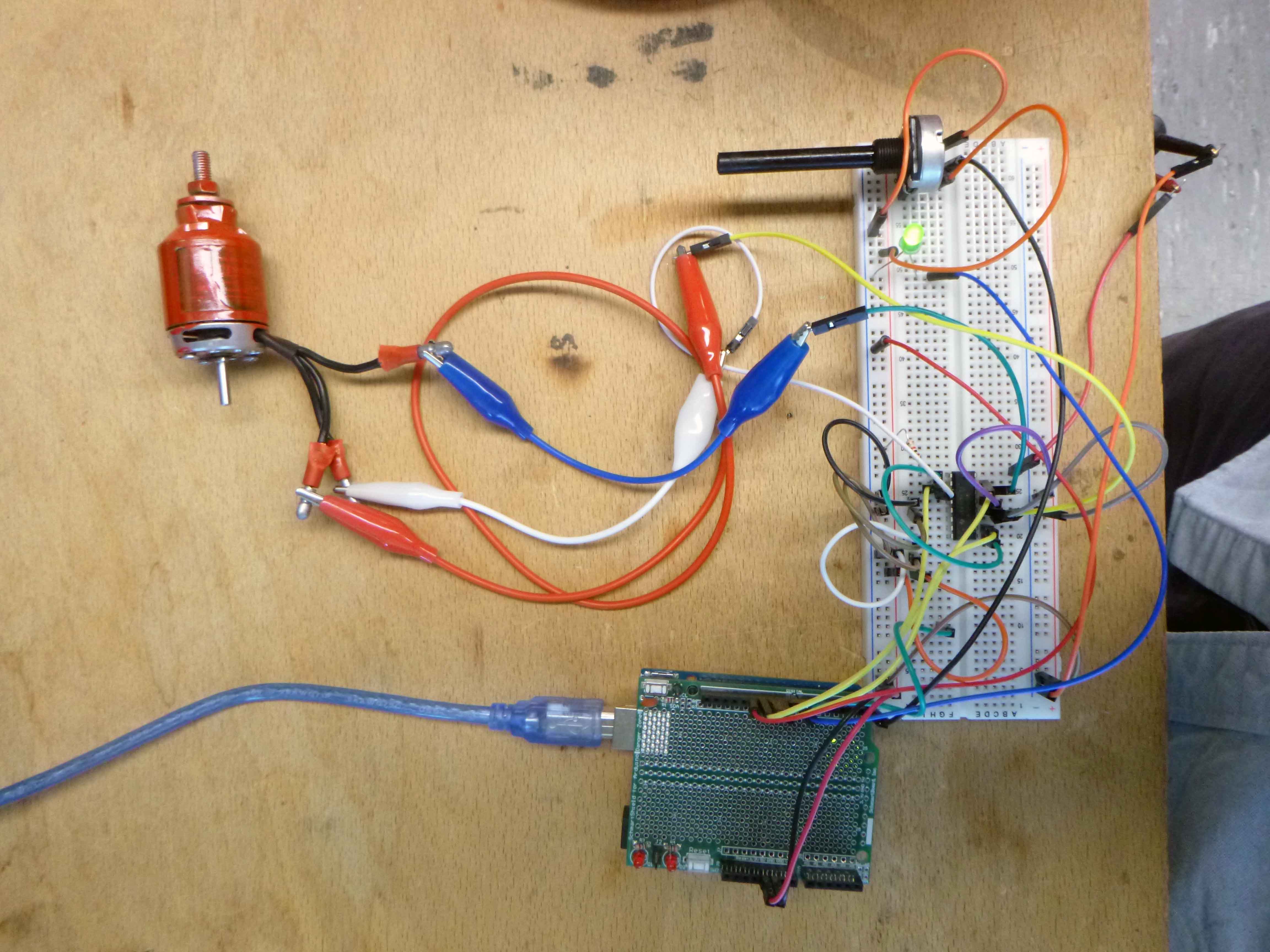

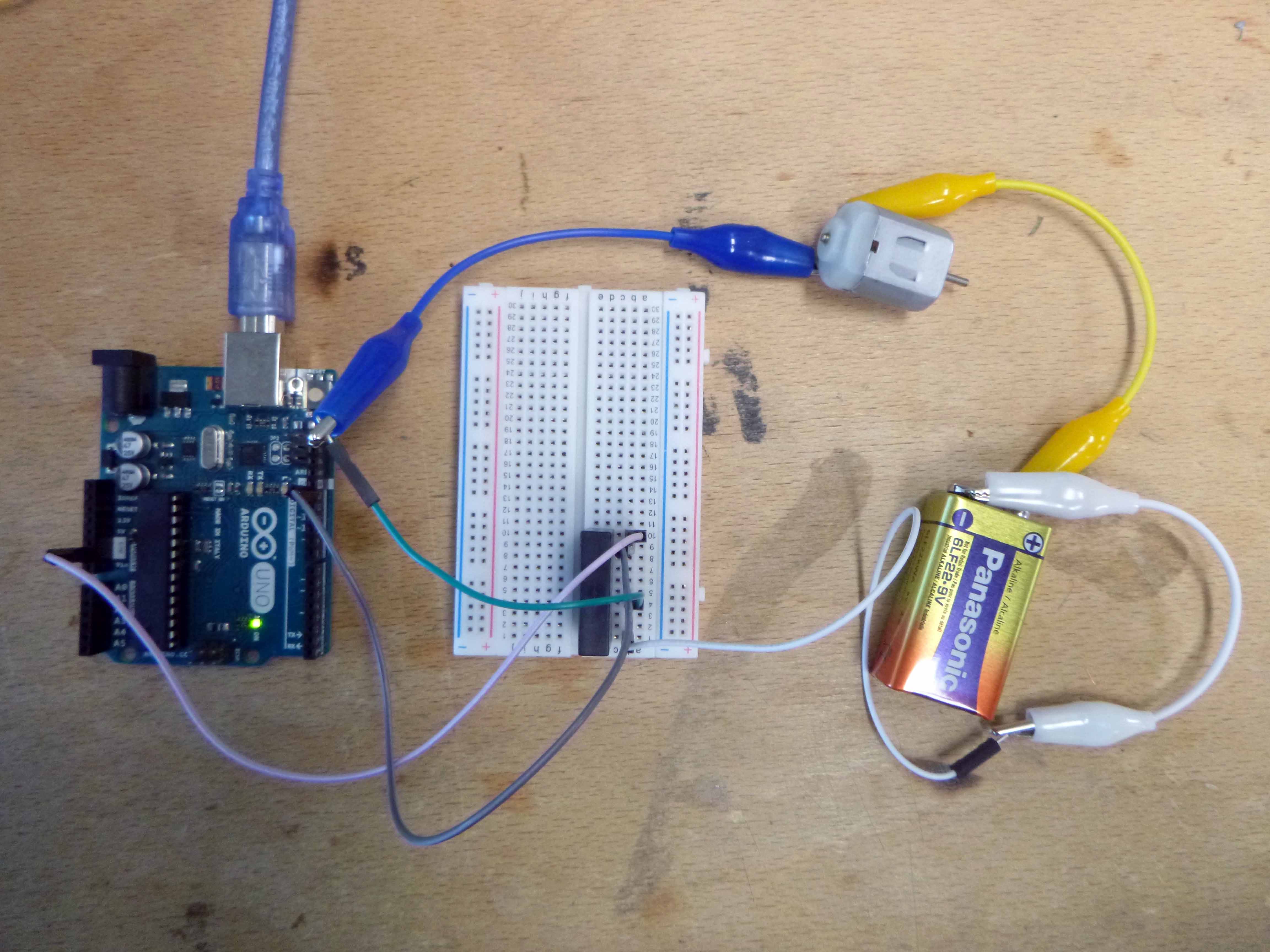

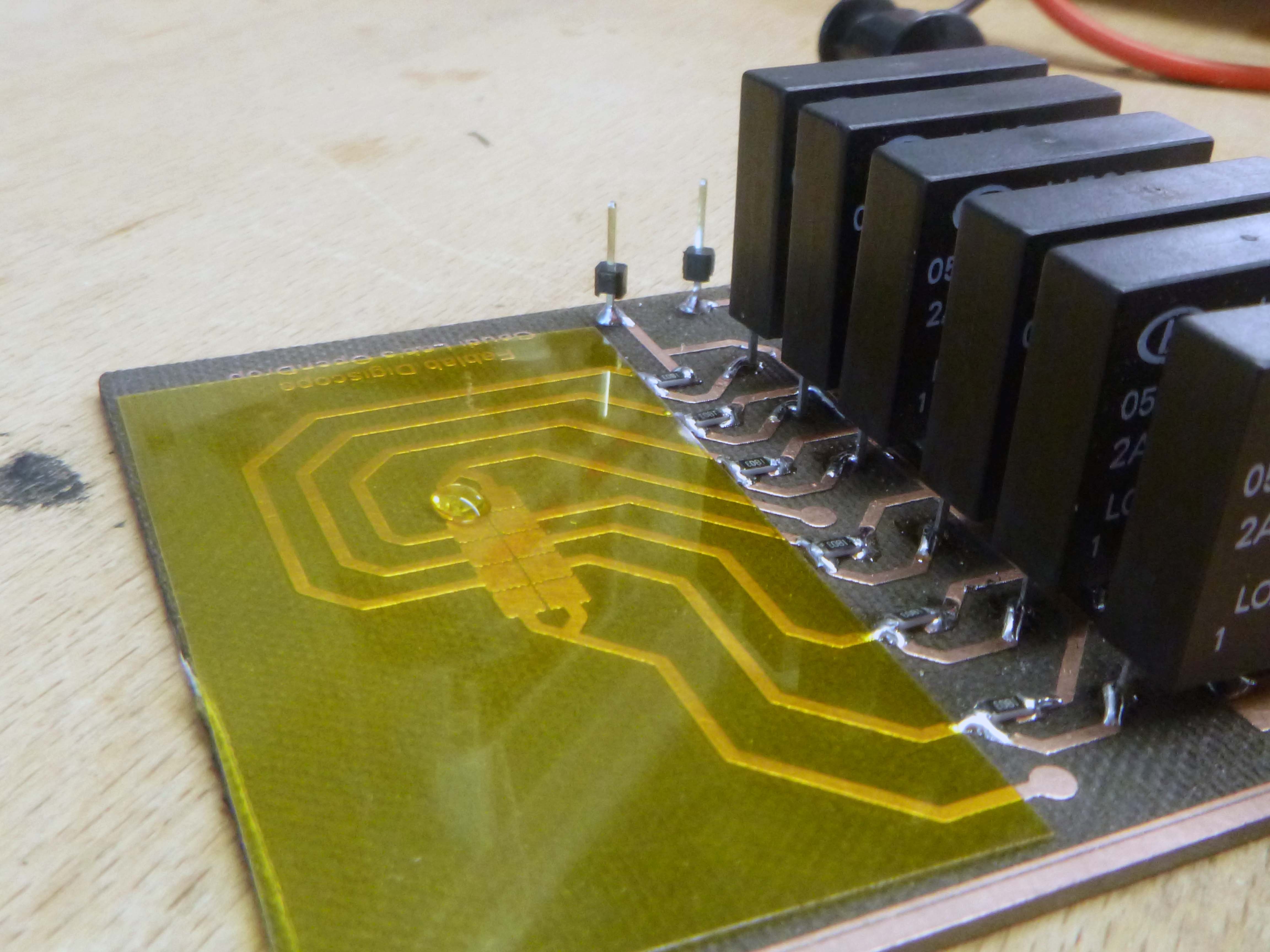

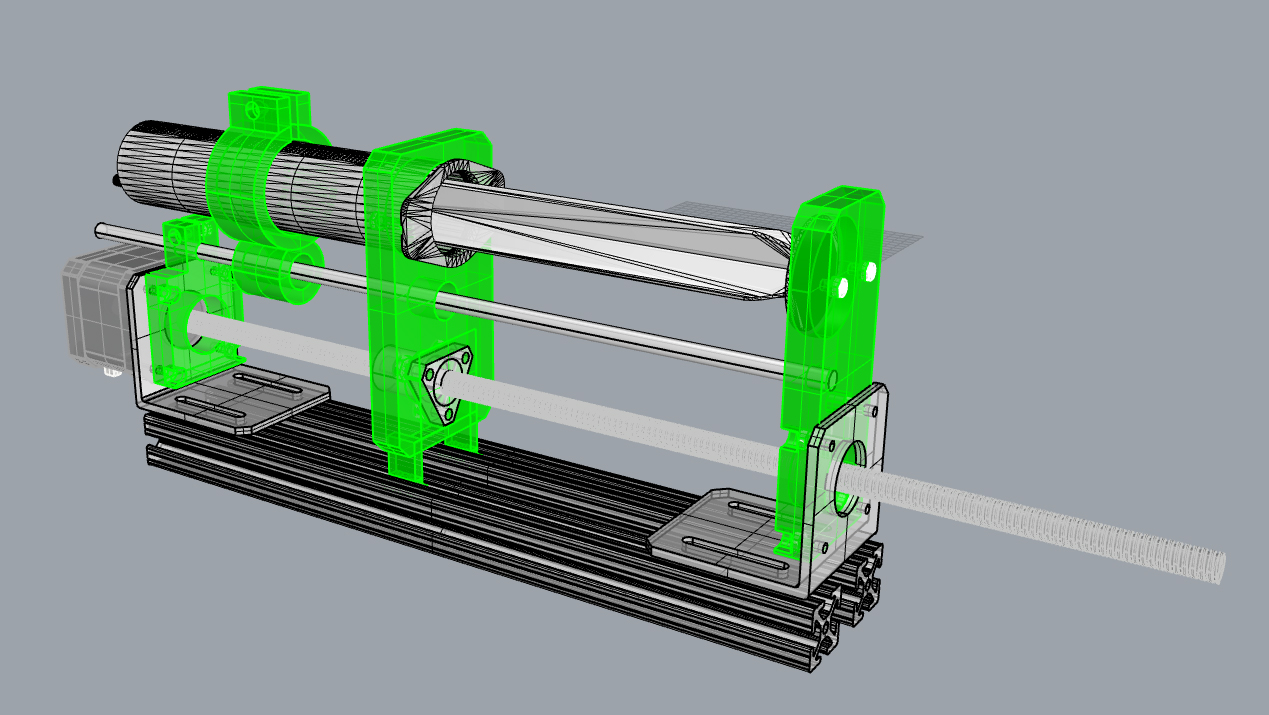

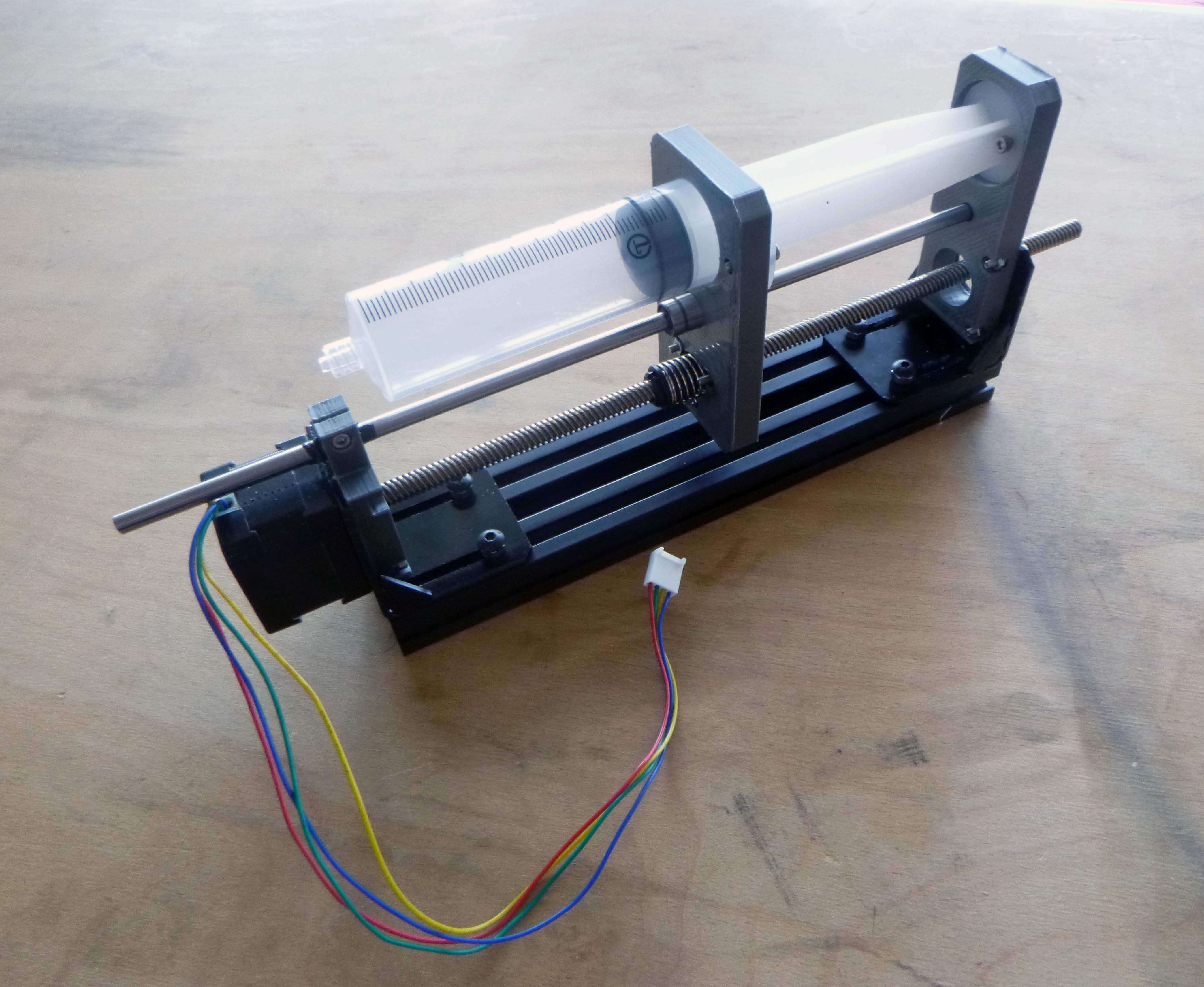

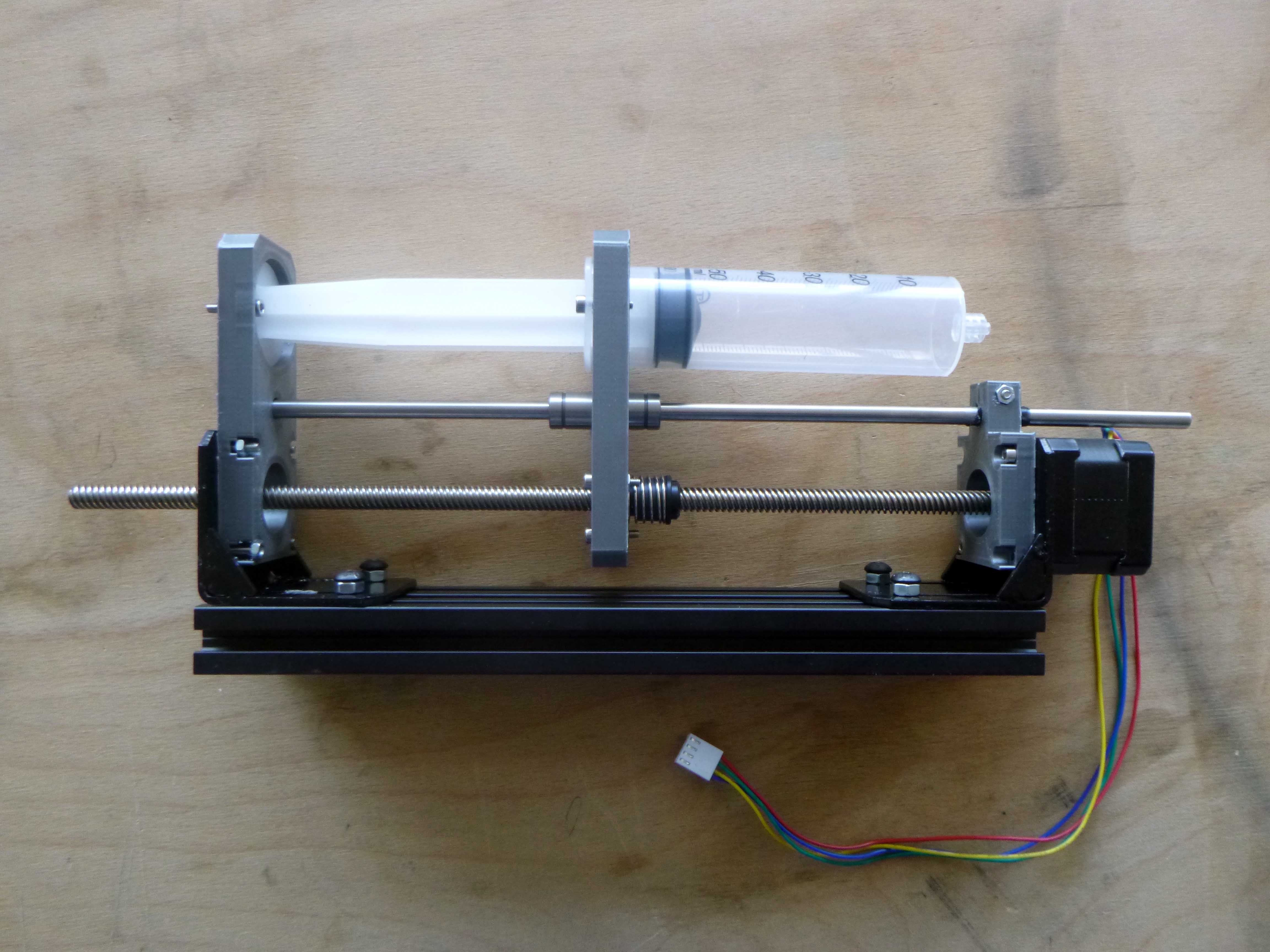

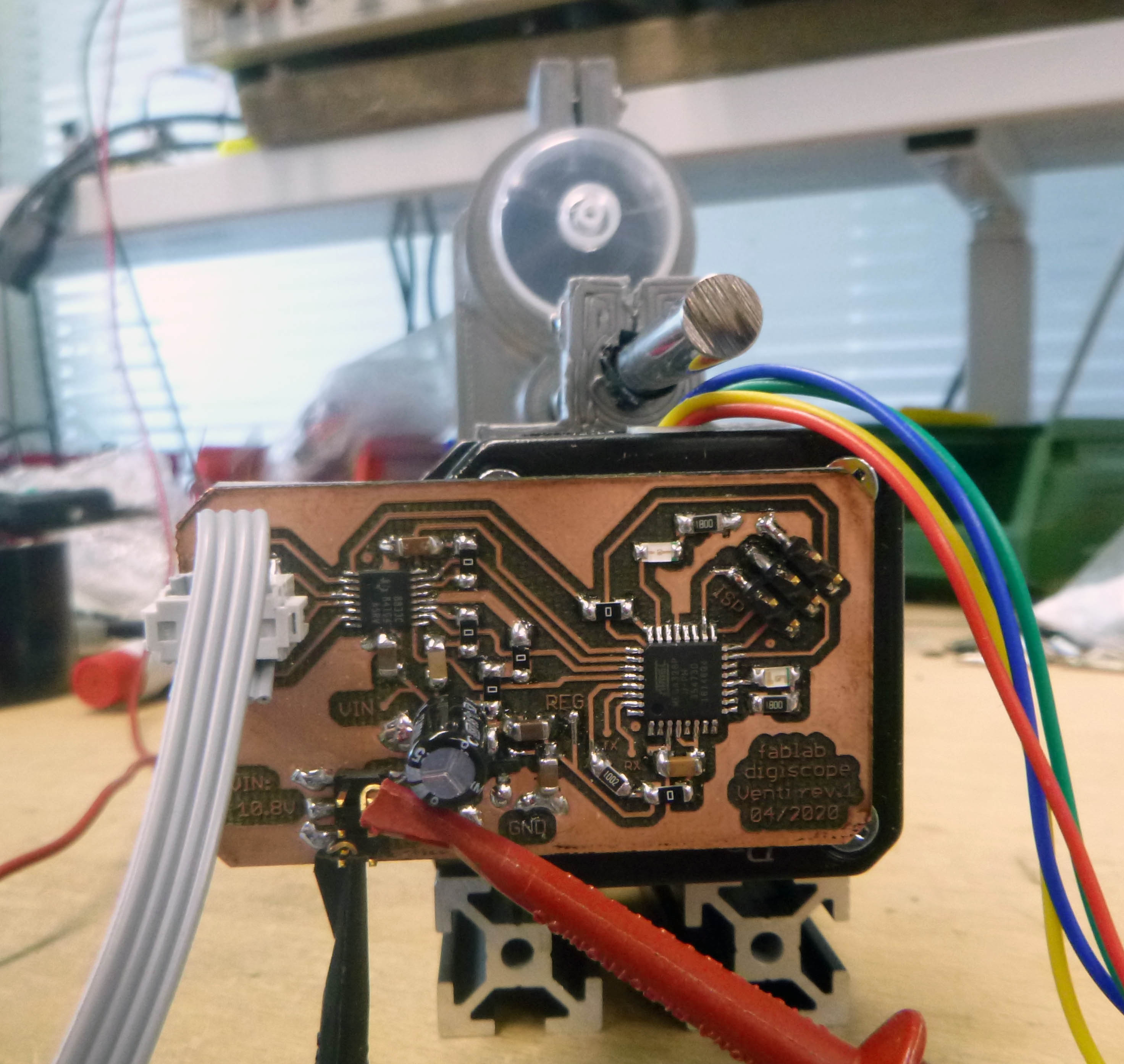

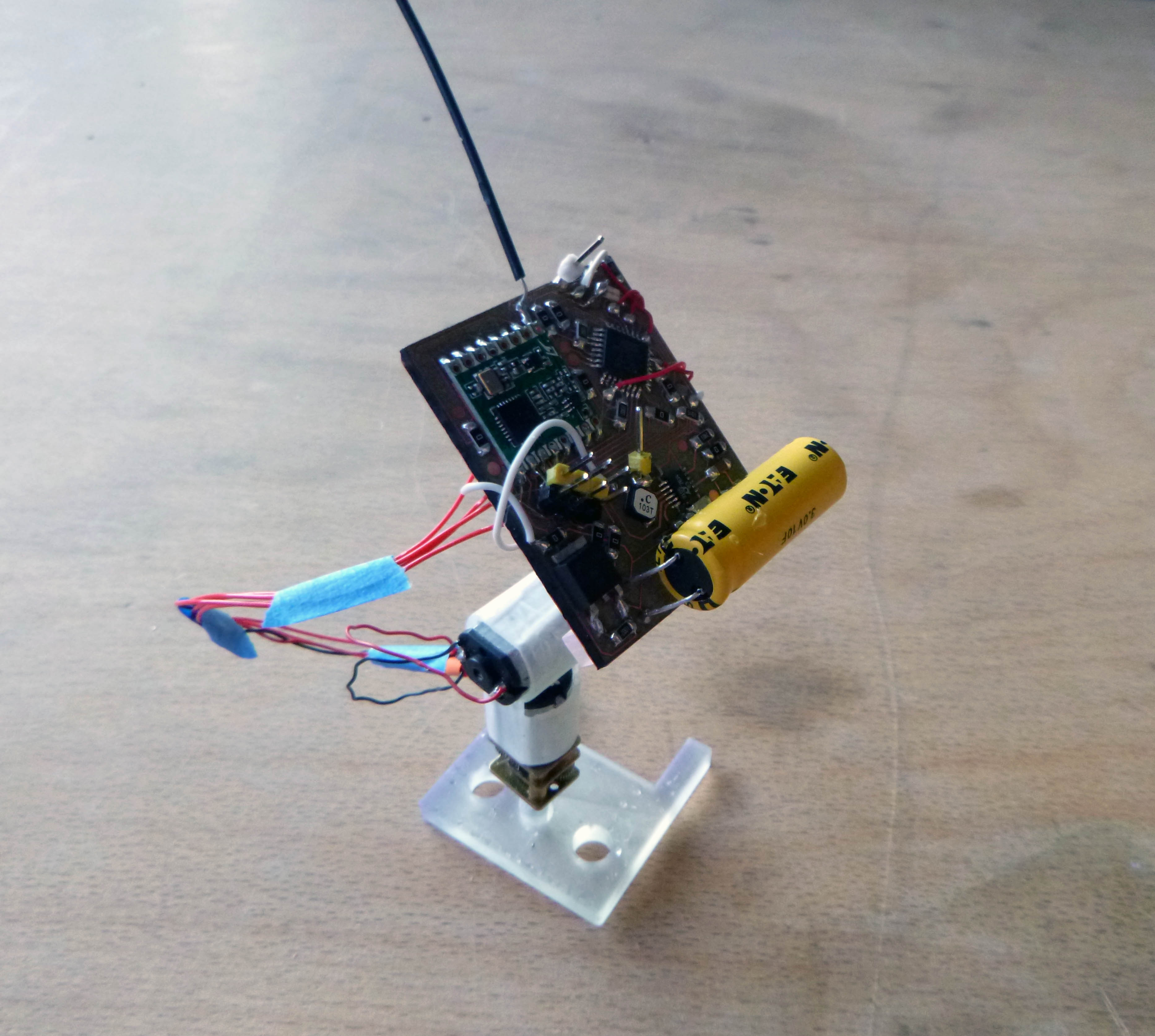

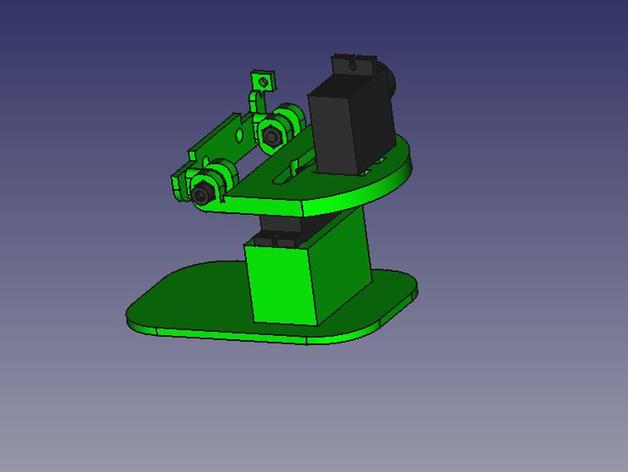

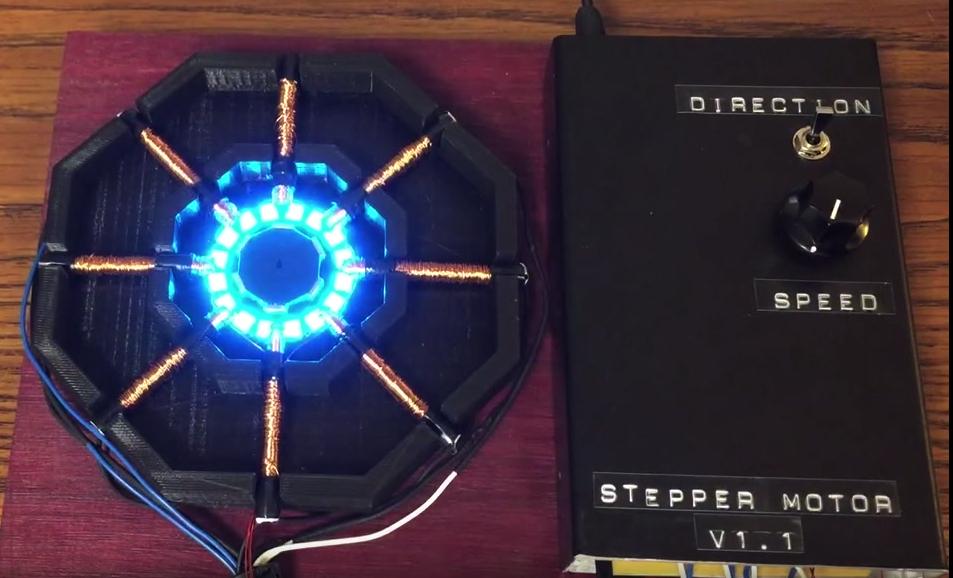

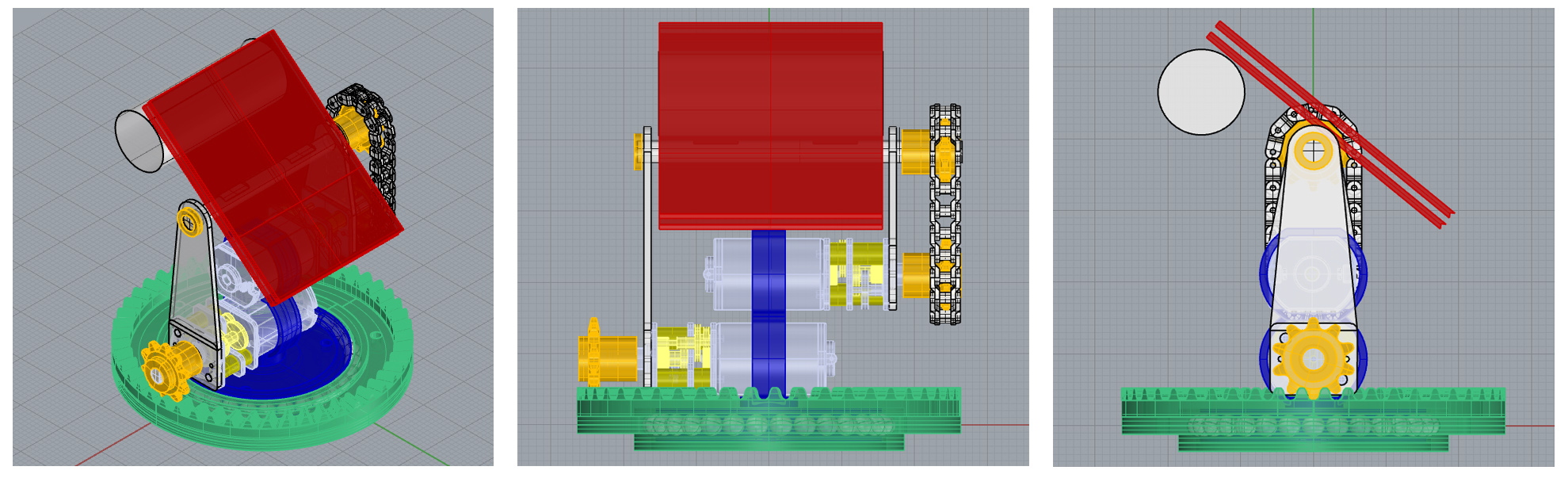

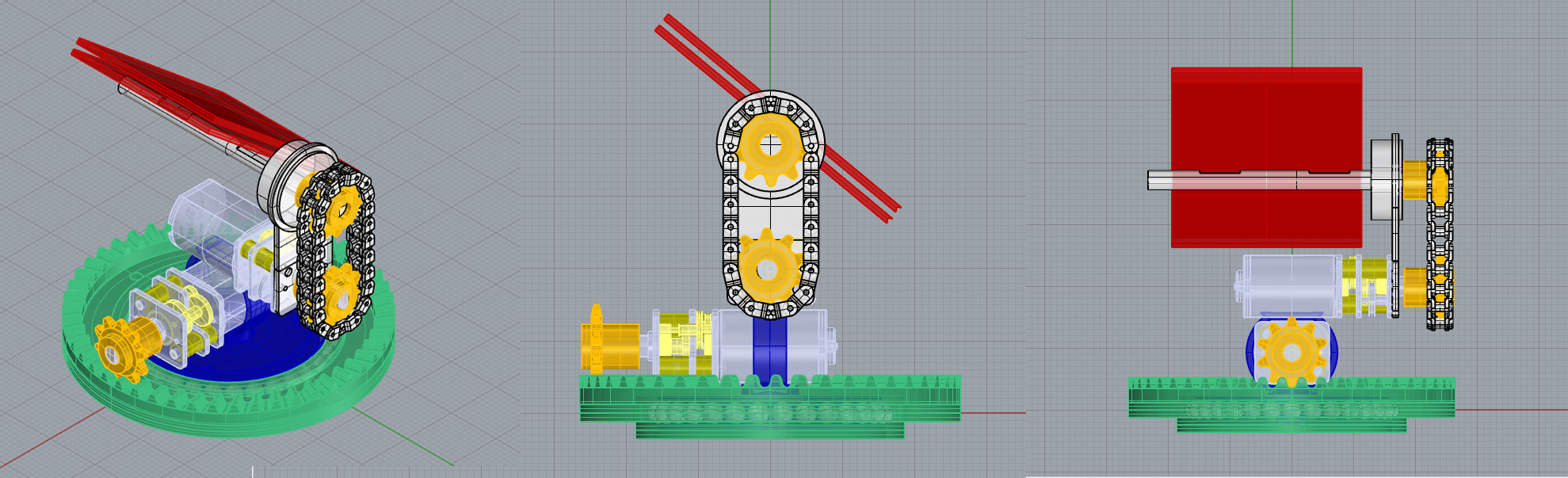

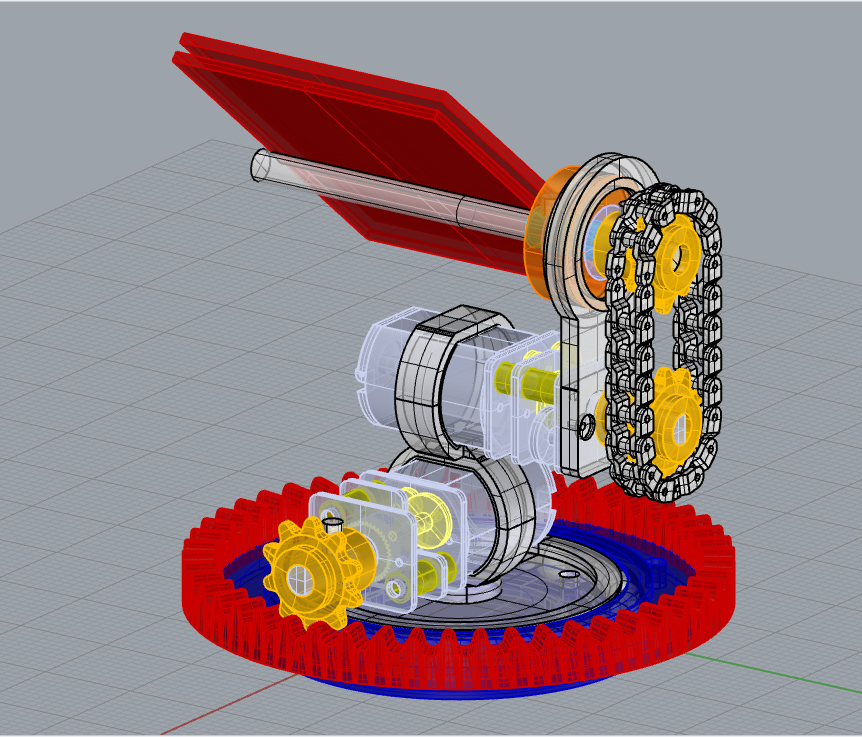

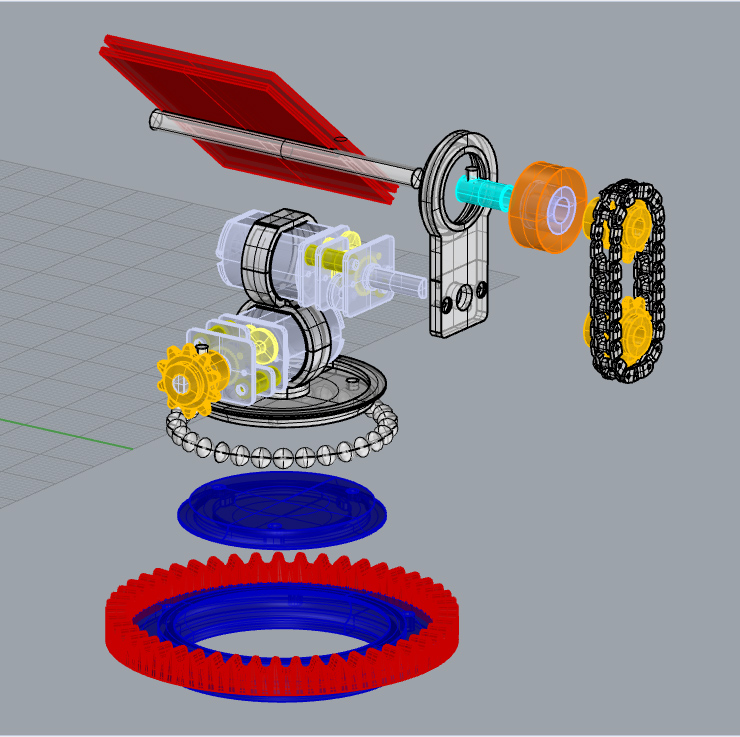

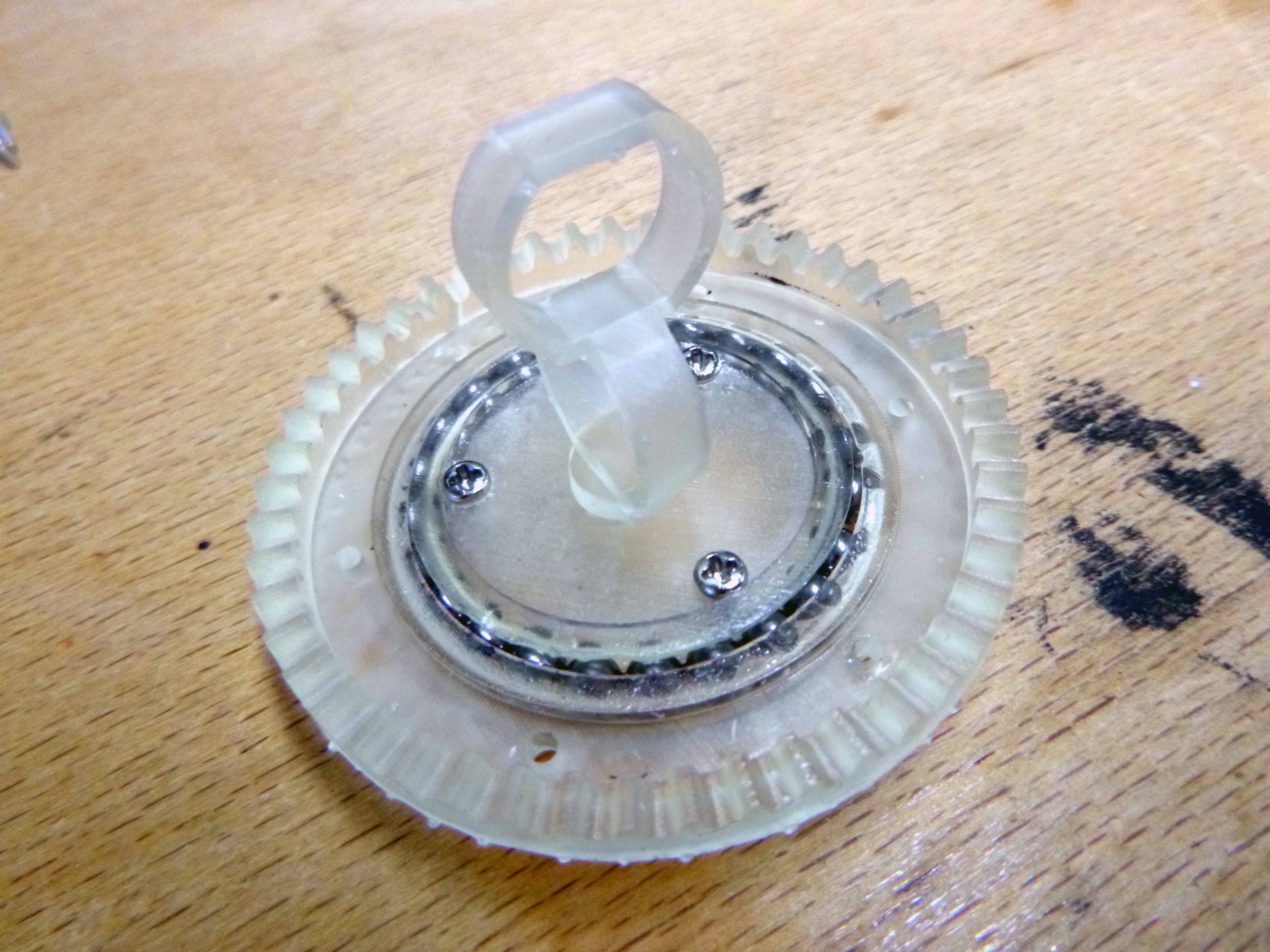

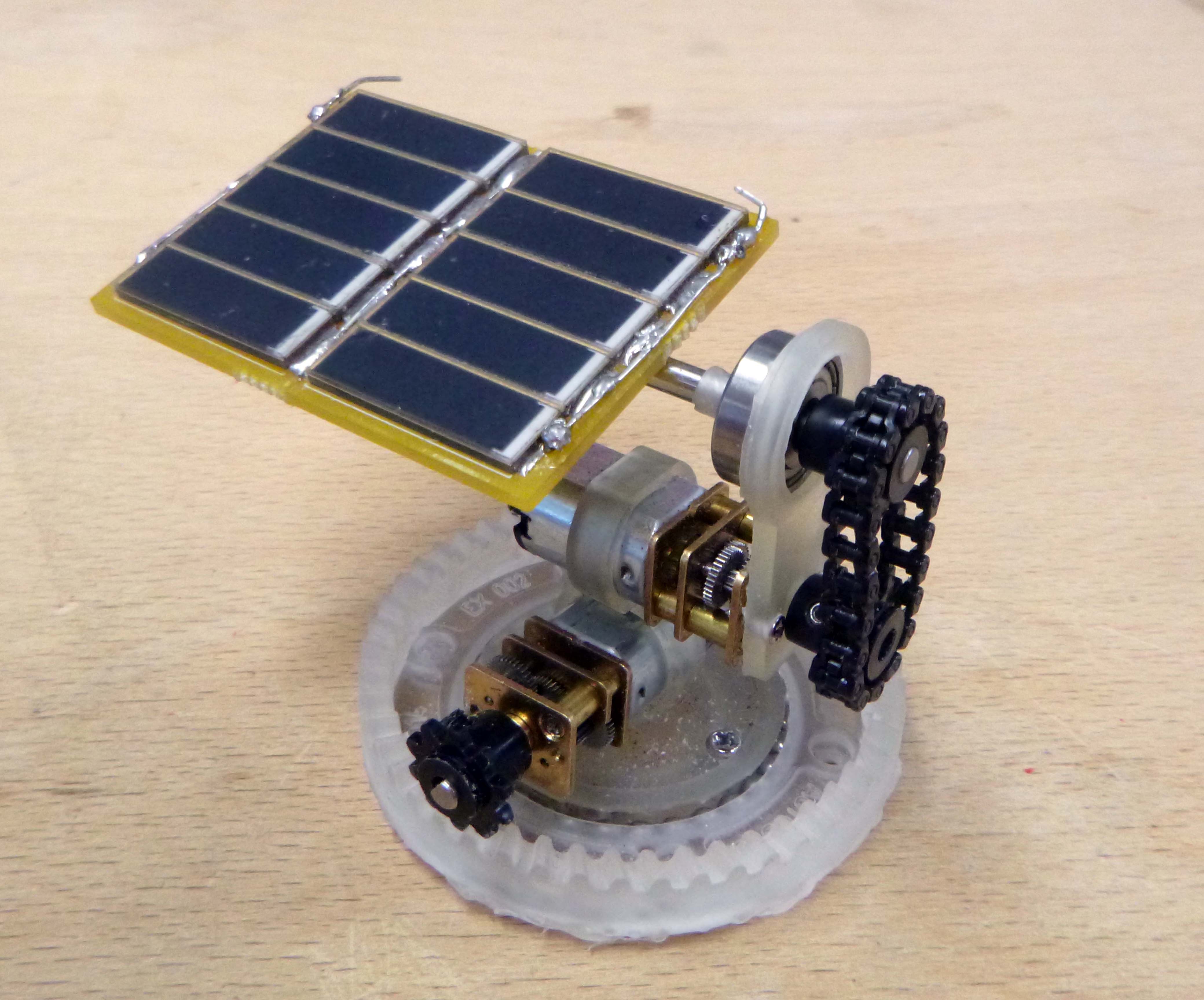

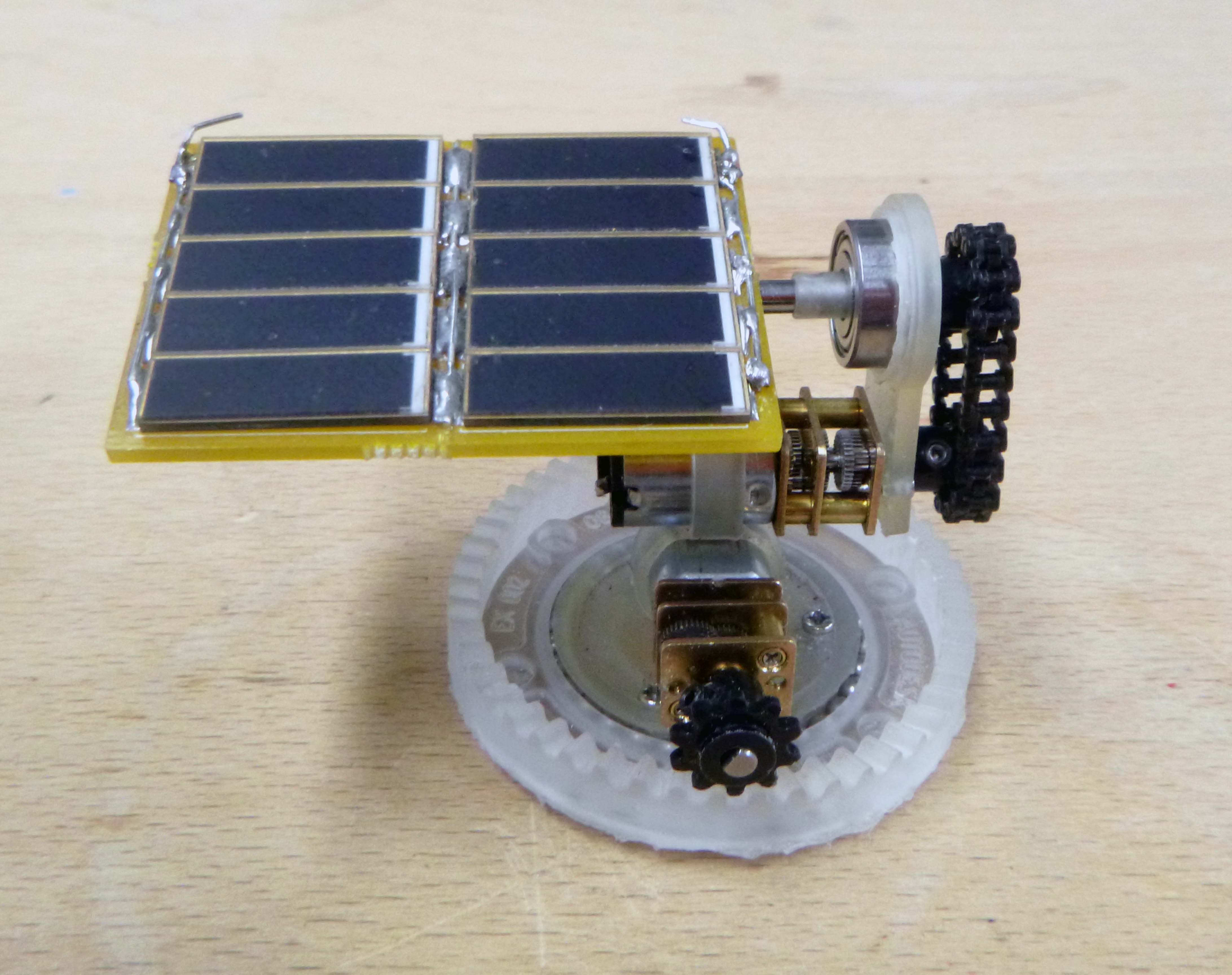

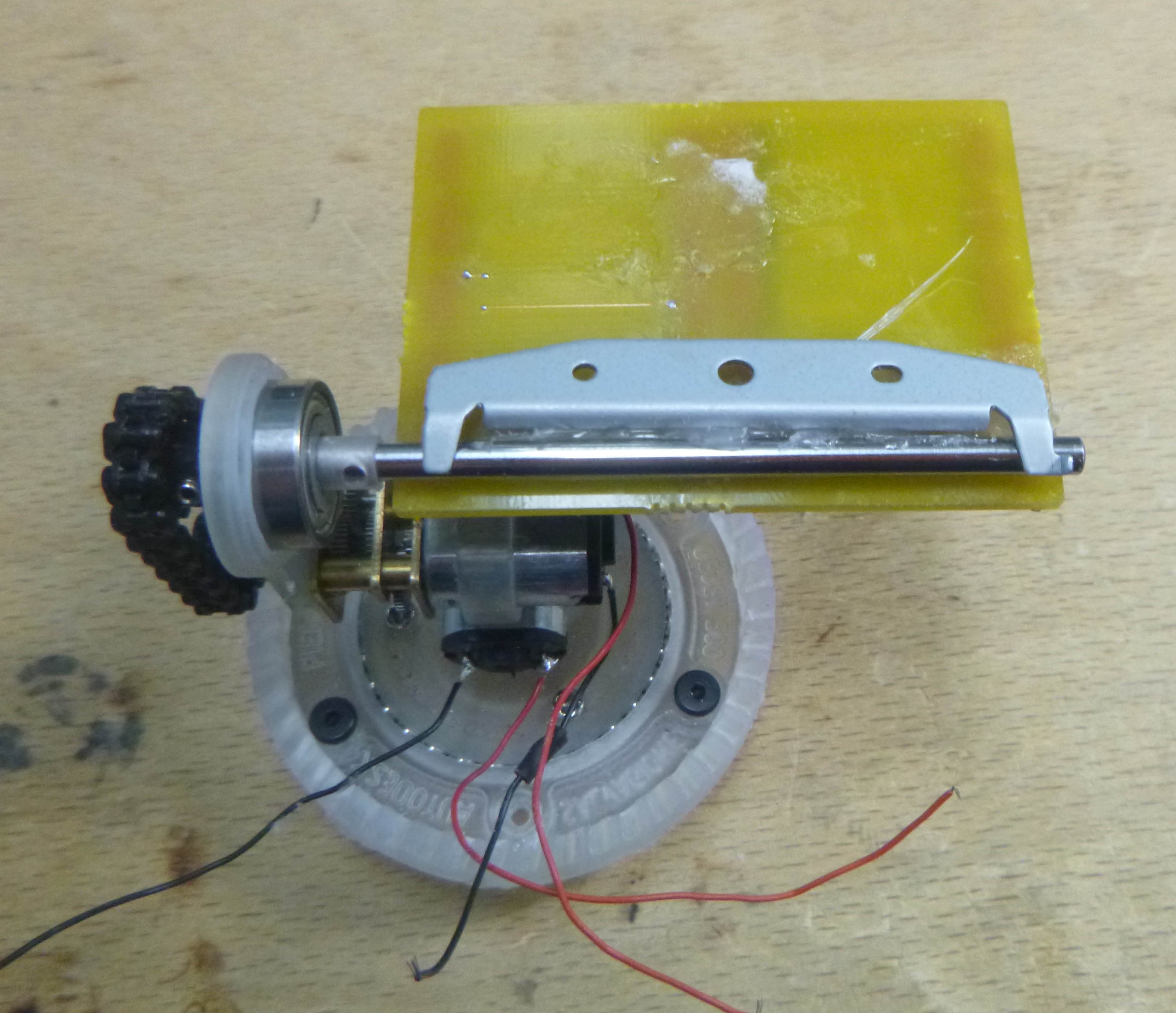

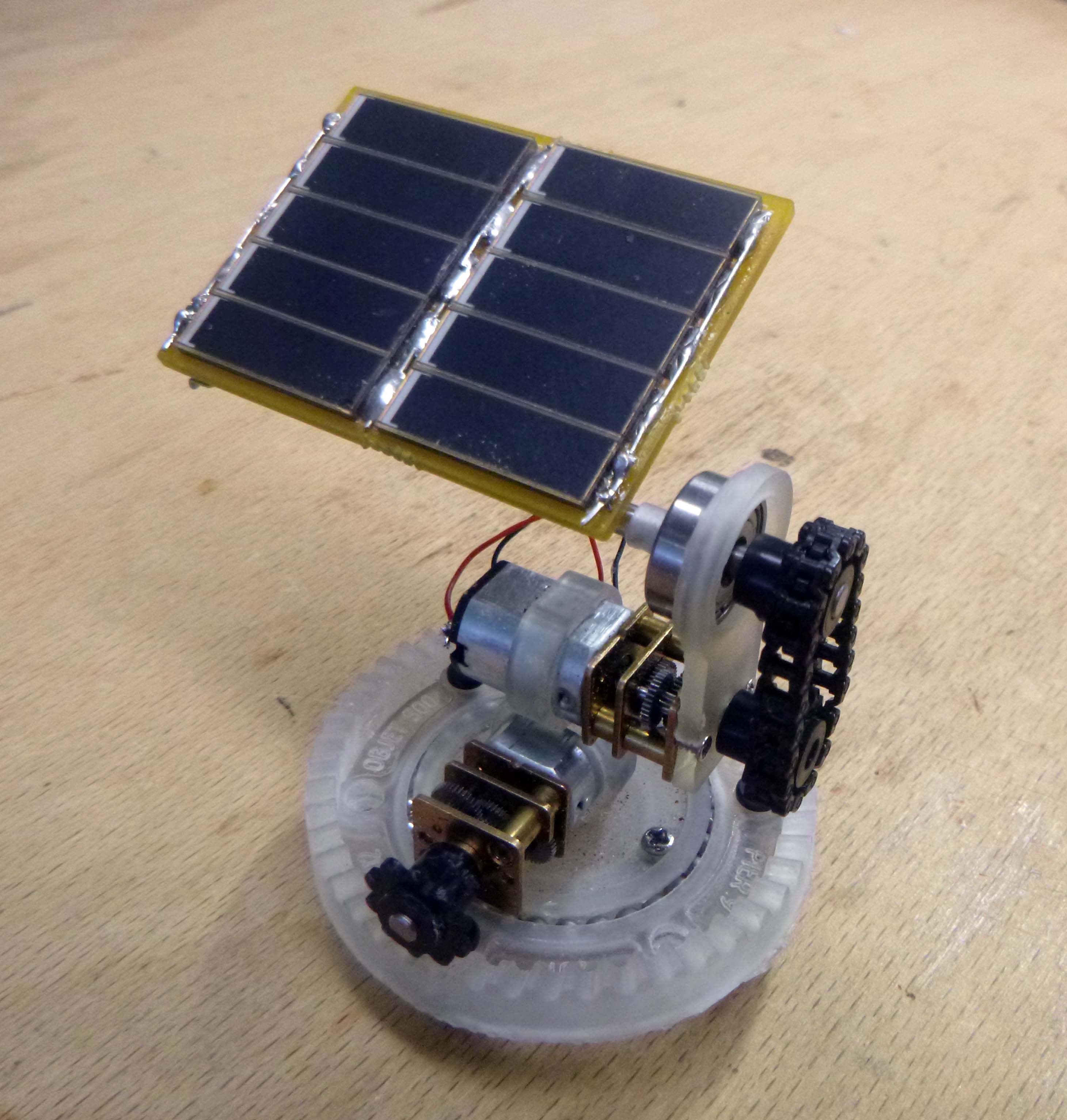

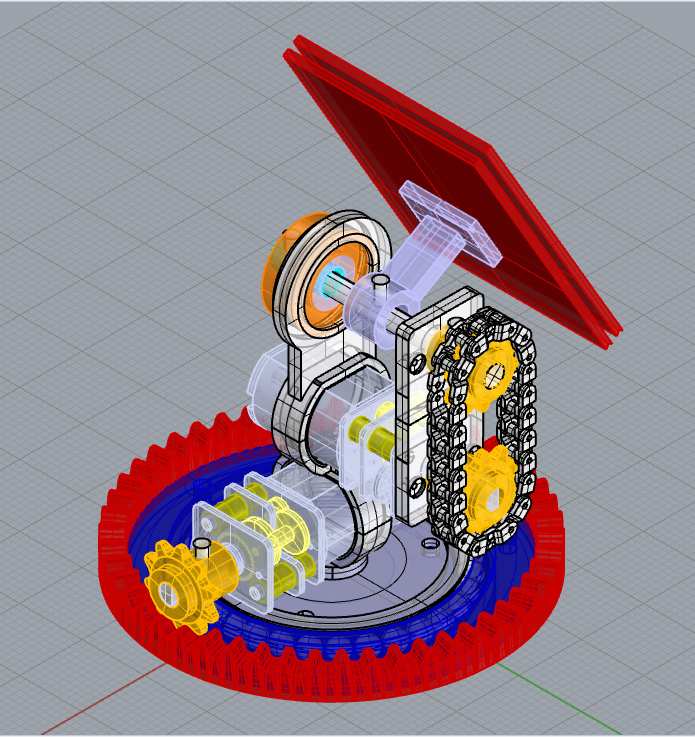

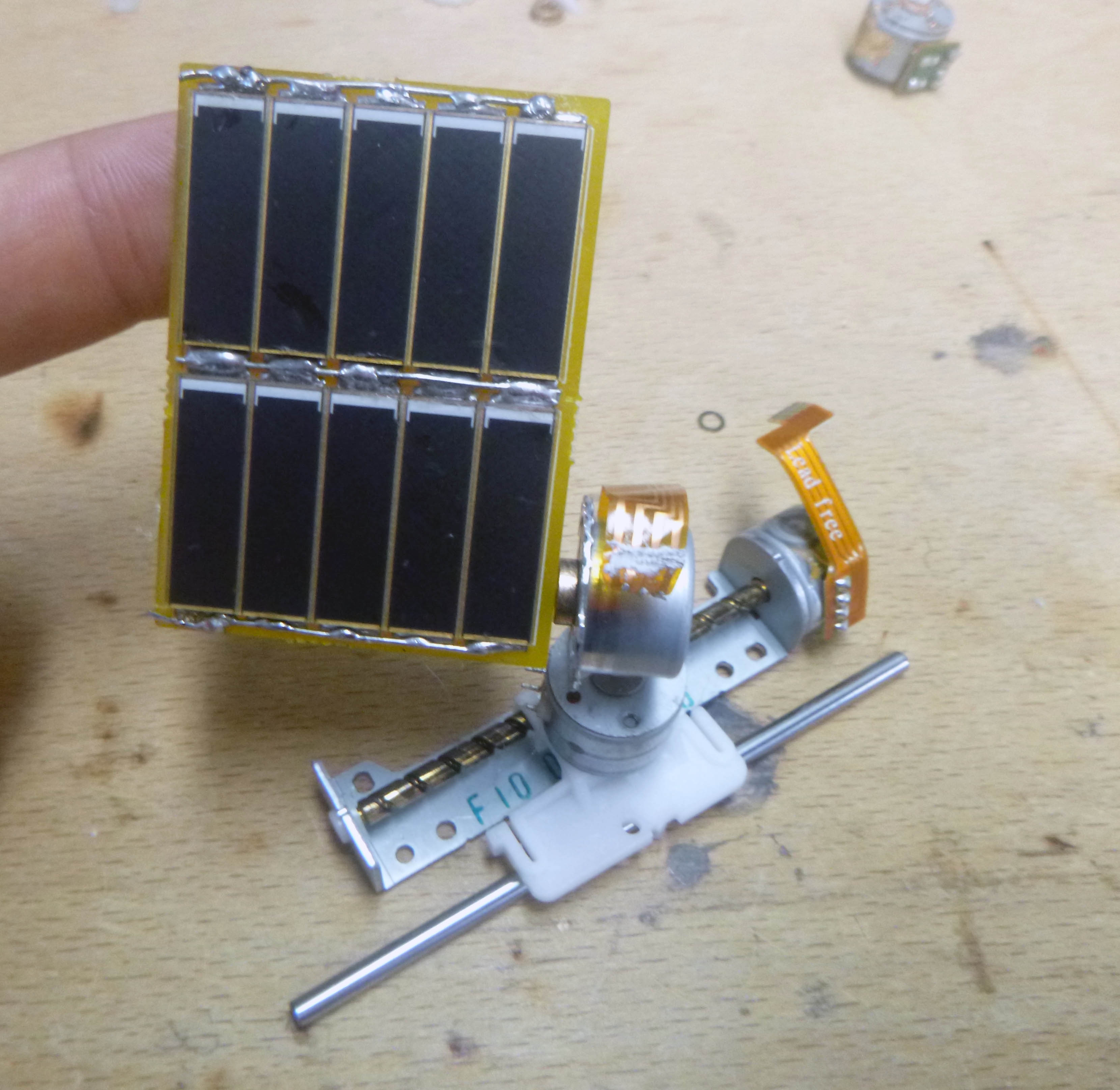

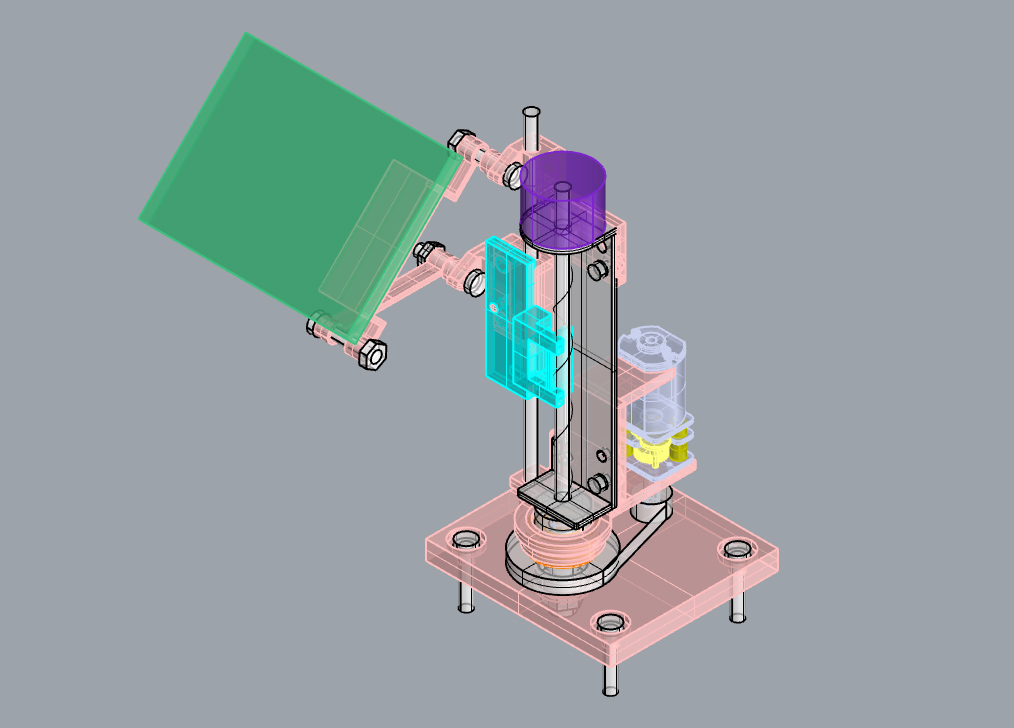

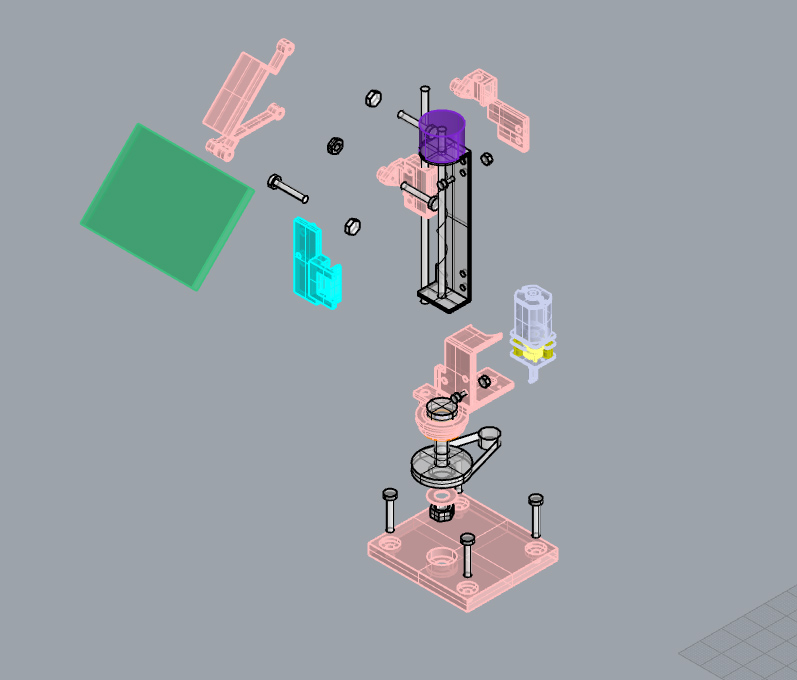

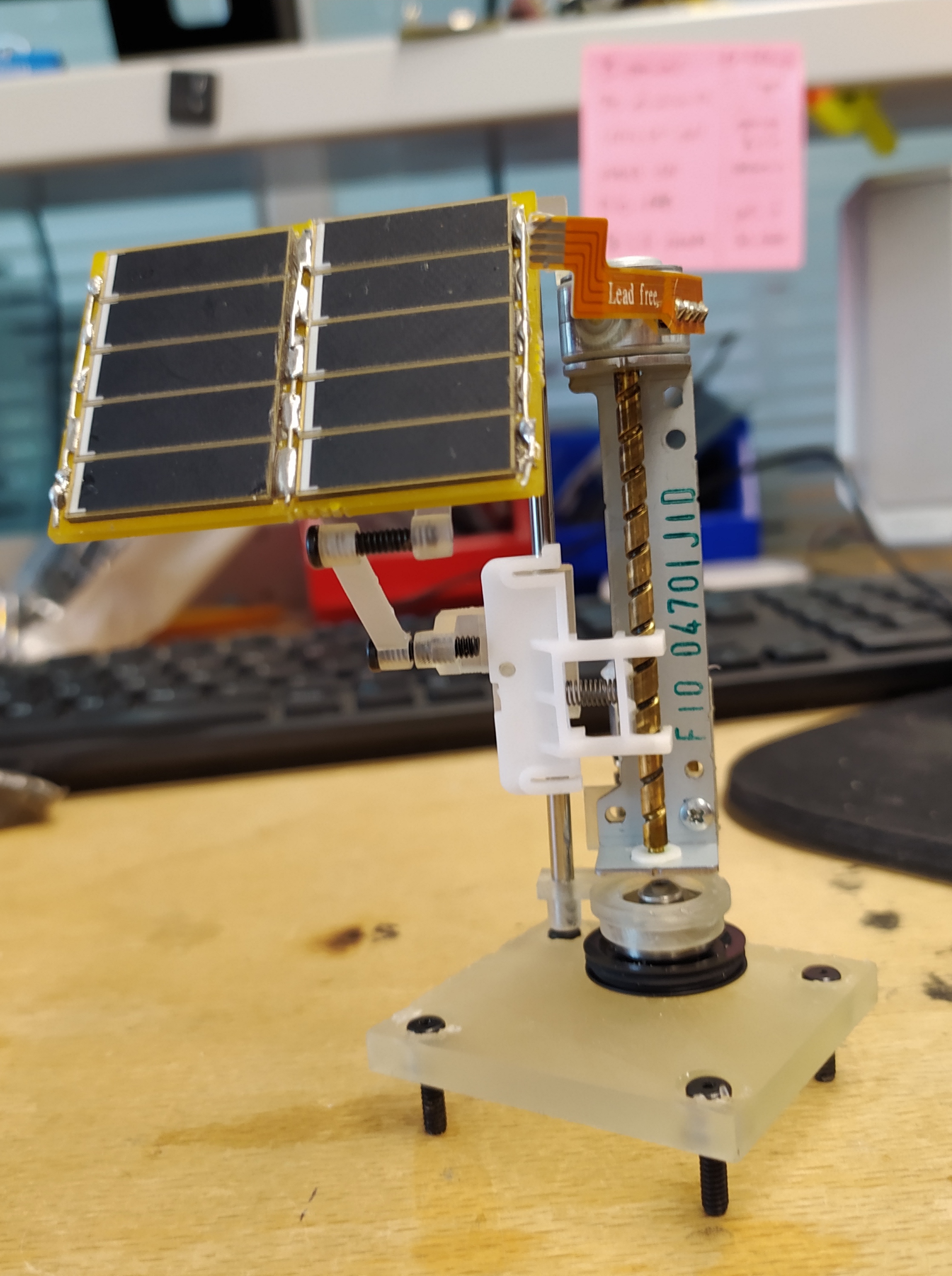

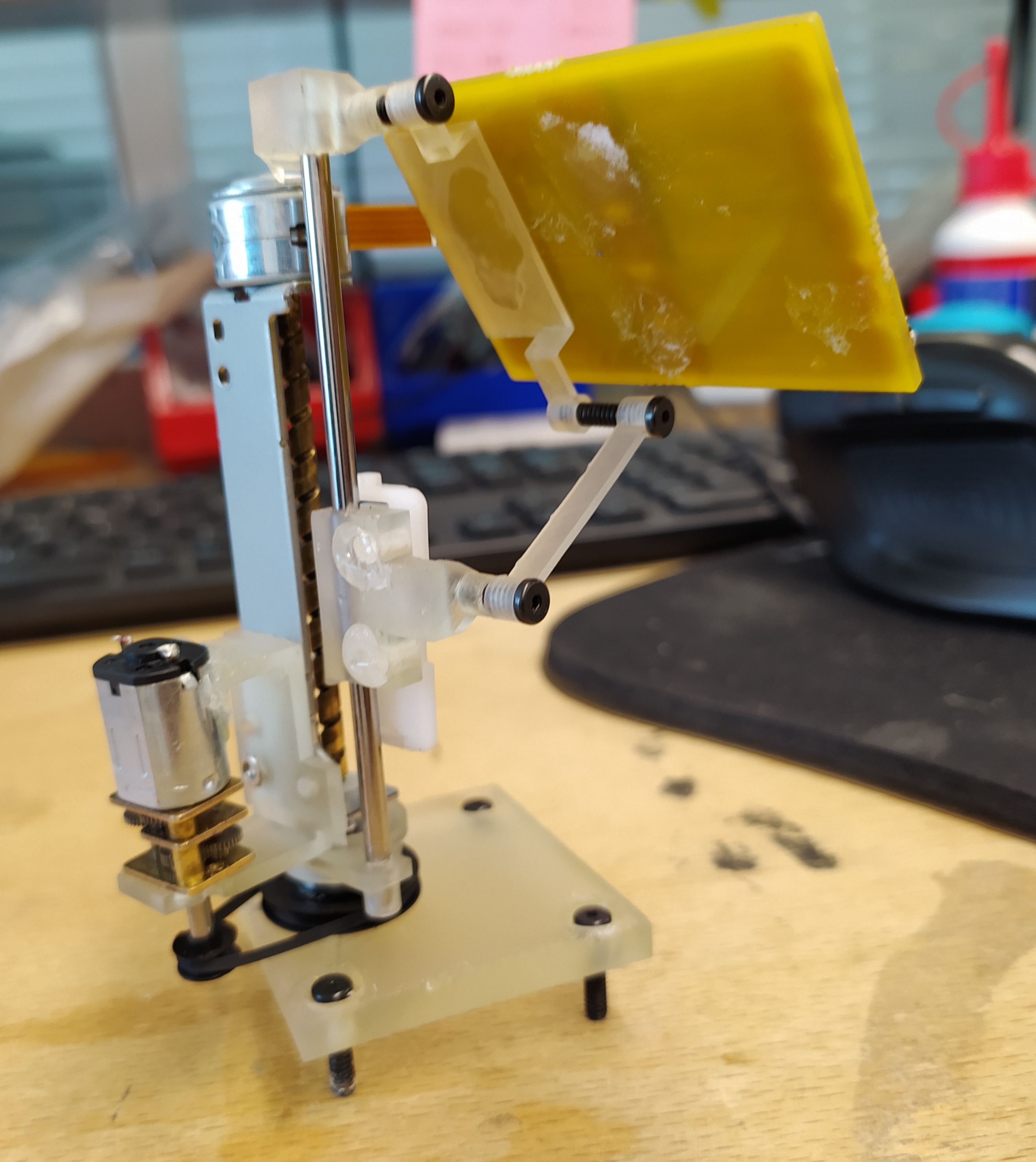

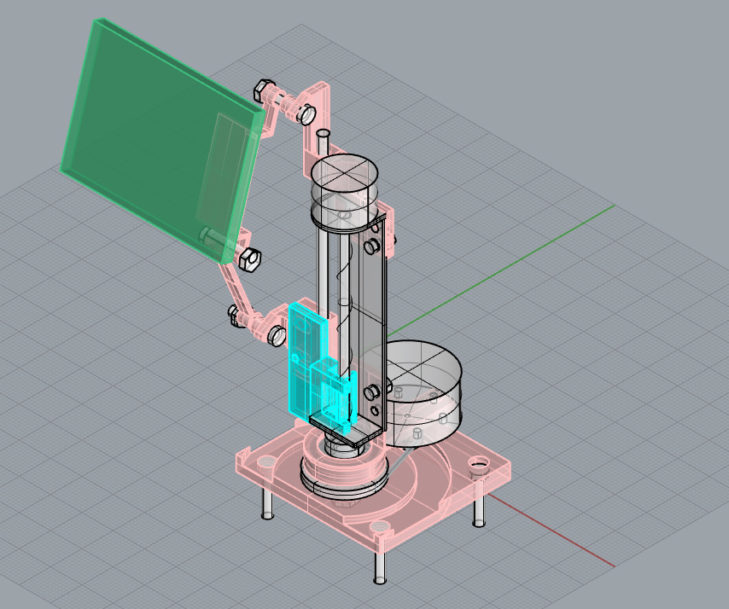

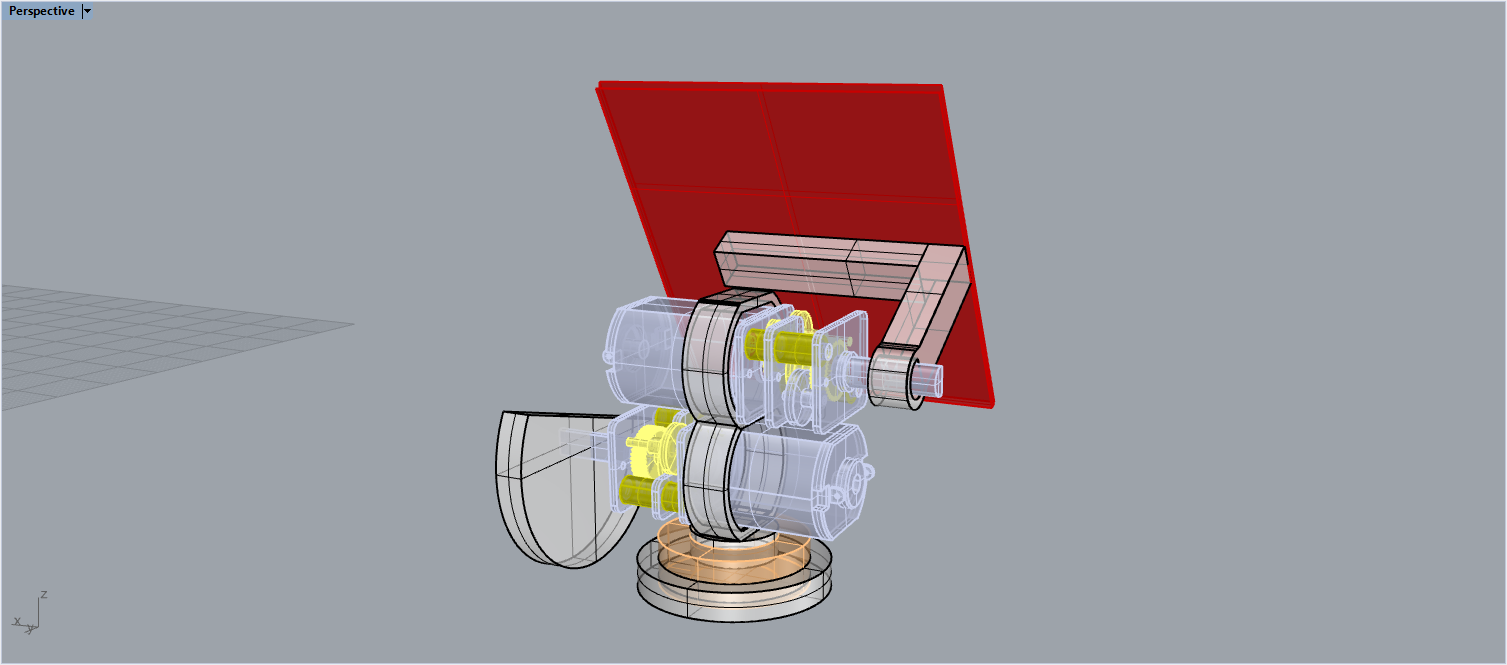

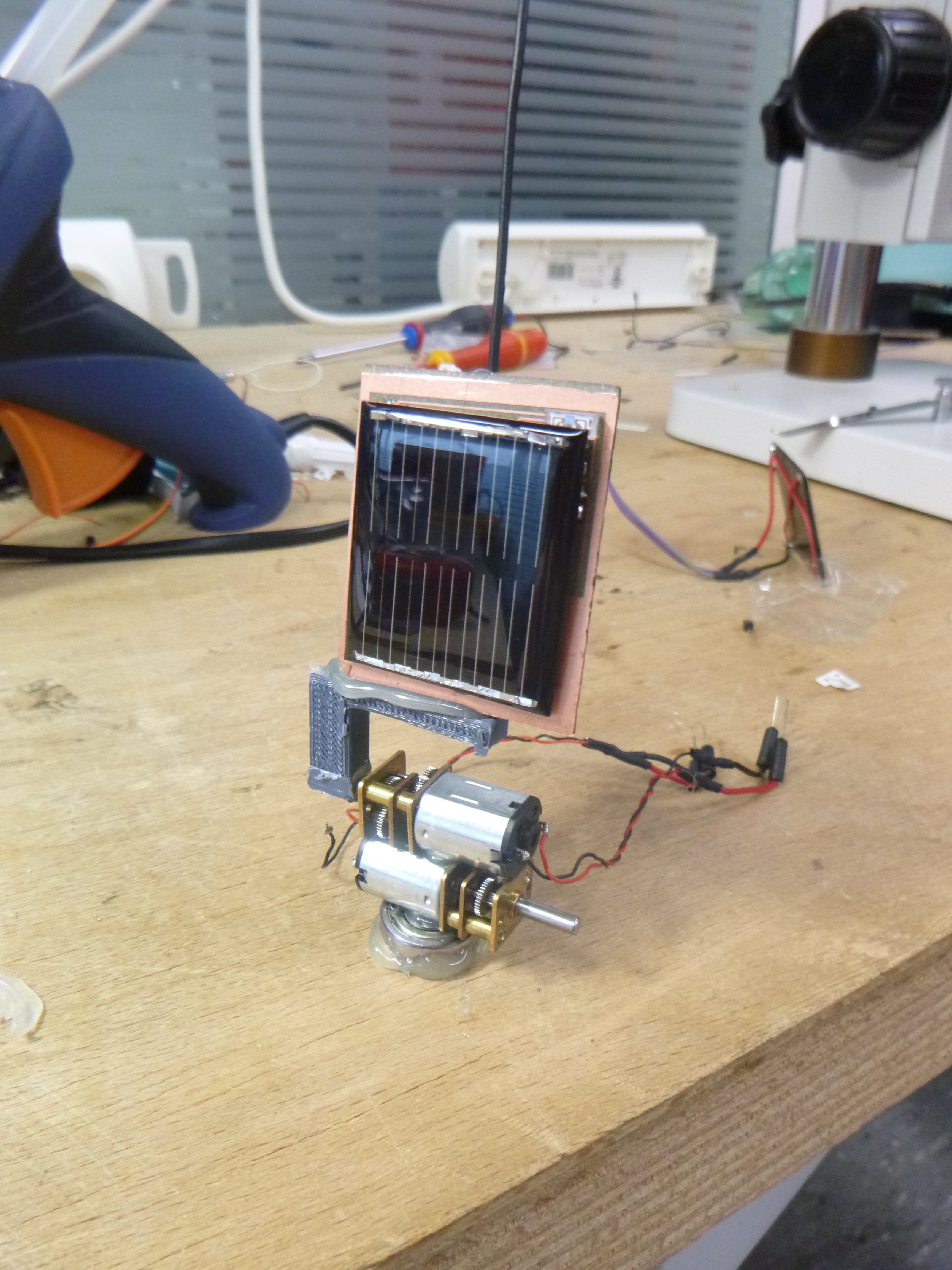

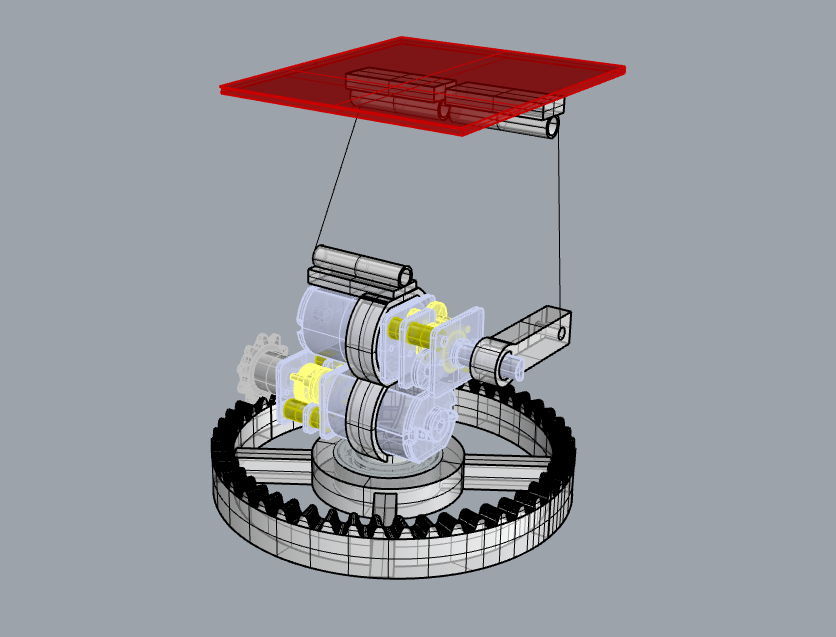

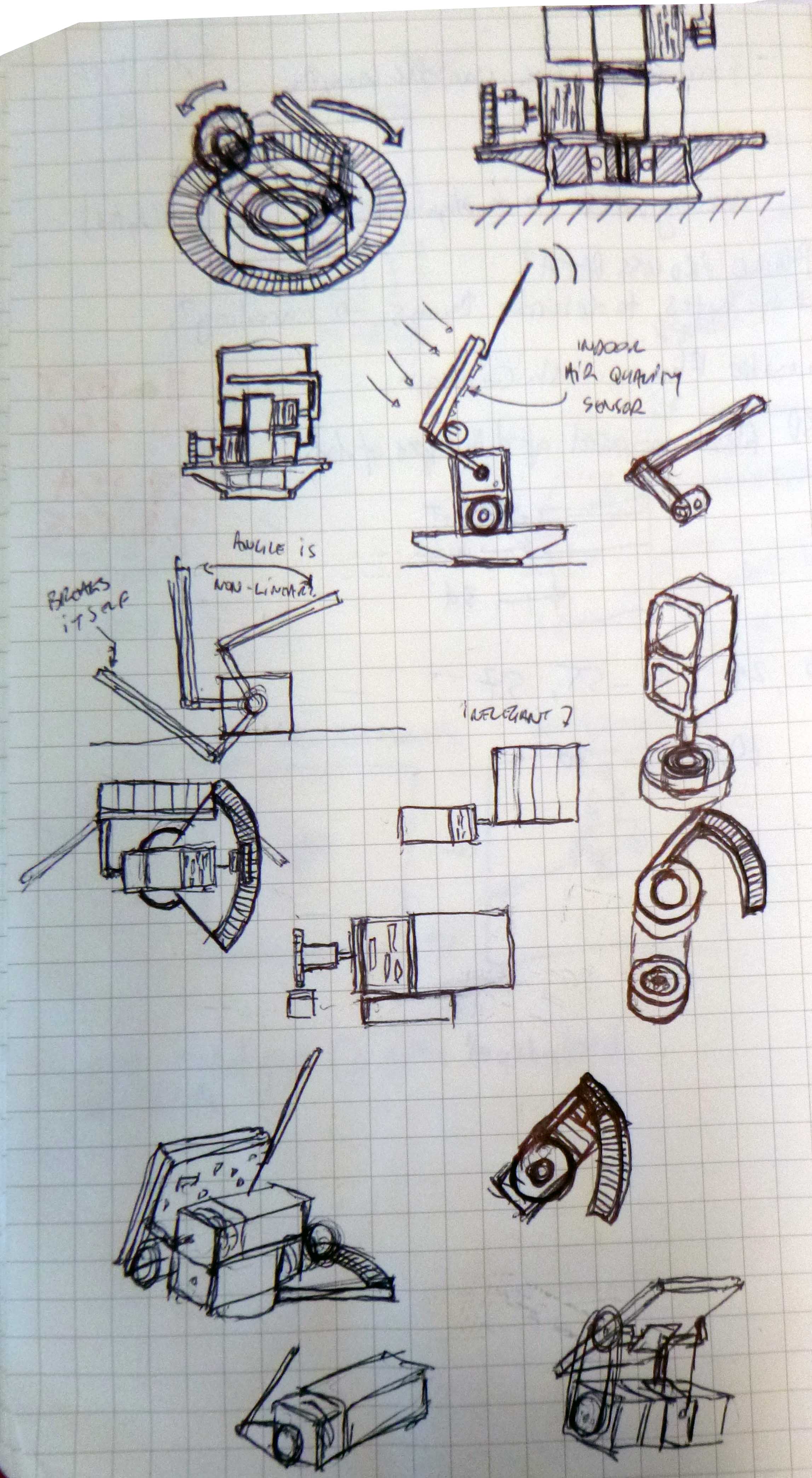

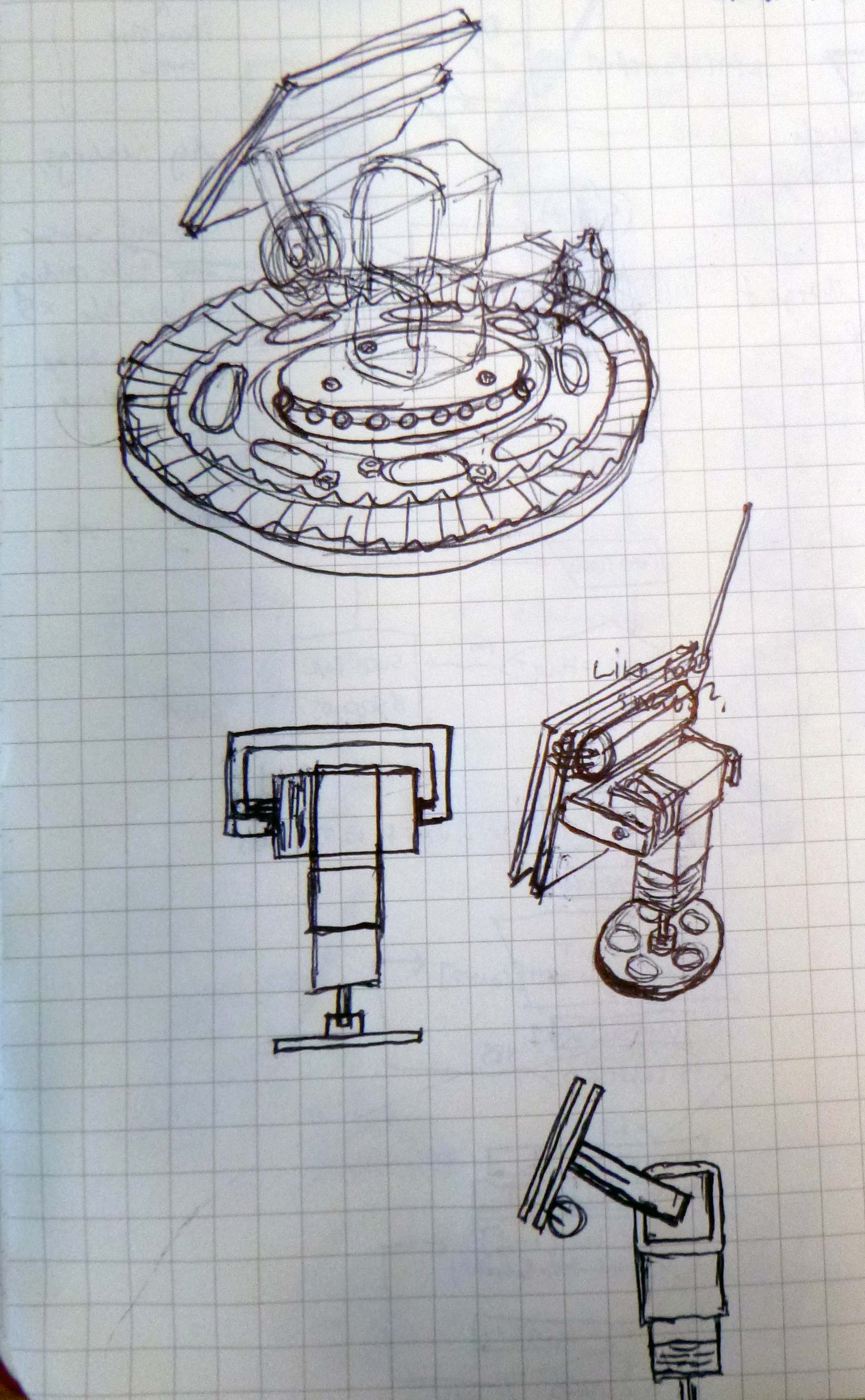

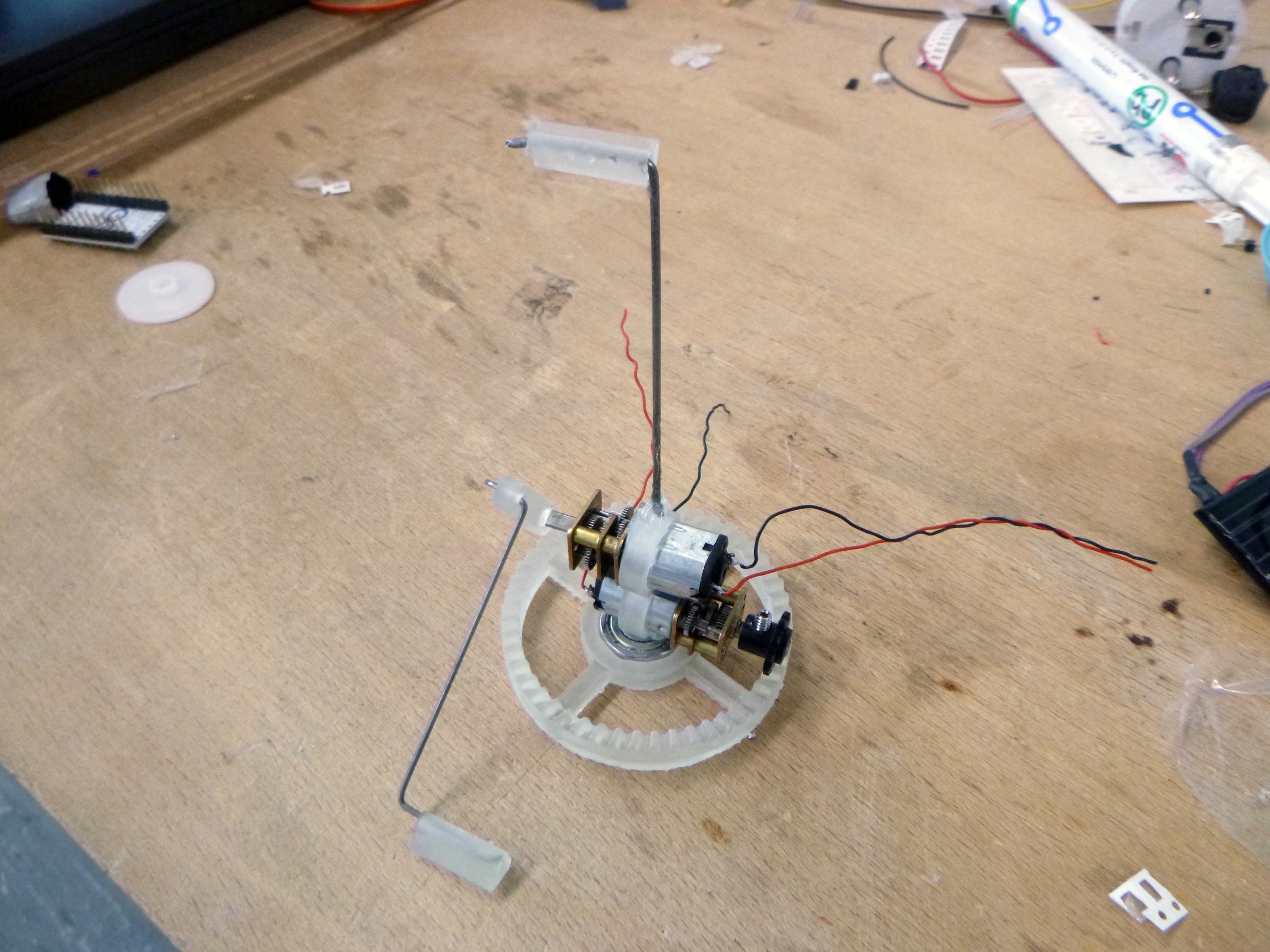

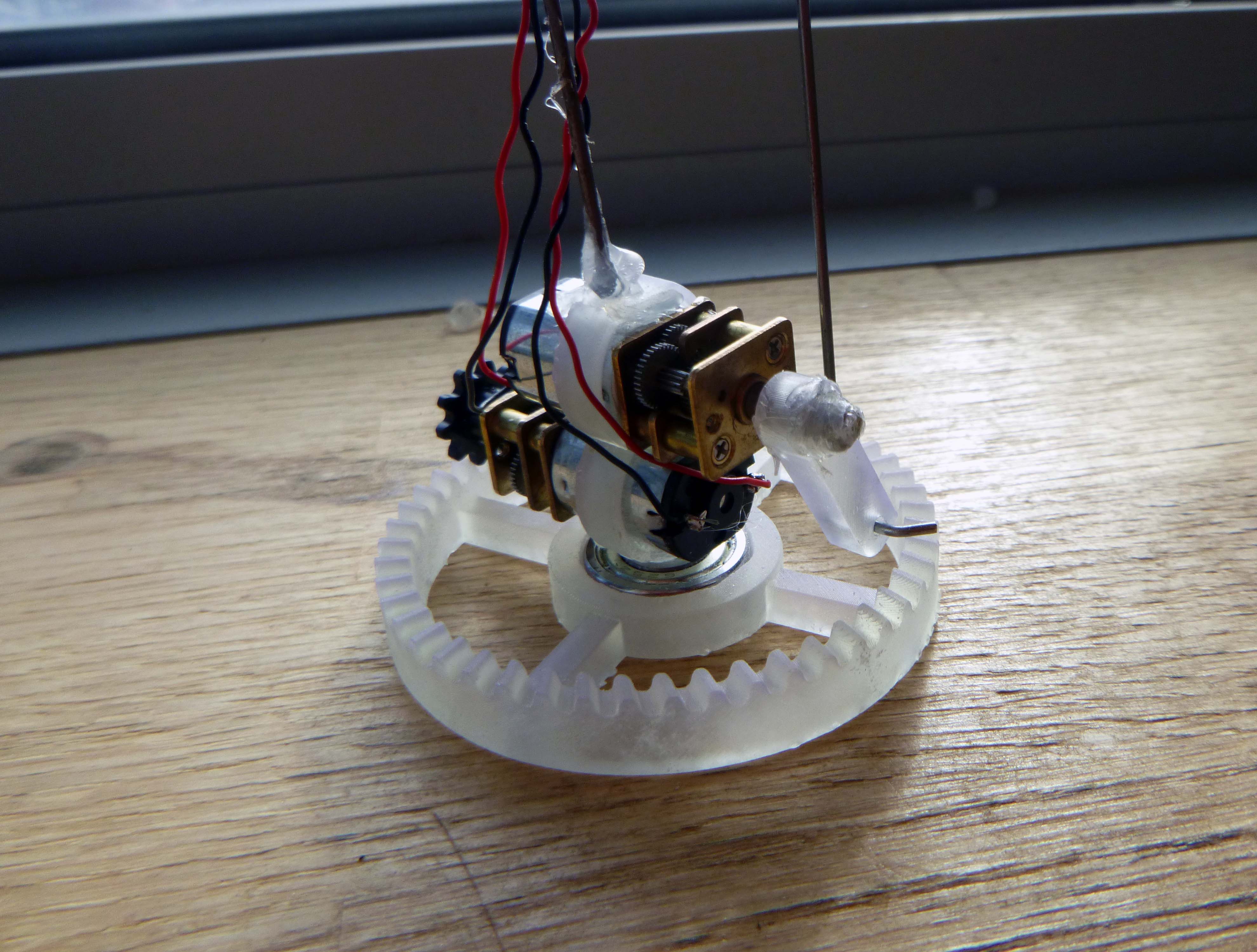

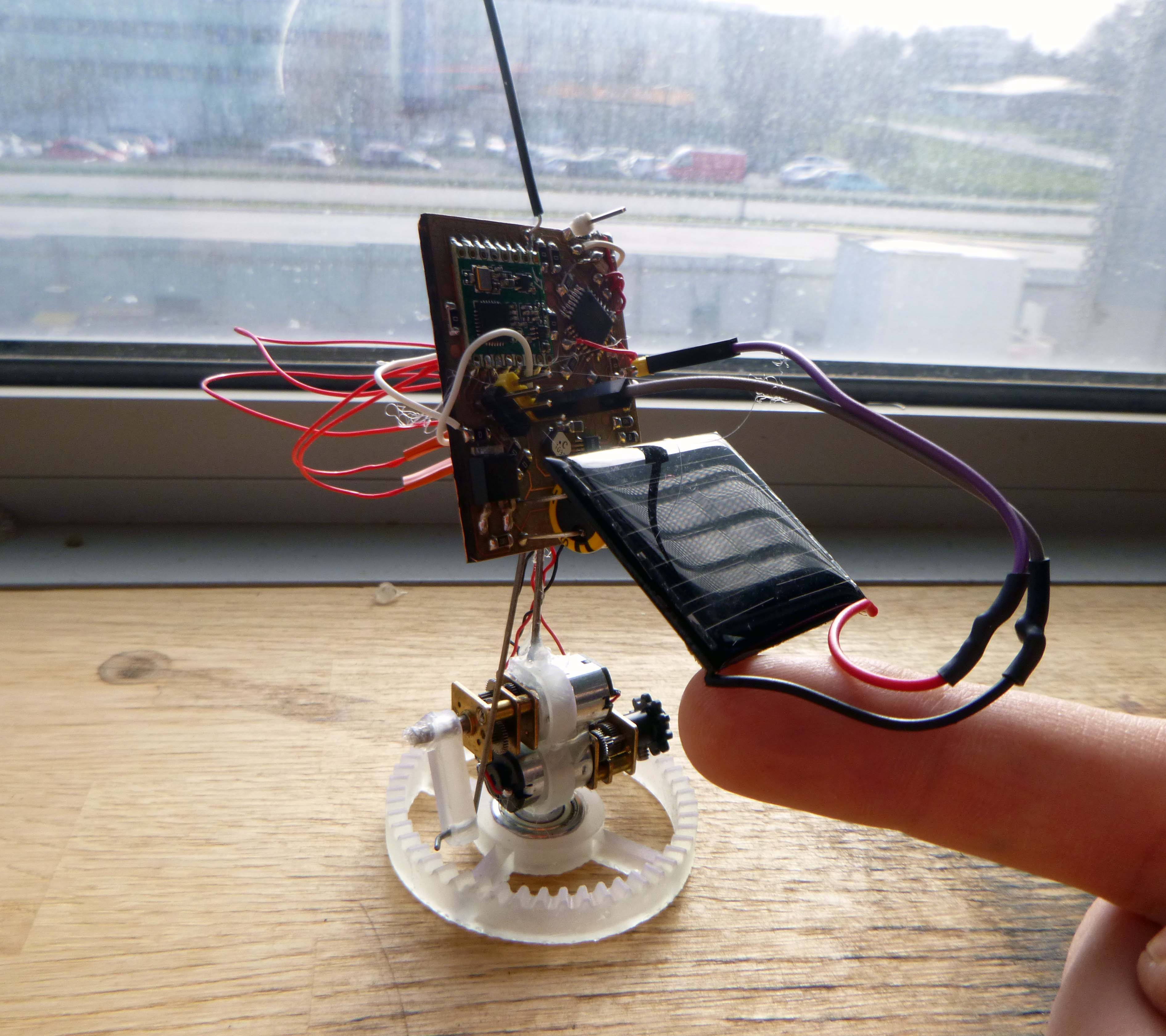

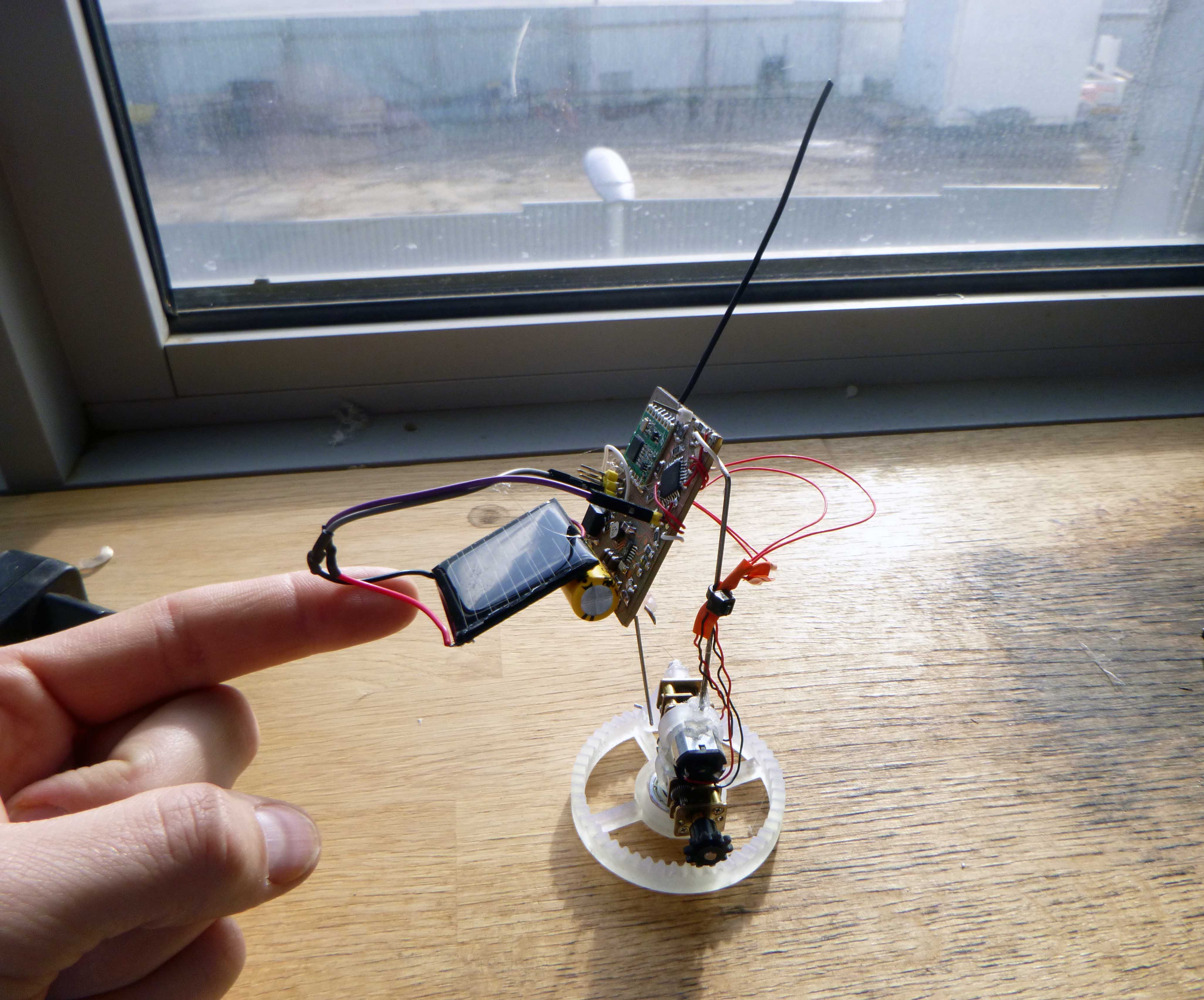

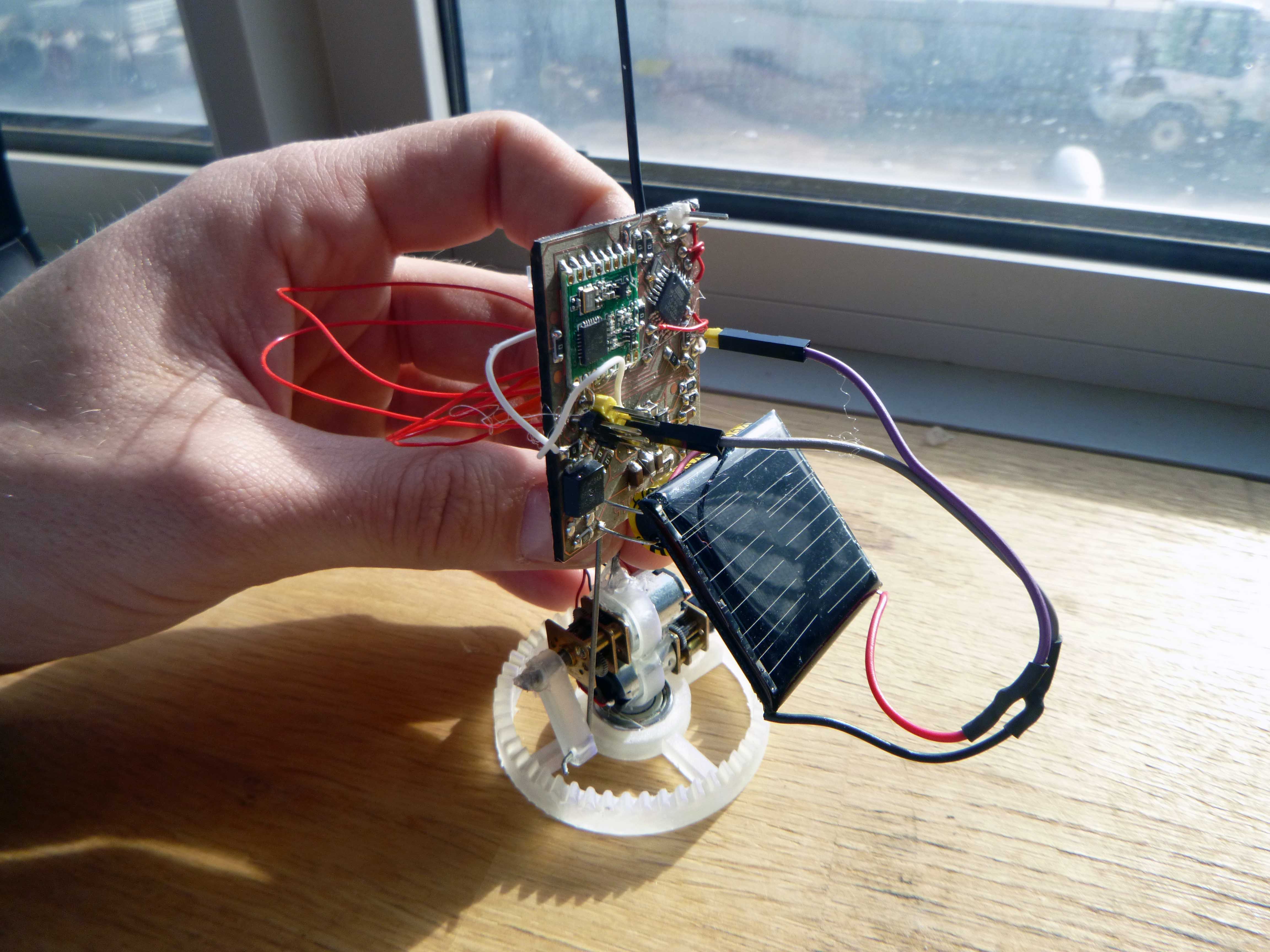

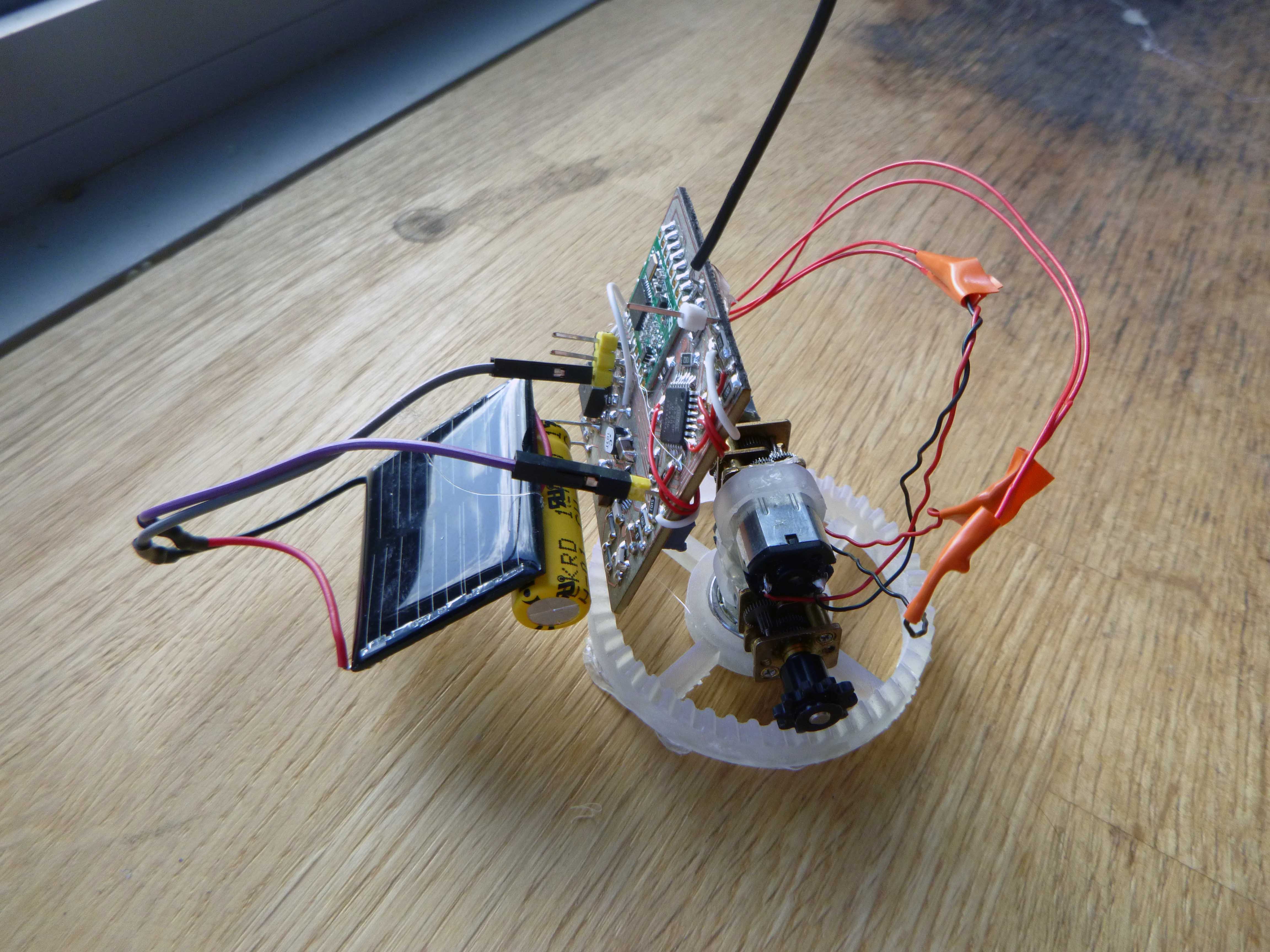

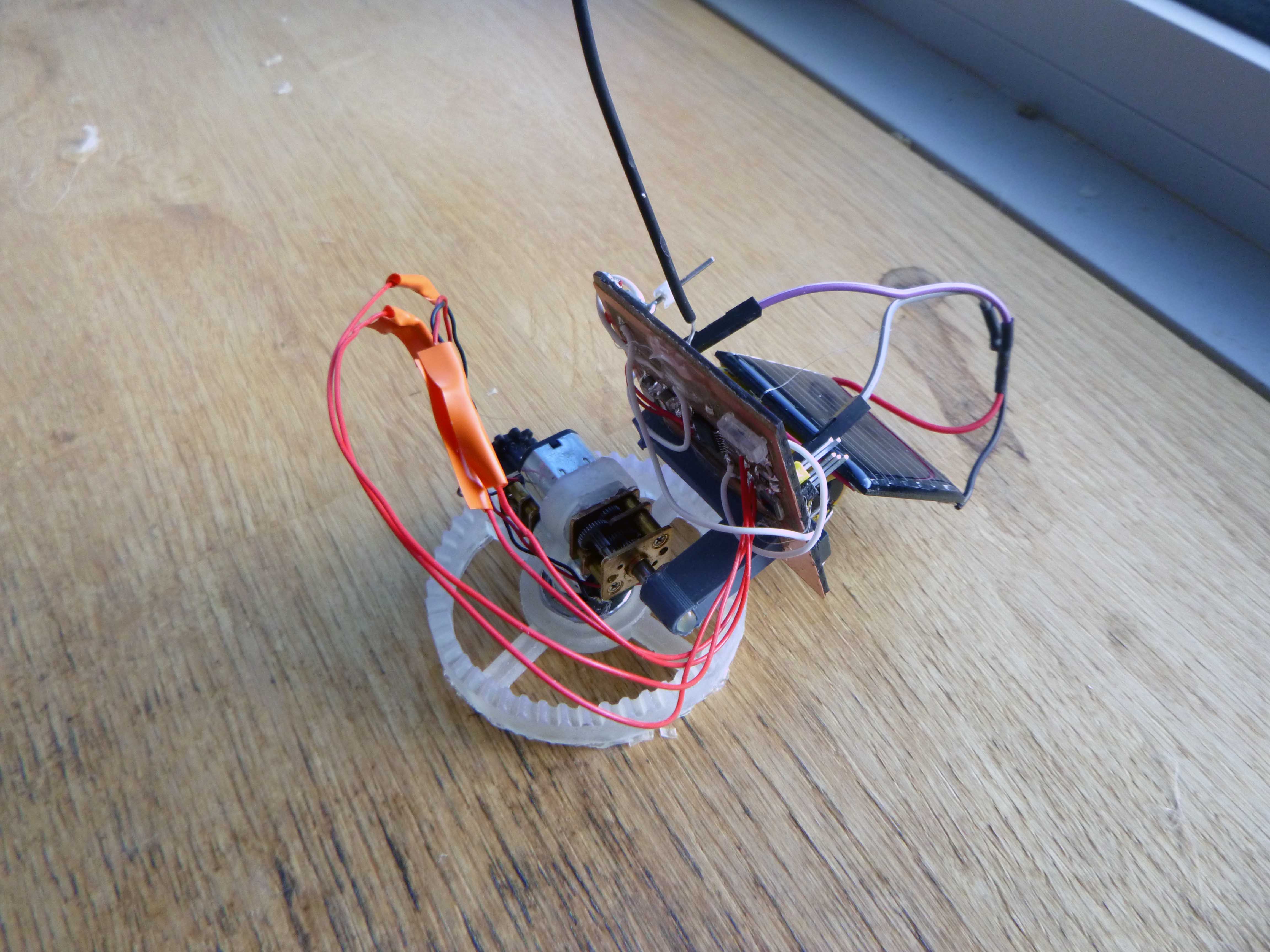

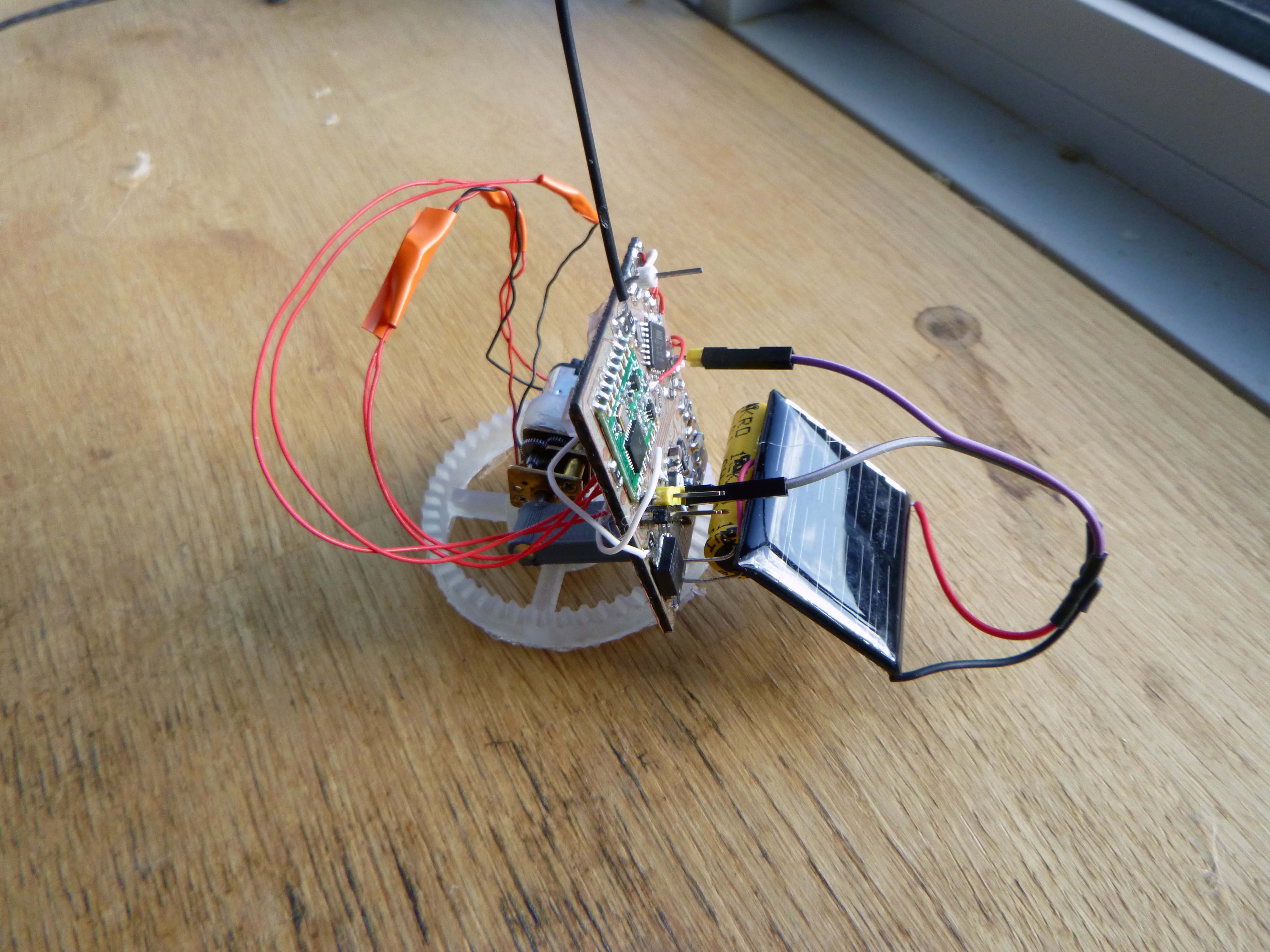

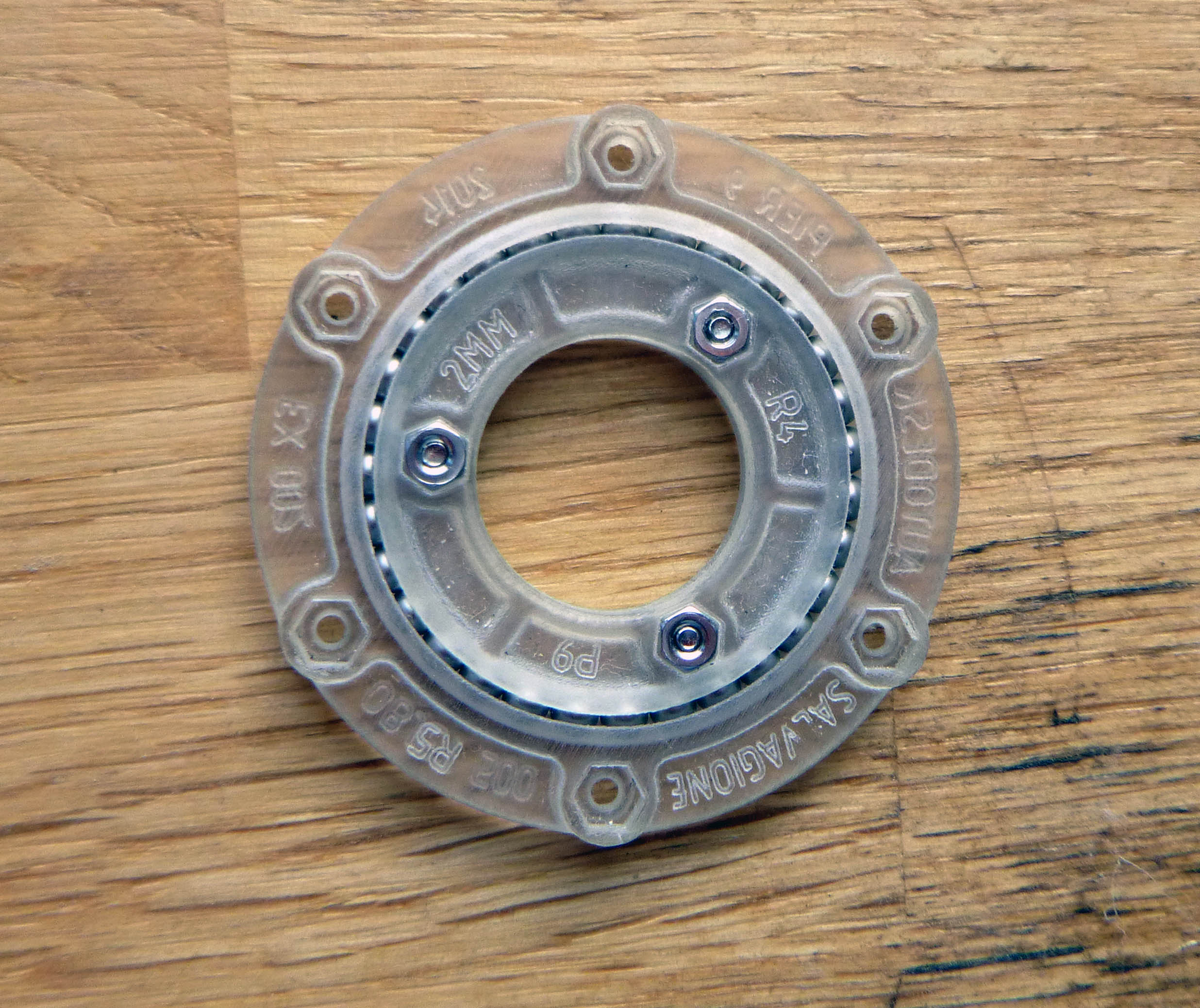

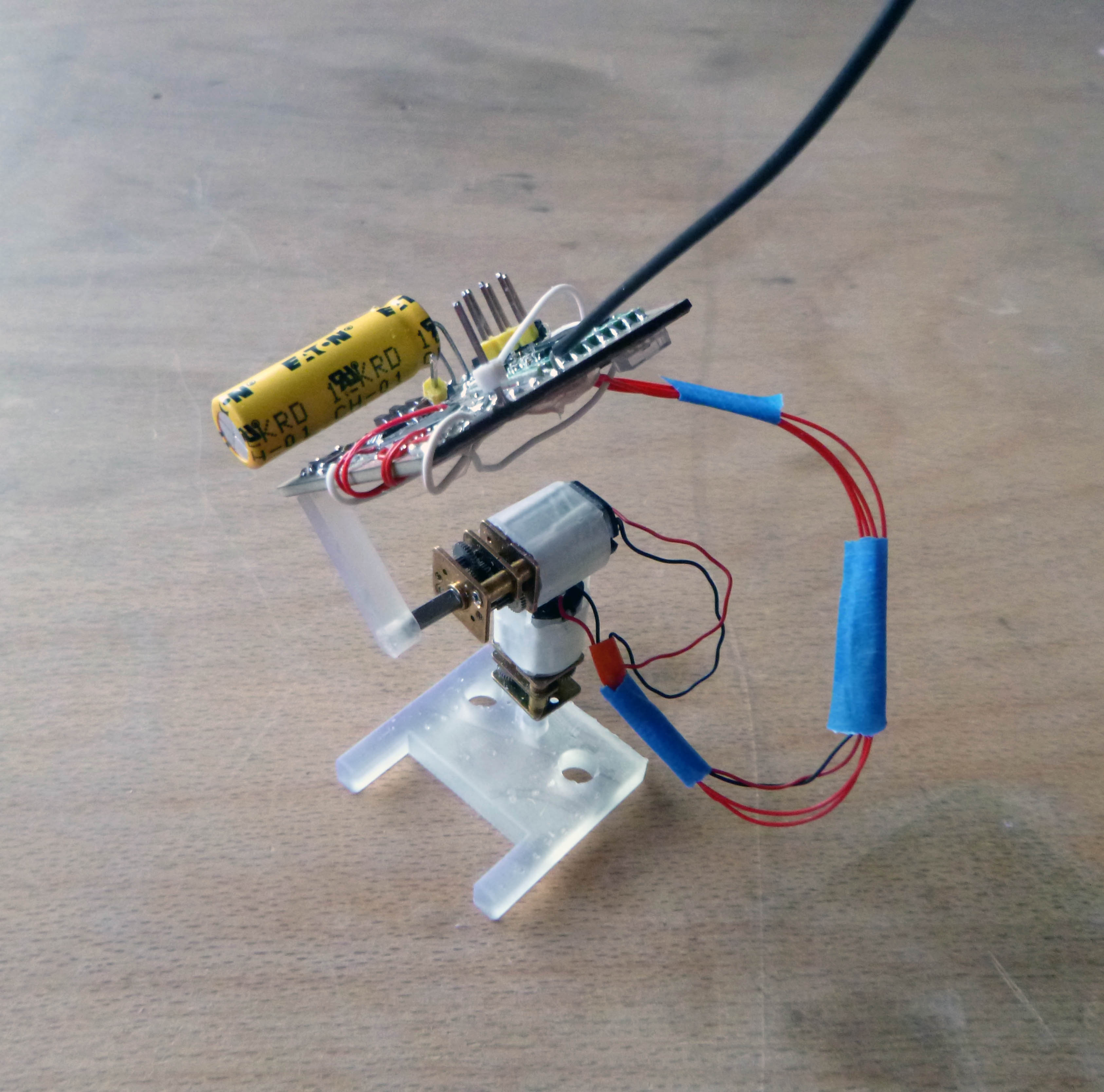

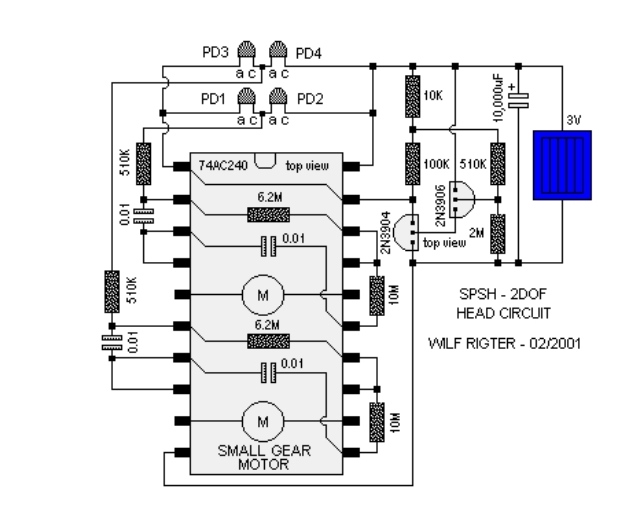

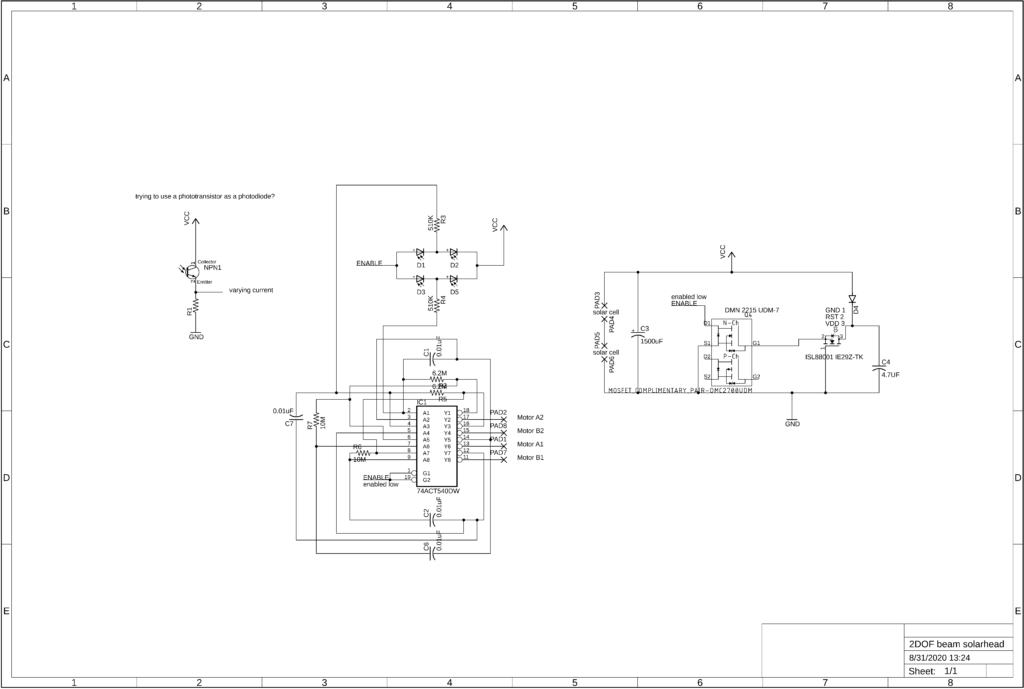

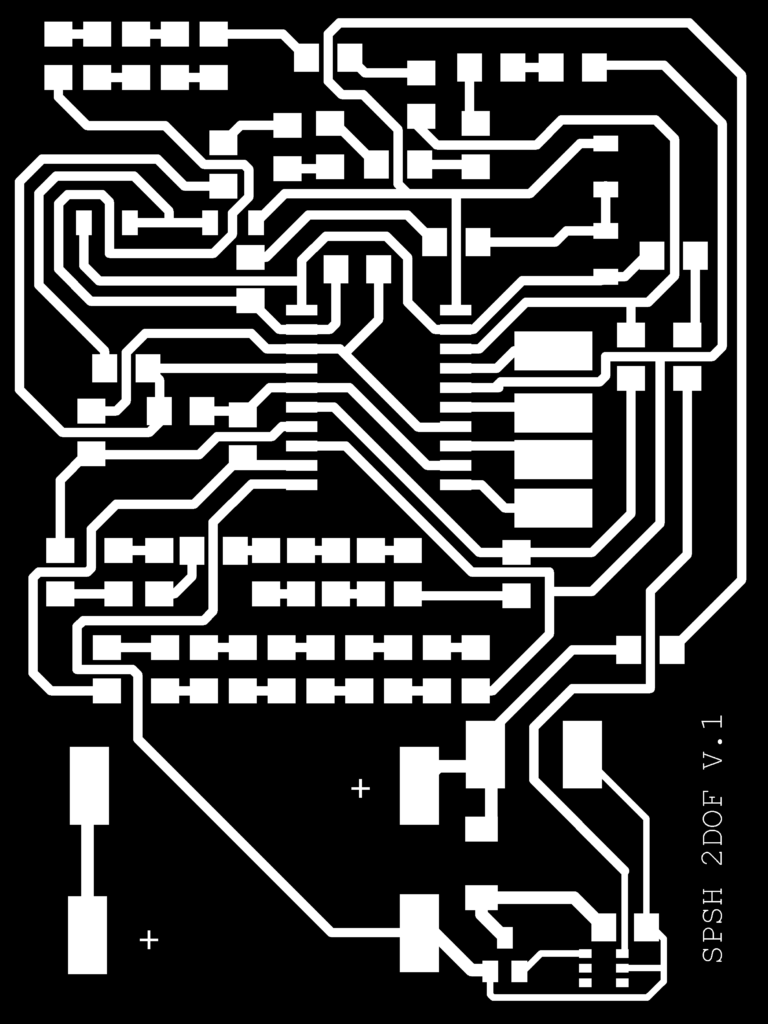

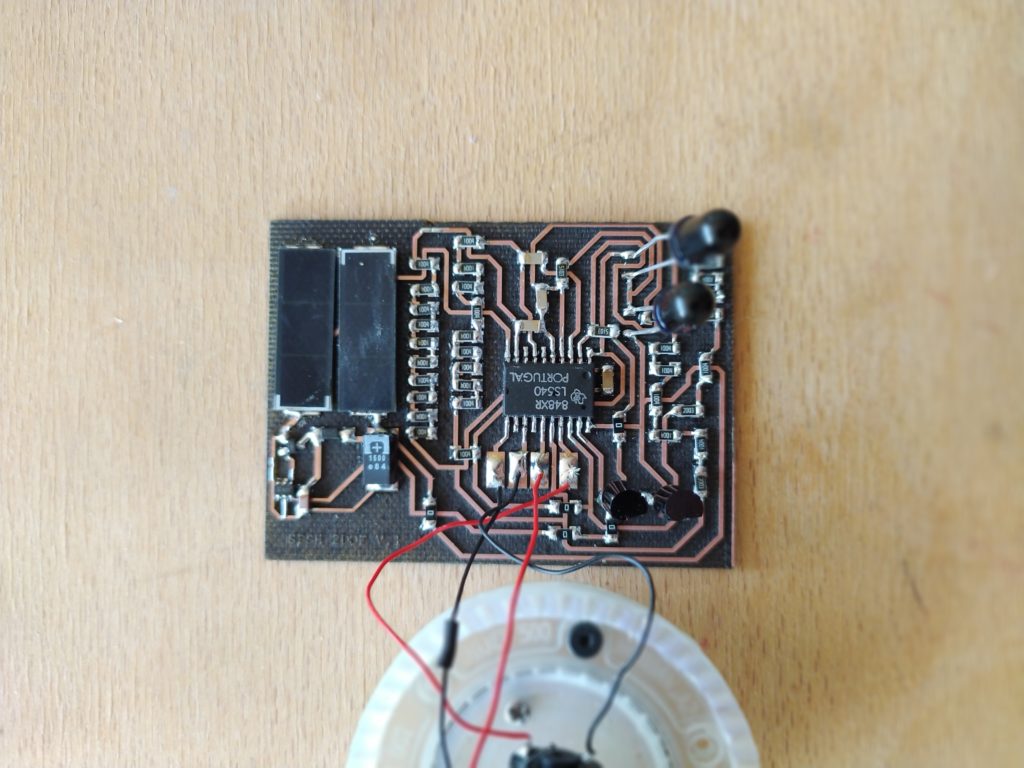

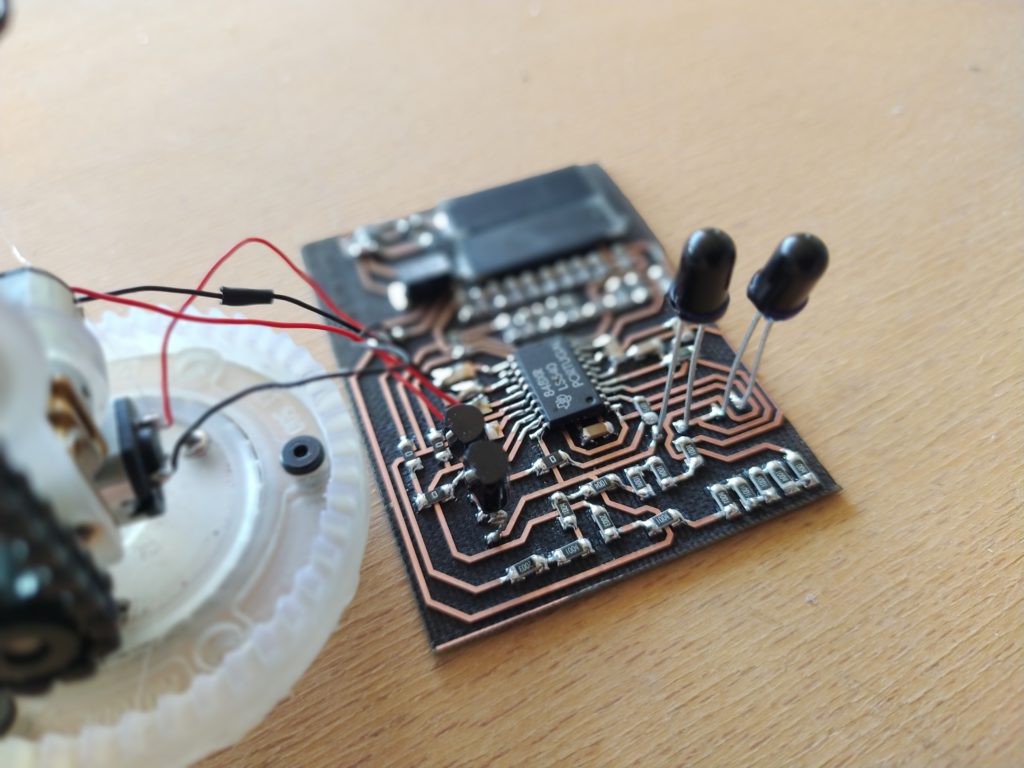

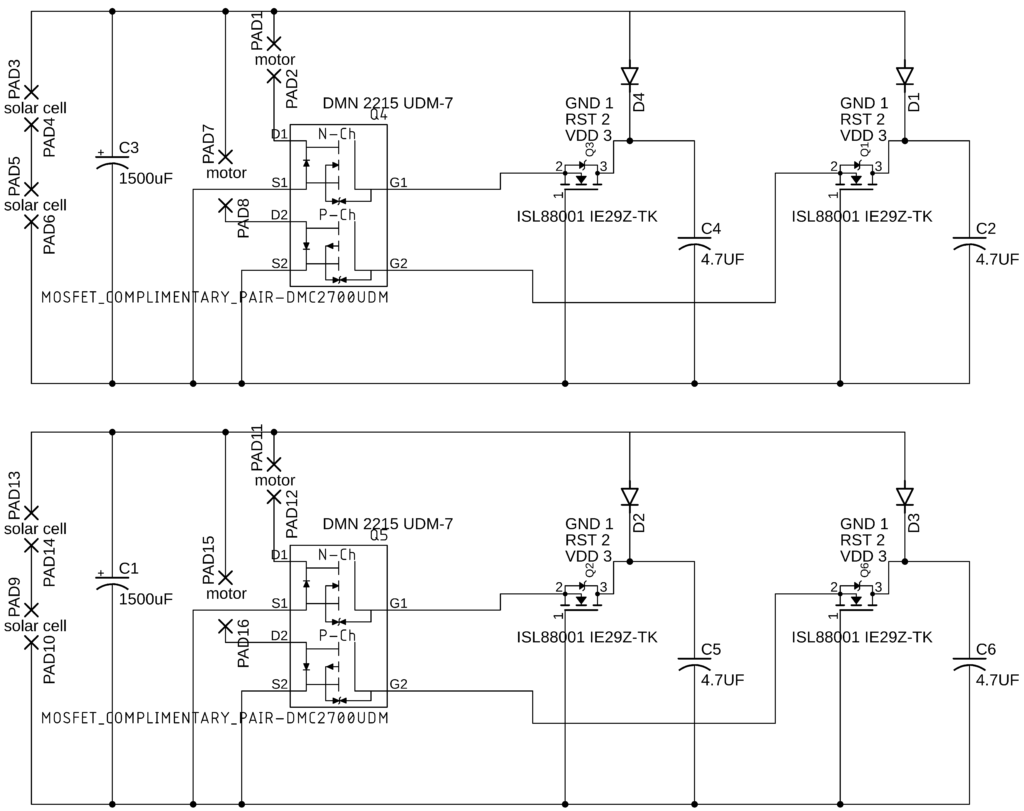

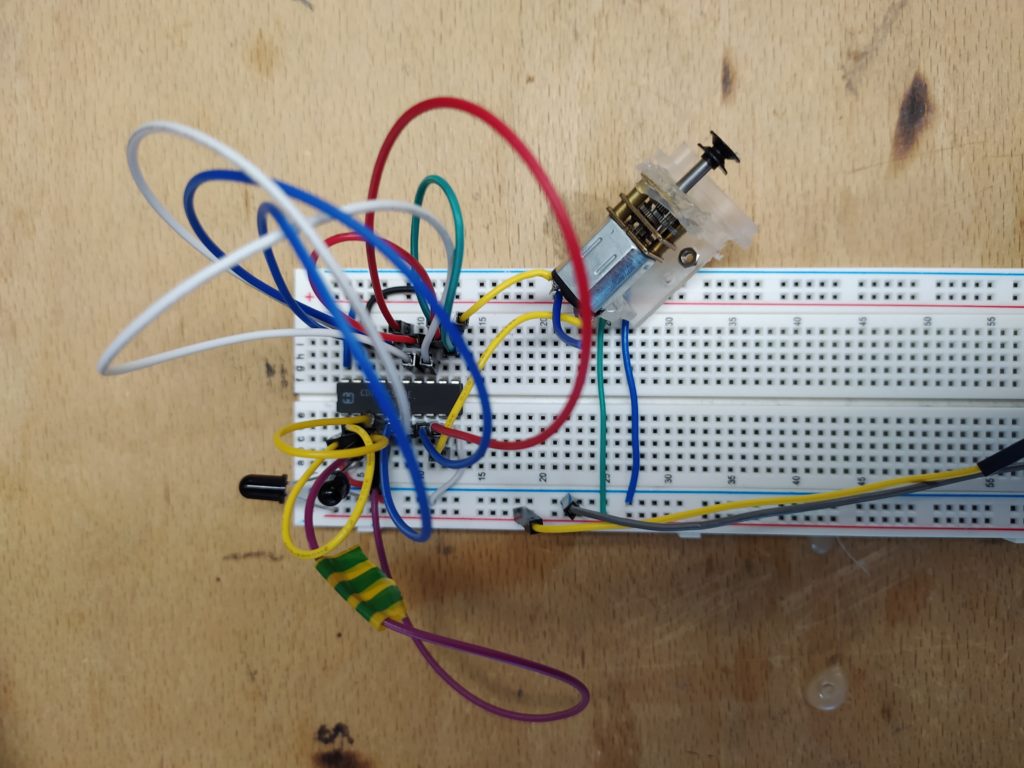

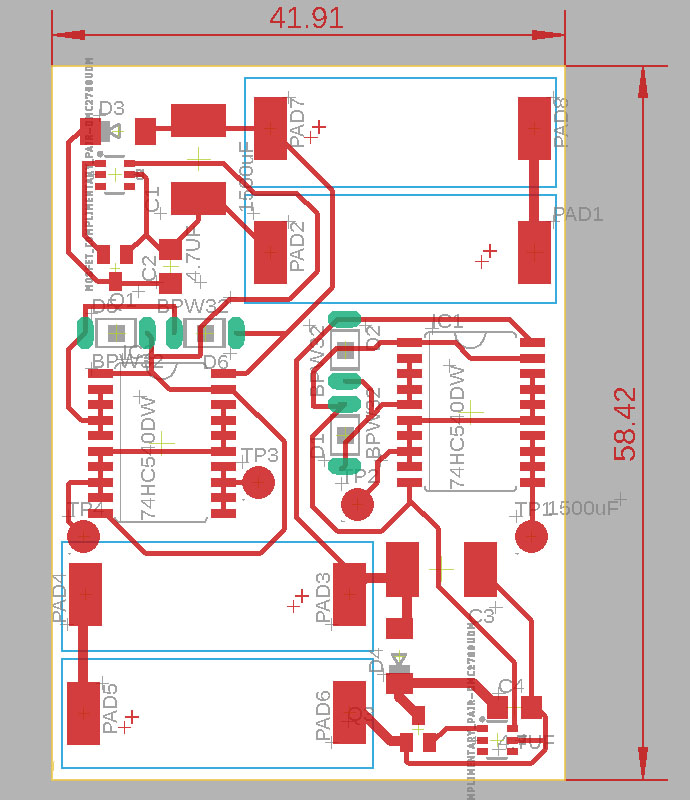

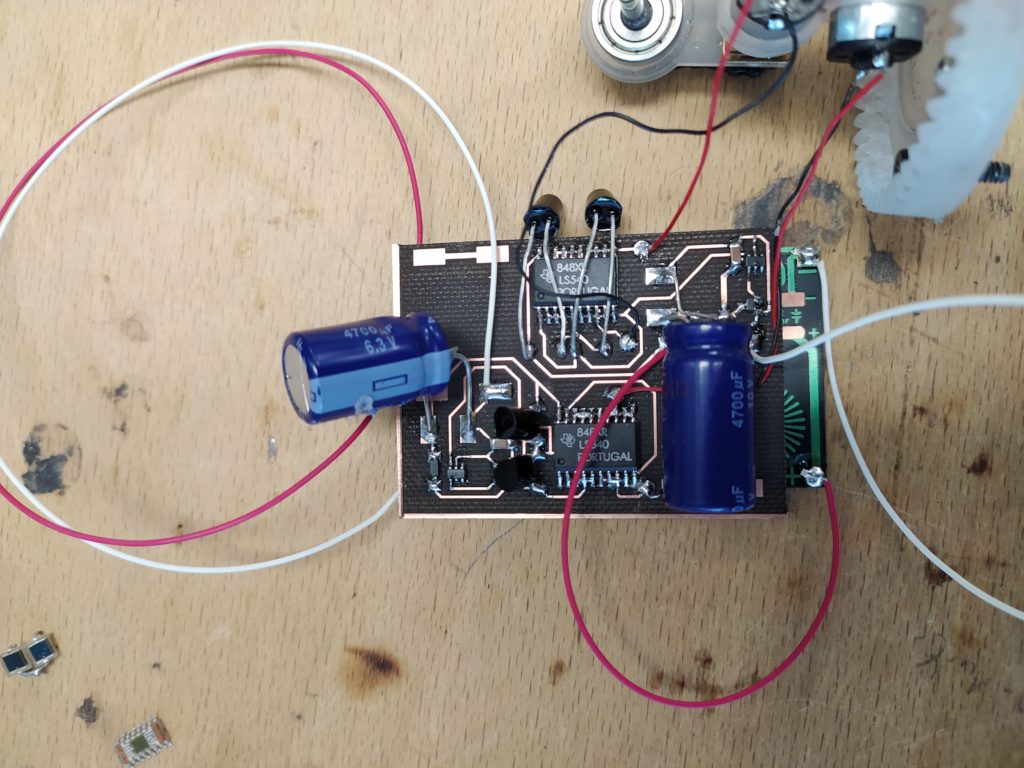

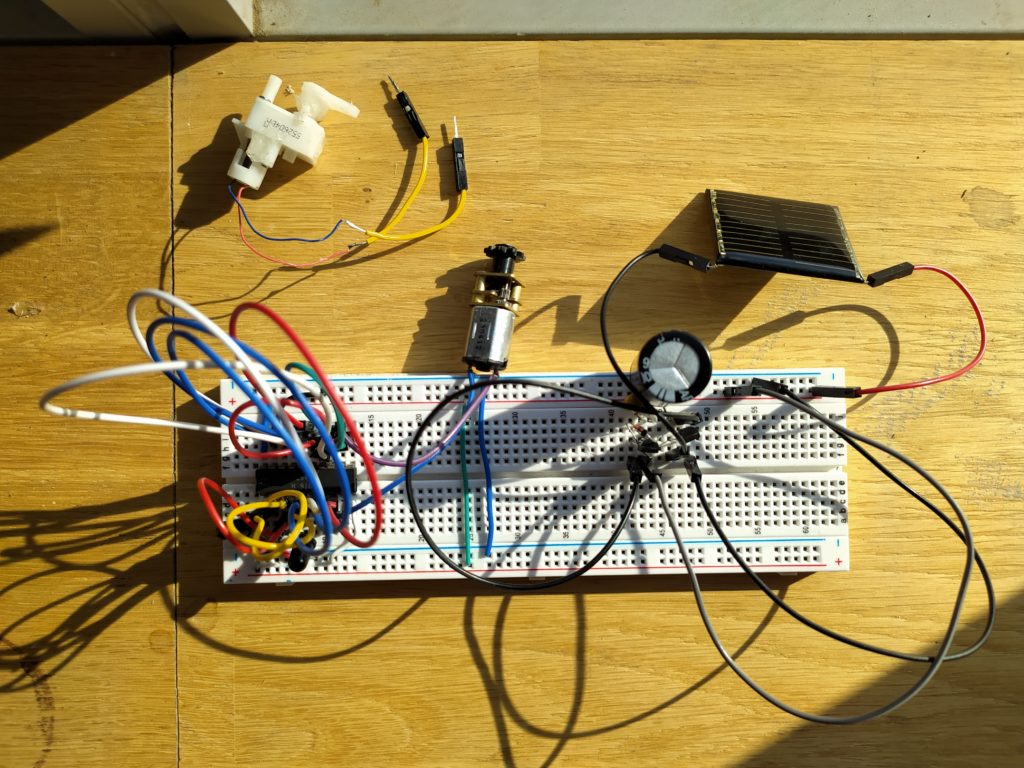

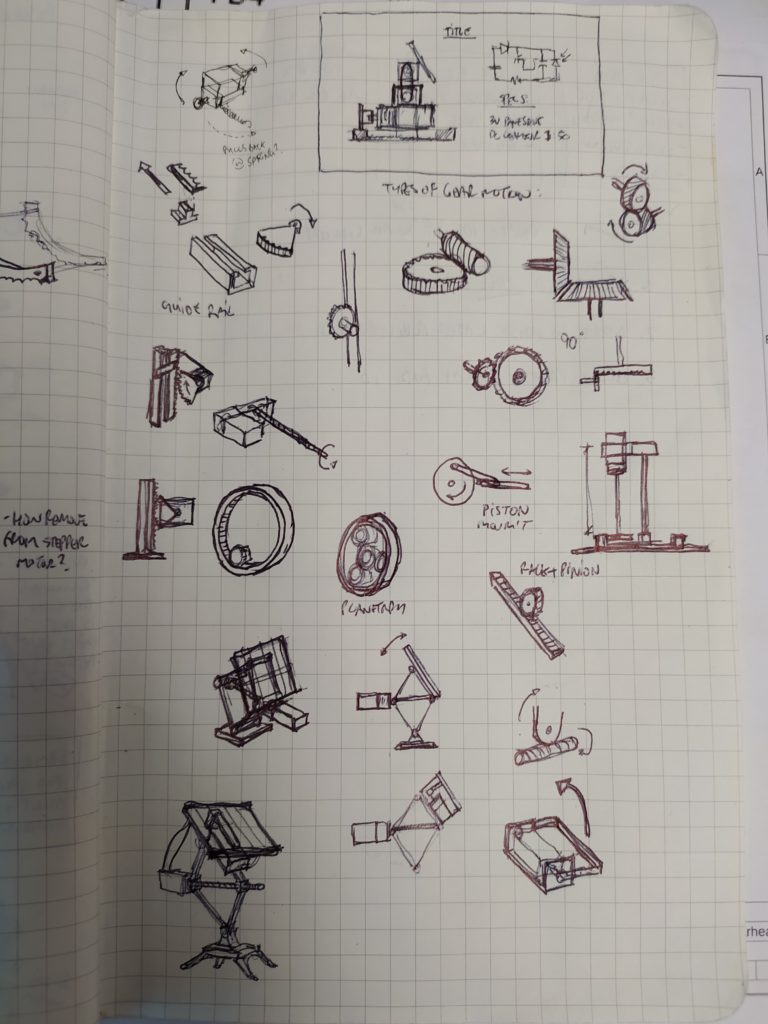

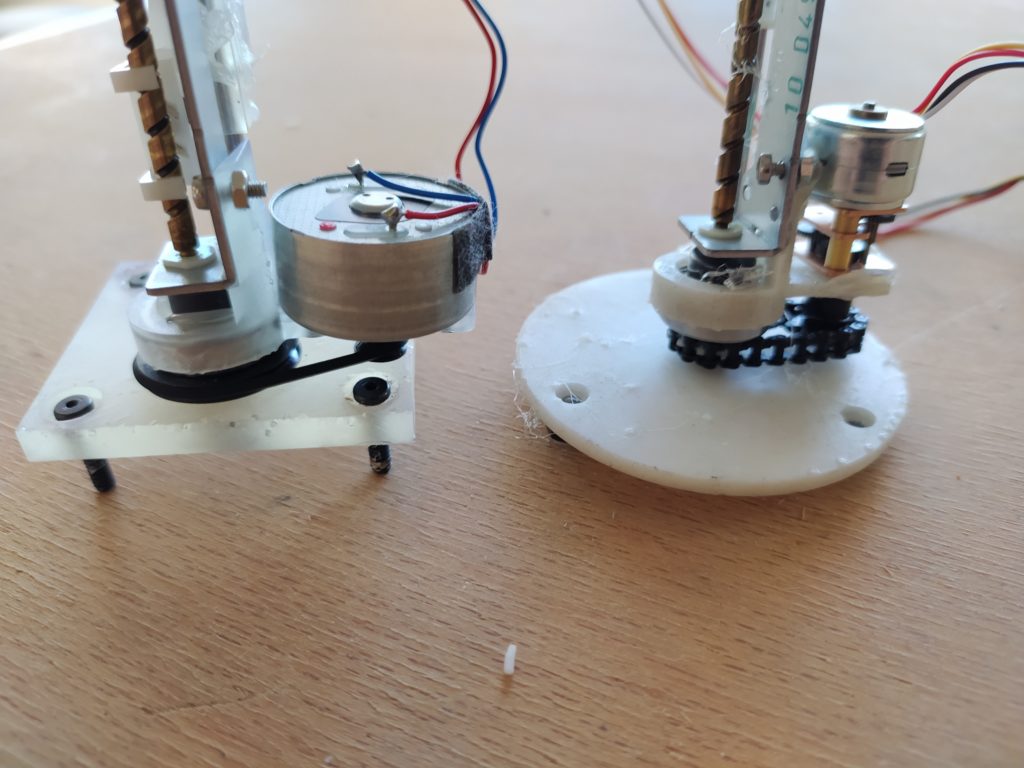

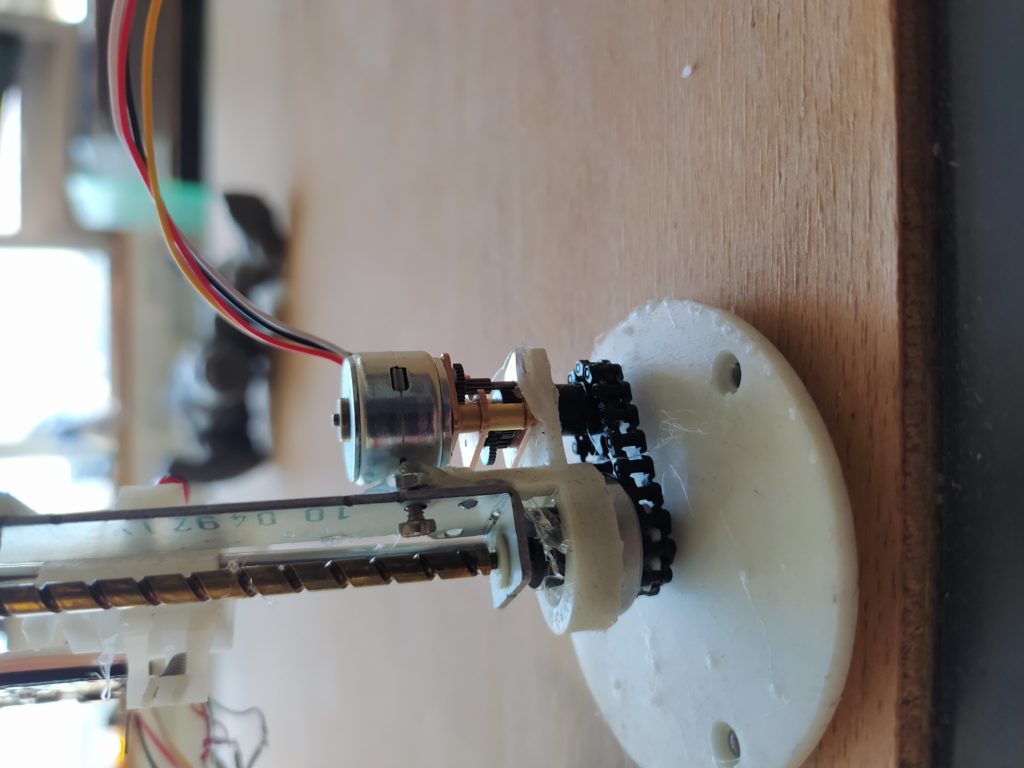

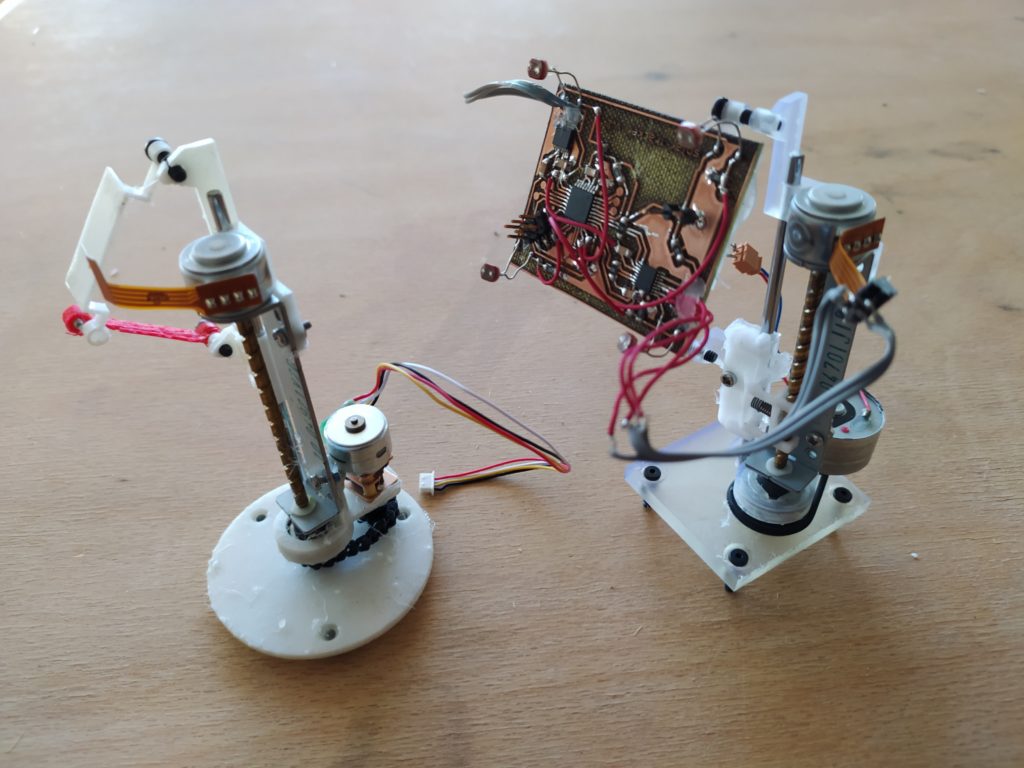

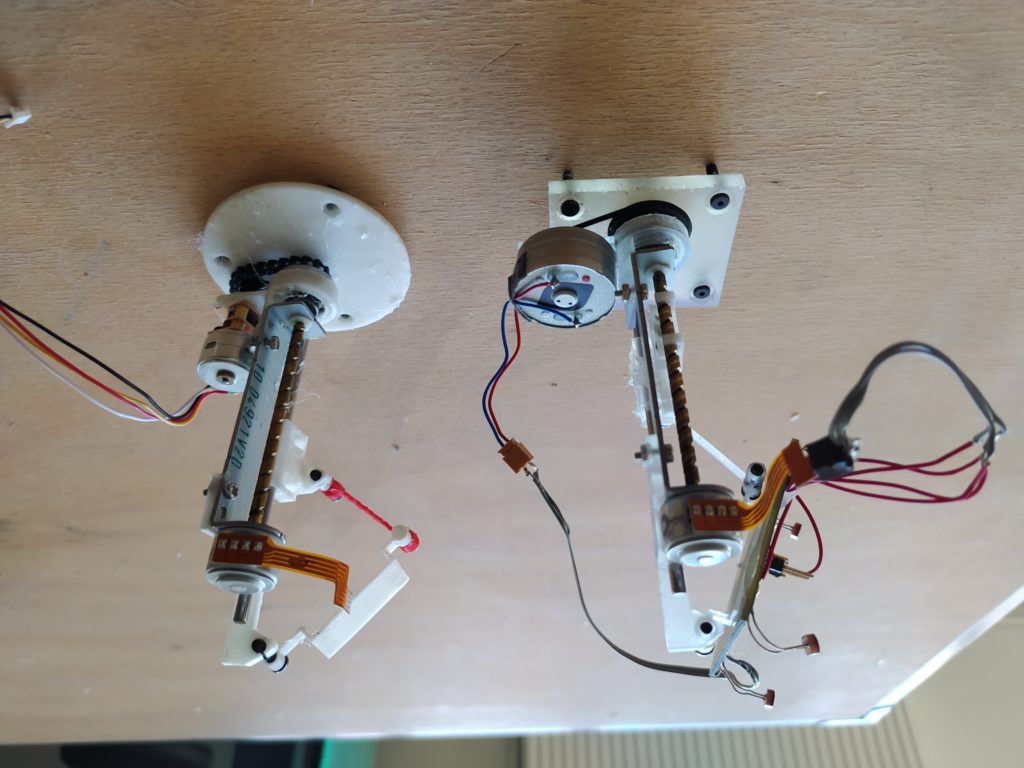

The 2 metal gear motor design I was working with early on.

The 2 metal gear motor design I was working with early on.

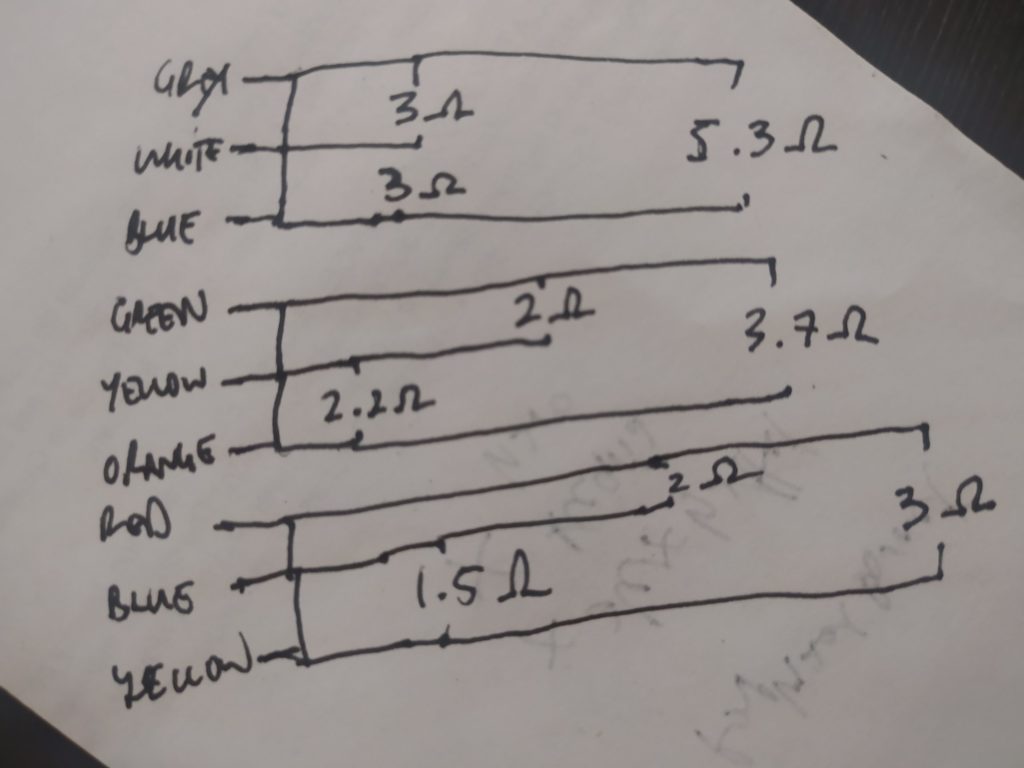

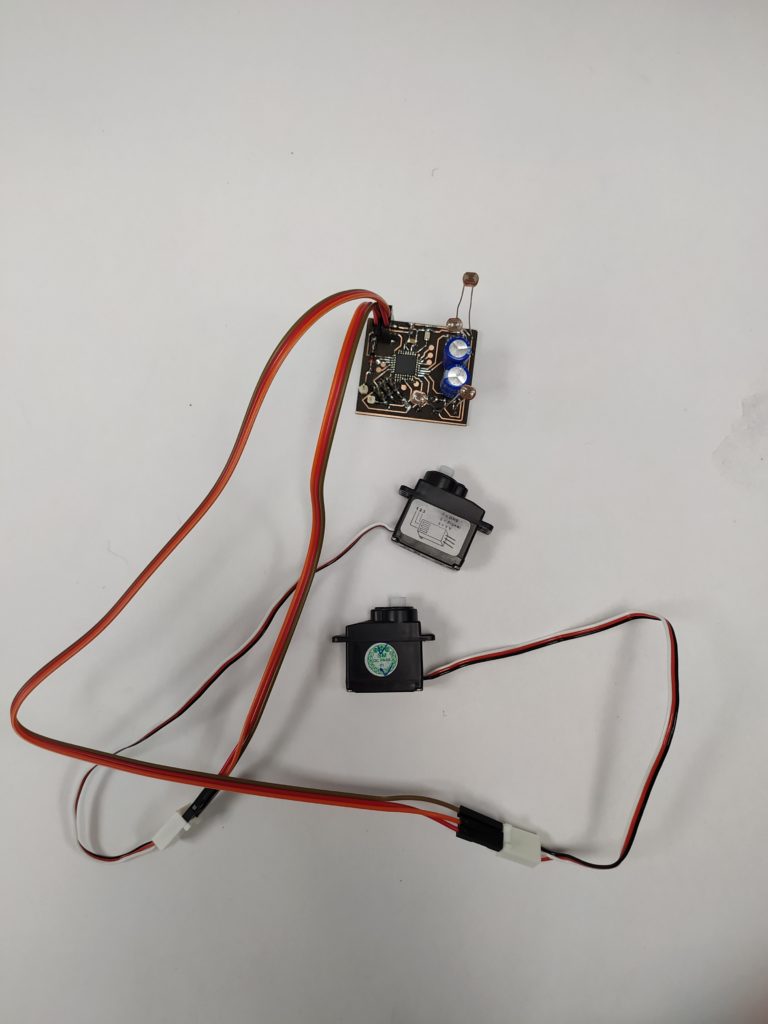

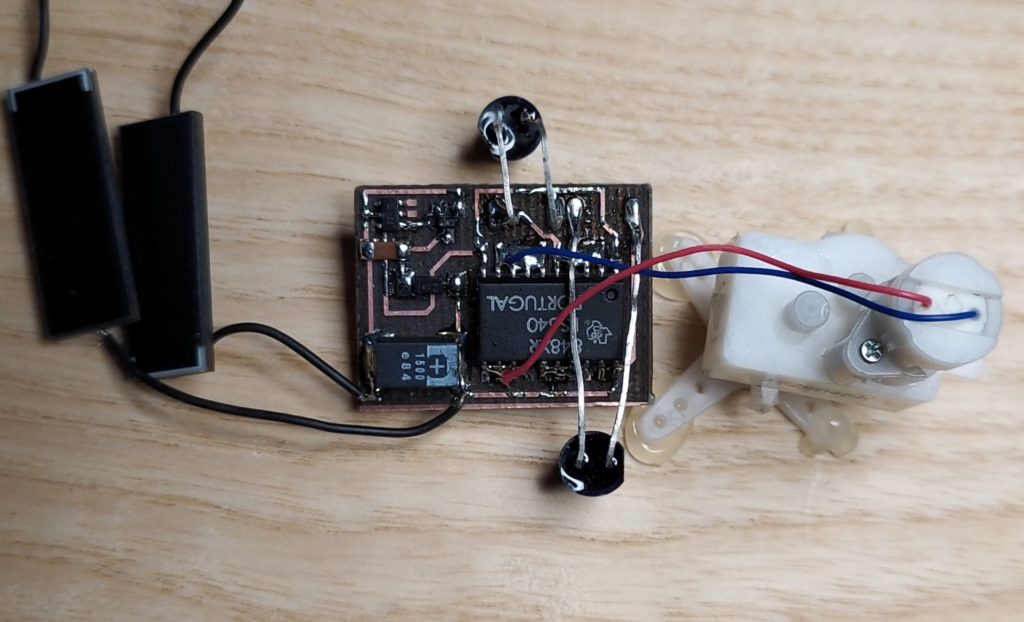

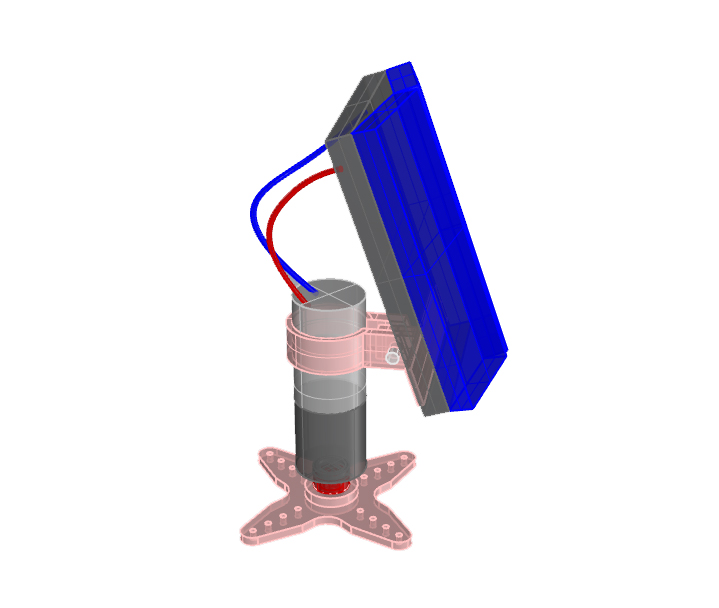

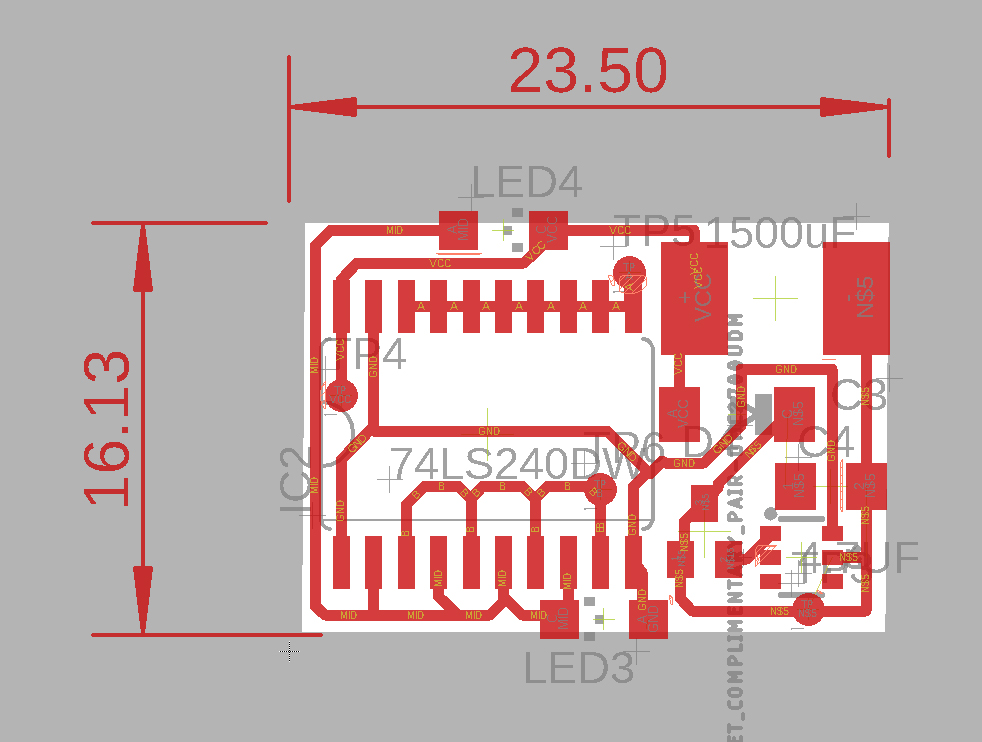

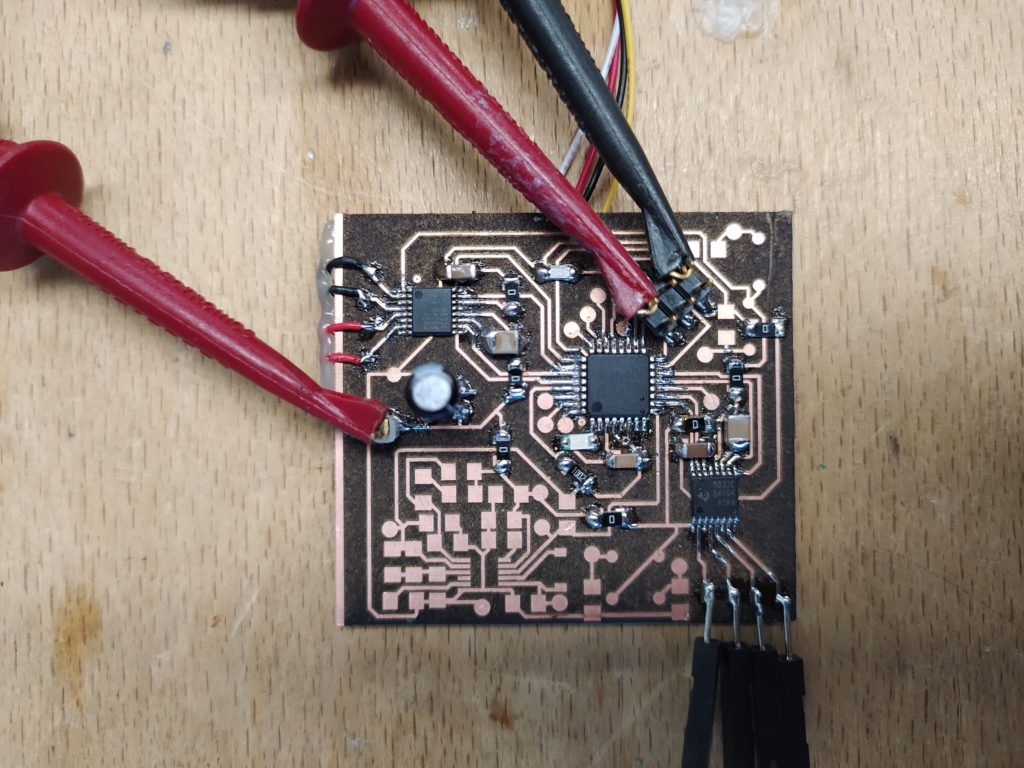

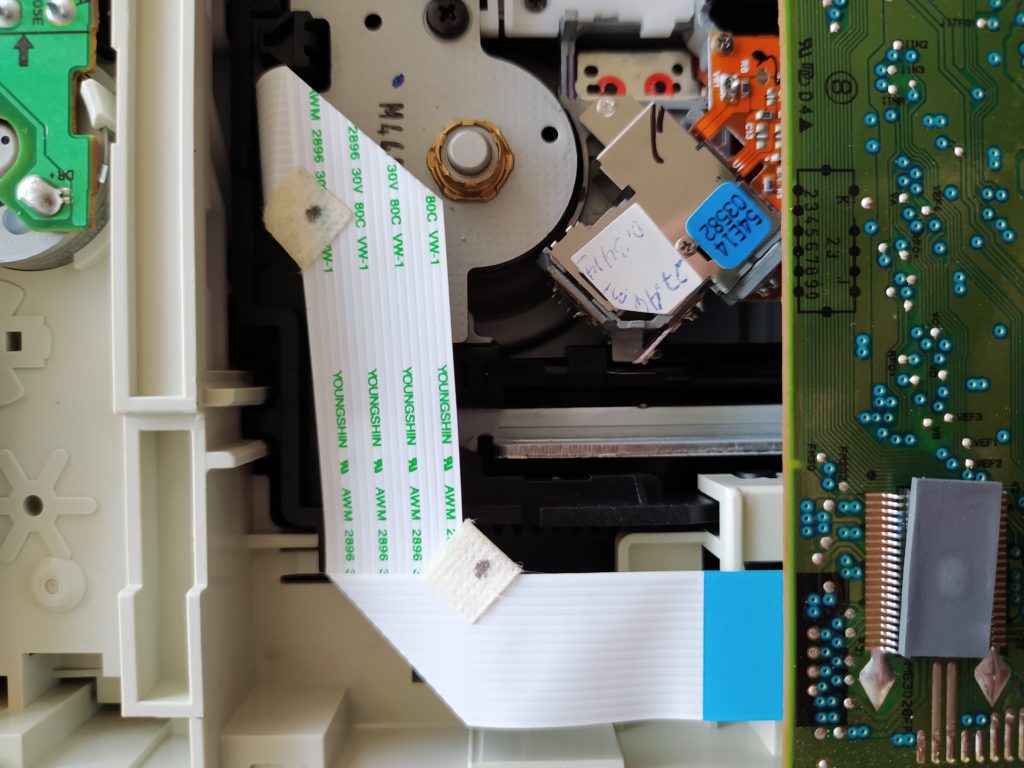

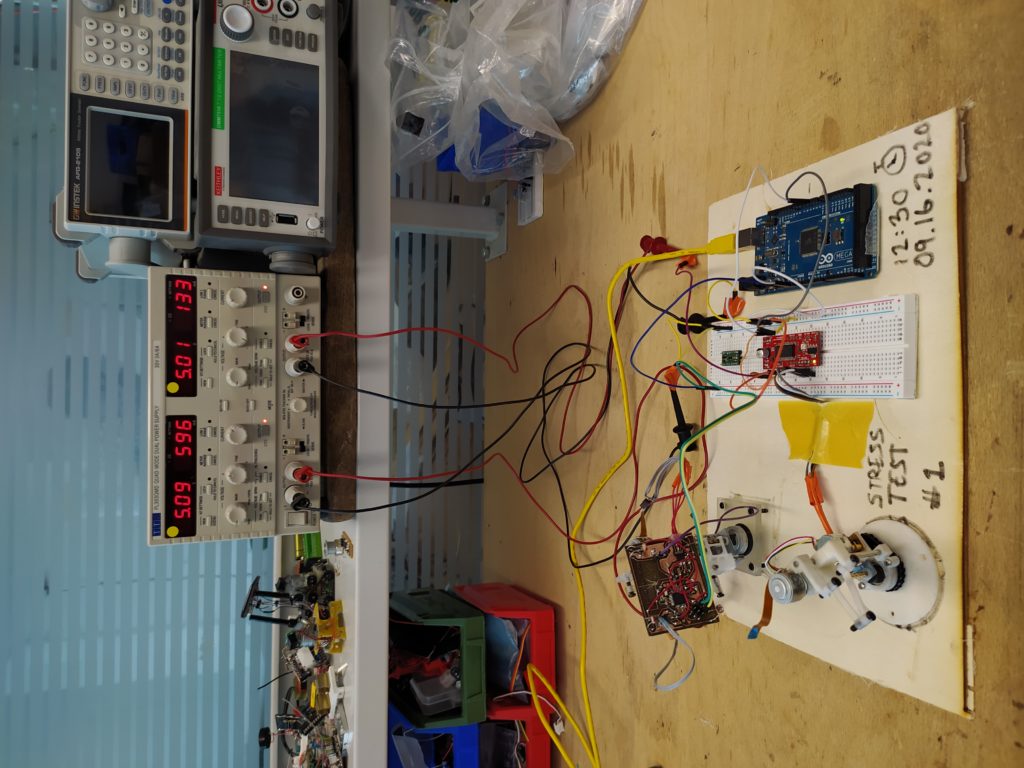

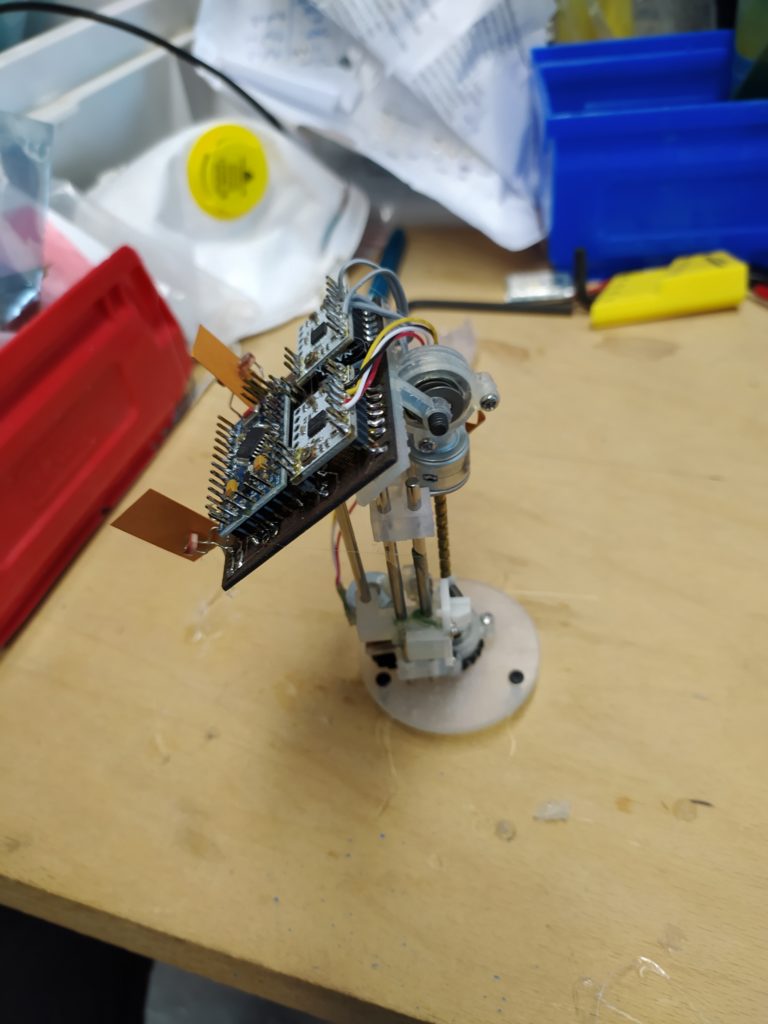

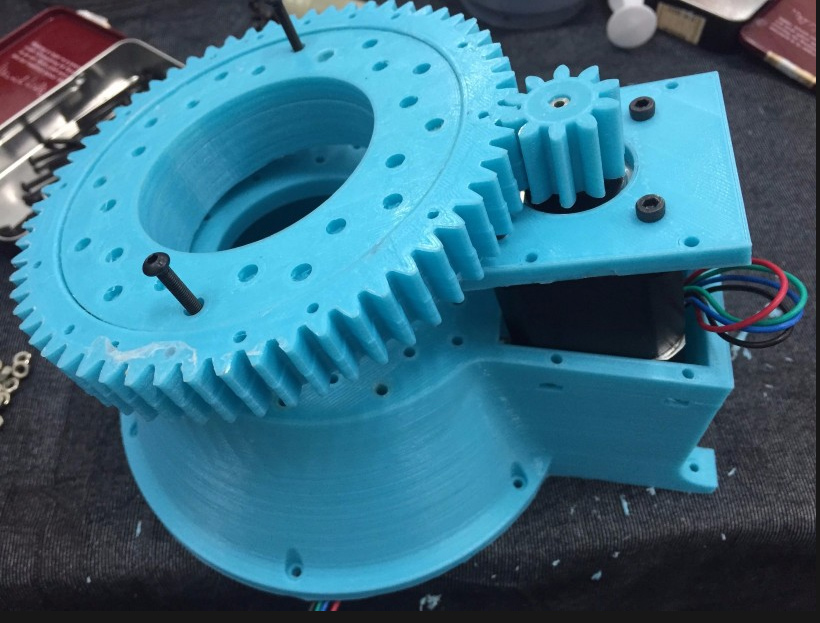

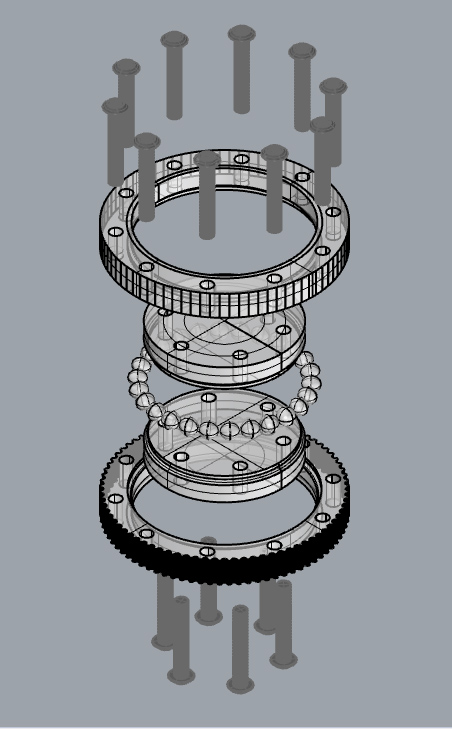

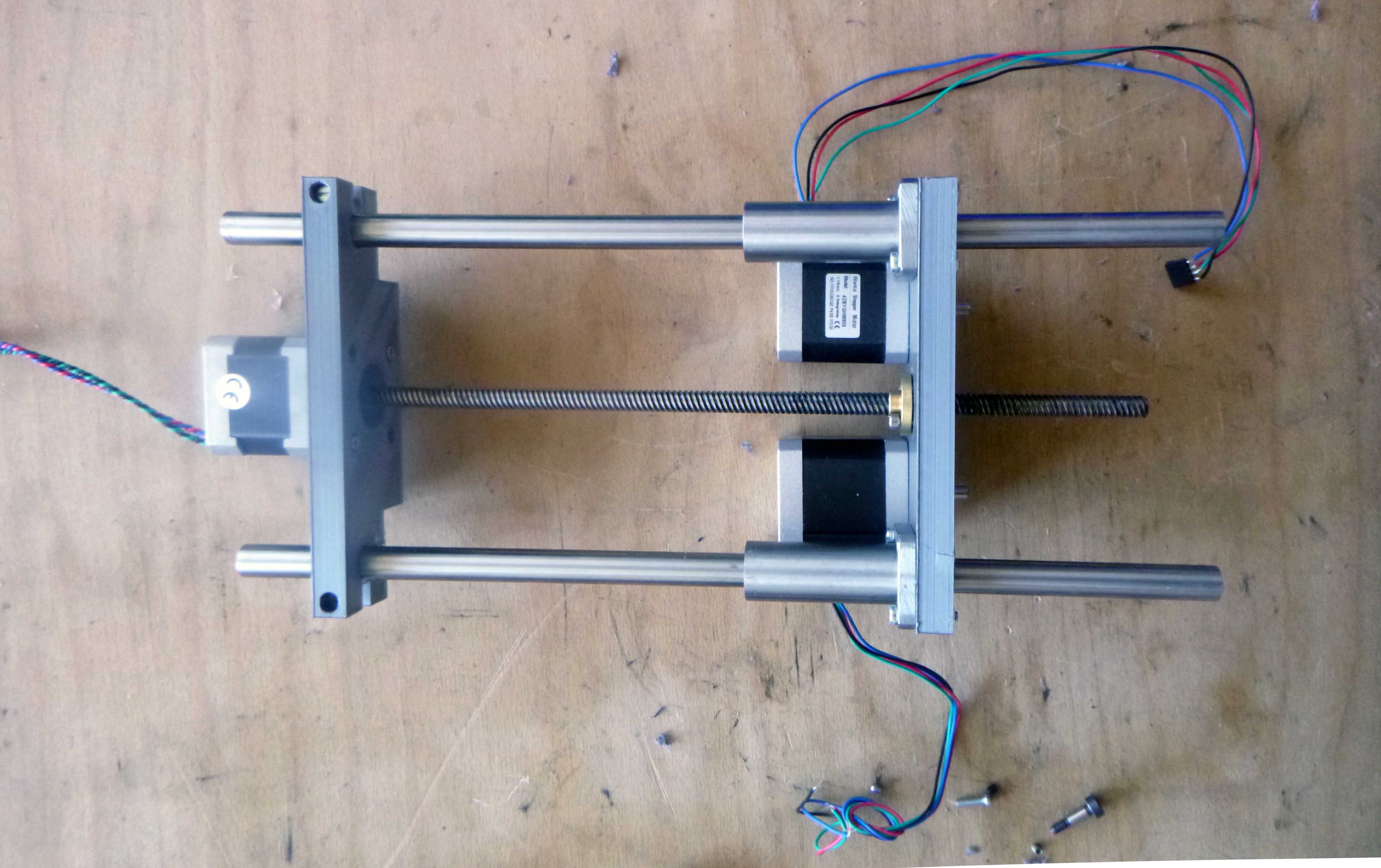

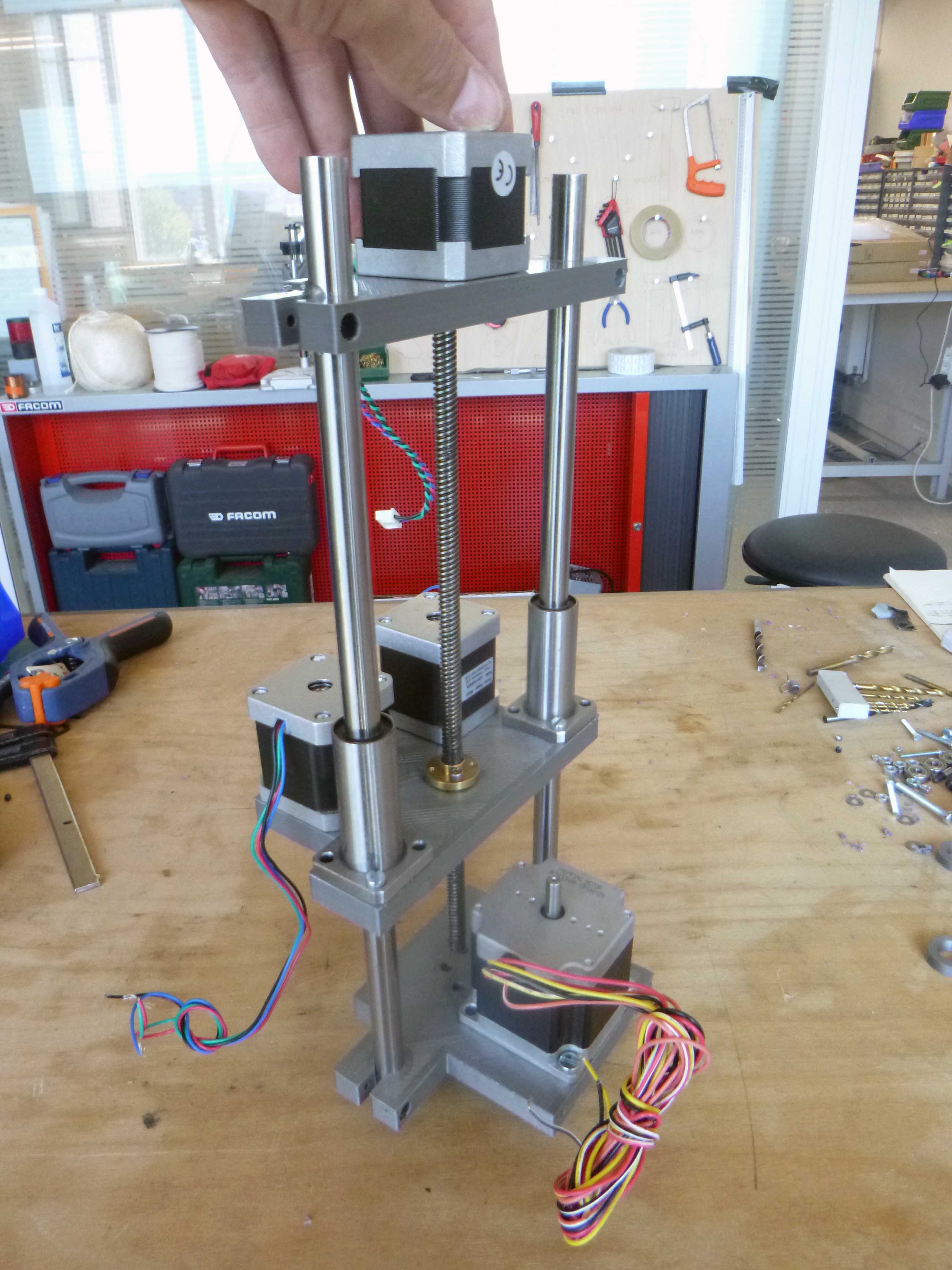

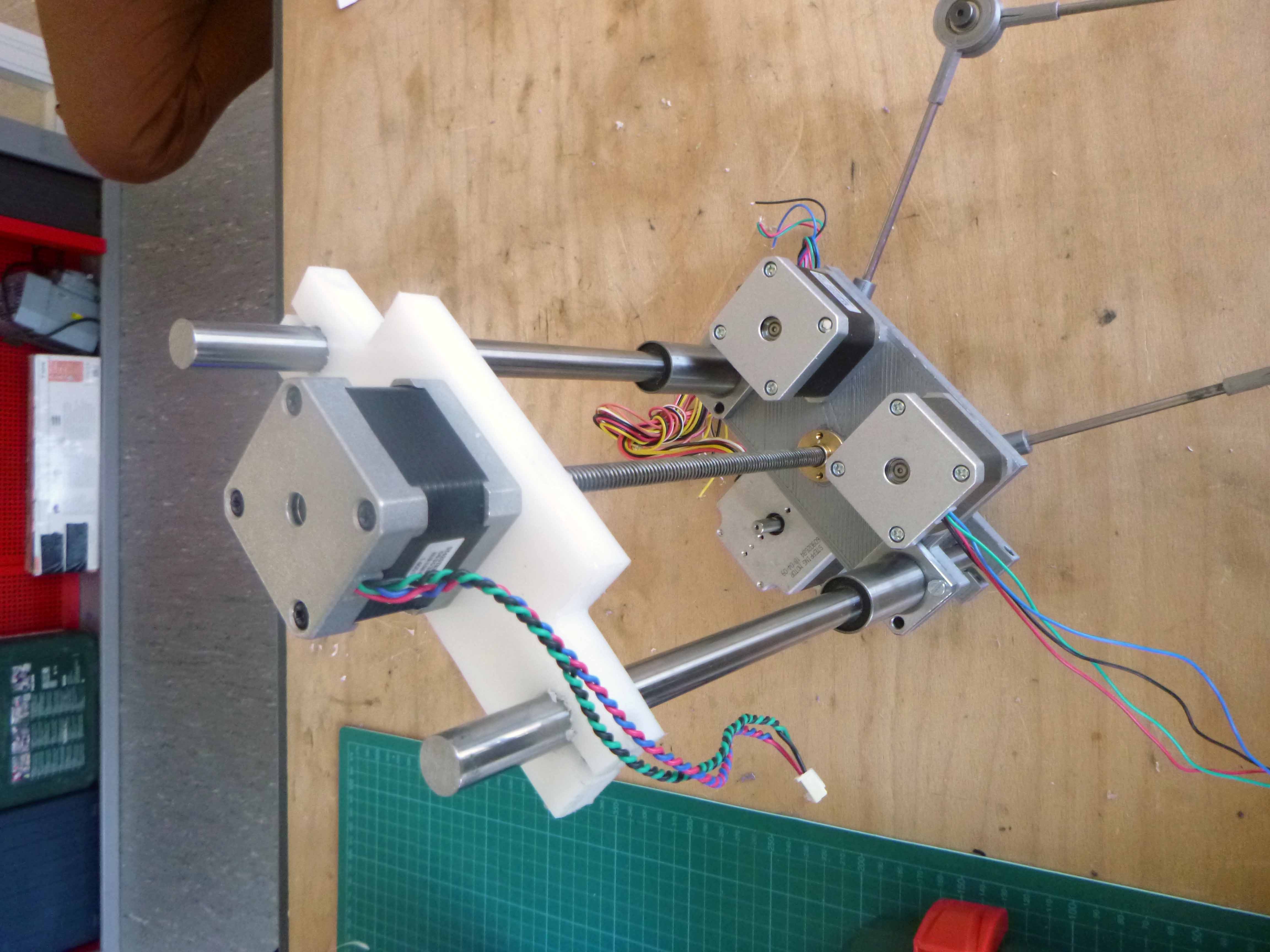

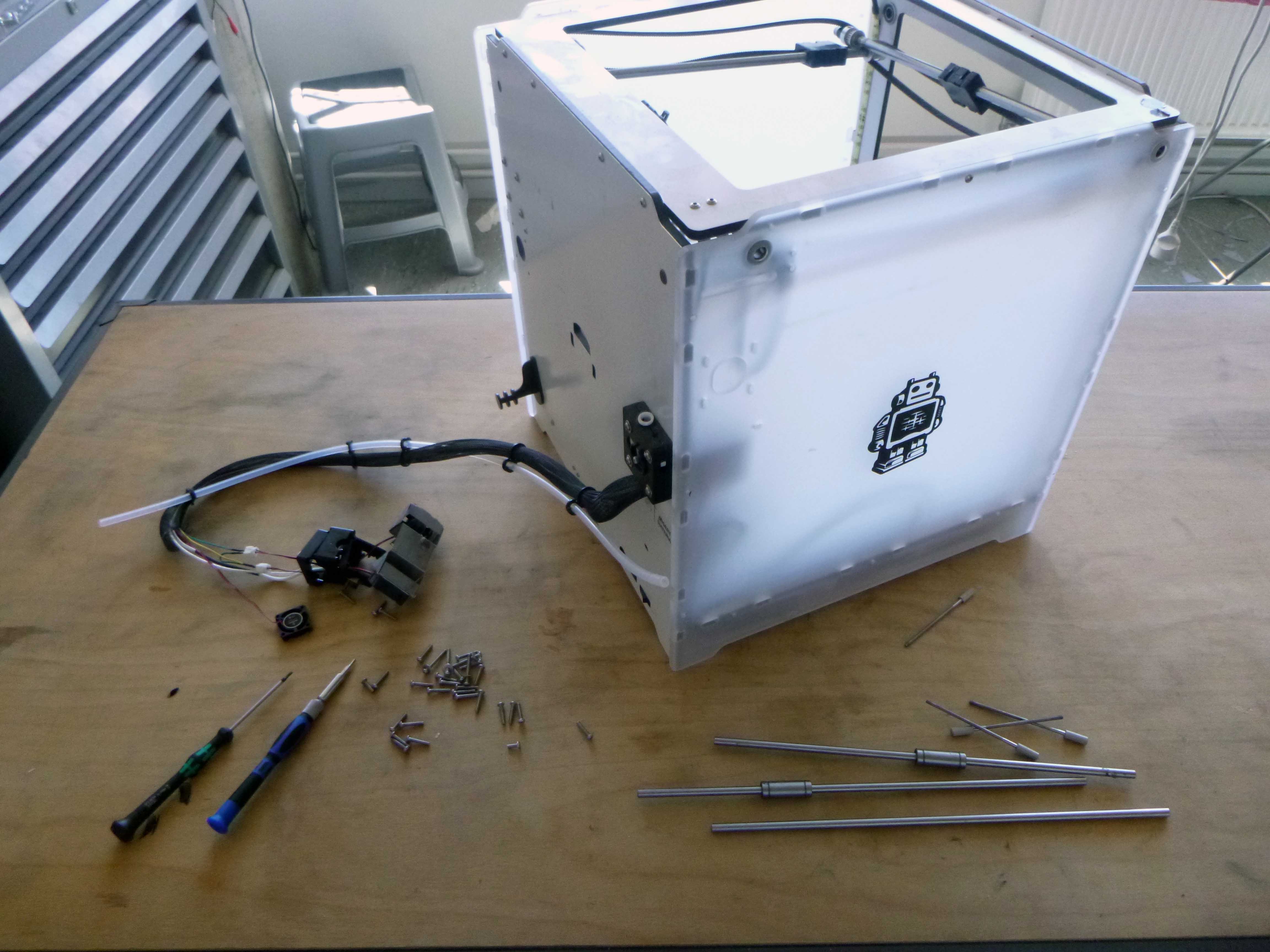

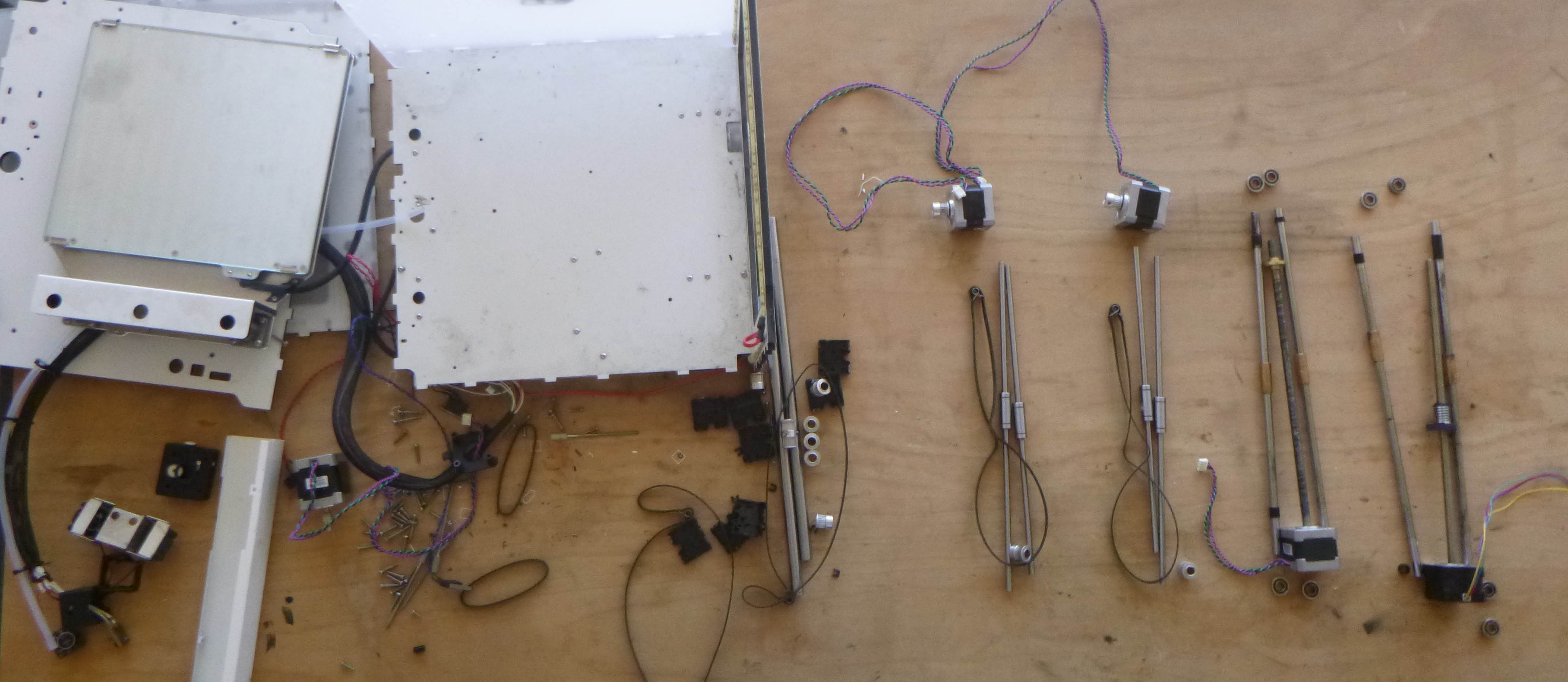

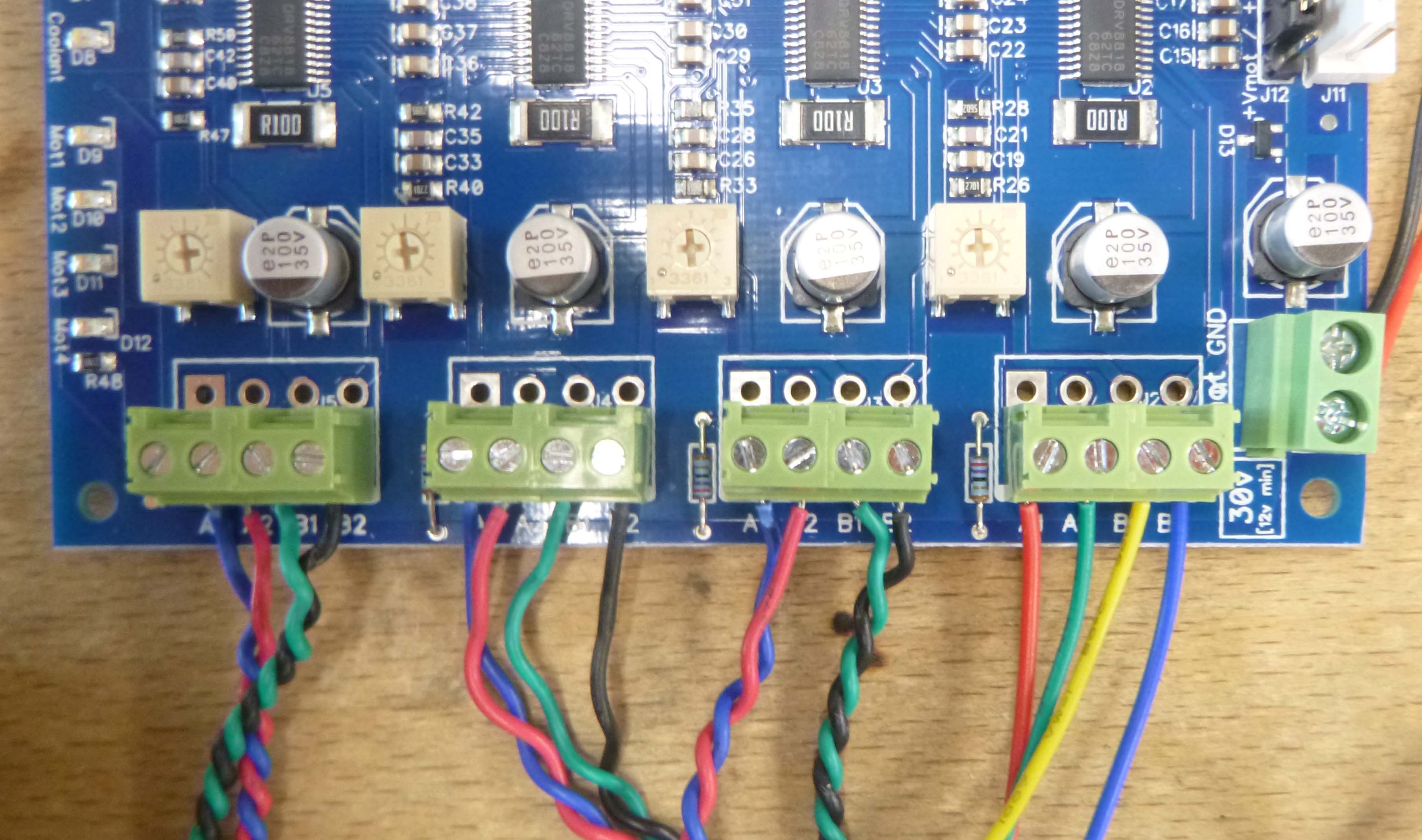

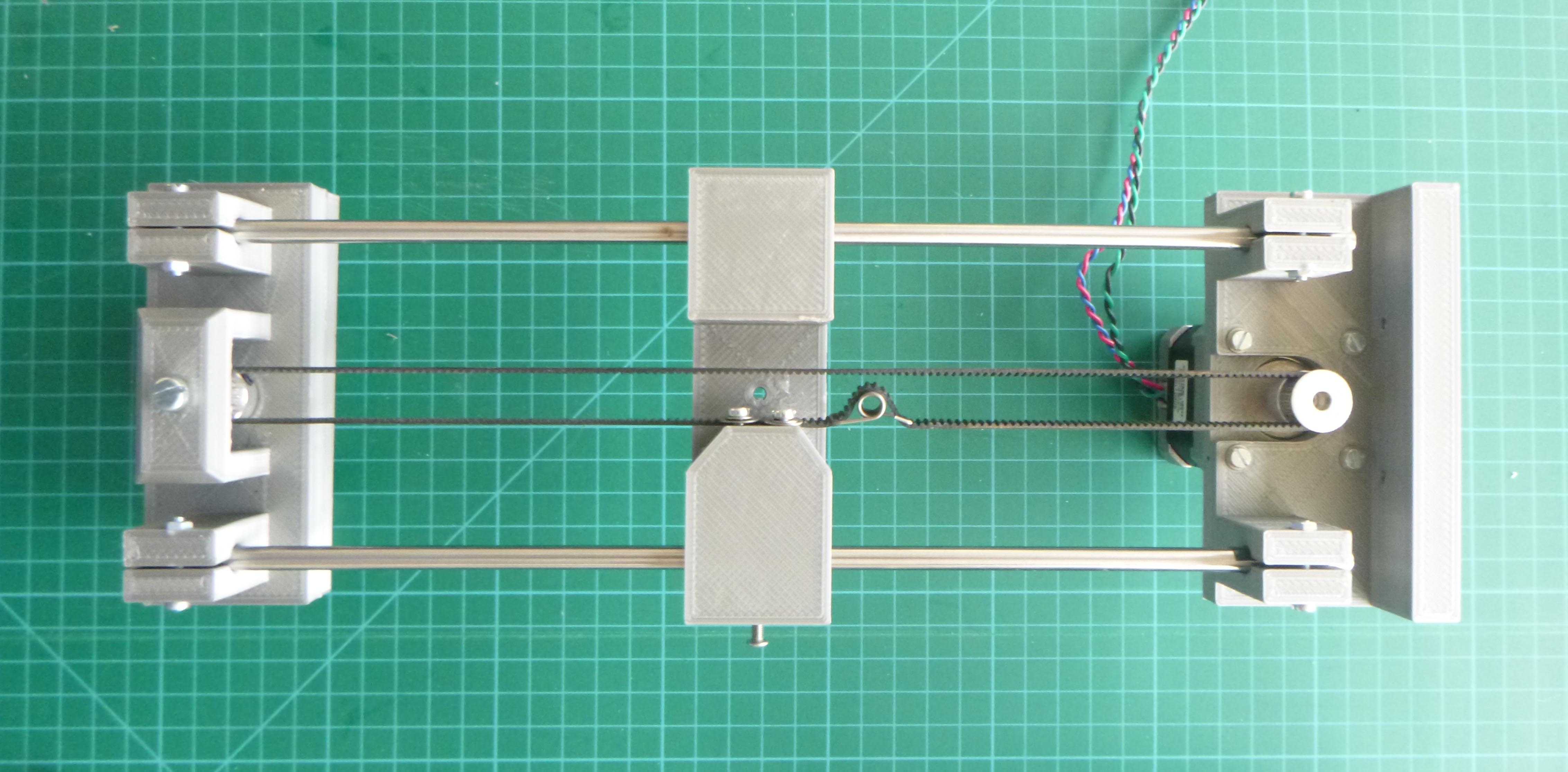

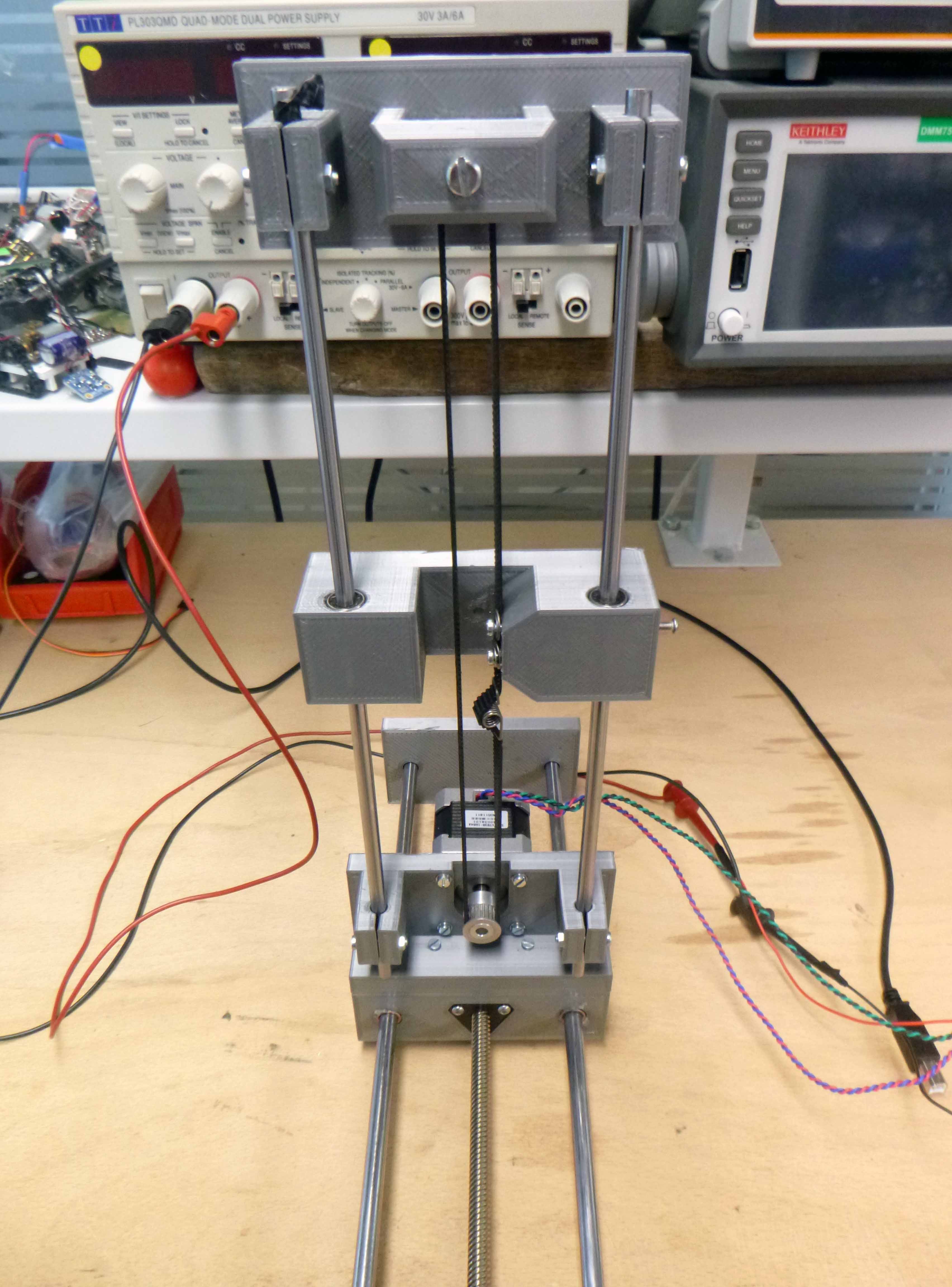

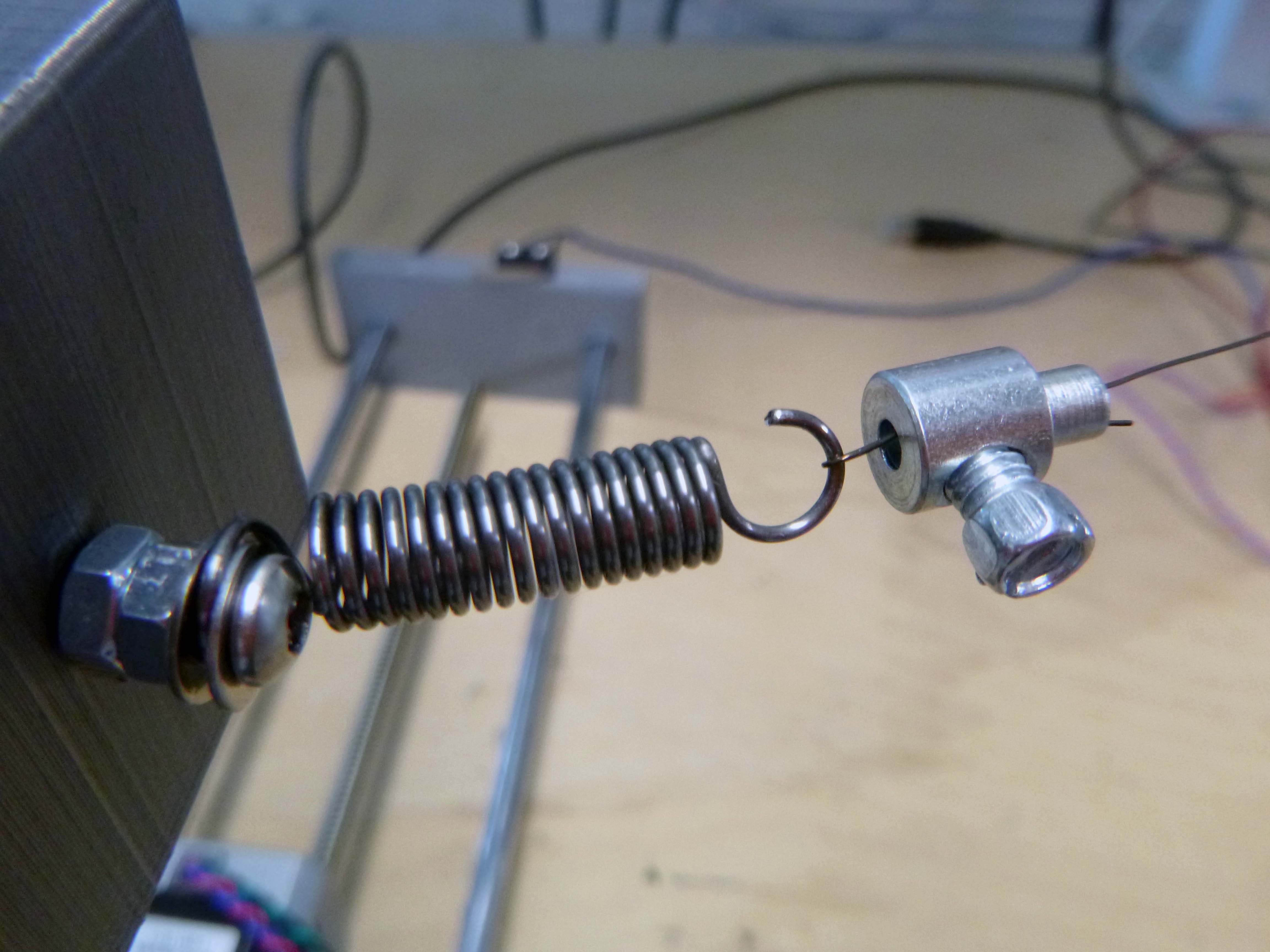

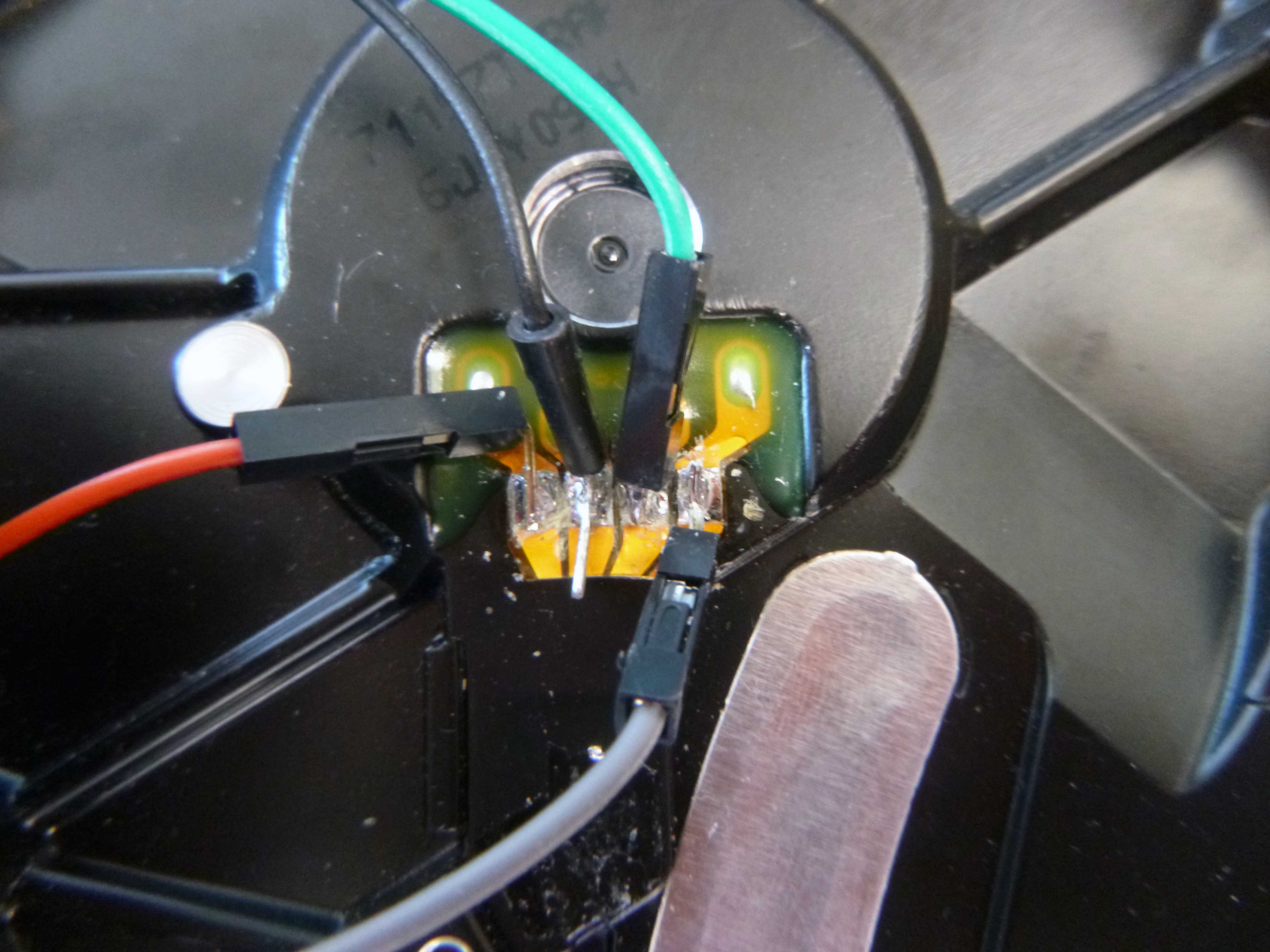

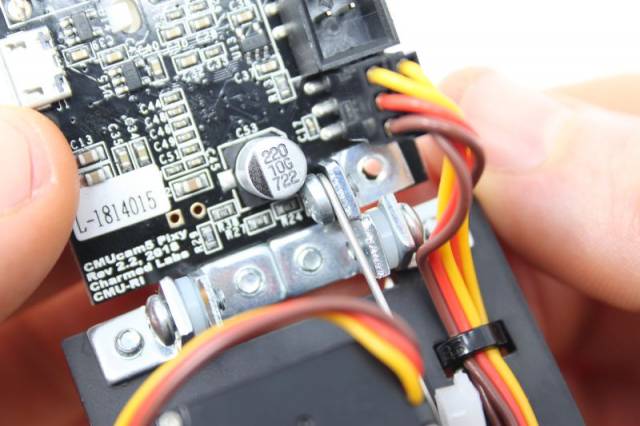

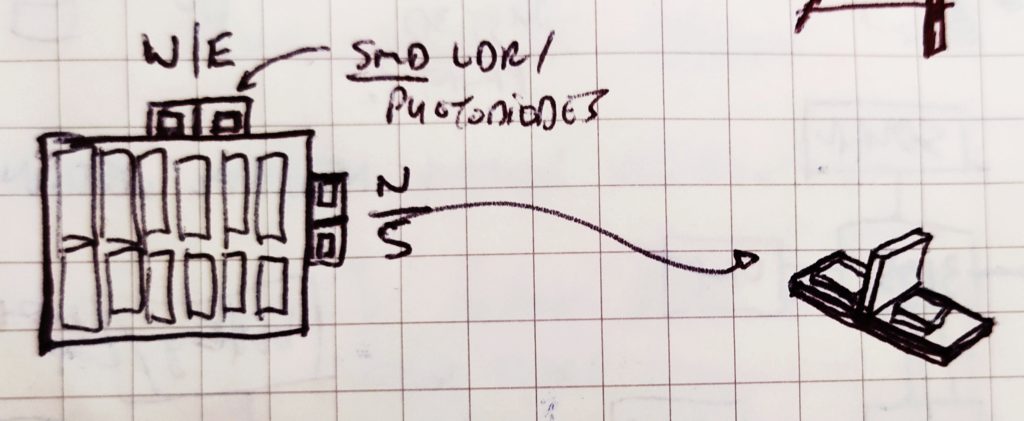

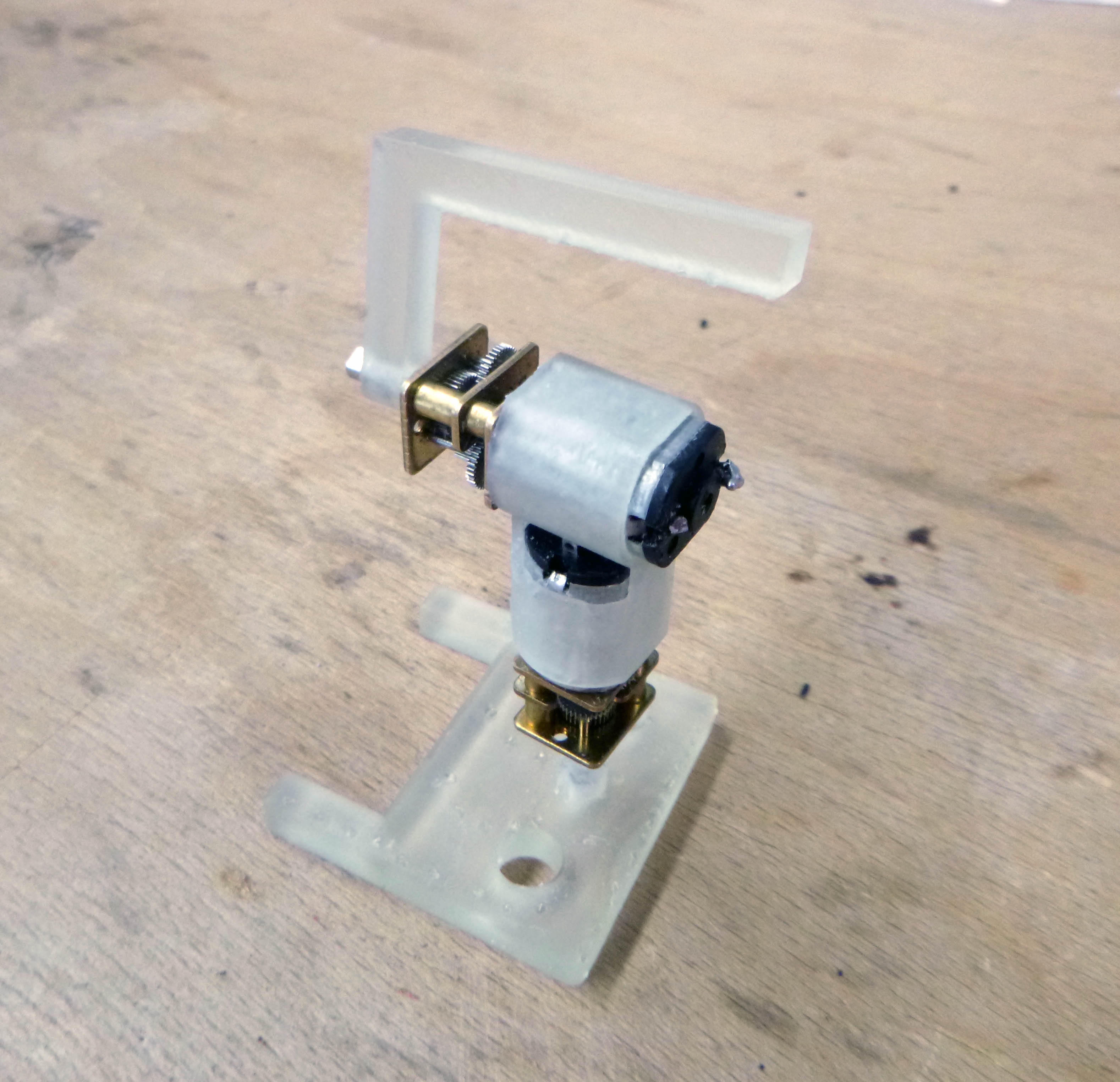

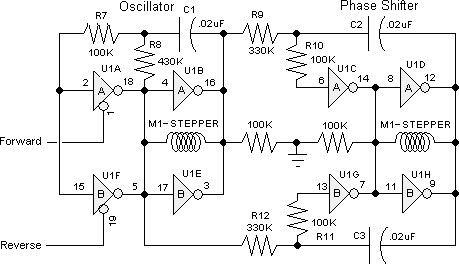

The electrical connections to the TinyG:

The electrical connections to the TinyG:

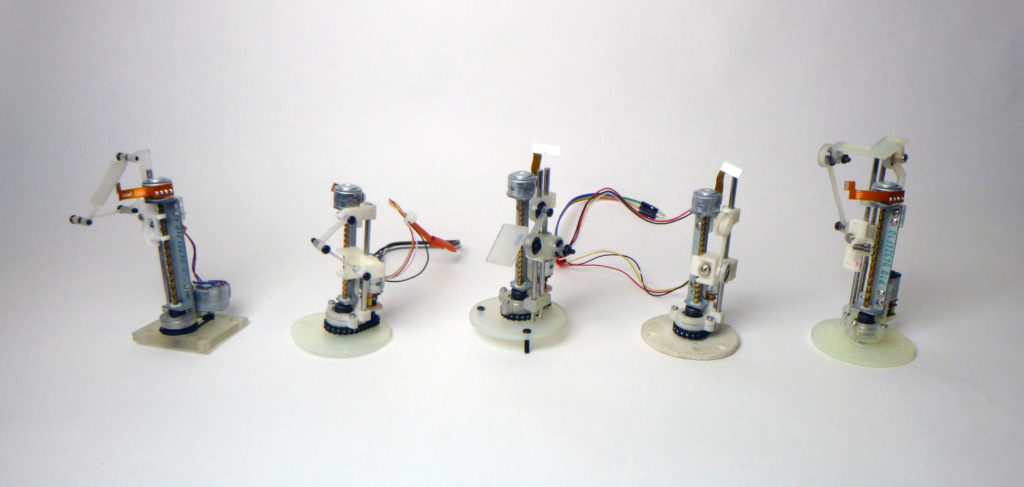

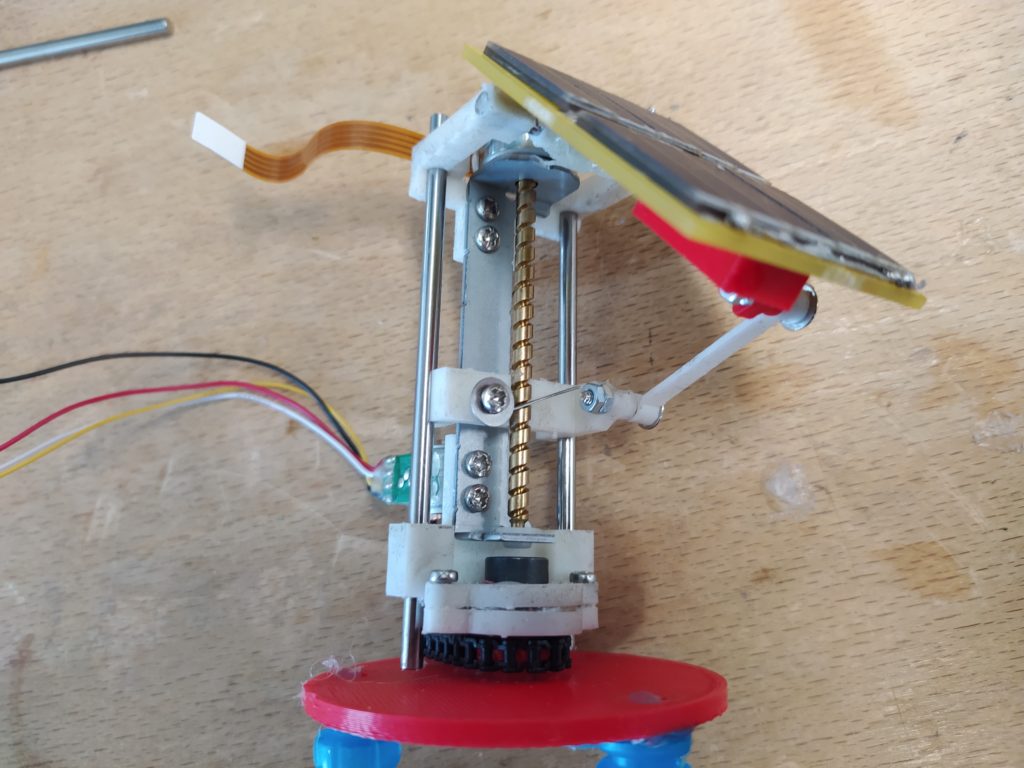

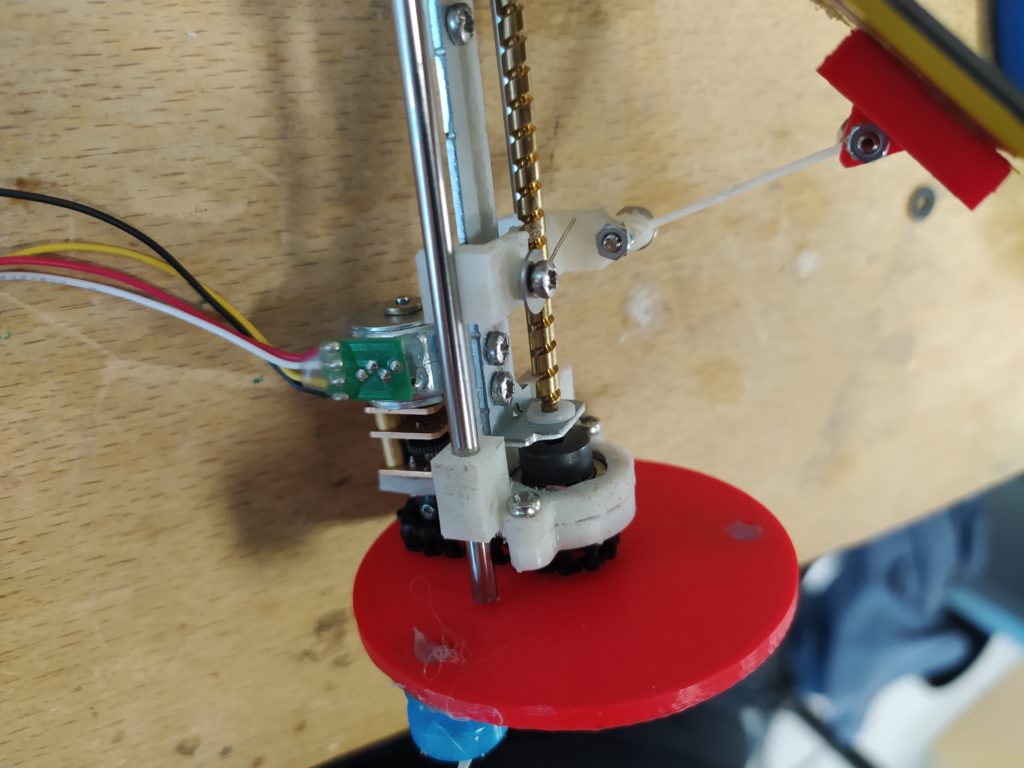

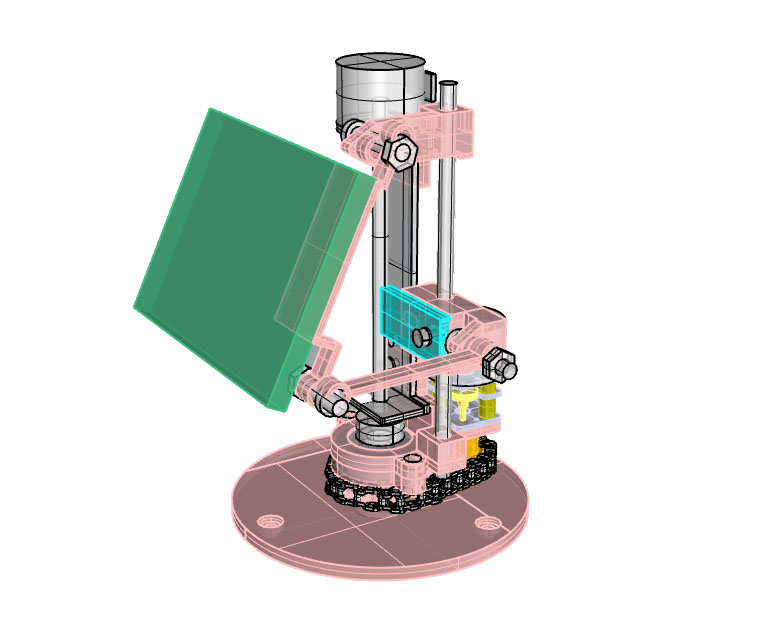

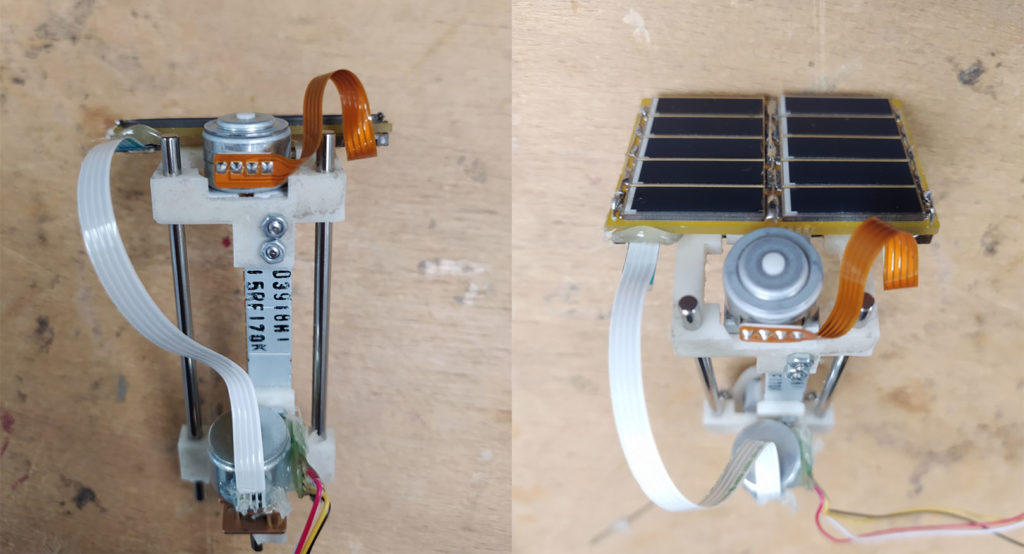

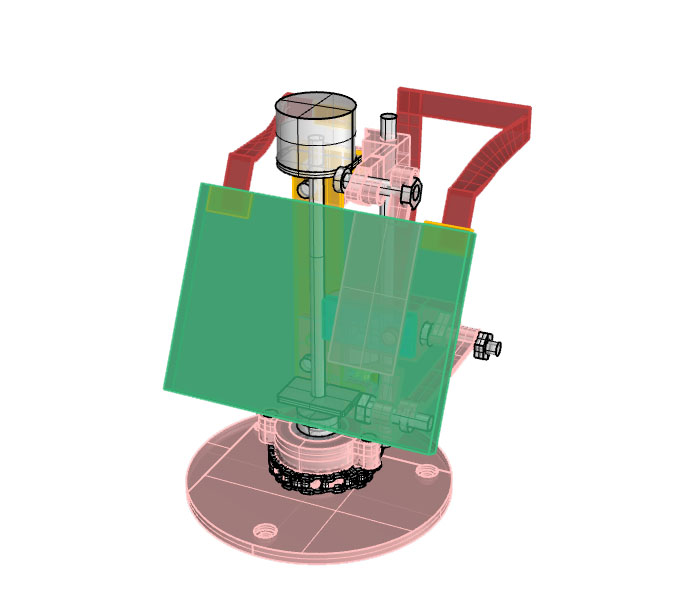

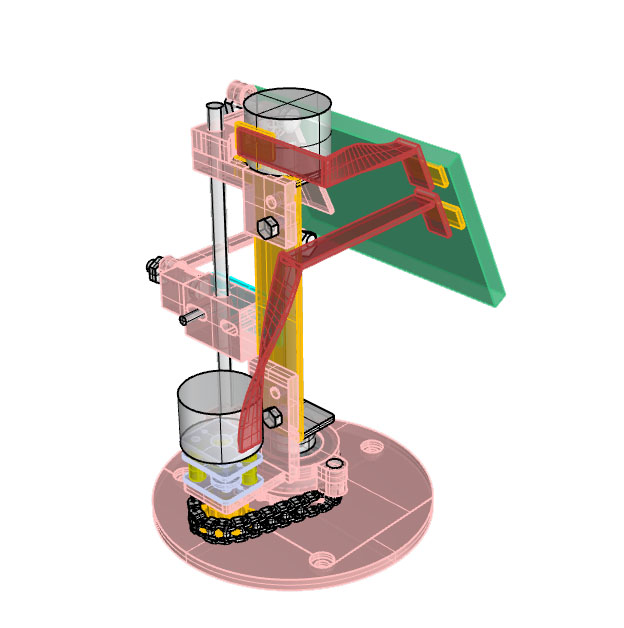

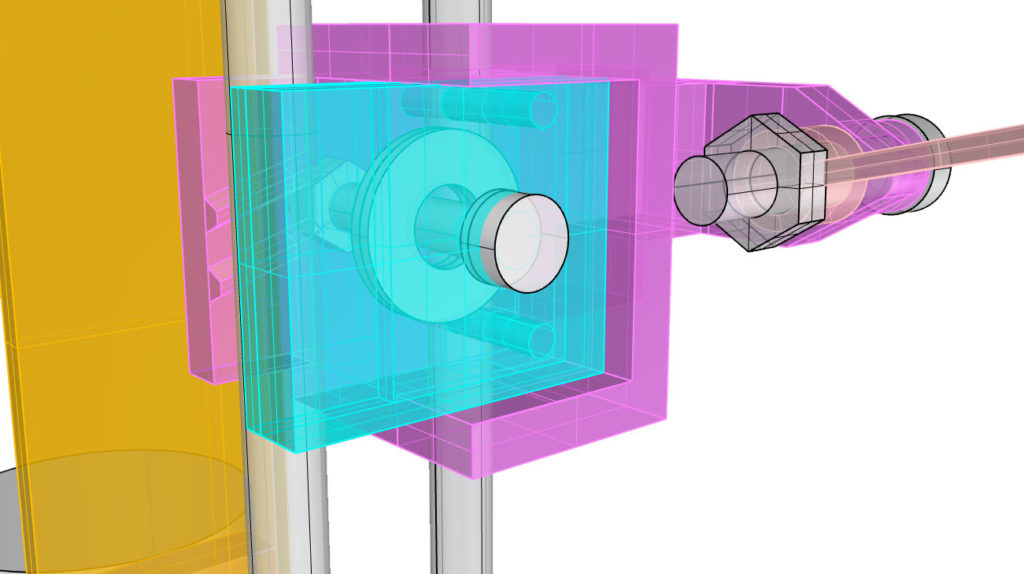

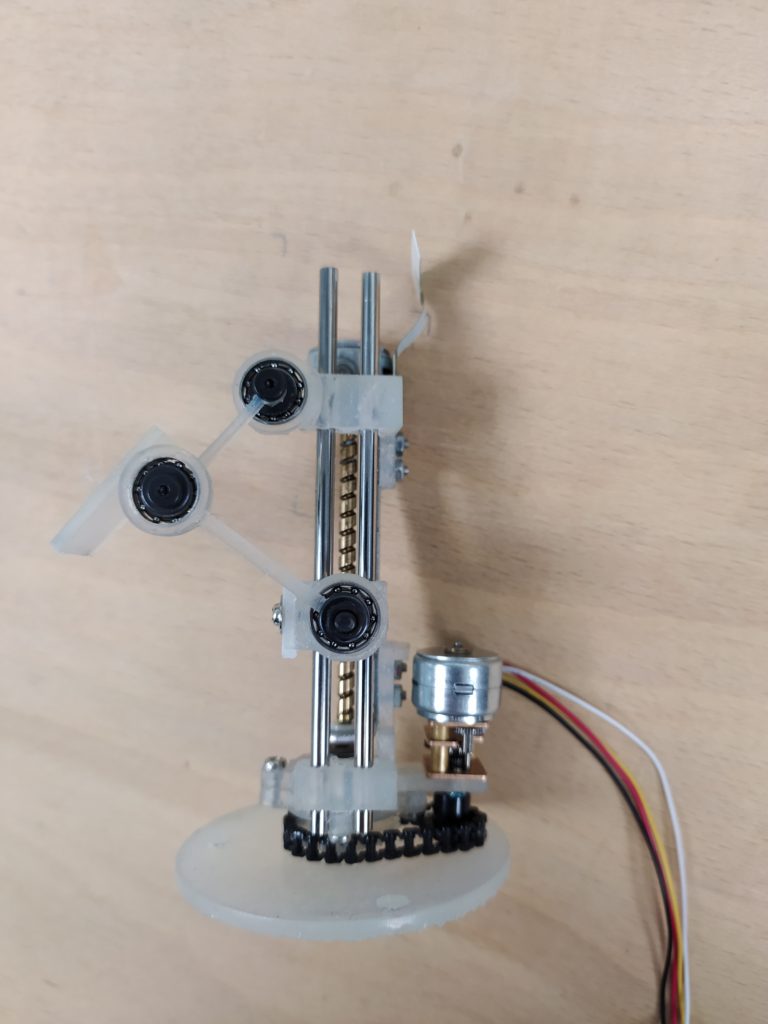

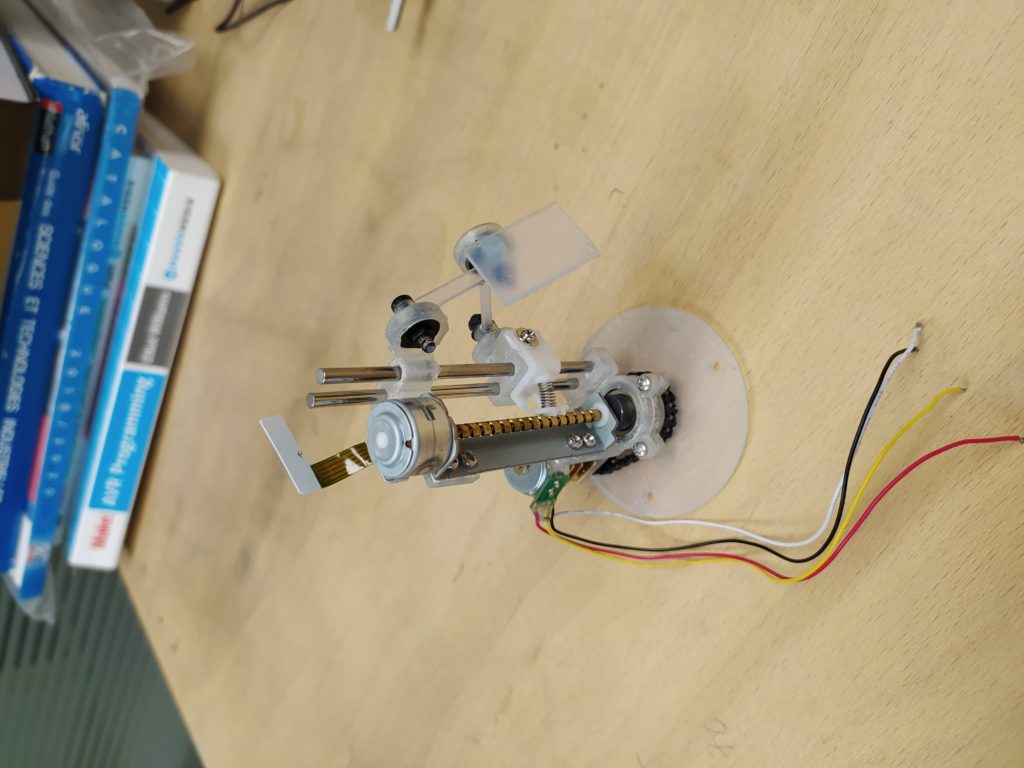

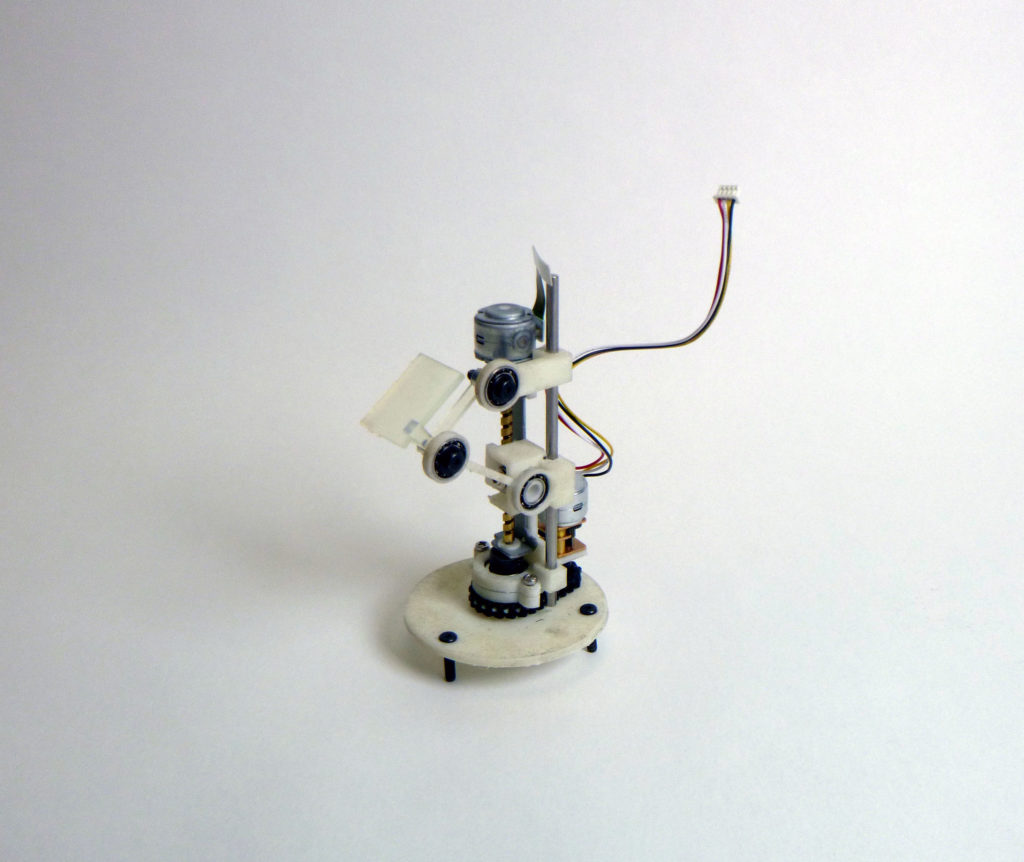

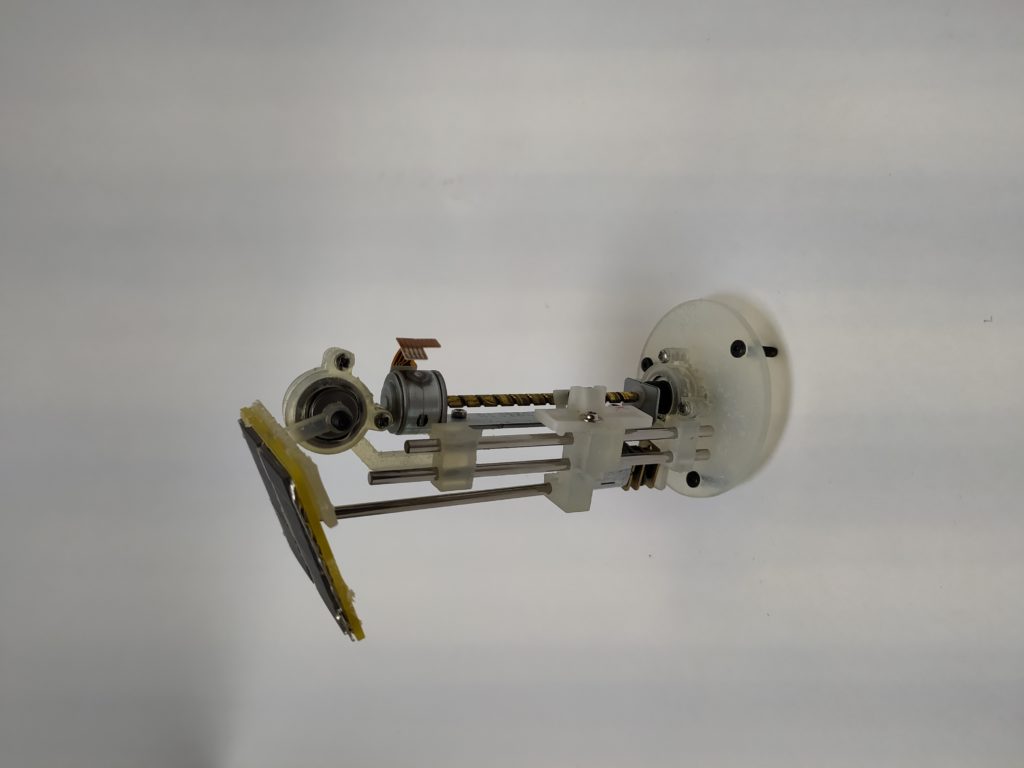

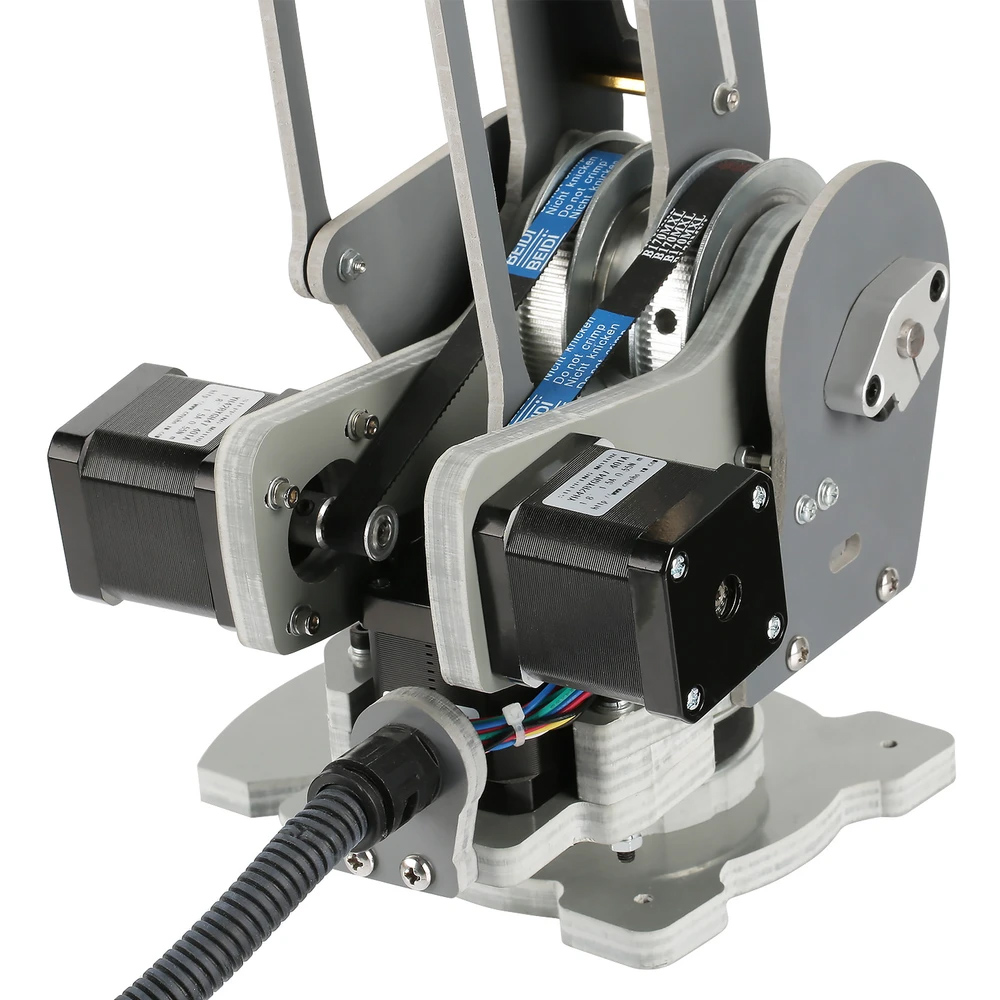

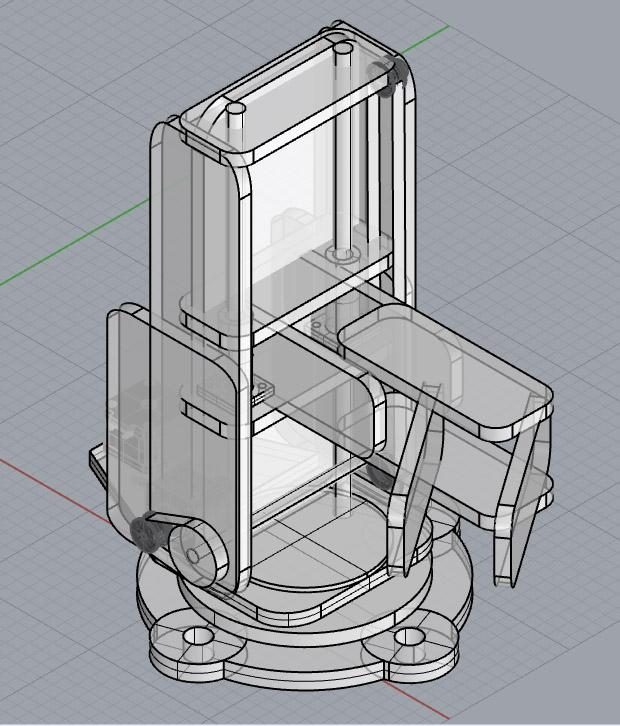

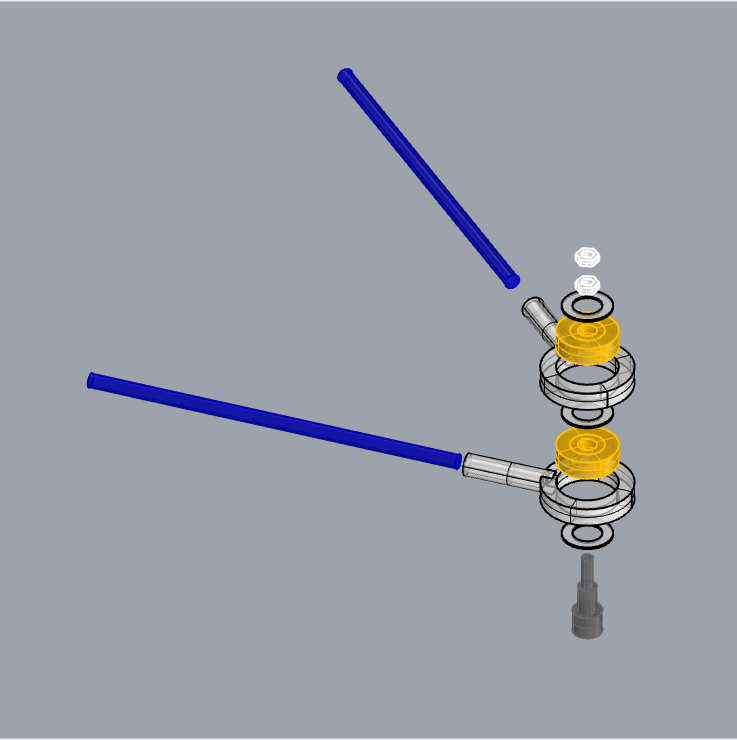

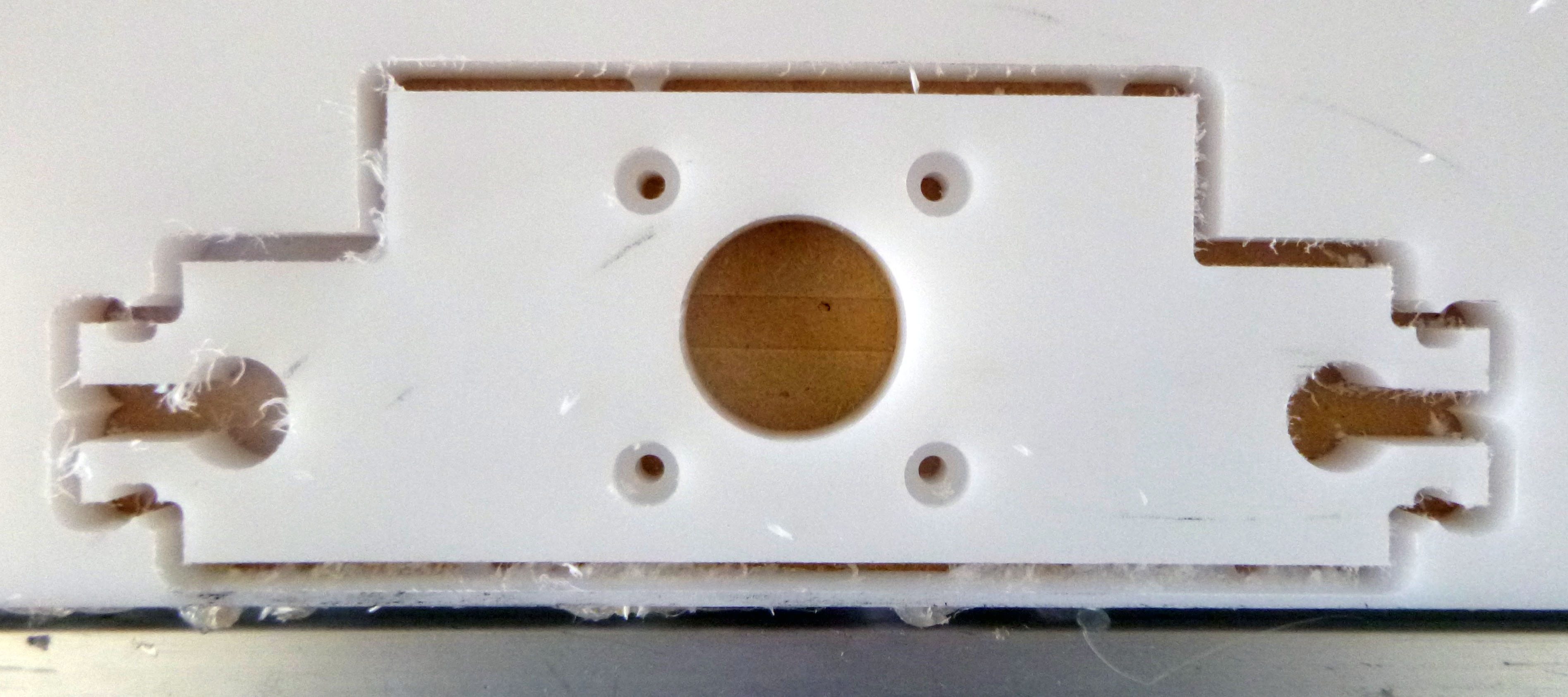

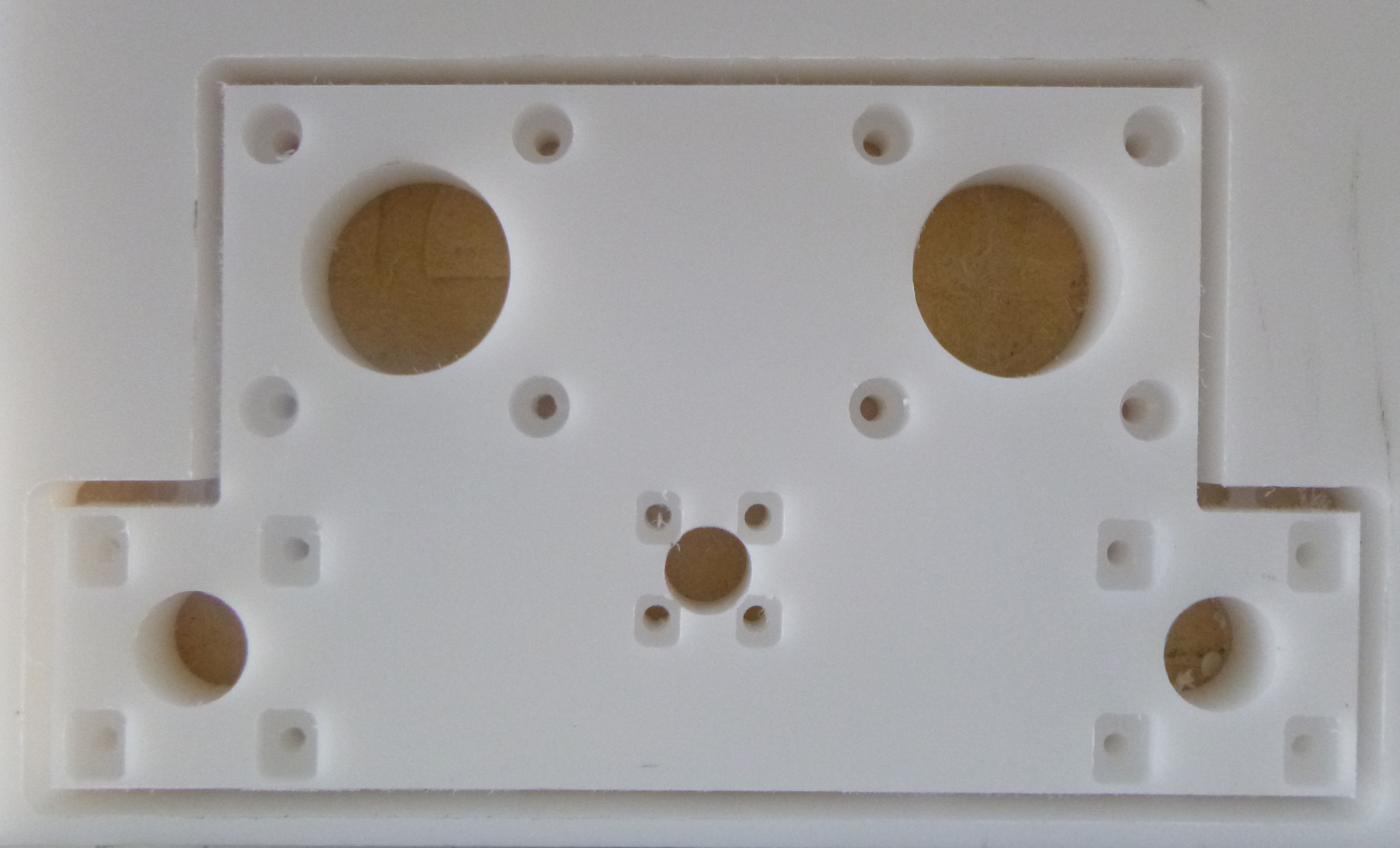

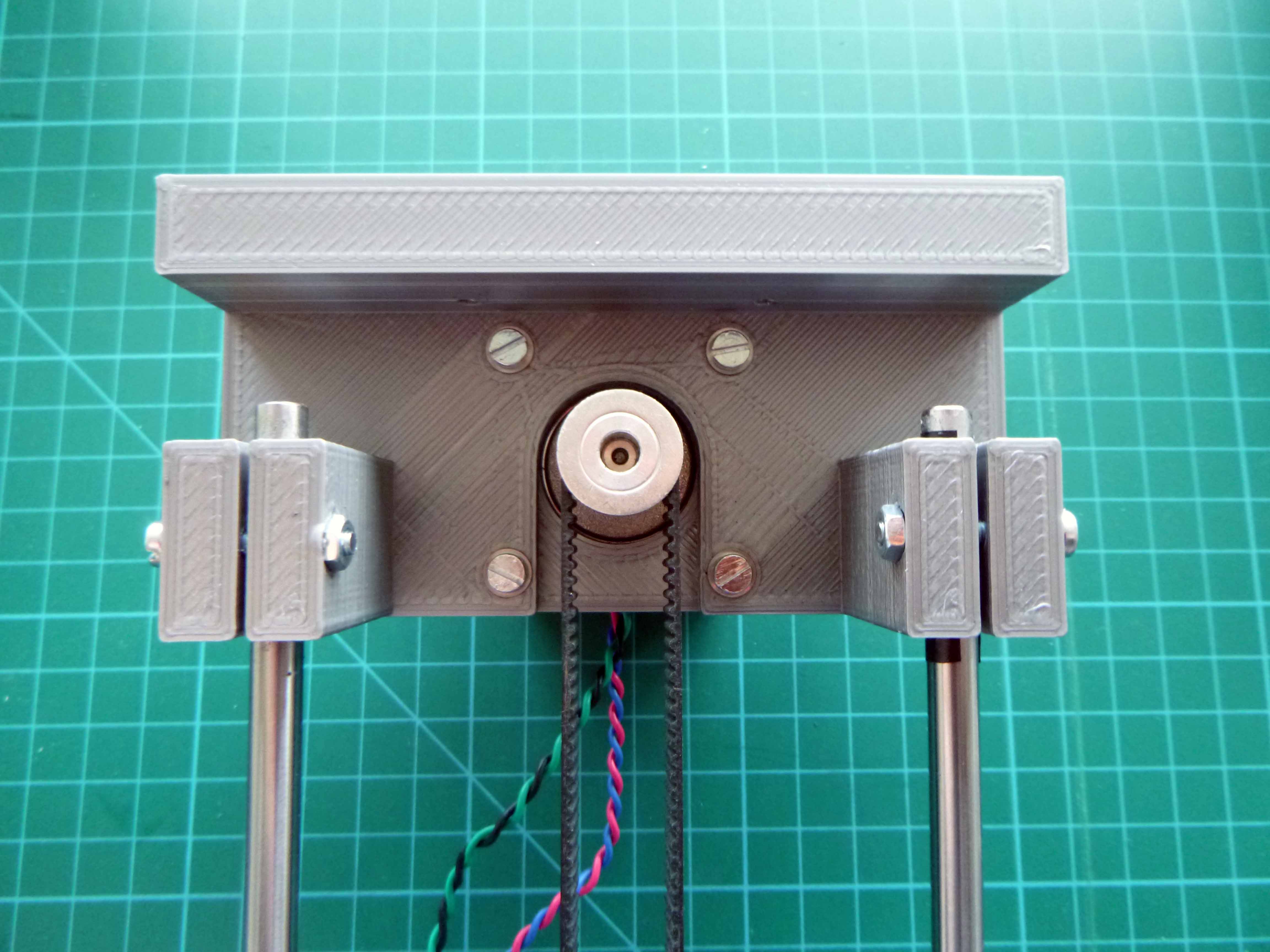

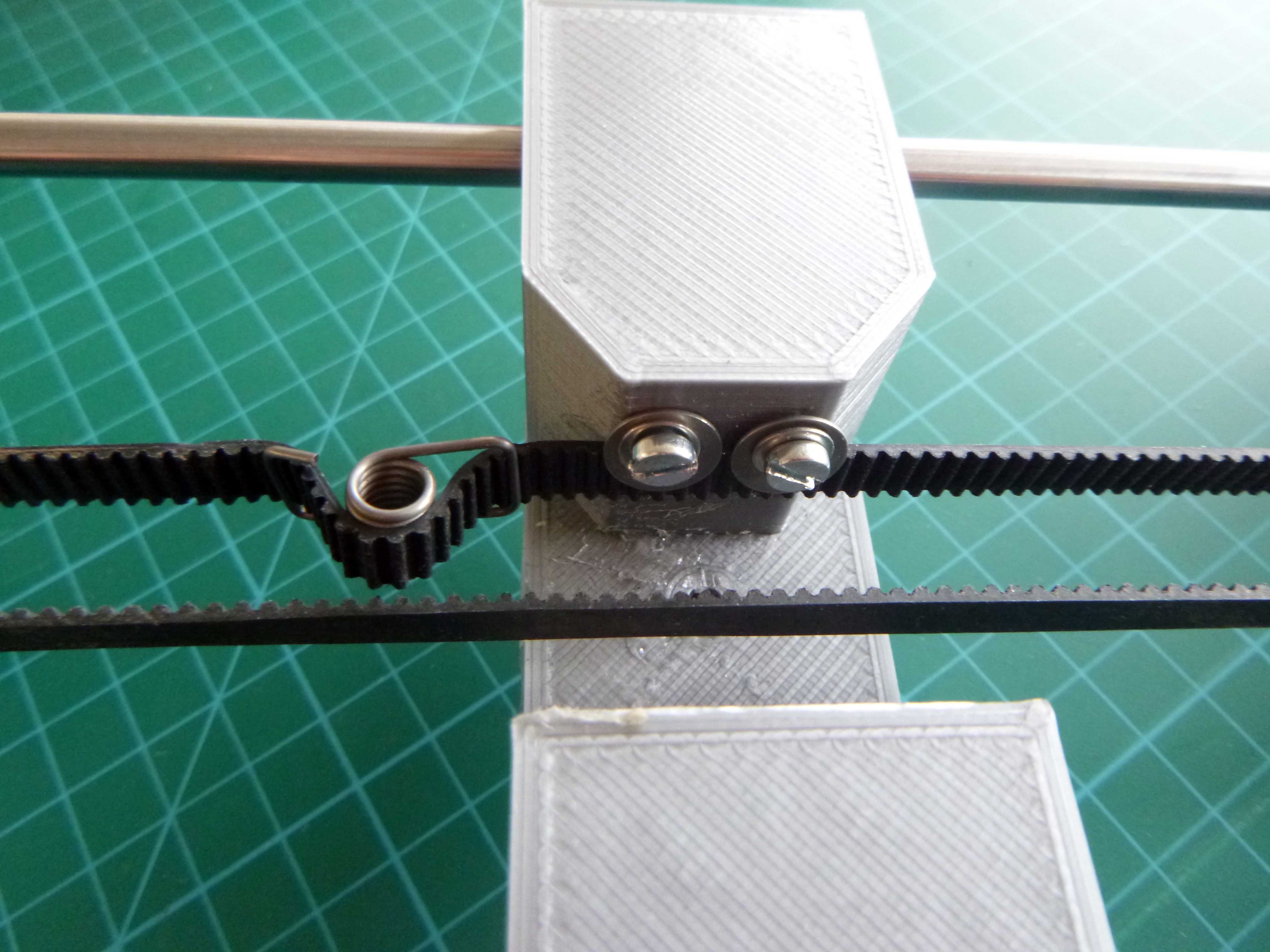

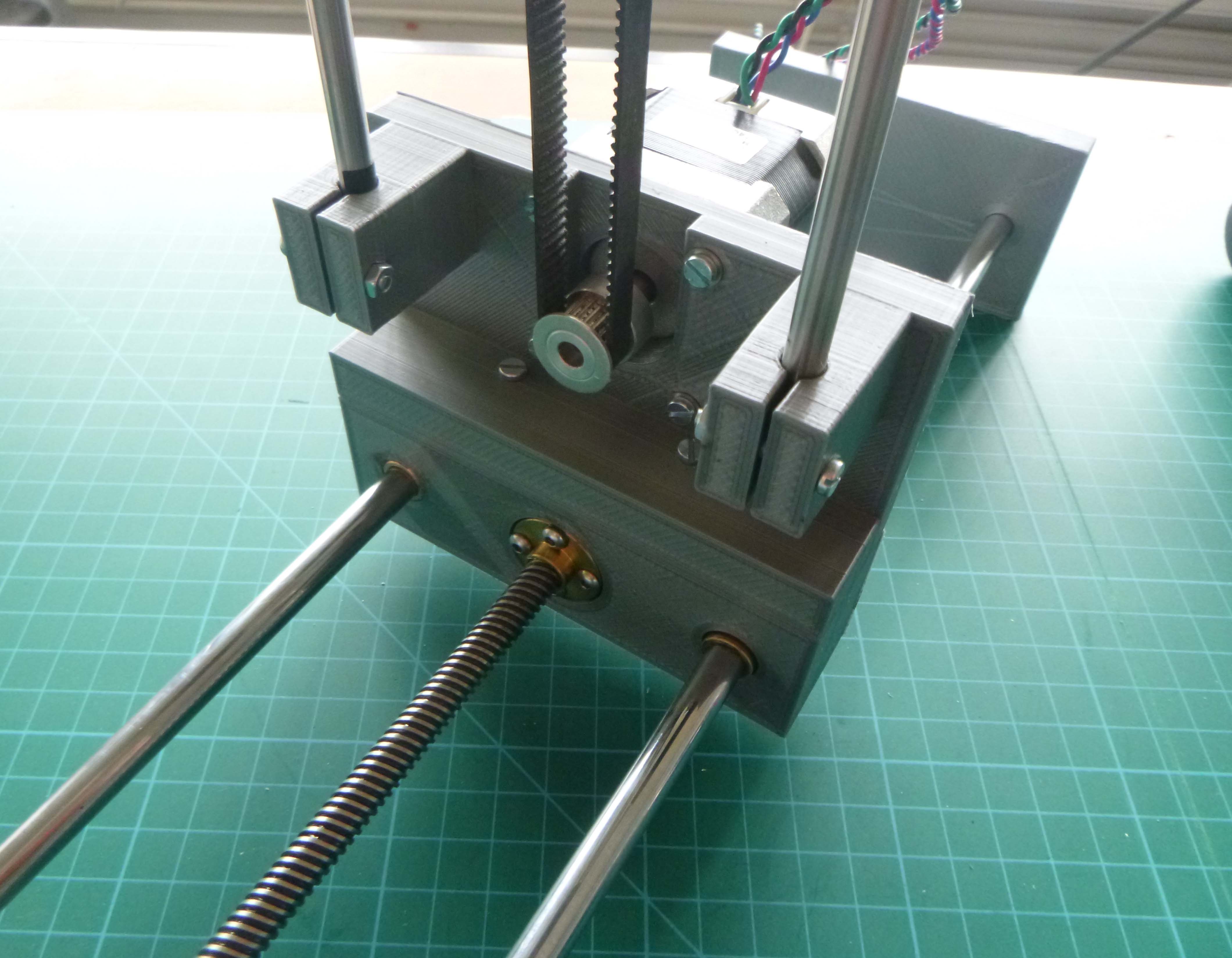

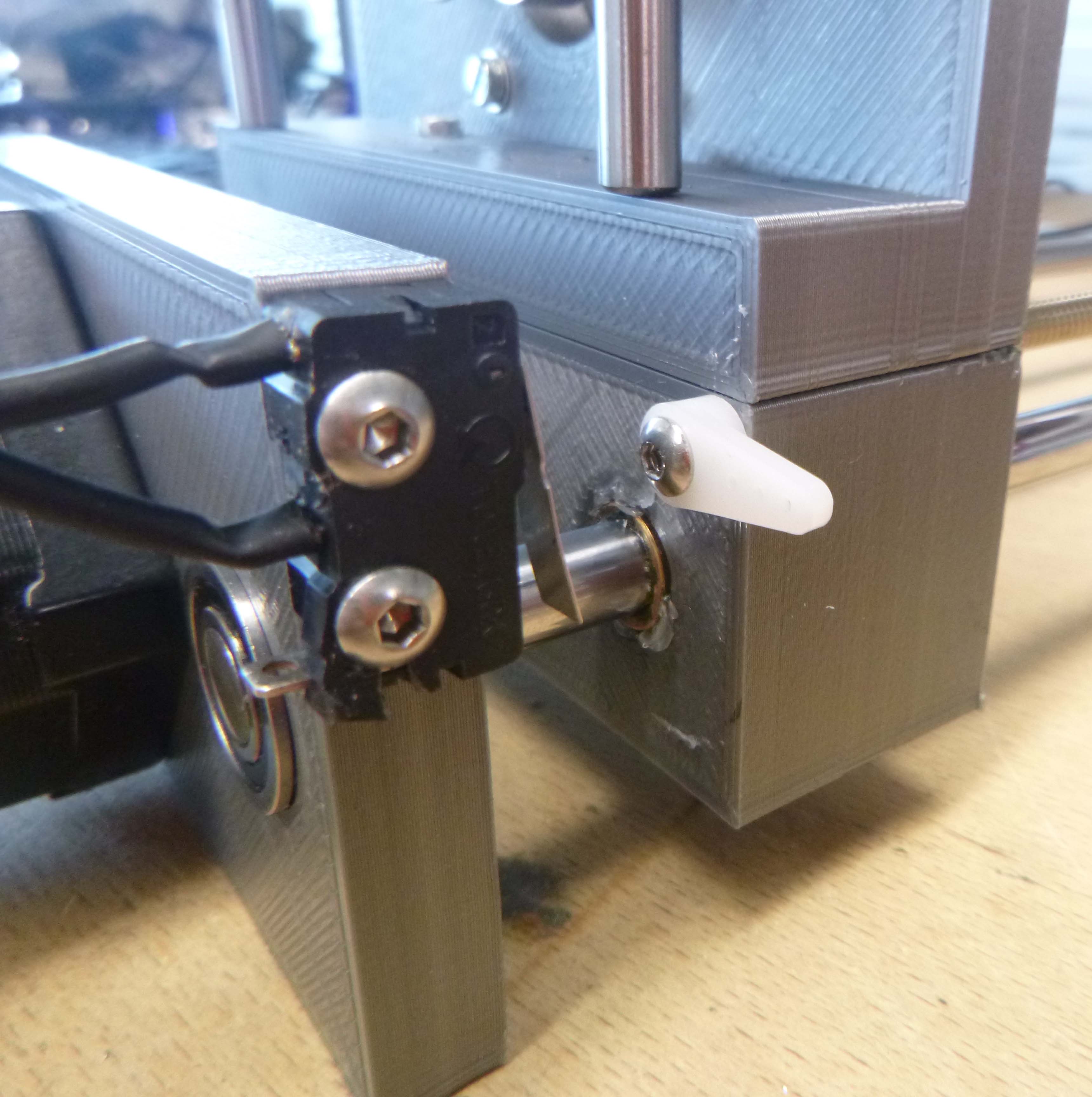

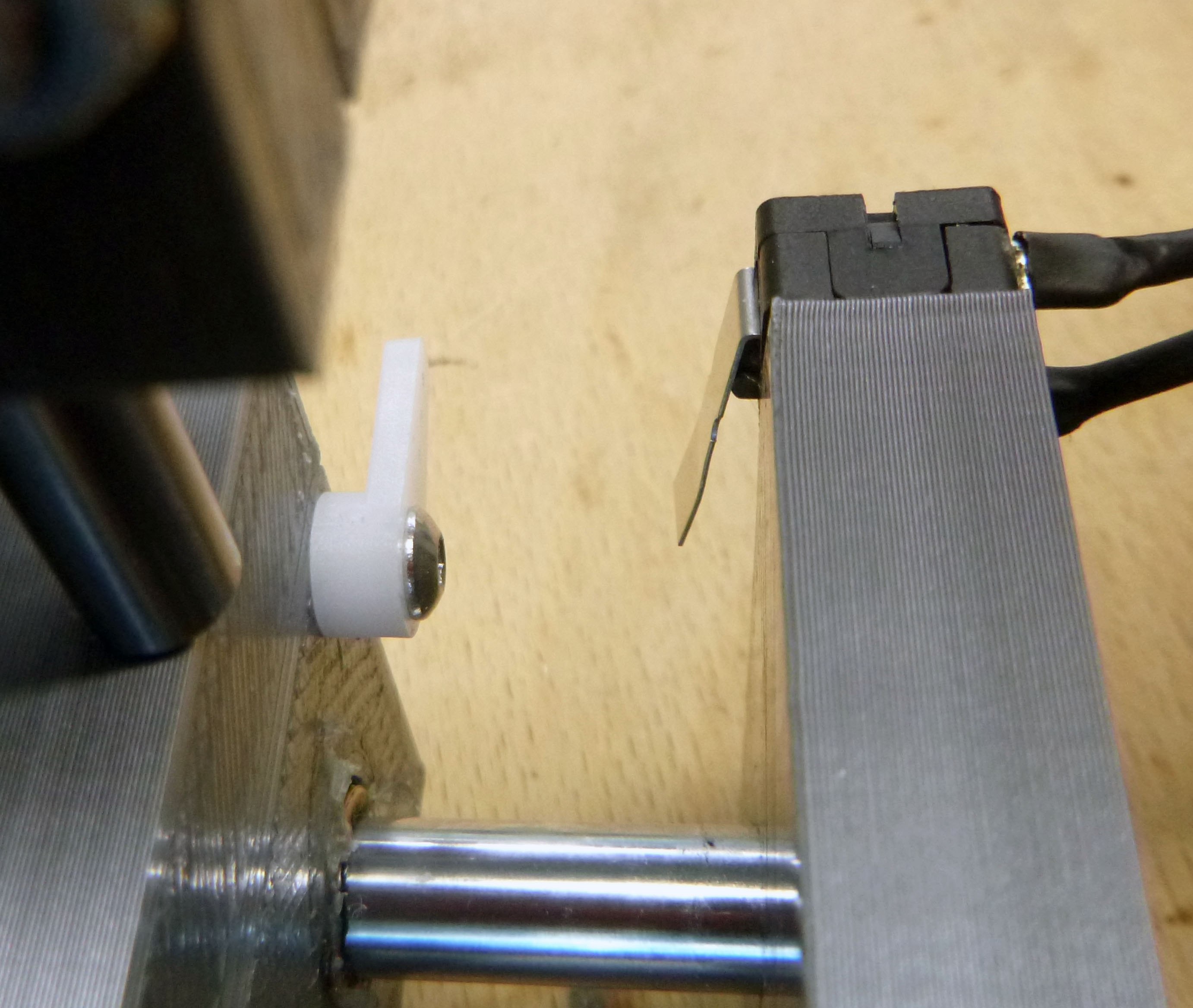

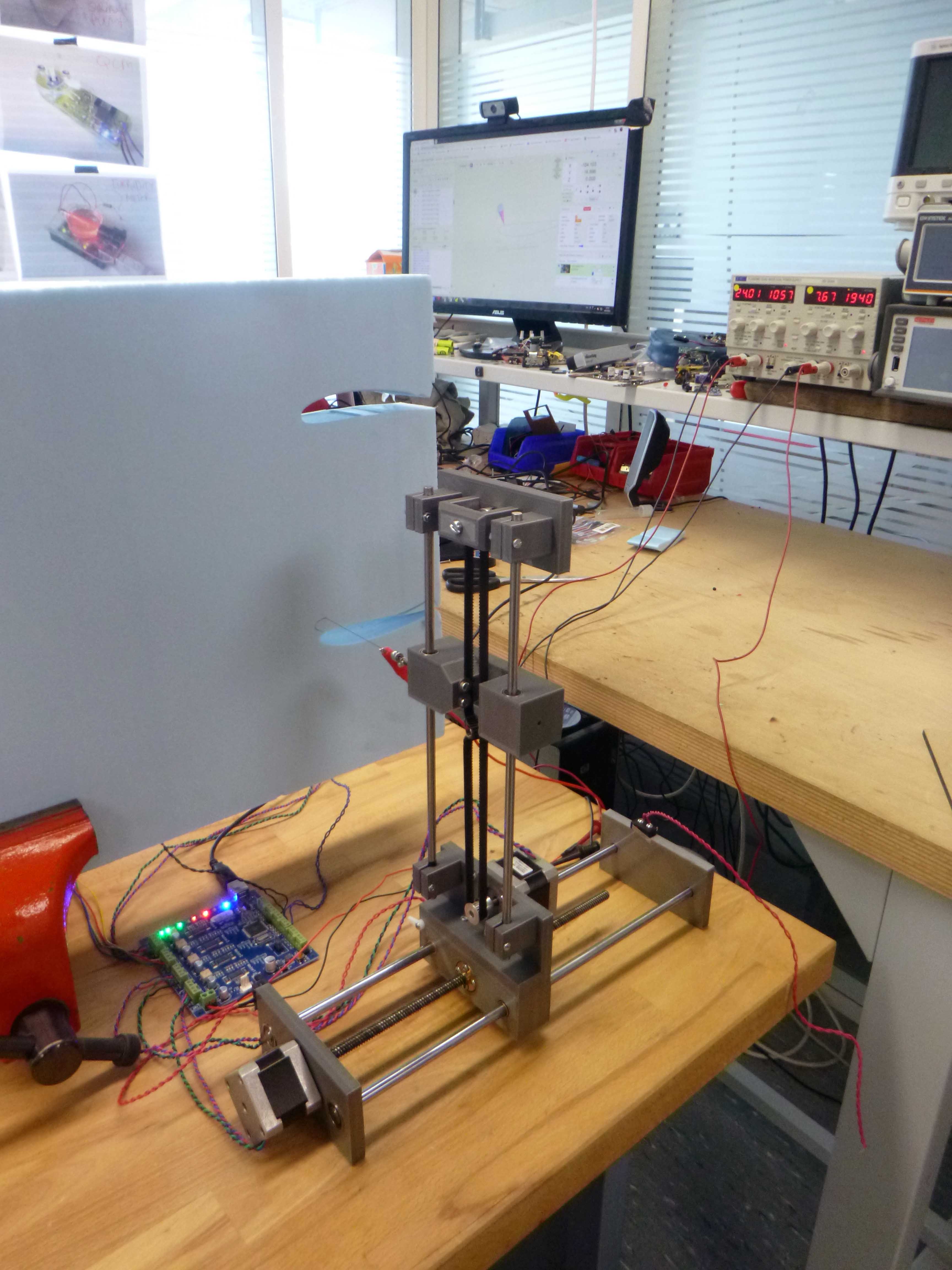

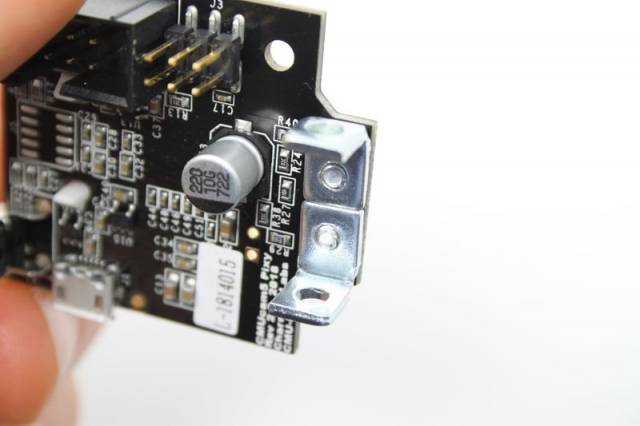

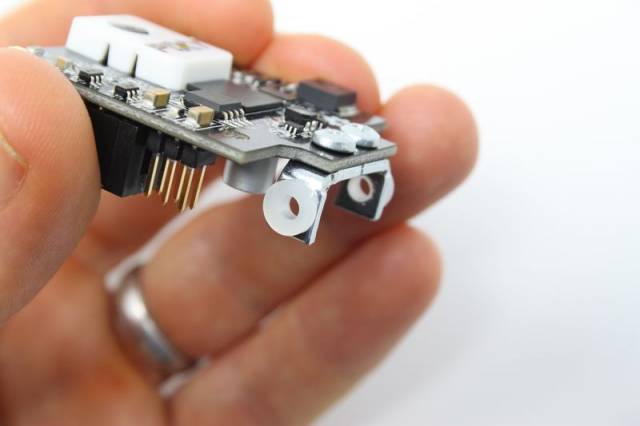

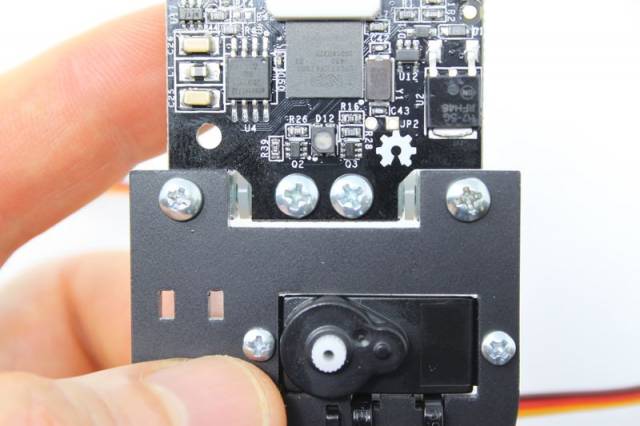

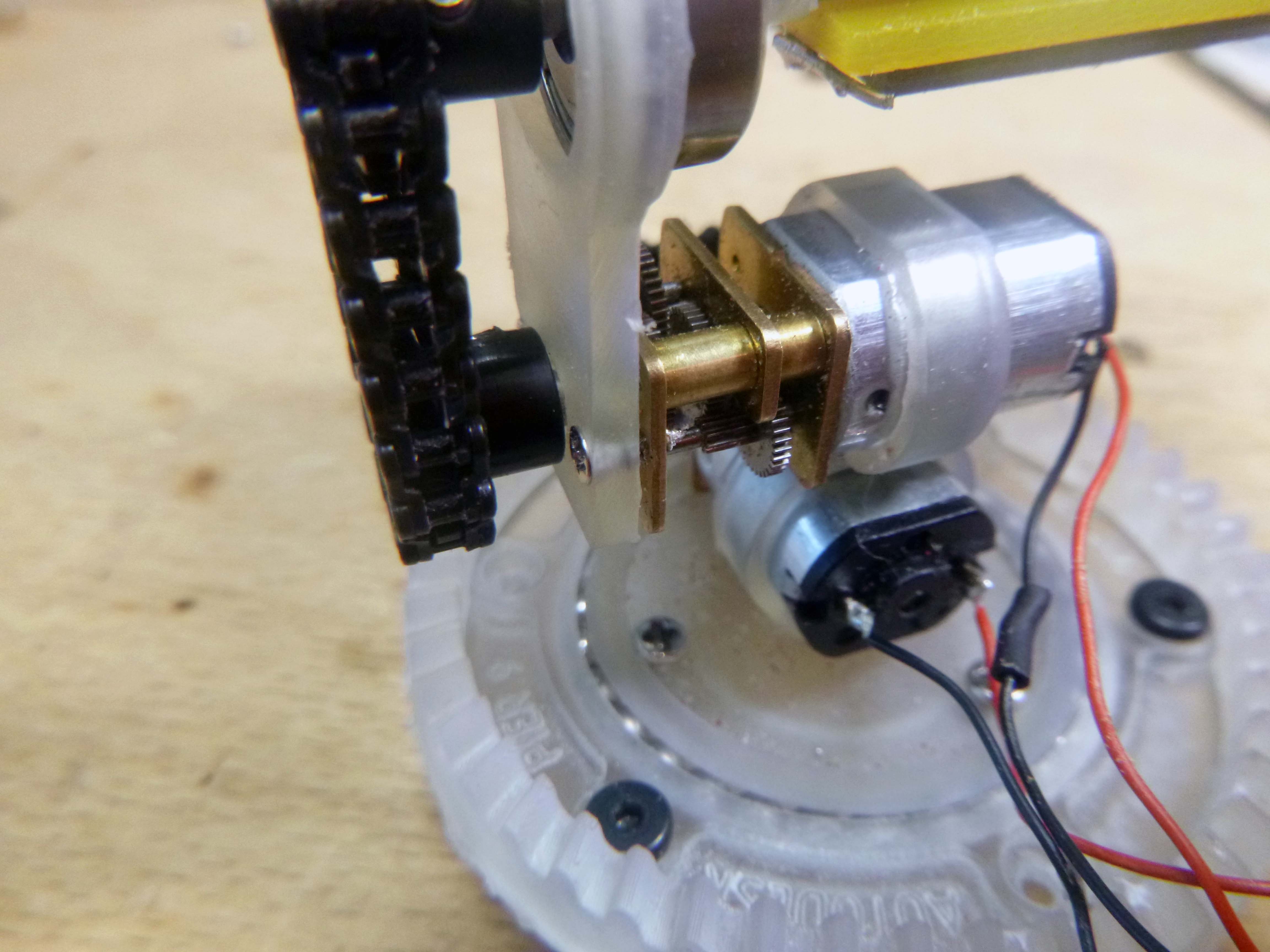

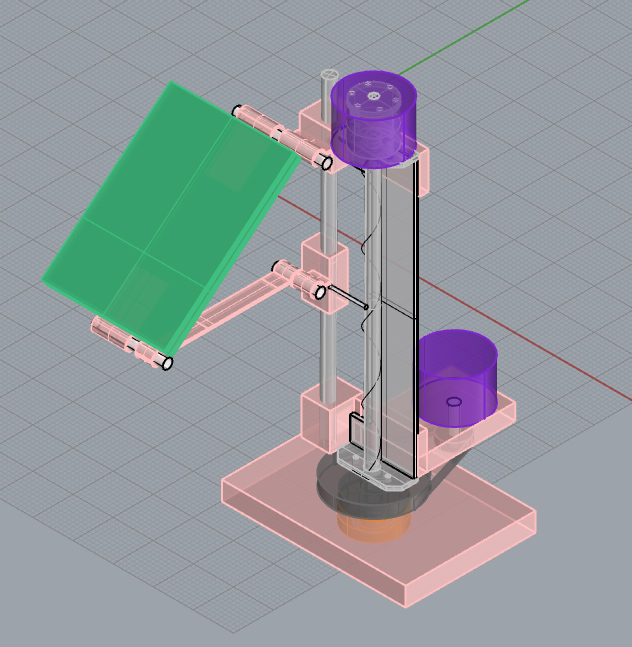

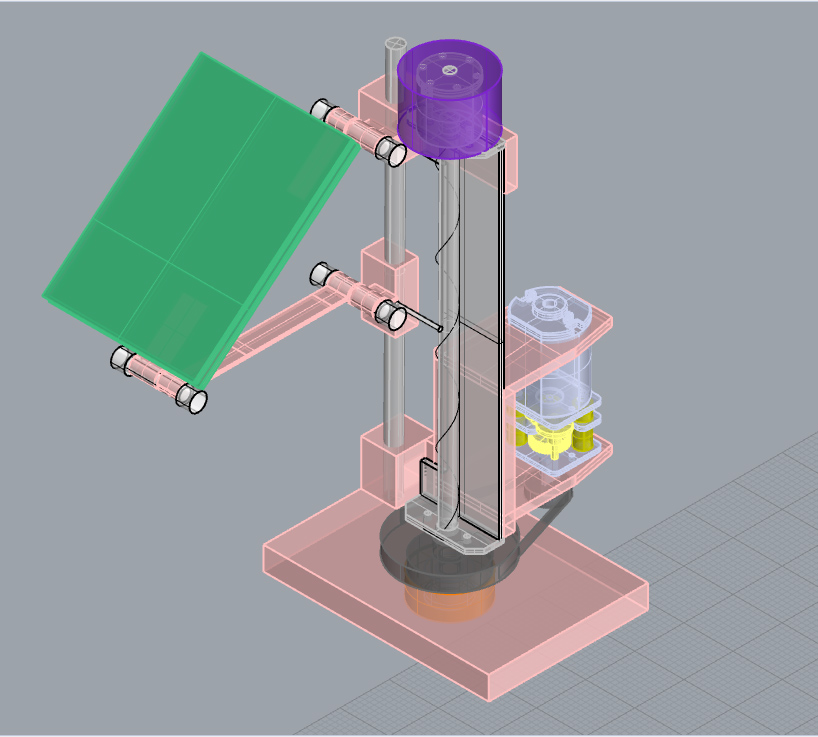

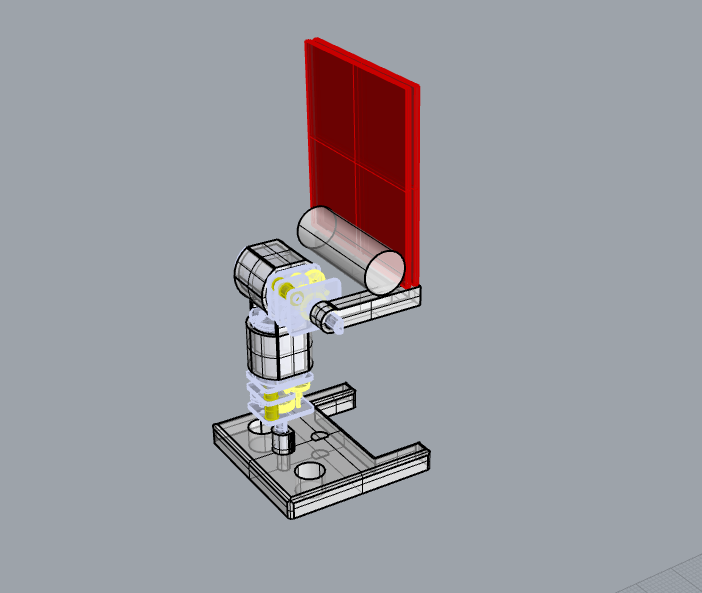

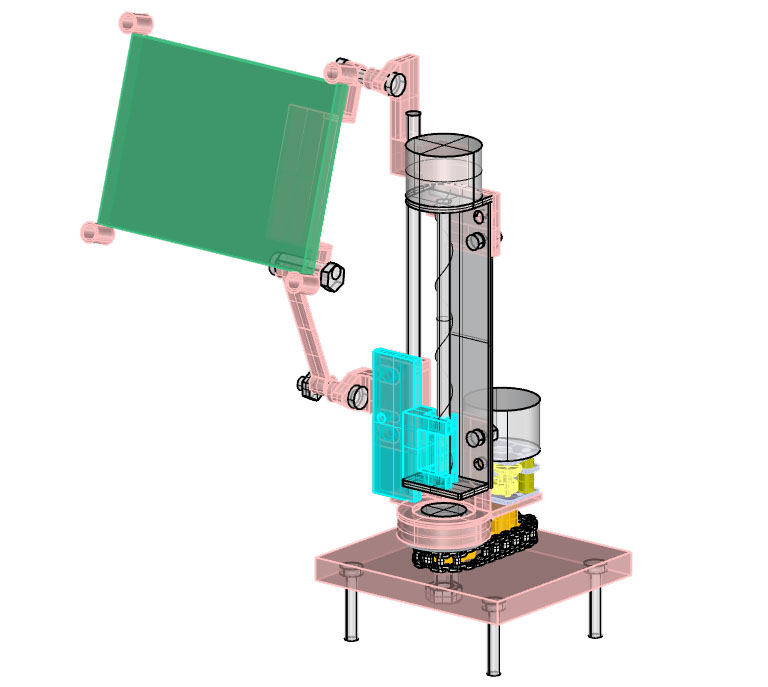

Some detail shots of the assembly (from https://docs.pixycam.com/wiki/doku.php?id=wiki:v2:assembling_pantilt_mechanism):

Some detail shots of the assembly (from https://docs.pixycam.com/wiki/doku.php?id=wiki:v2:assembling_pantilt_mechanism):

•••••••••••••••

•••••••••••••••

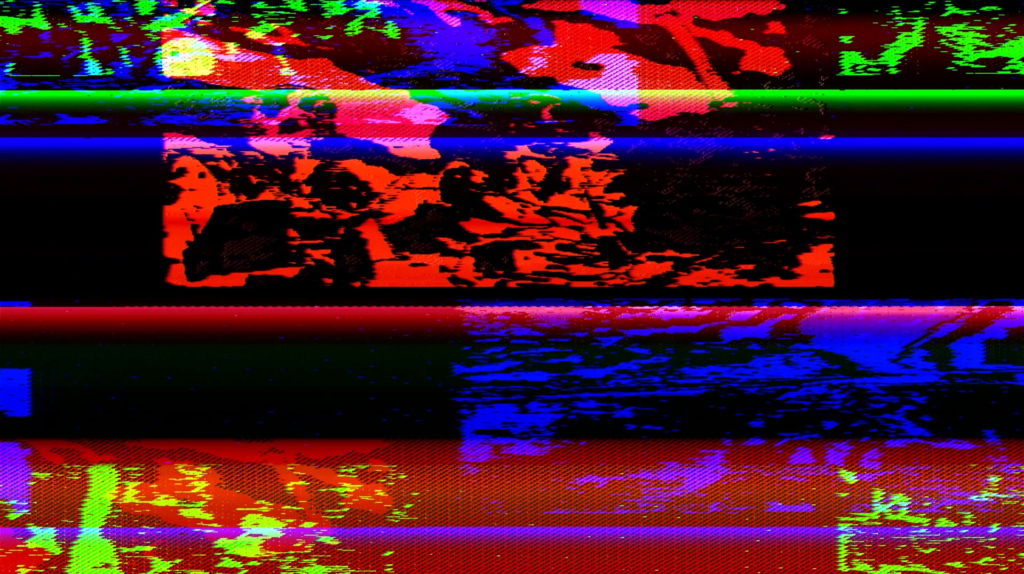

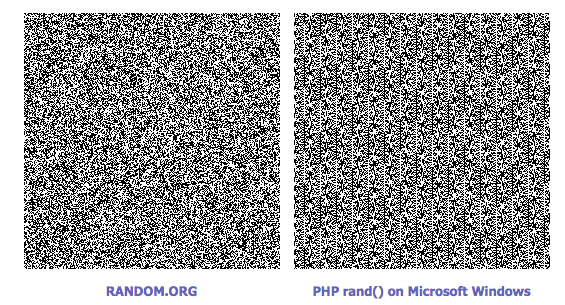

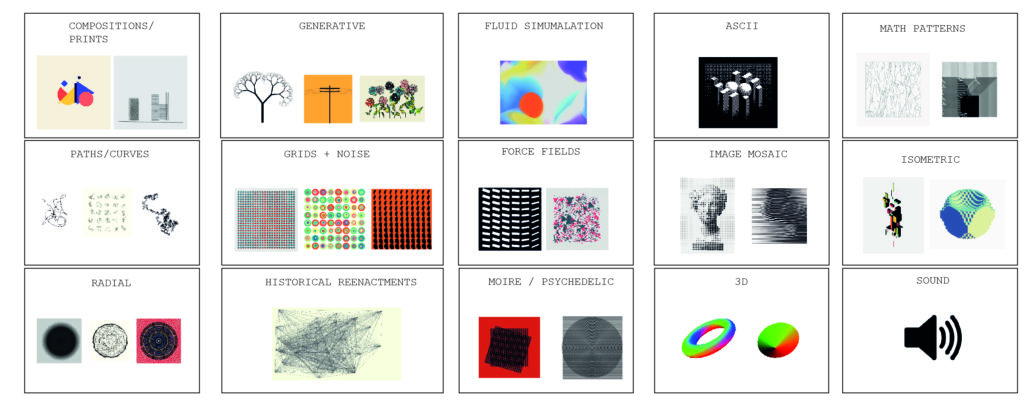

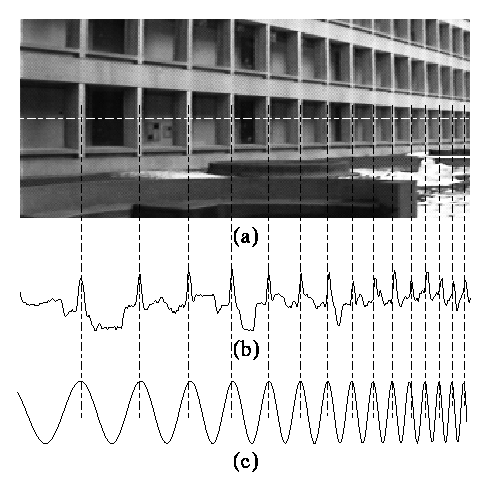

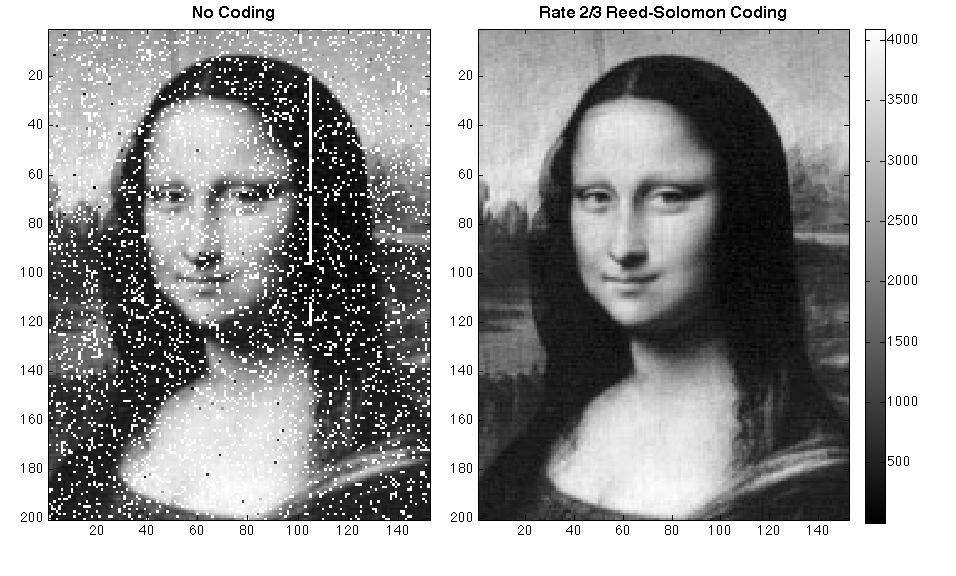

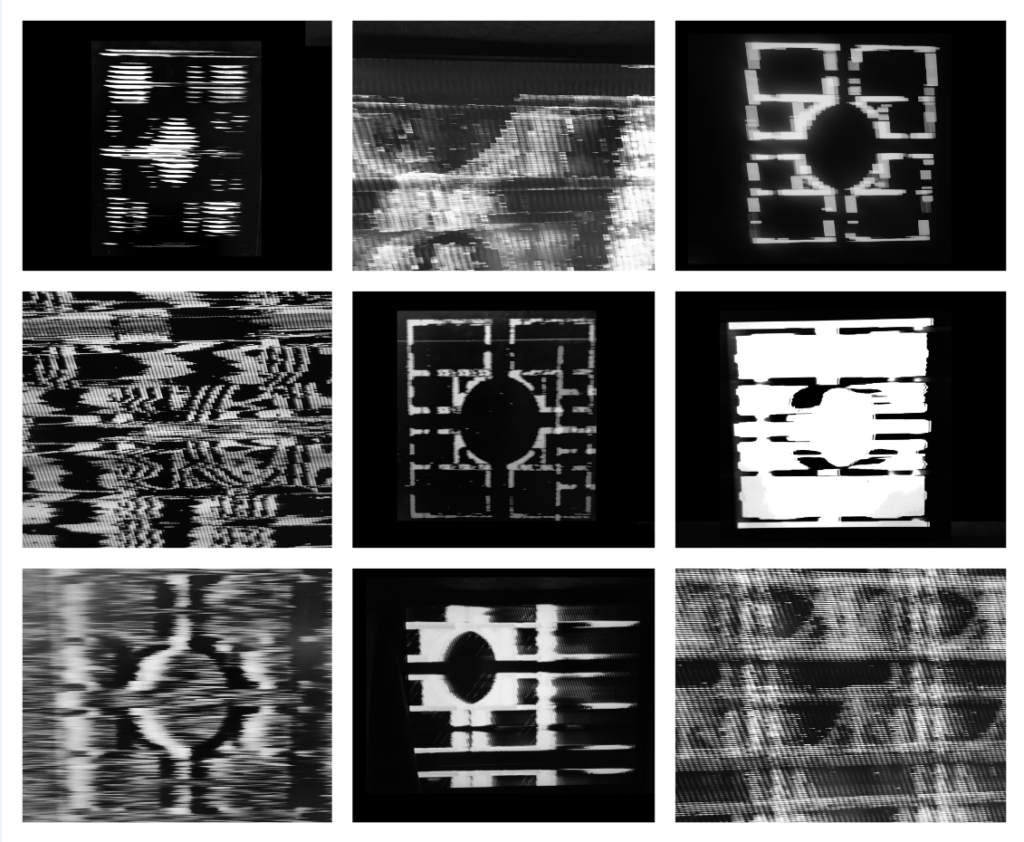

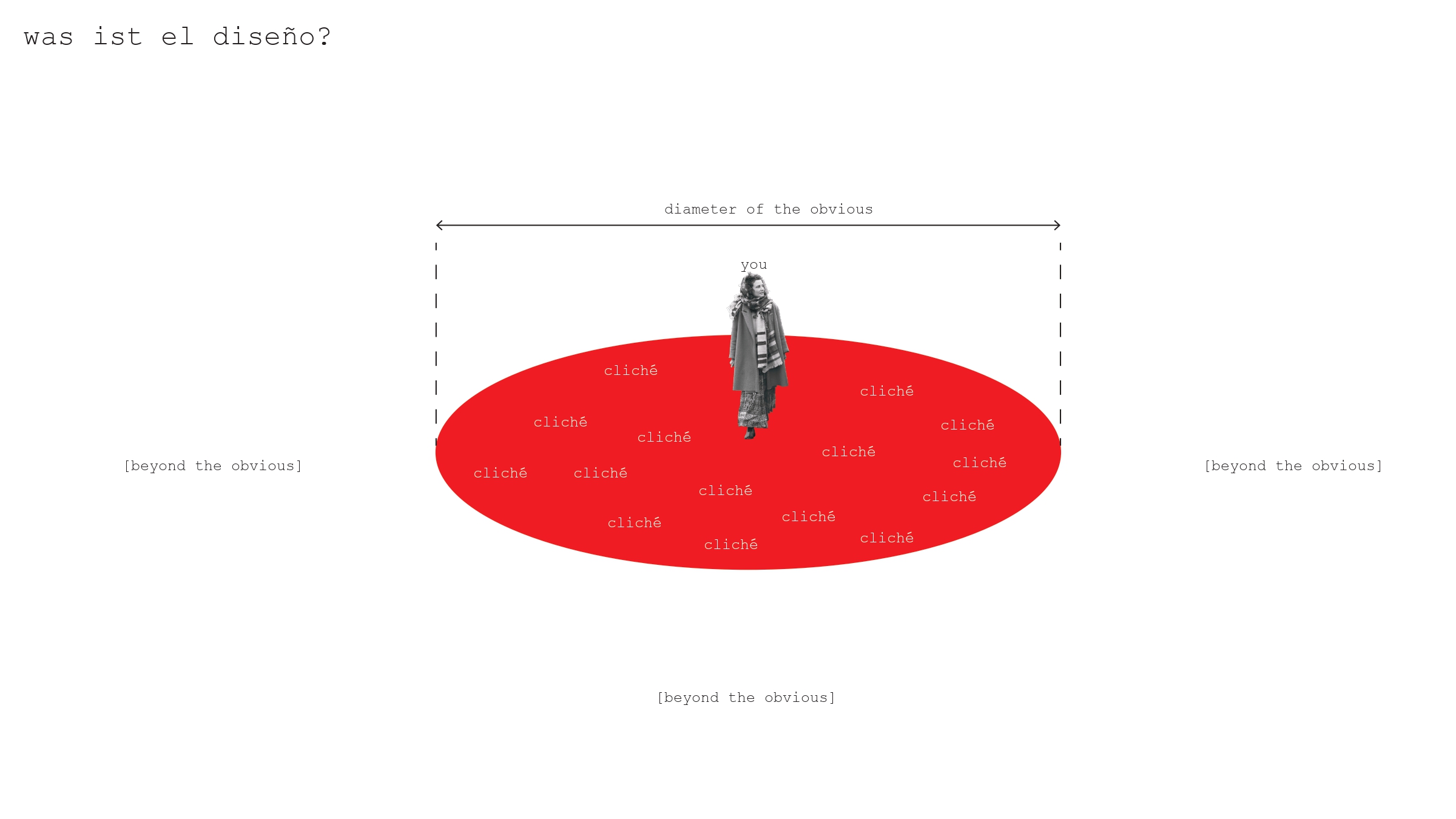

could try to visualize series of repeated pixel patterns and the "live" processing of these by different algorithms, some greedy others with different priorities?

Check out this stuff on frame buffers:

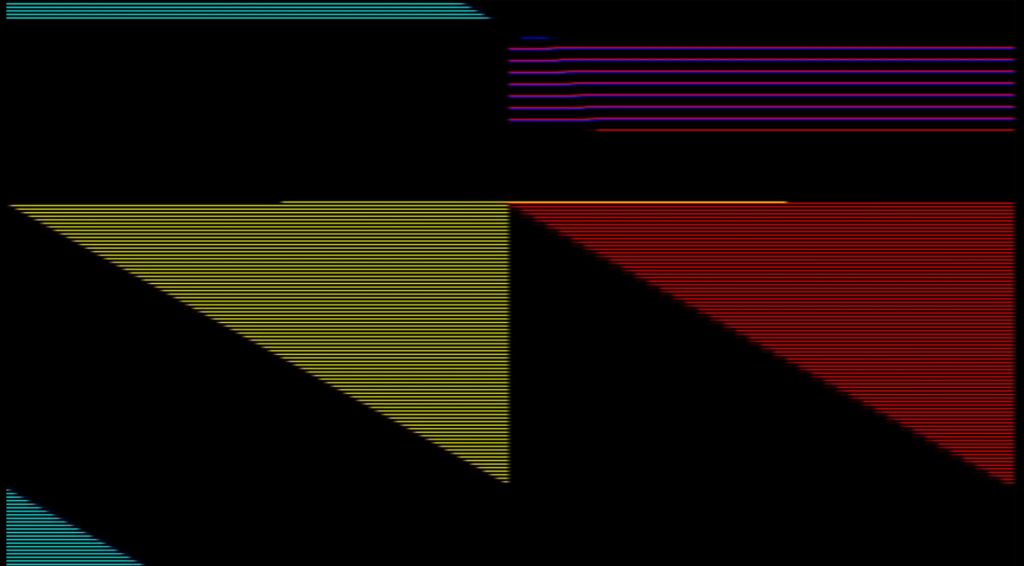

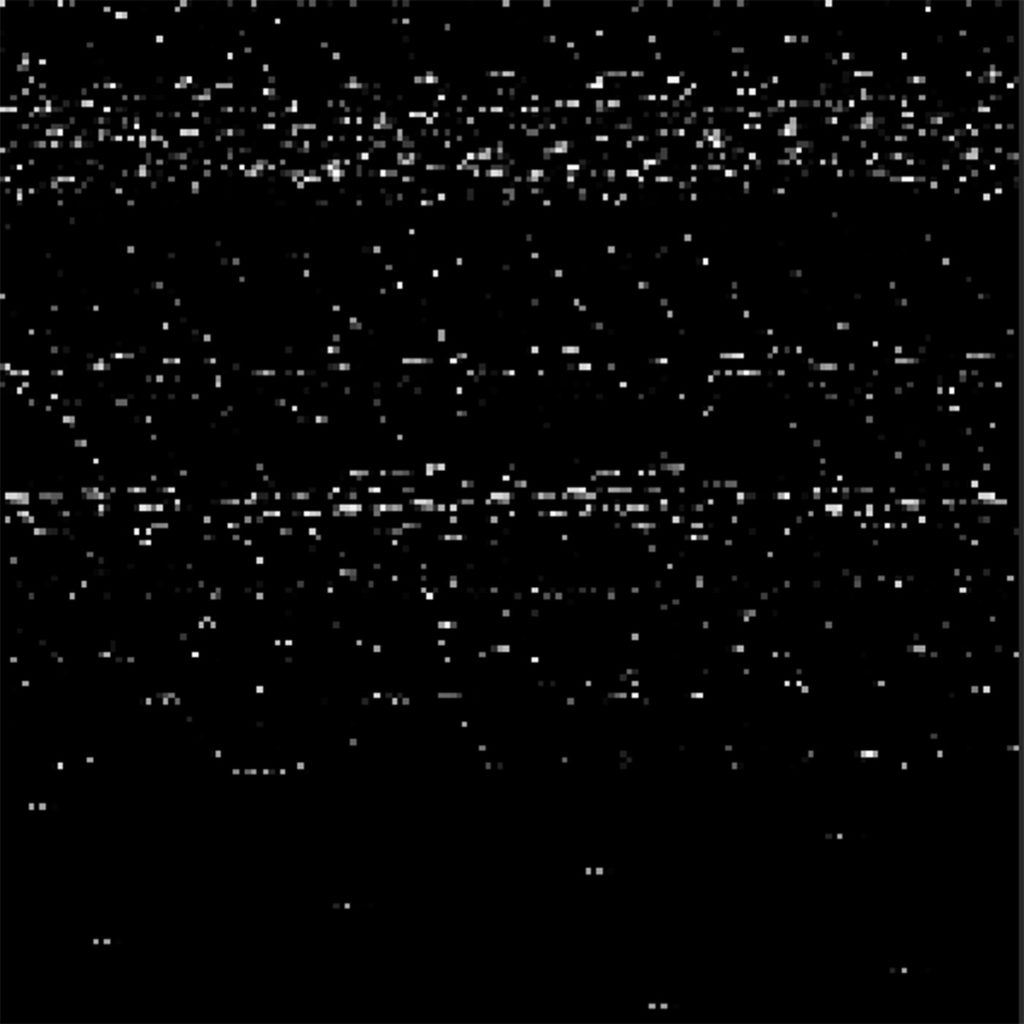

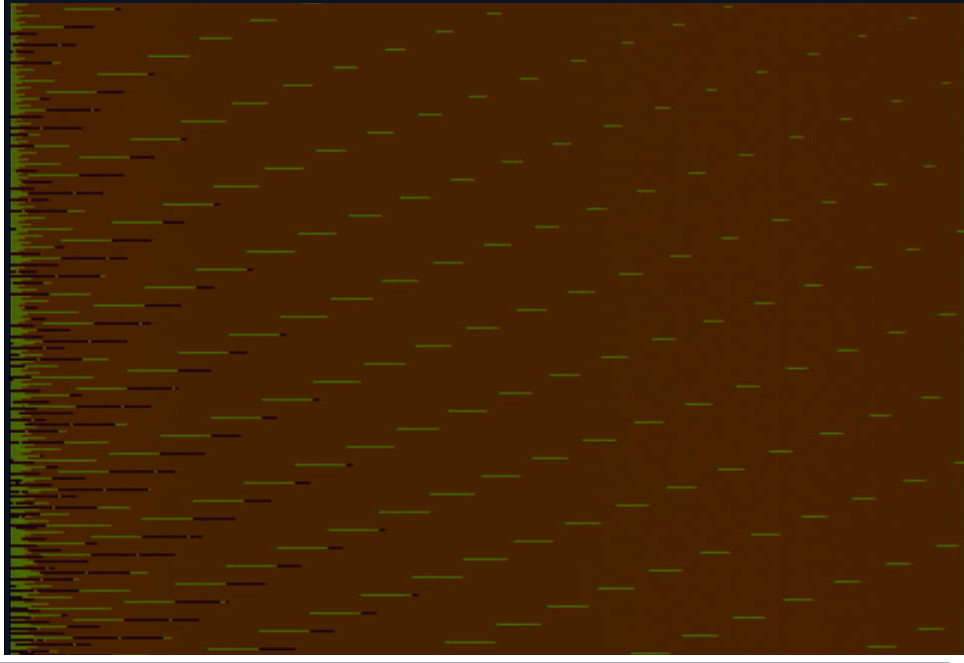

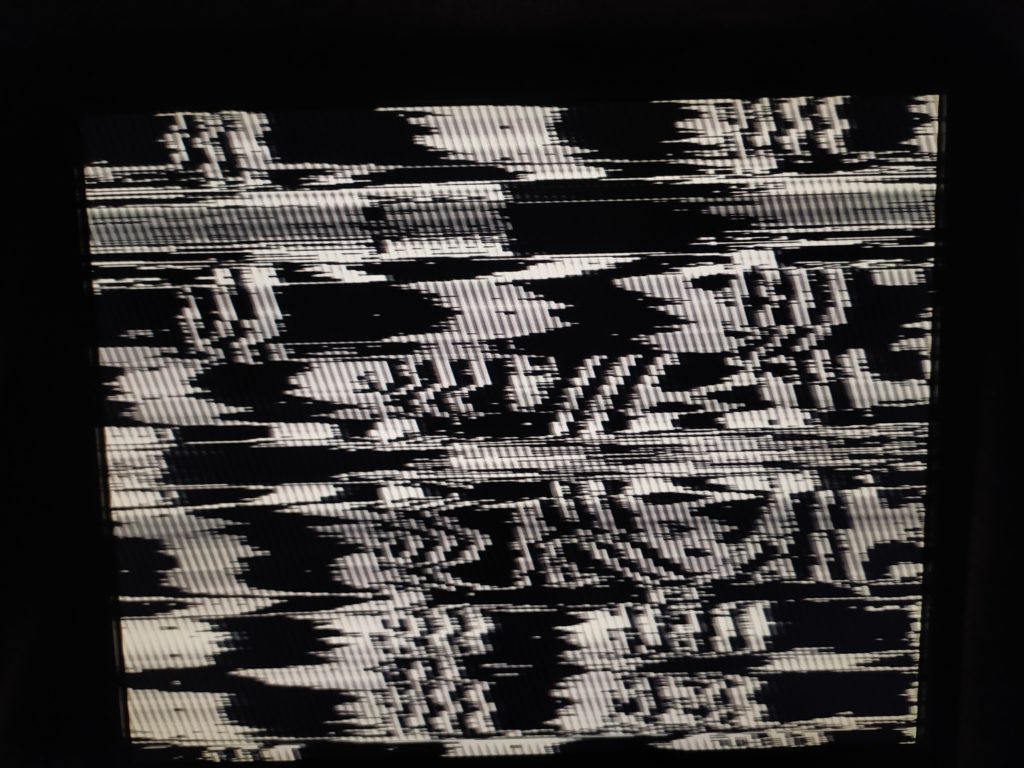

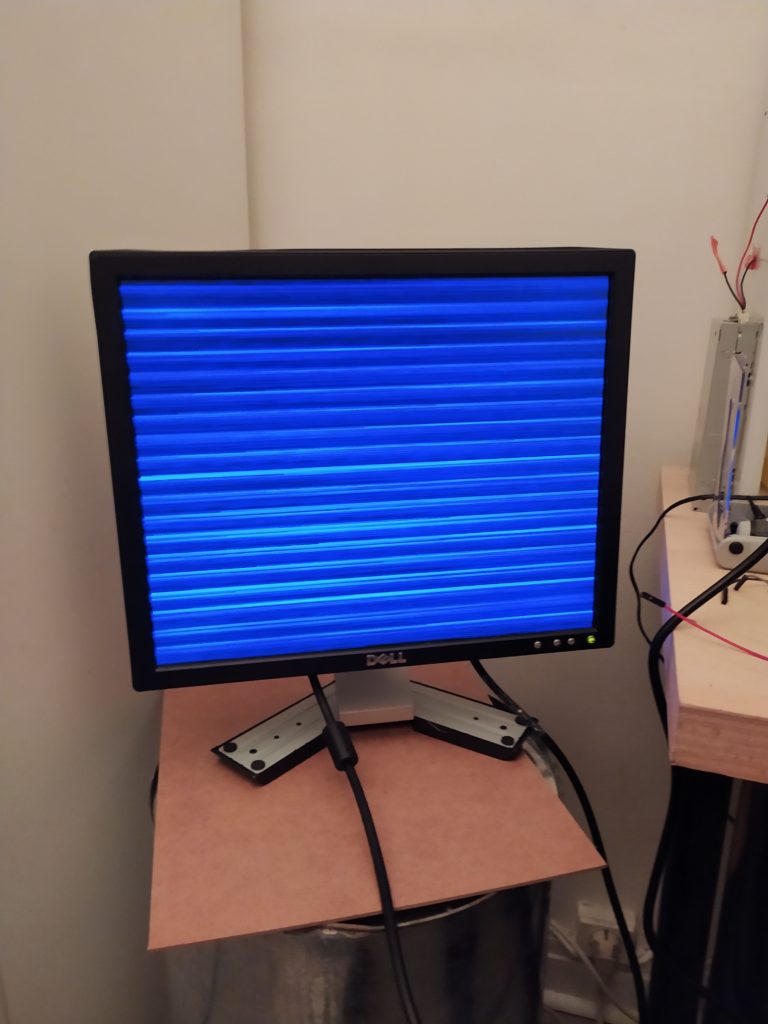

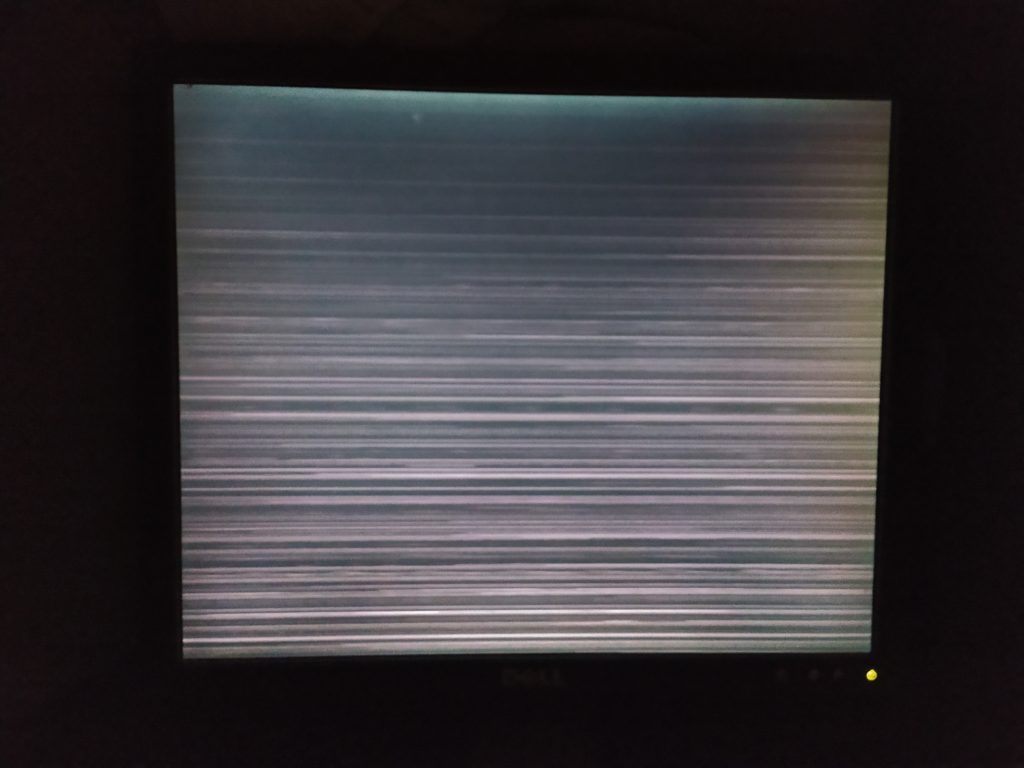

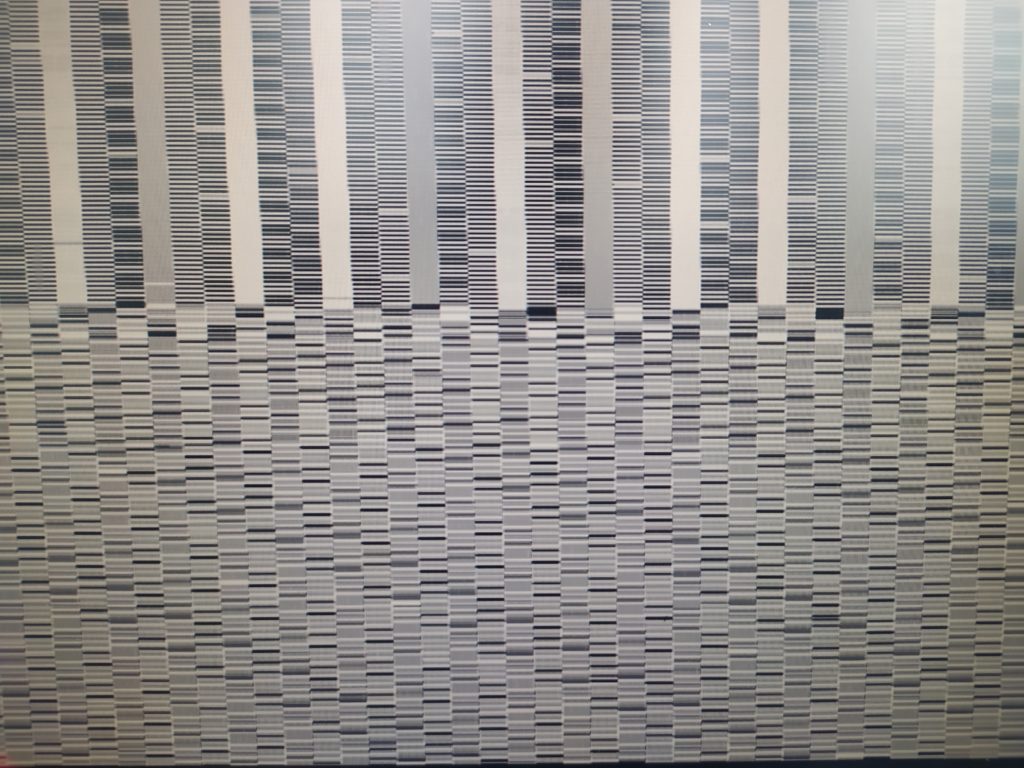

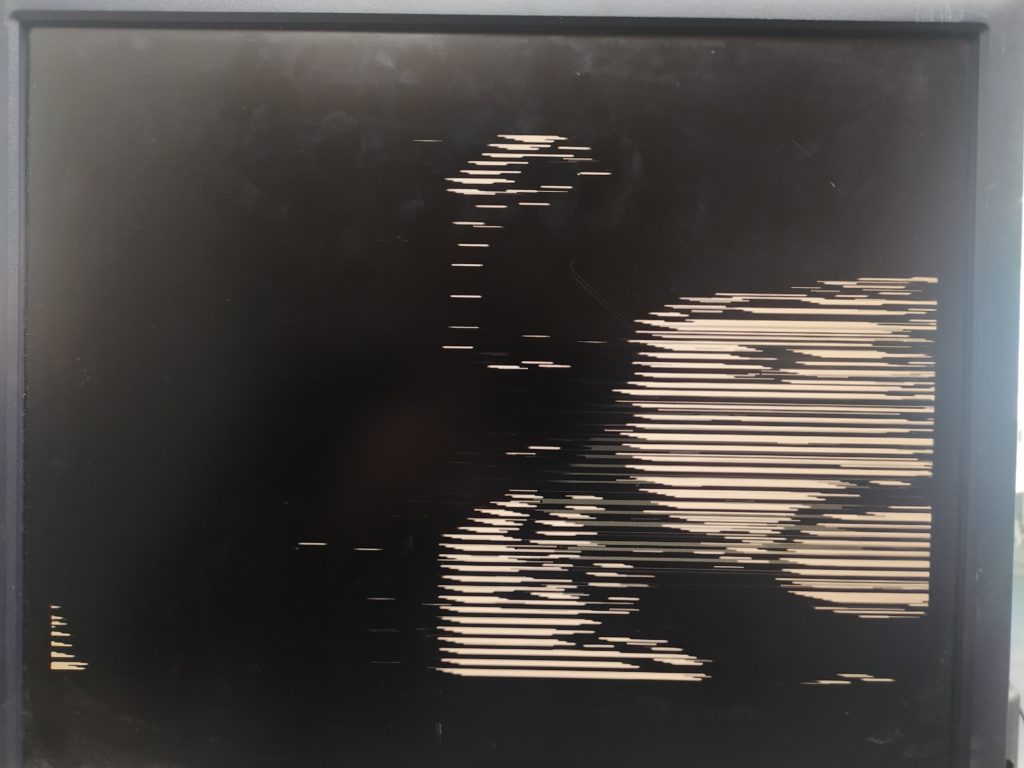

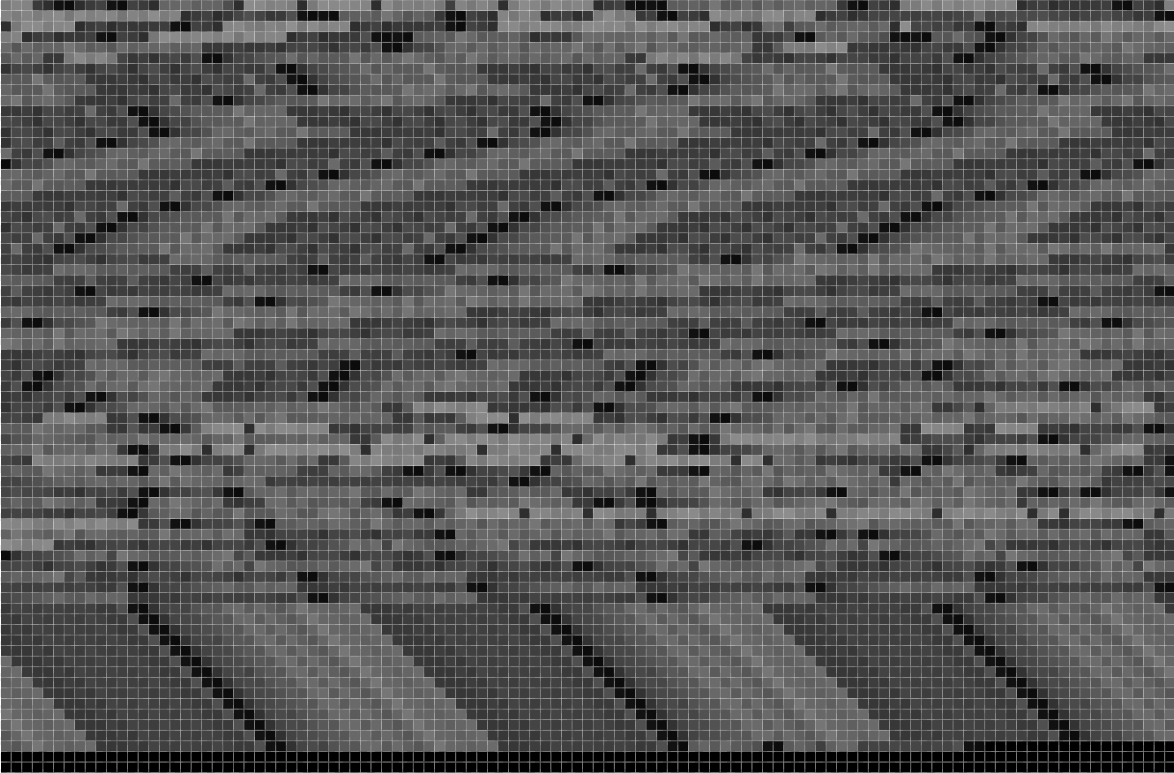

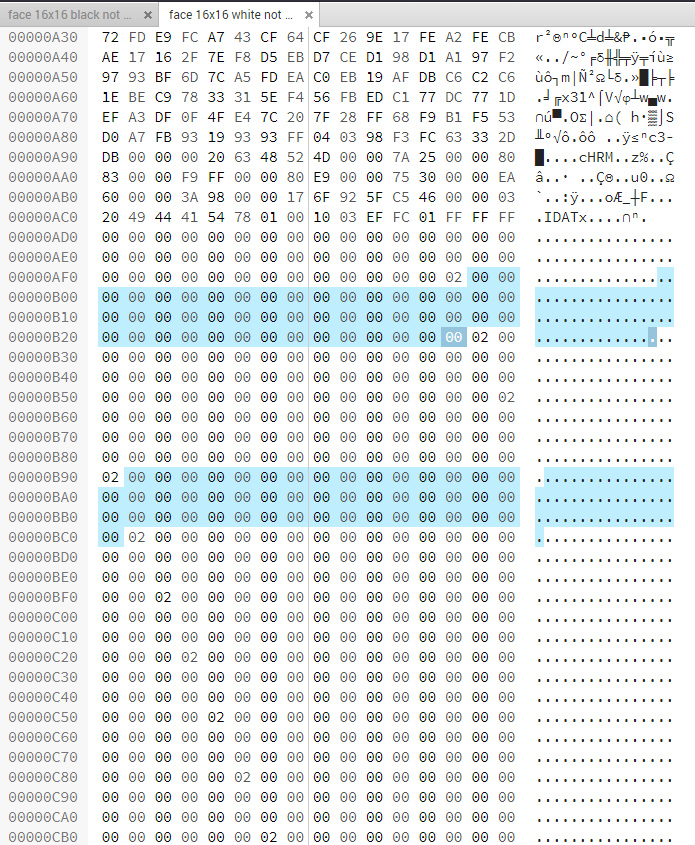

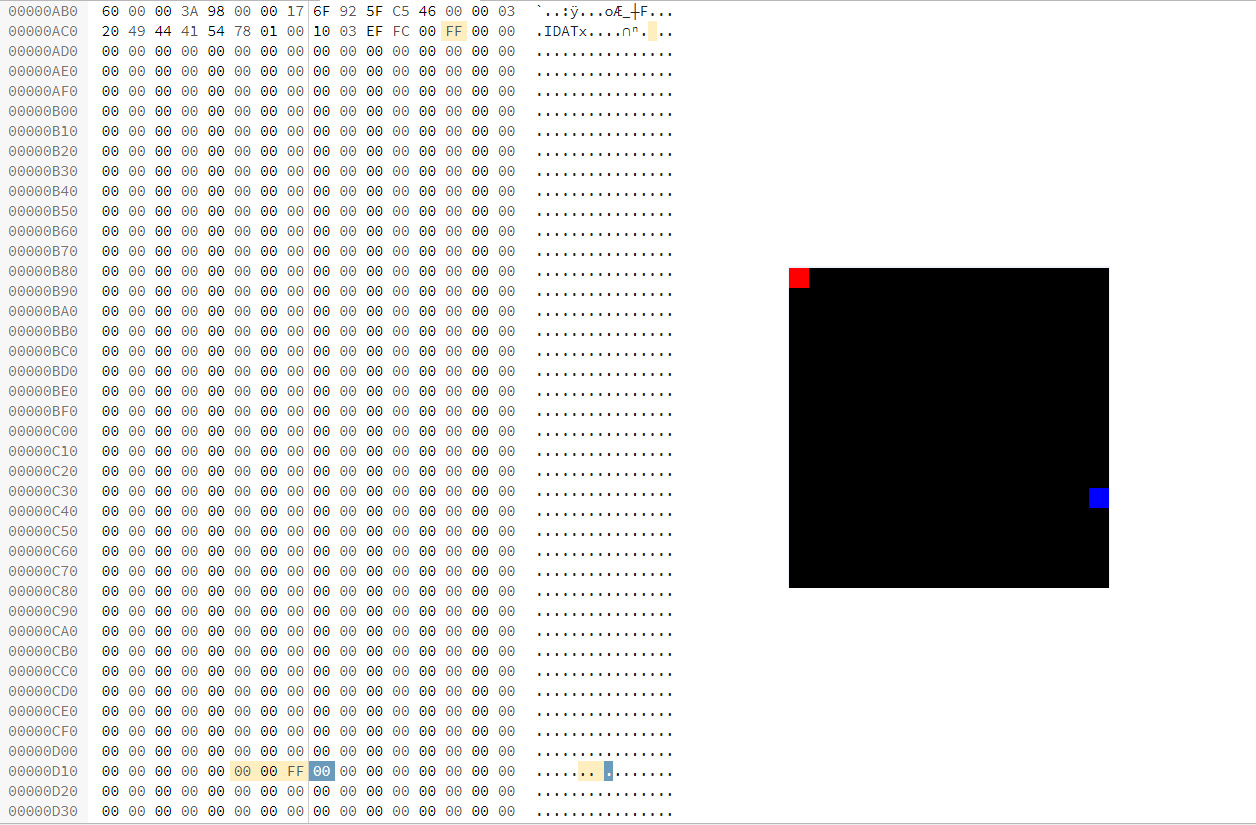

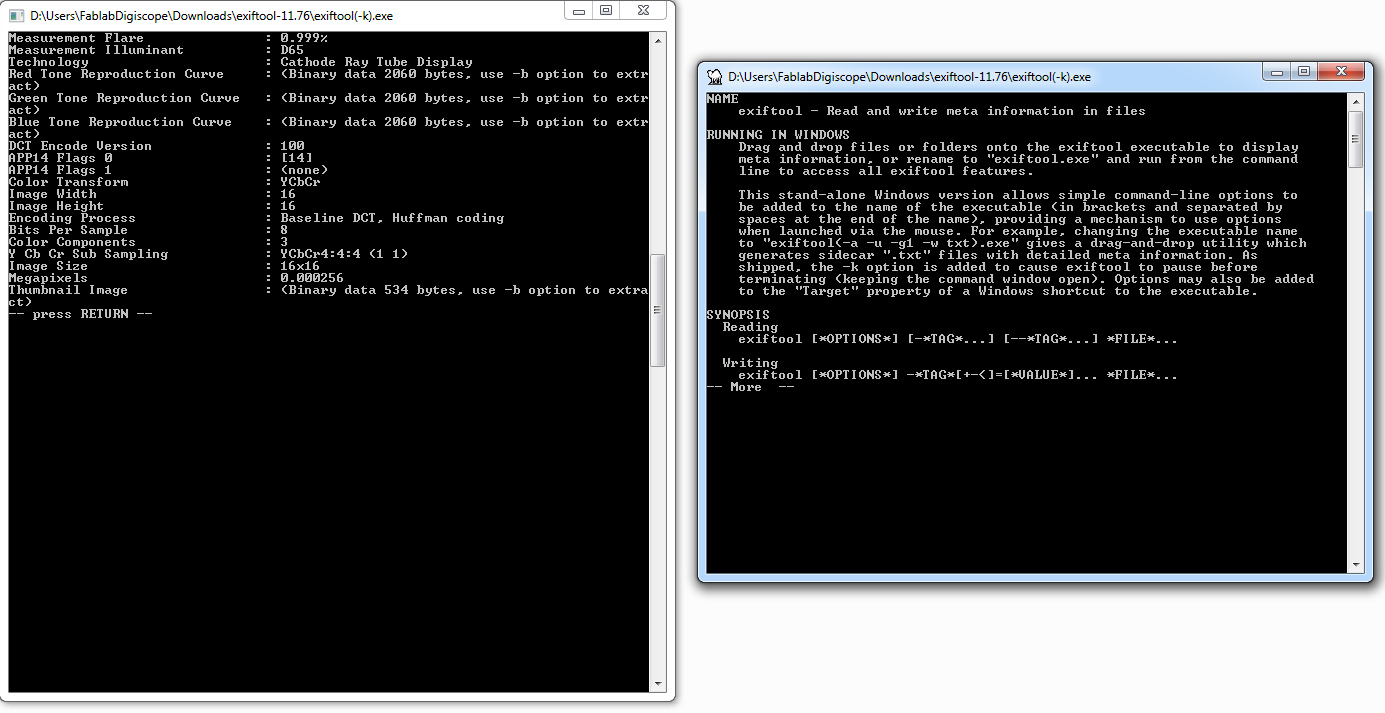

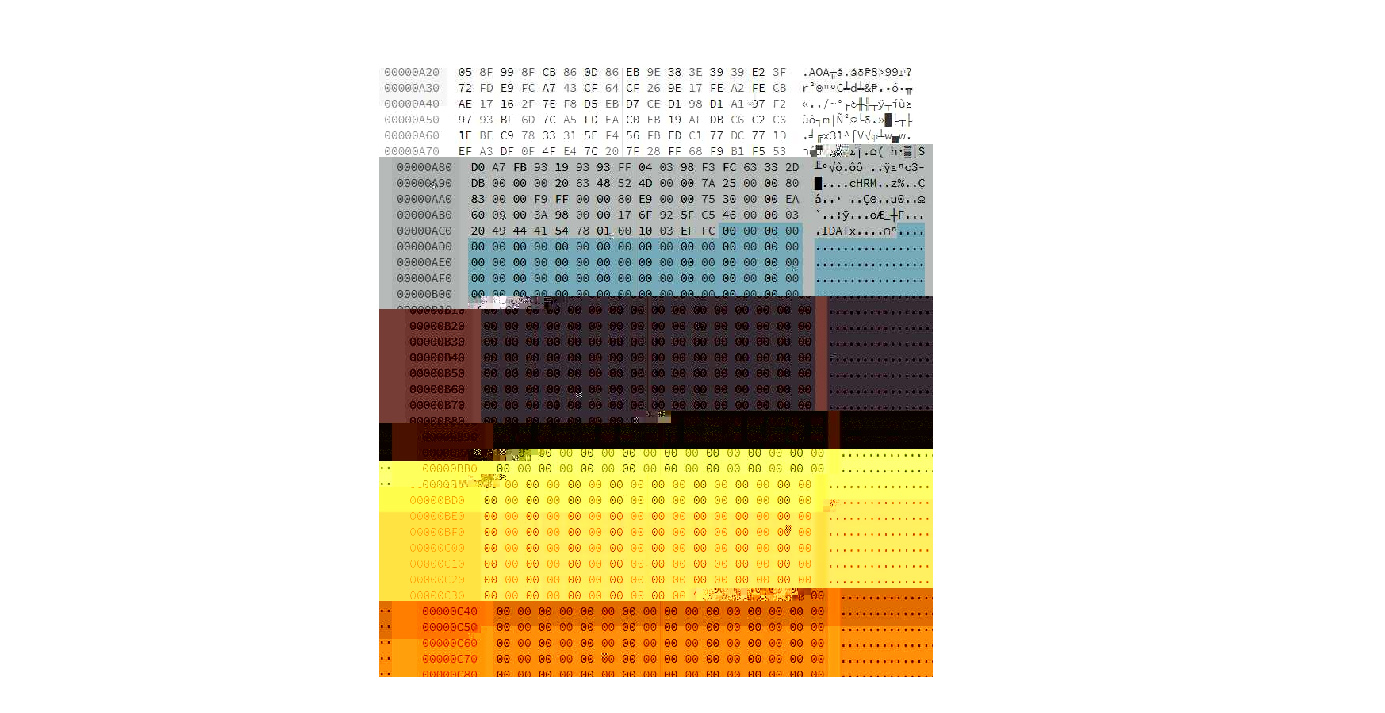

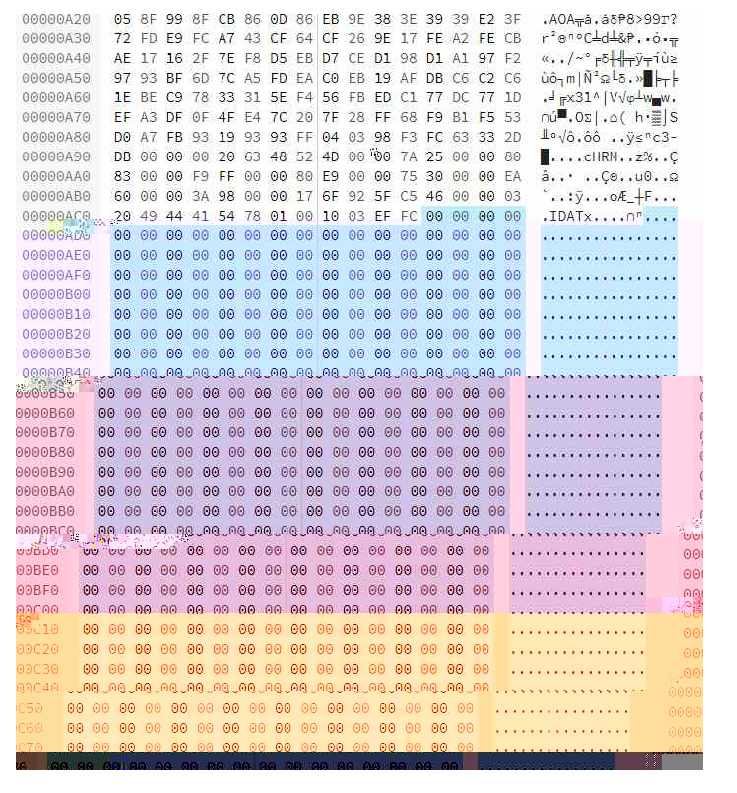

This is a CRT screen showing it's memory from wikipedia https://en.wikipedia.org/wiki/Framebuffer:

could try to visualize series of repeated pixel patterns and the "live" processing of these by different algorithms, some greedy others with different priorities?

Check out this stuff on frame buffers:

This is a CRT screen showing it's memory from wikipedia https://en.wikipedia.org/wiki/Framebuffer:

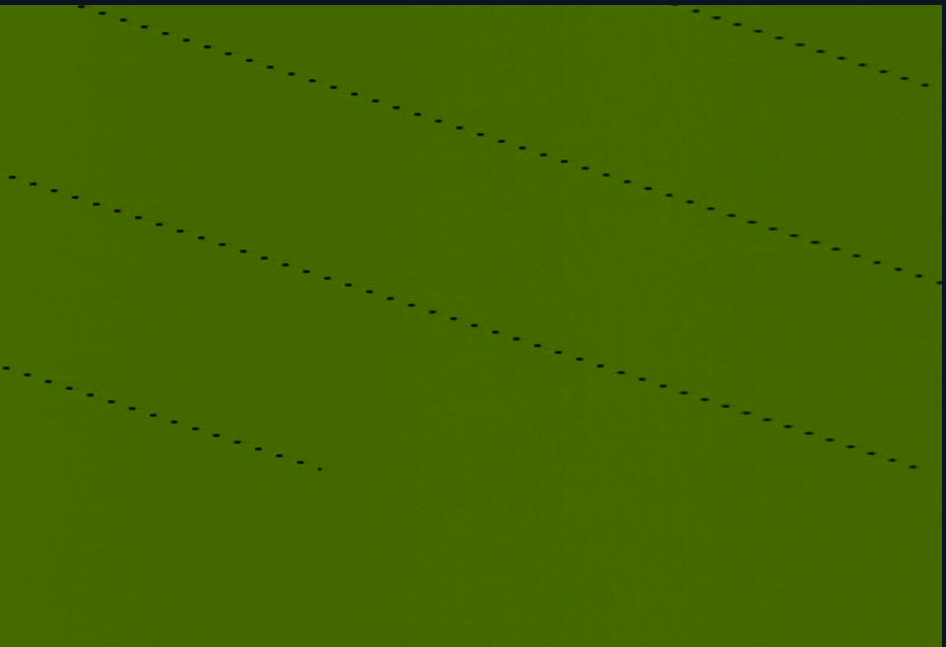

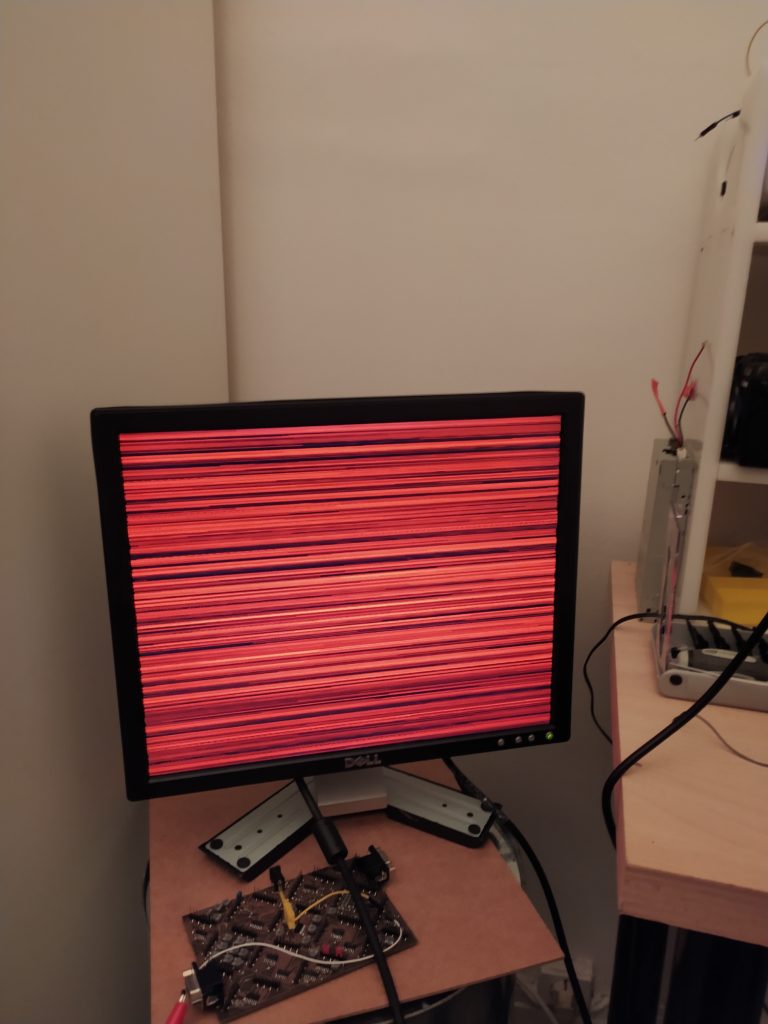

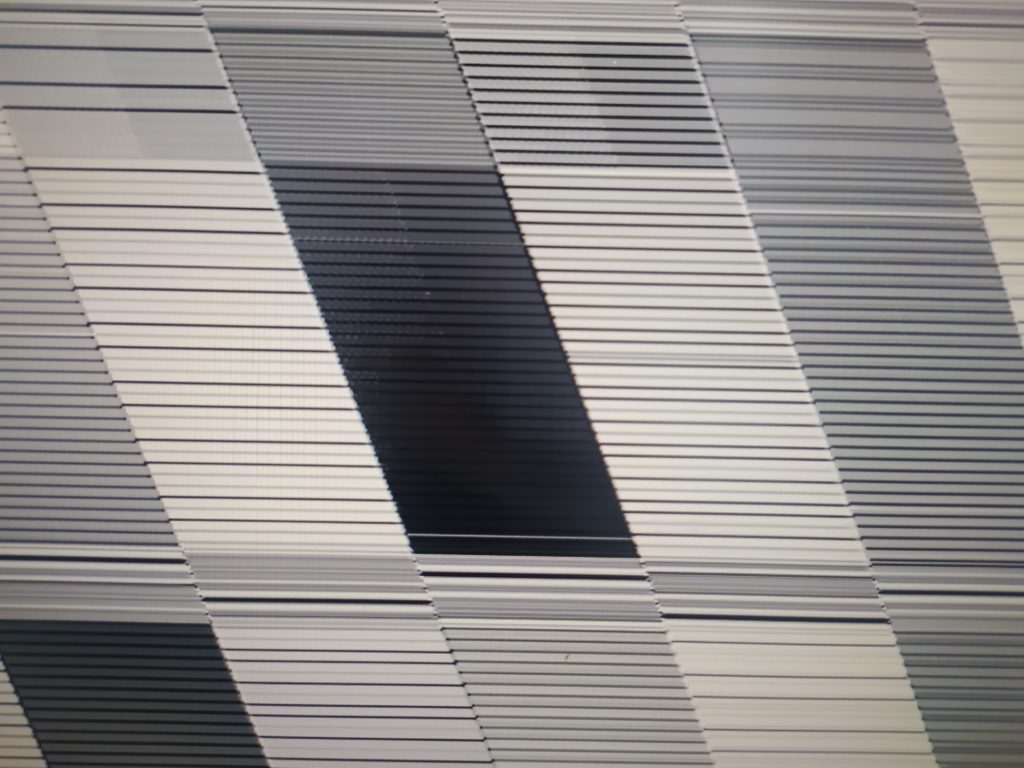

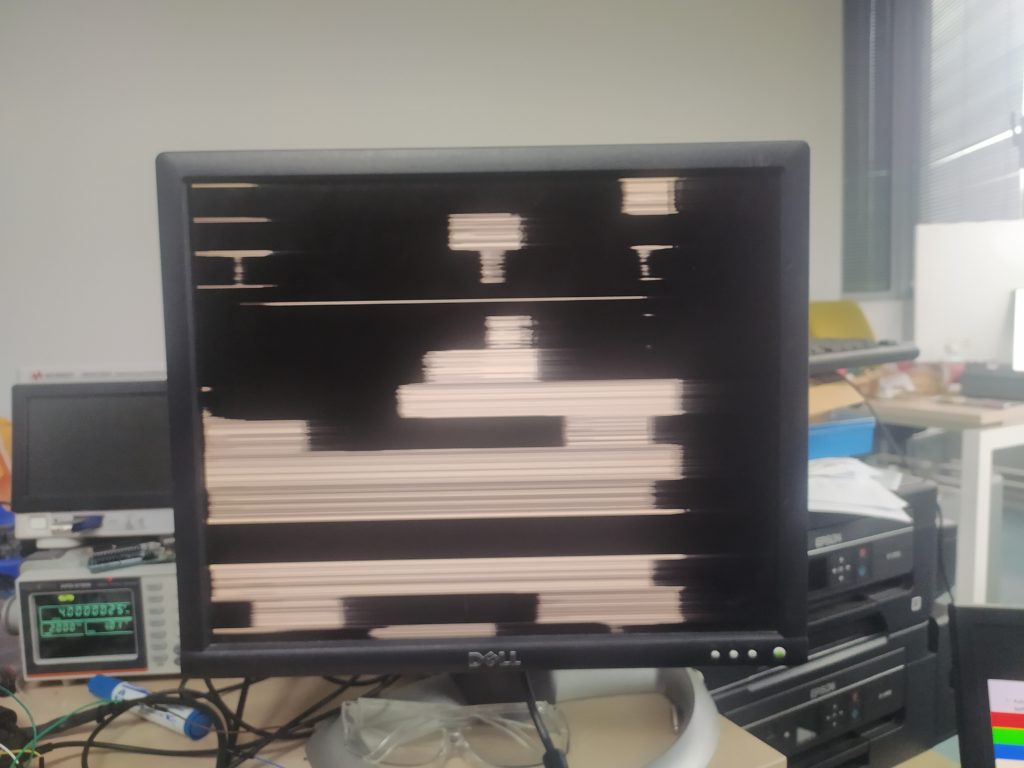

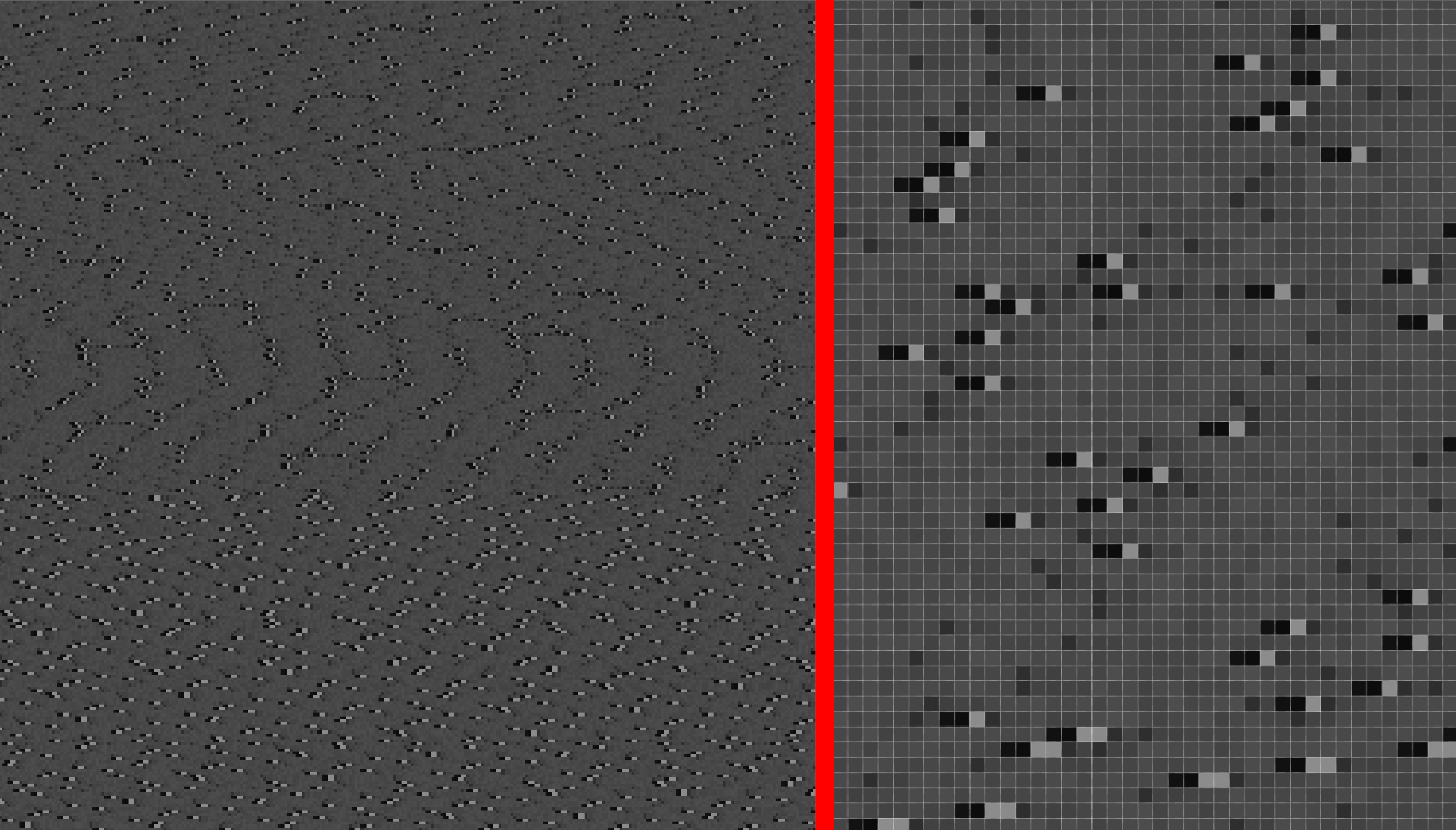

still from Wikipedia, here is that same image given the wrong color index:

still from Wikipedia, here is that same image given the wrong color index:

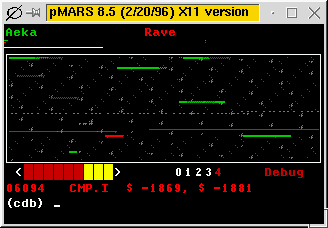

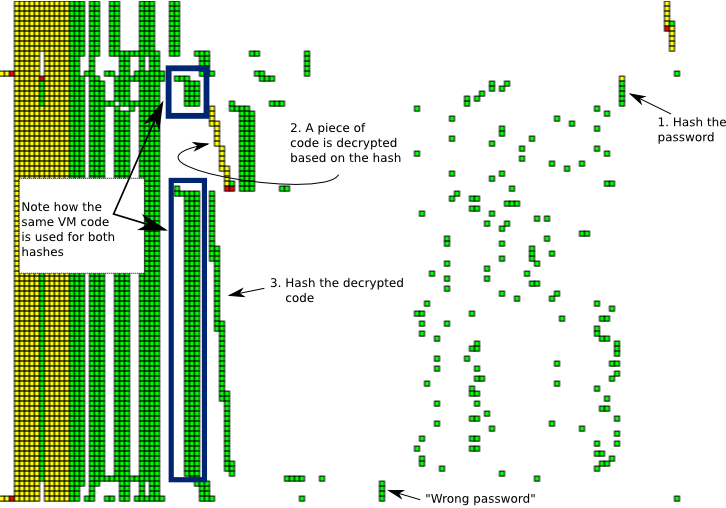

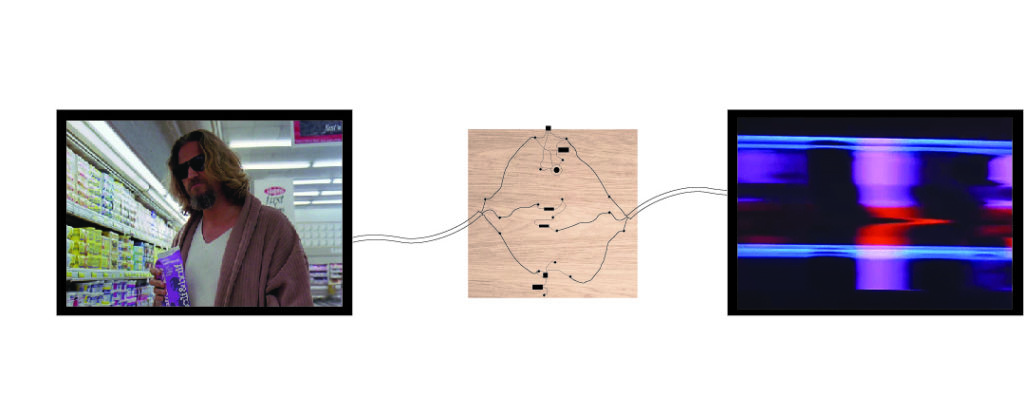

here is a visualization of LZ77 by Canadian programmer

here is a visualization of LZ77 by Canadian programmer

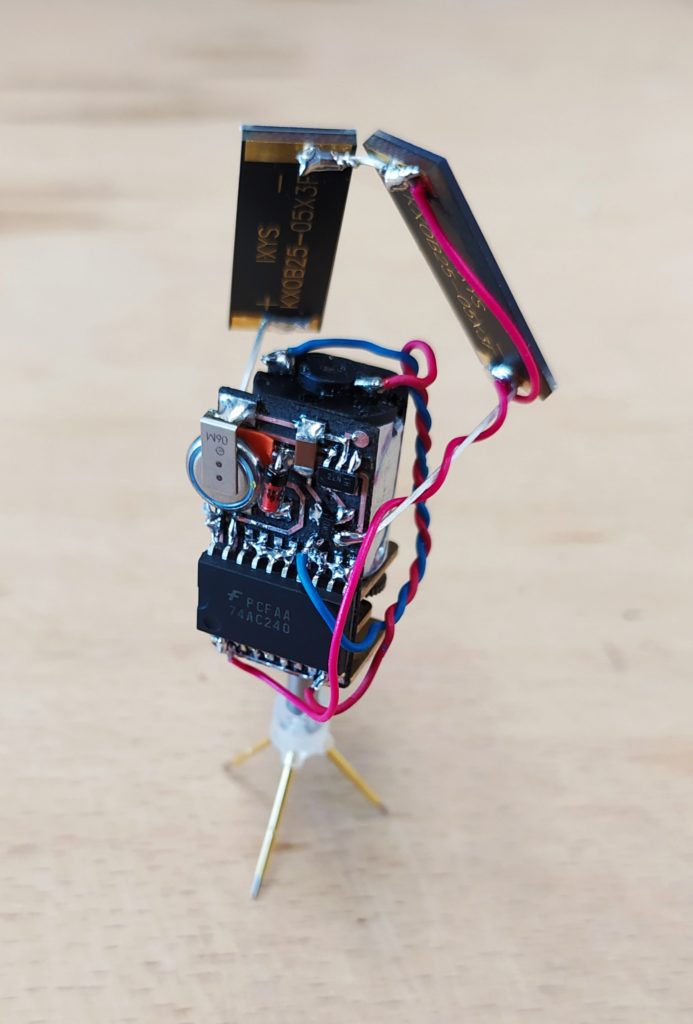

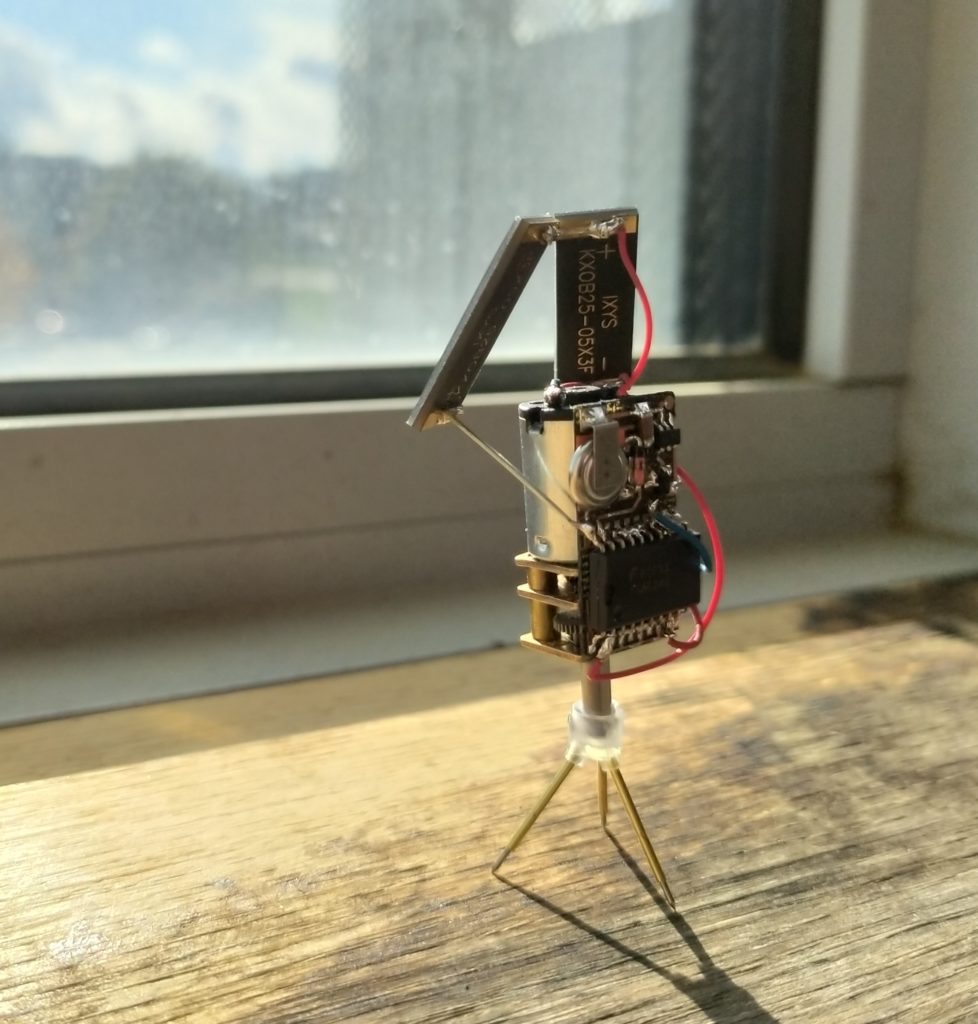

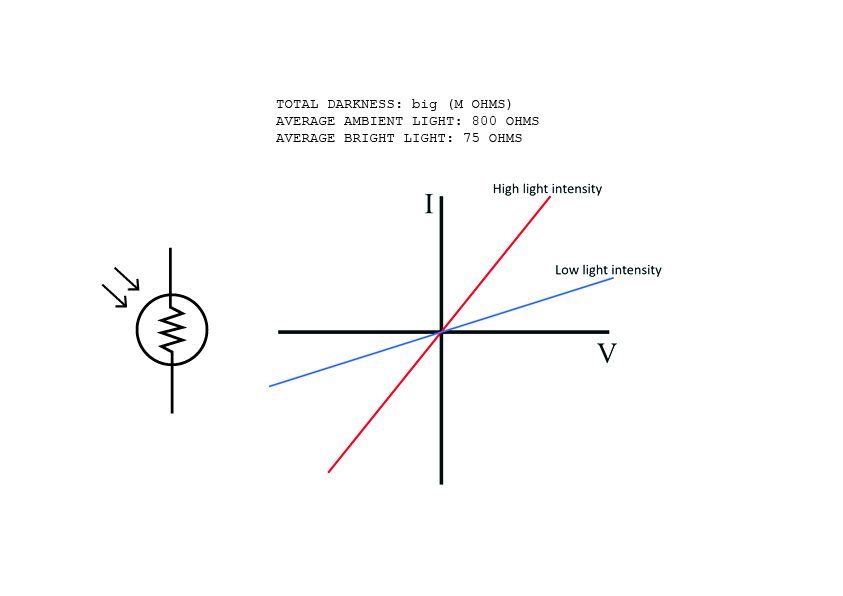

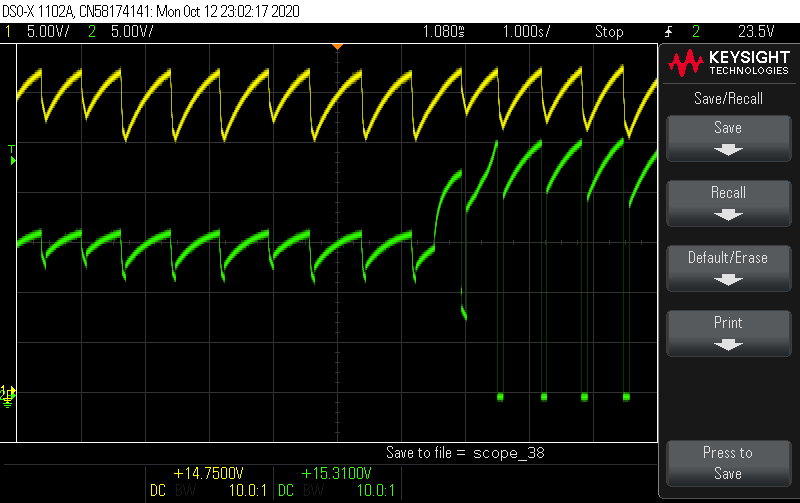

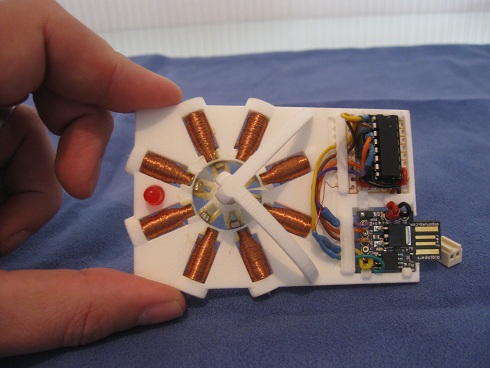

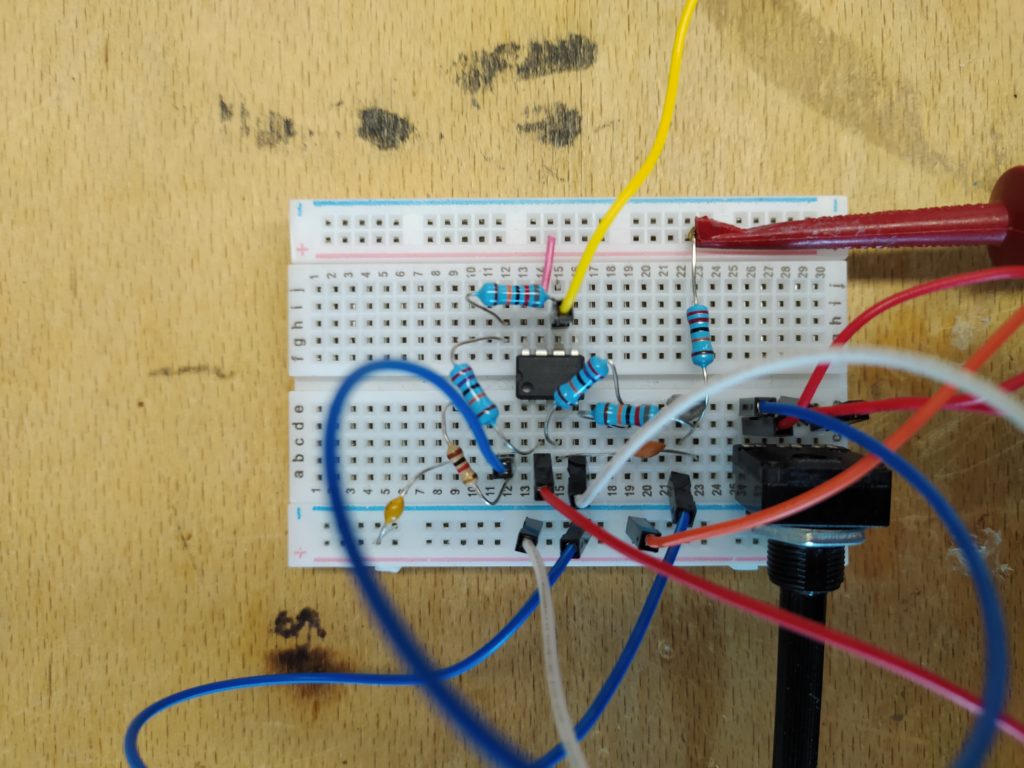

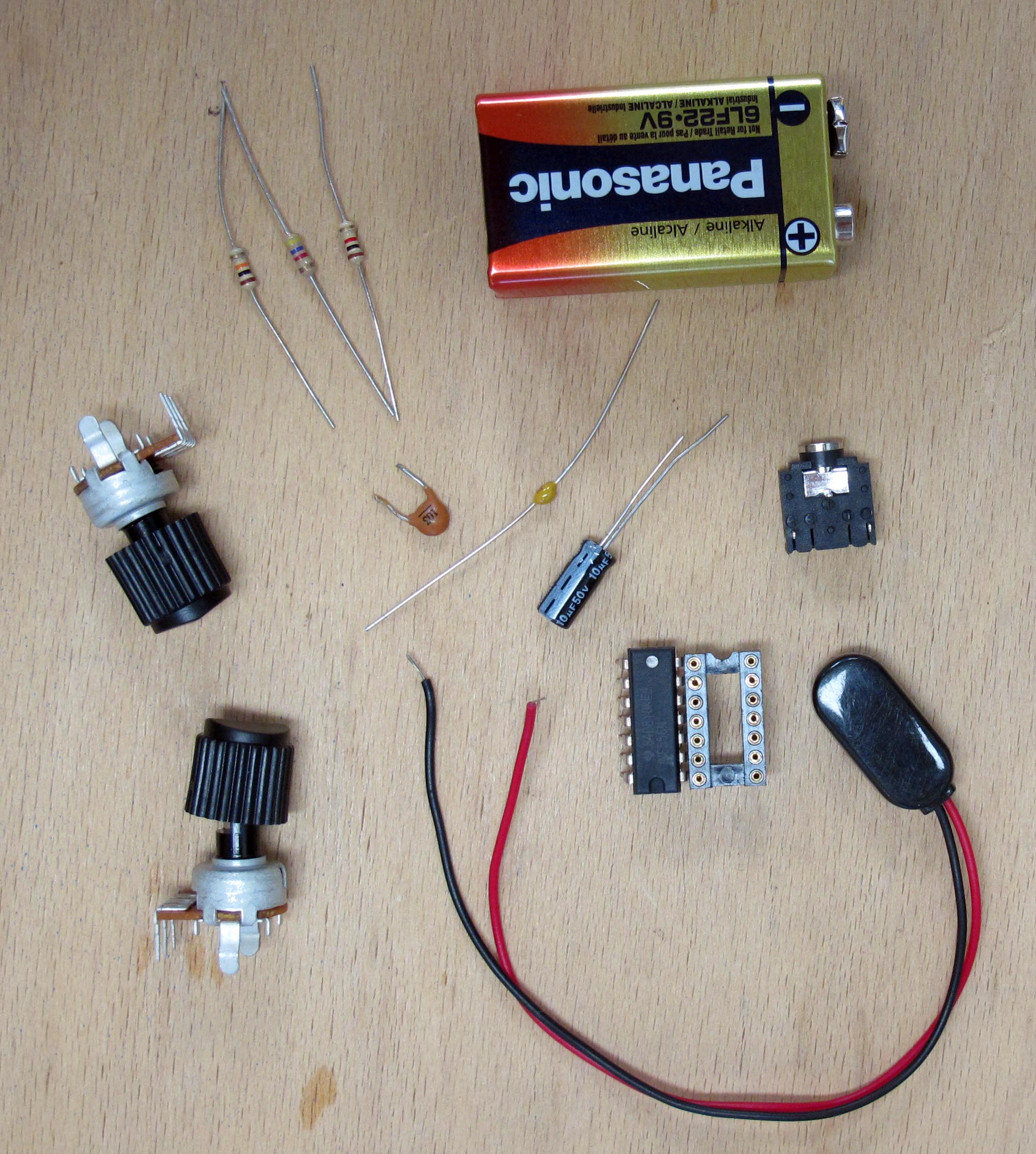

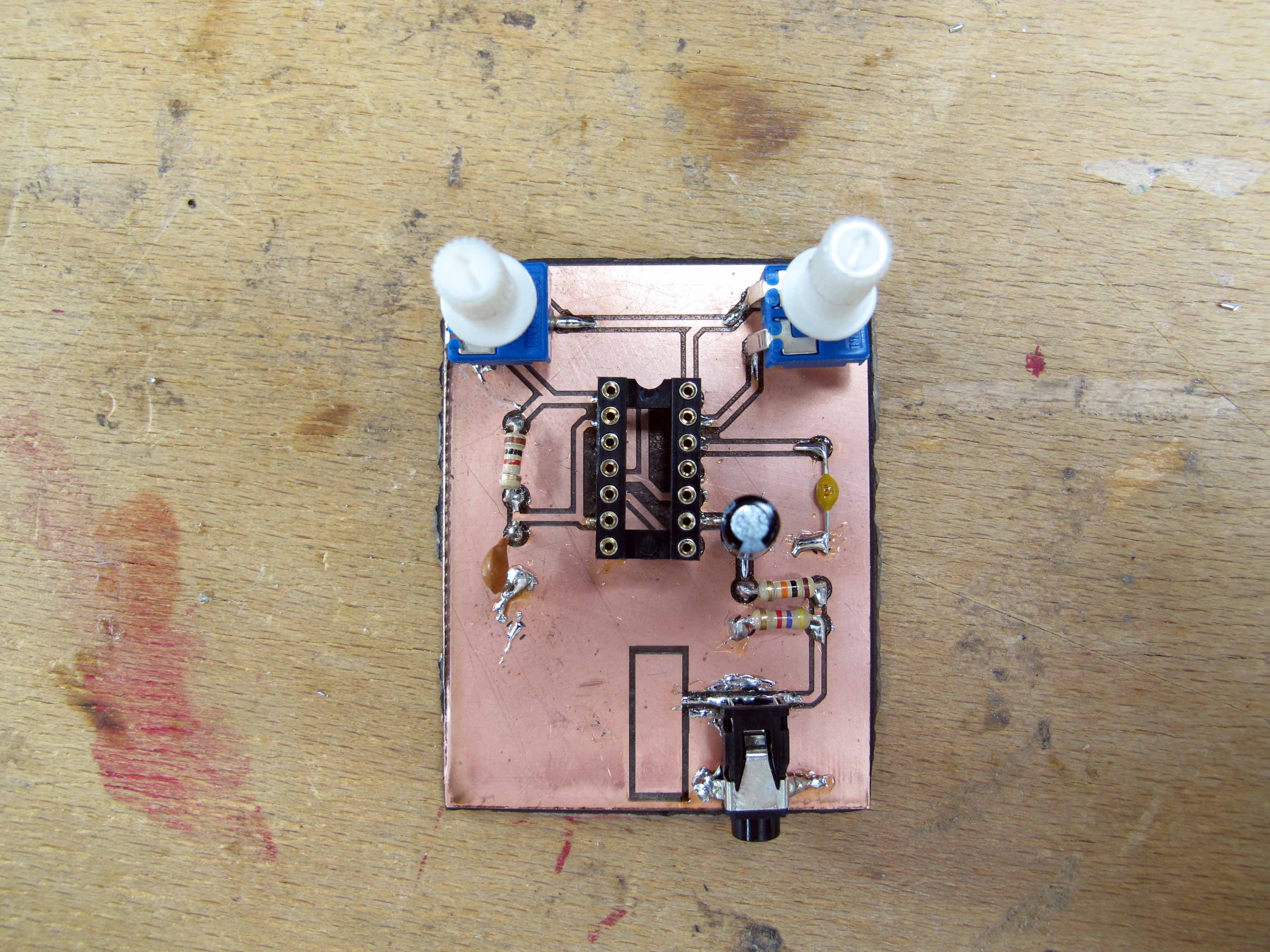

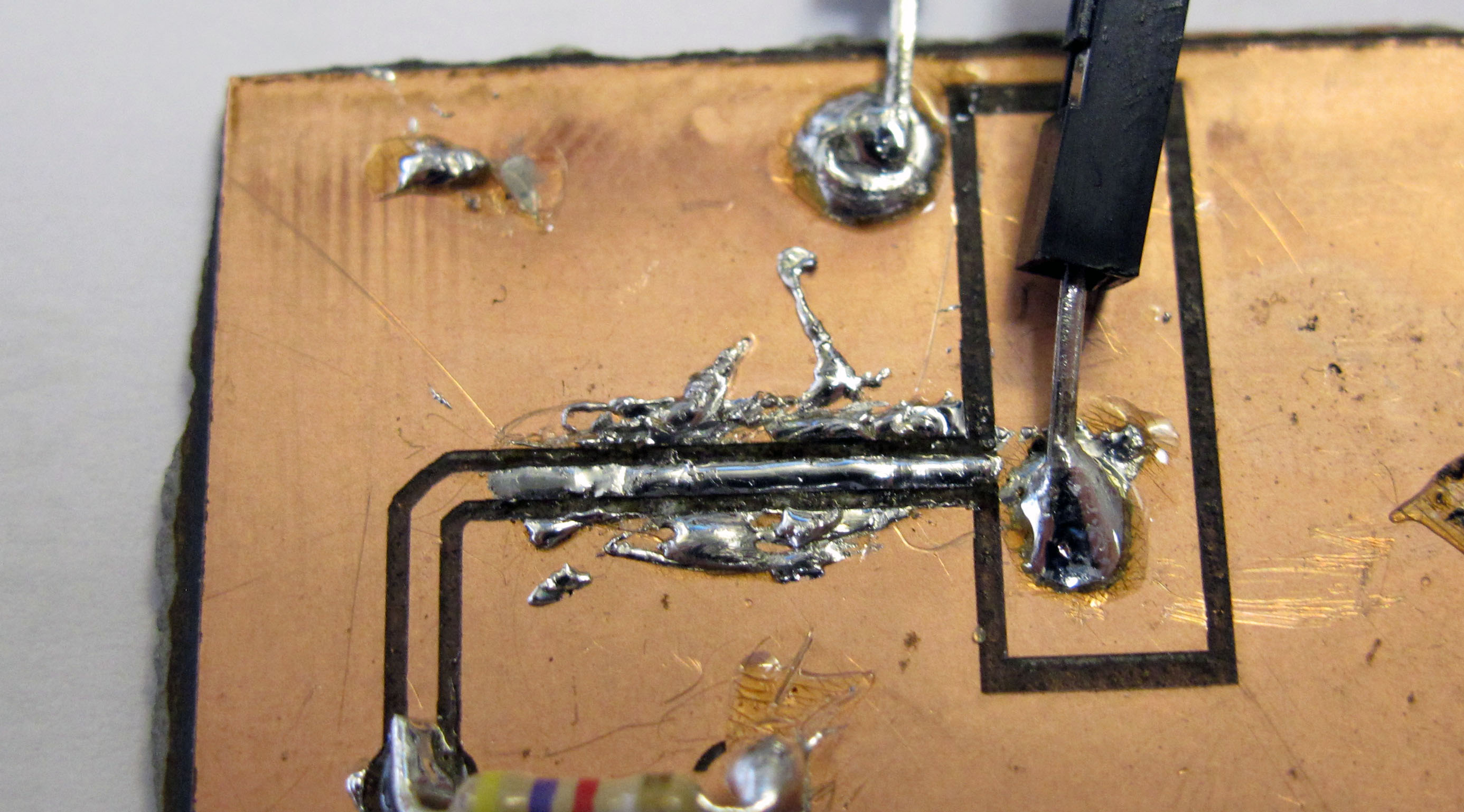

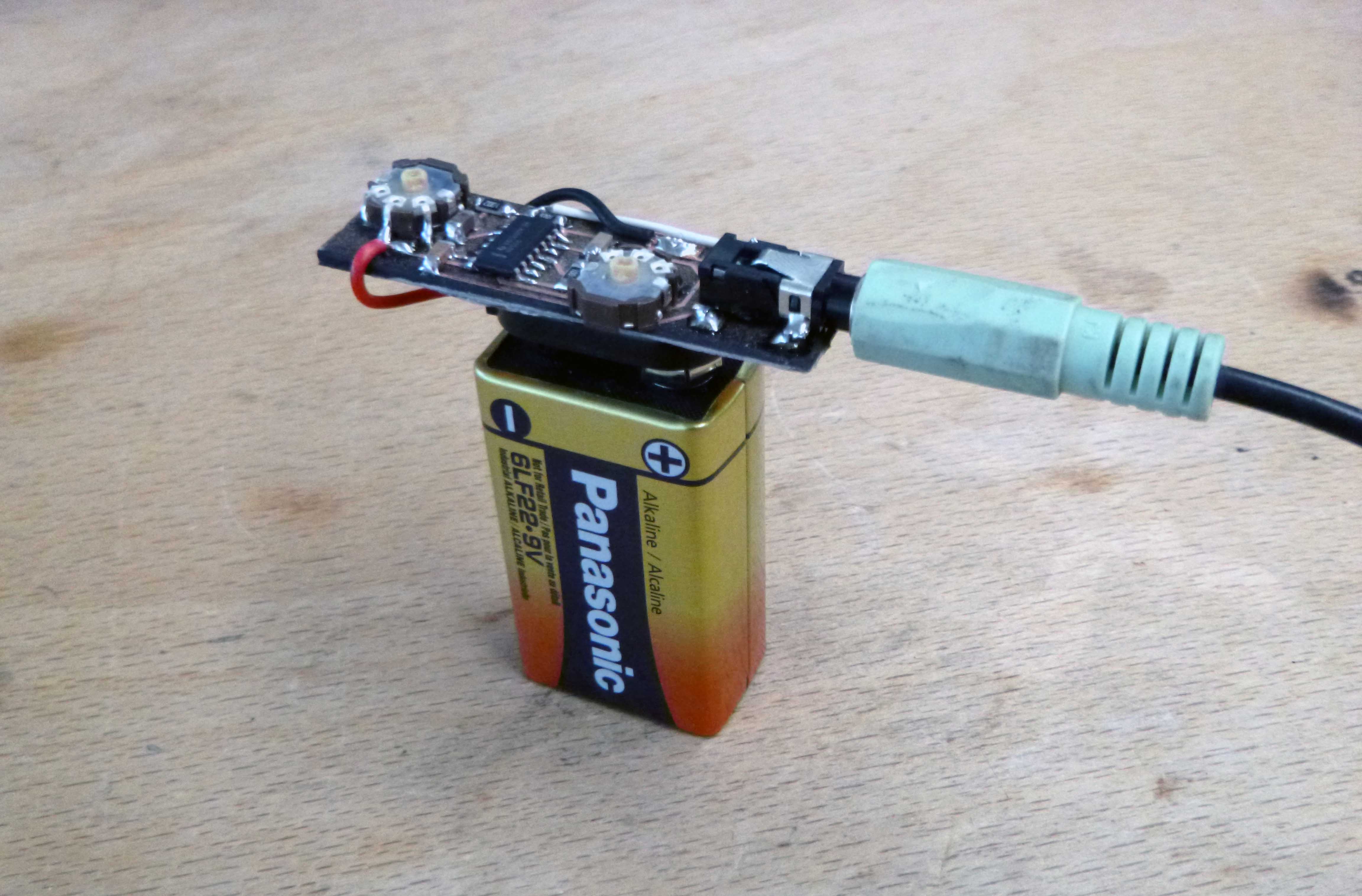

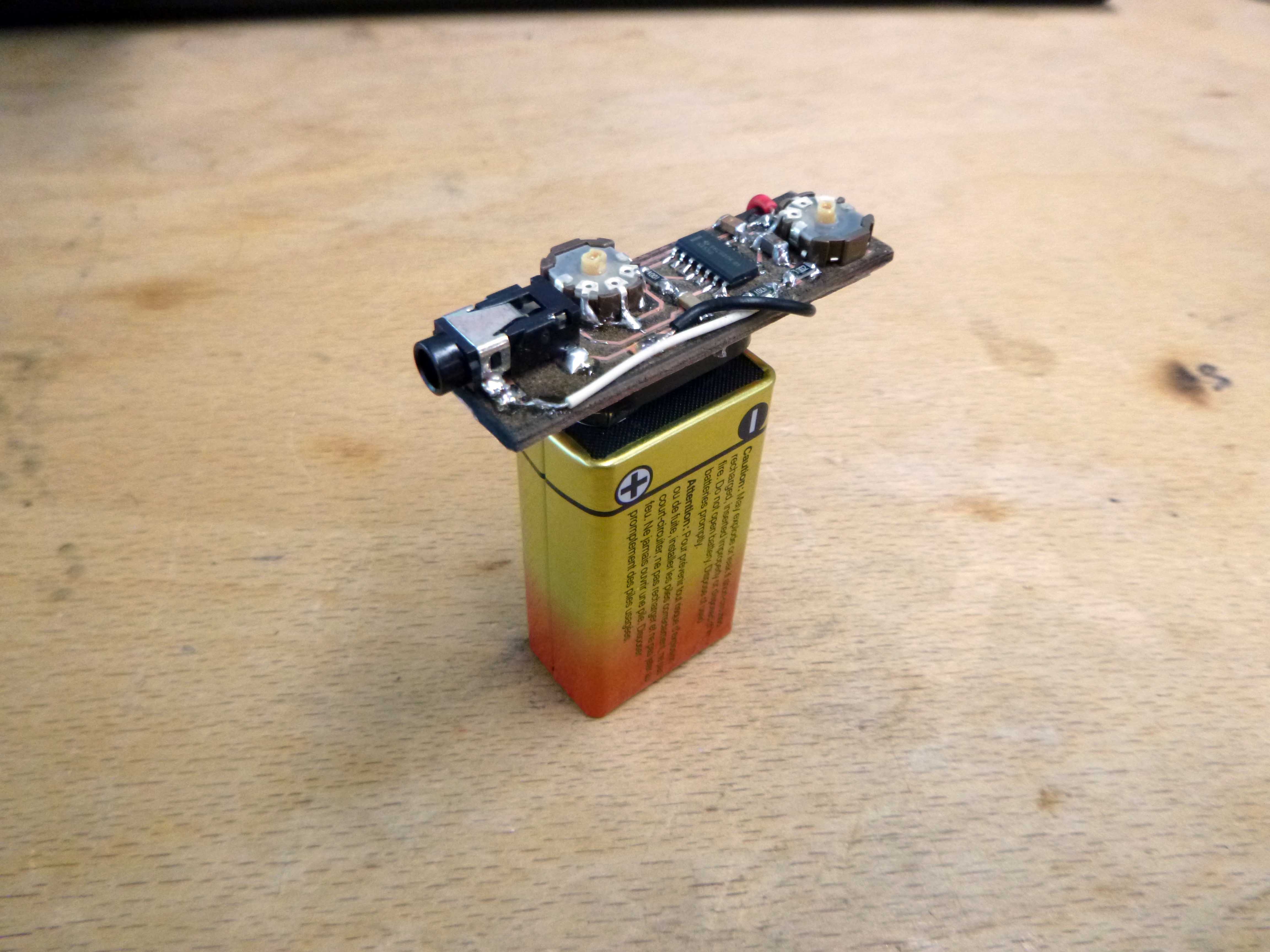

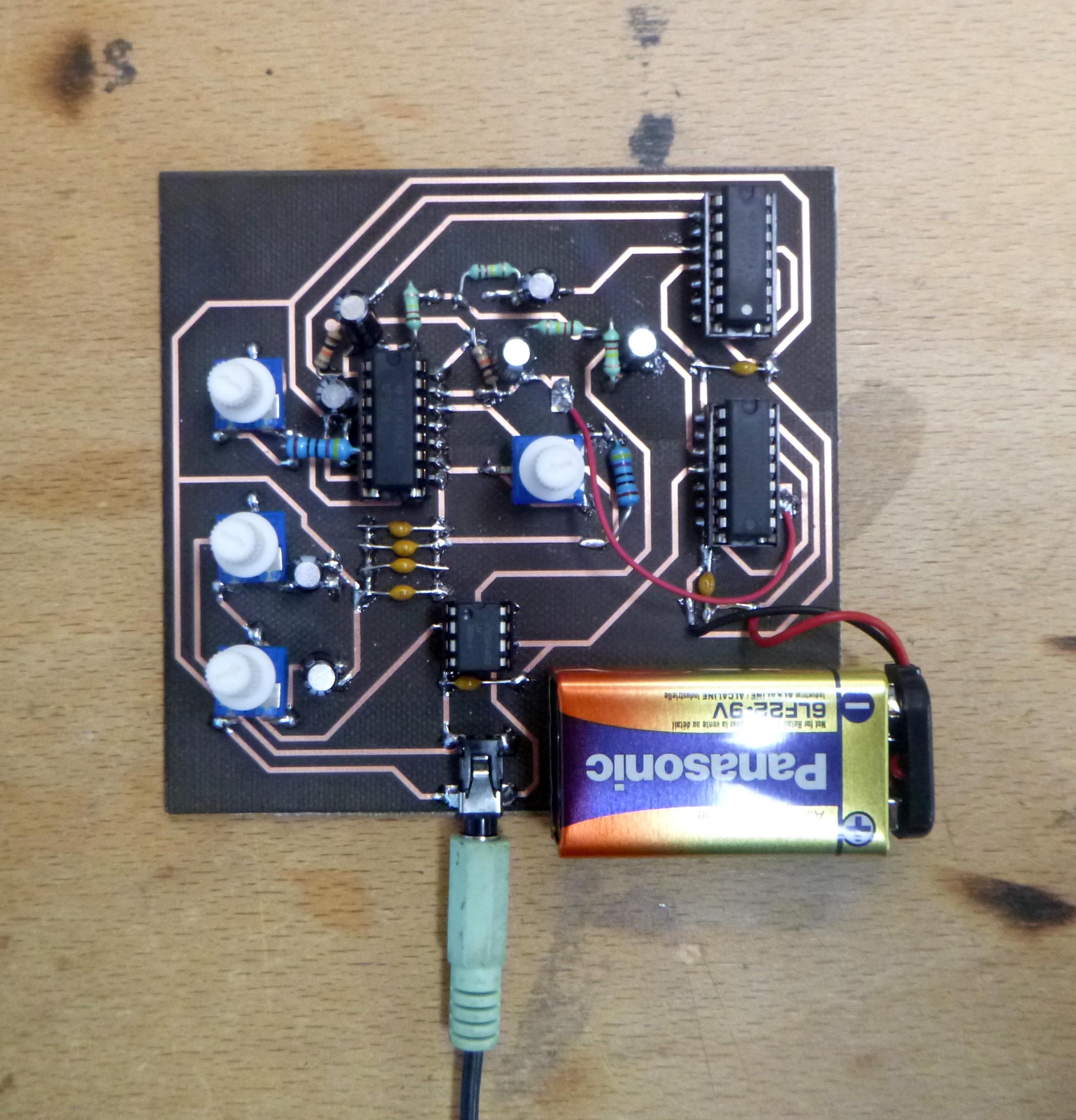

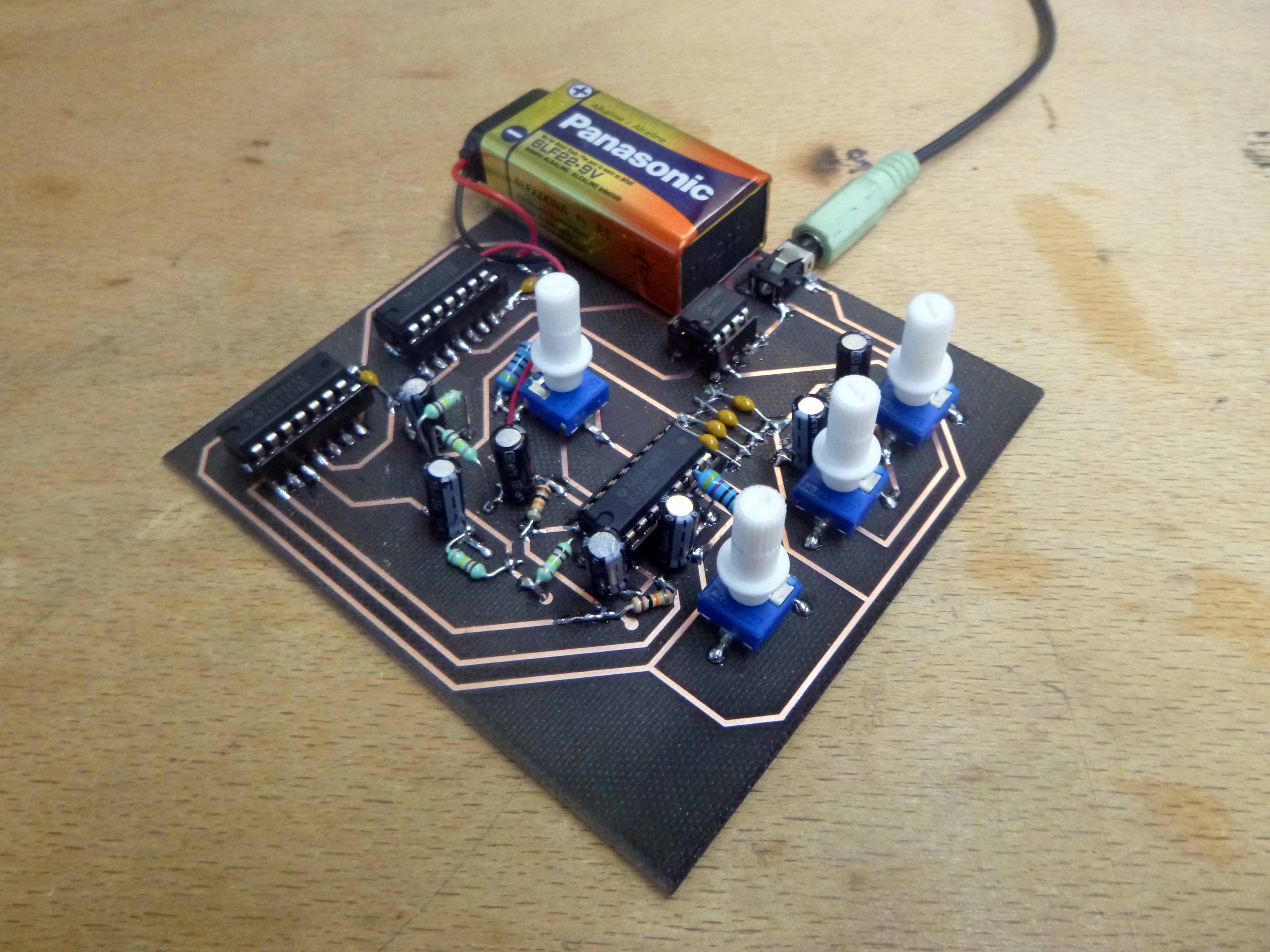

In this code I am using an Attiny 84 to produce different frequencies for a piezo buzzer (PB2). The Attiny ADC works a little differently than the Atmega.

In this code I am using an Attiny 84 to produce different frequencies for a piezo buzzer (PB2). The Attiny ADC works a little differently than the Atmega.

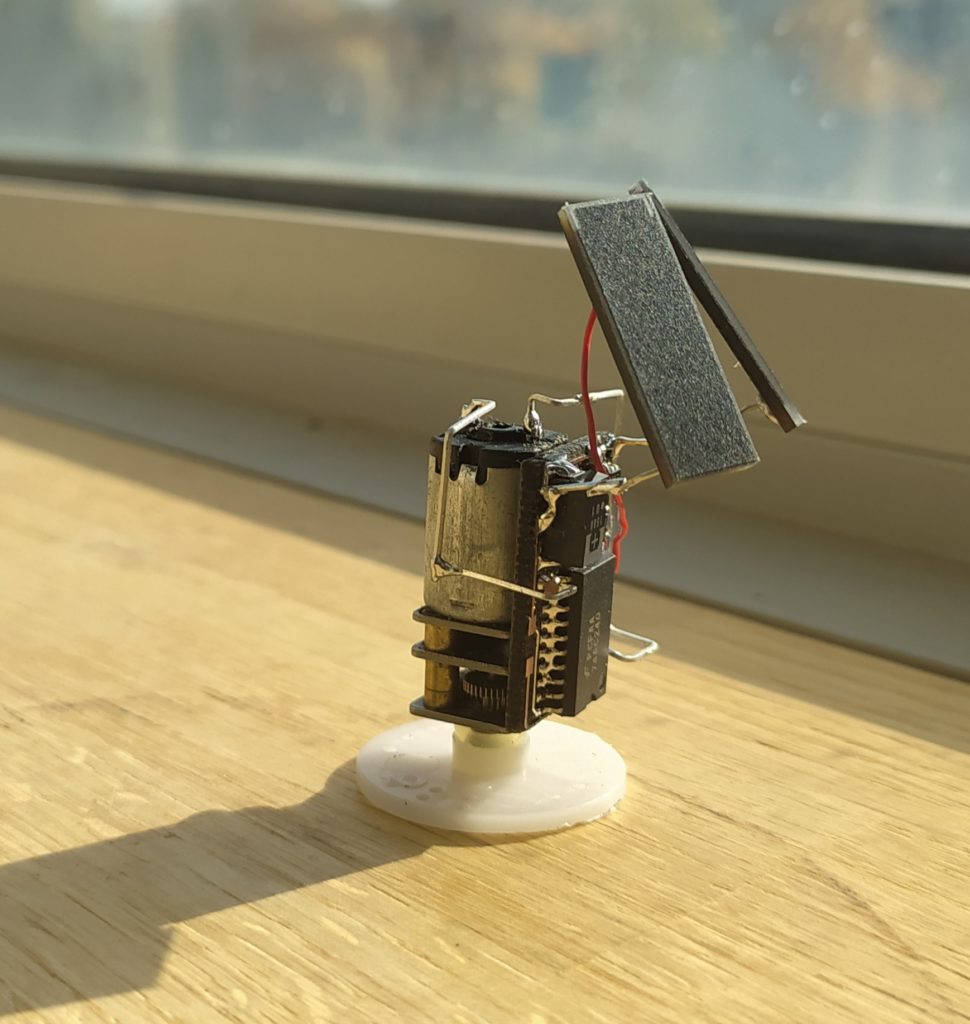

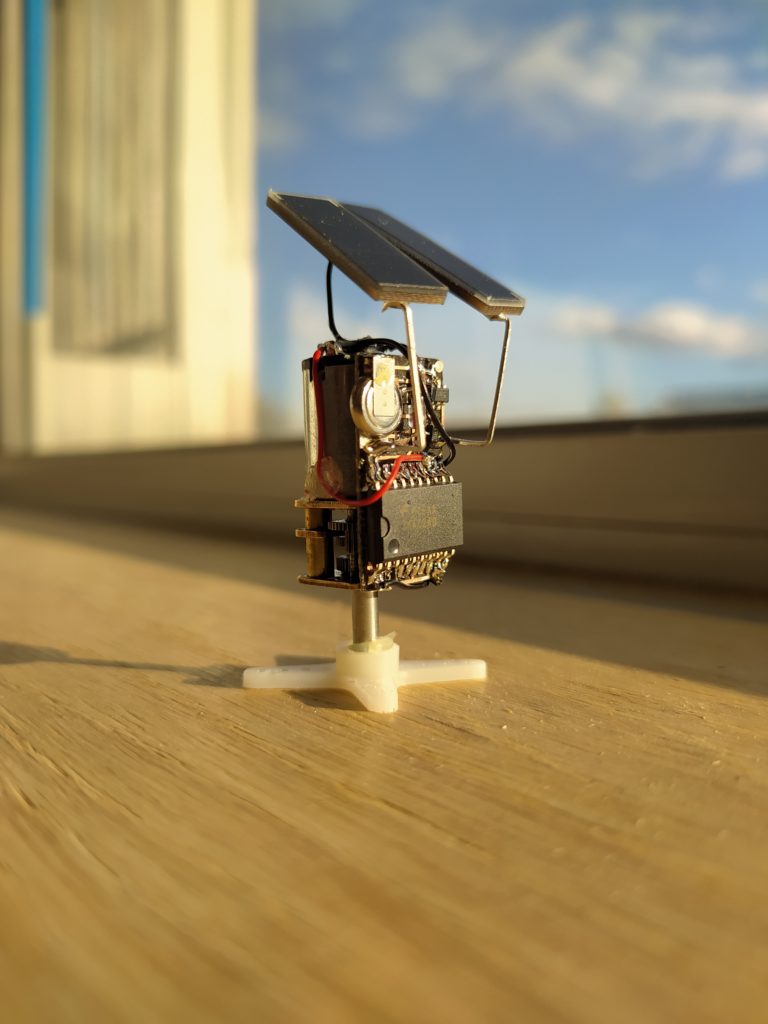

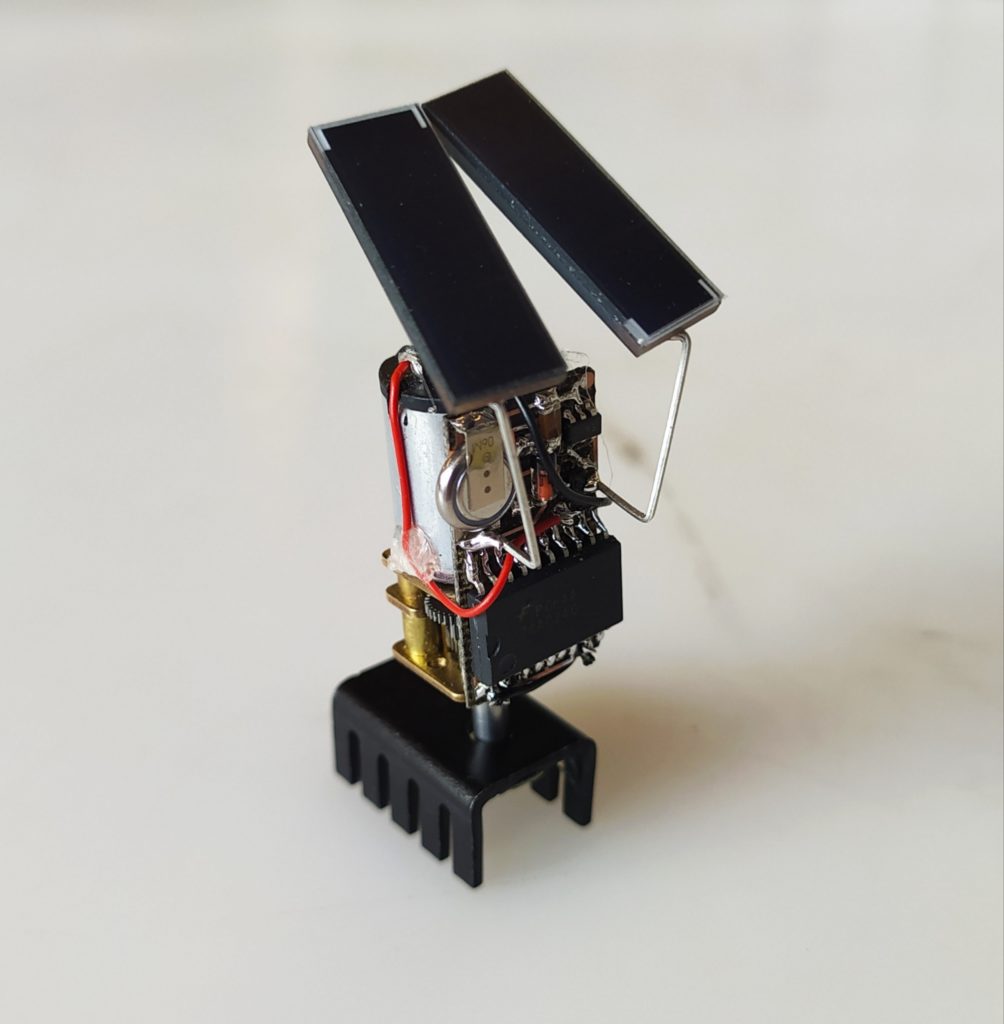

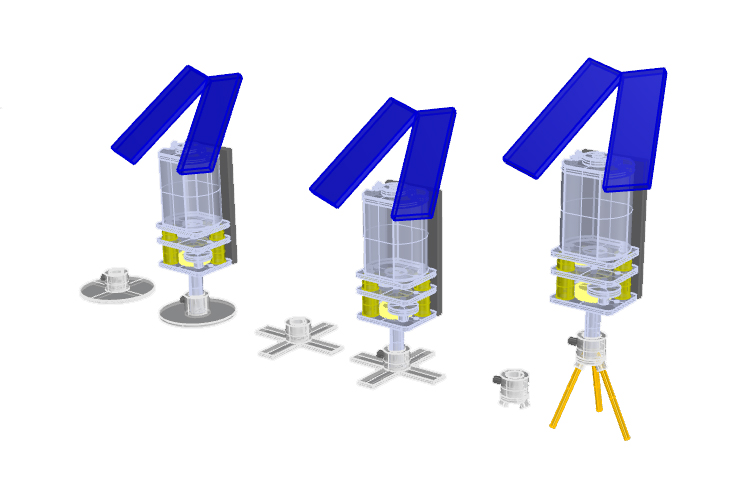

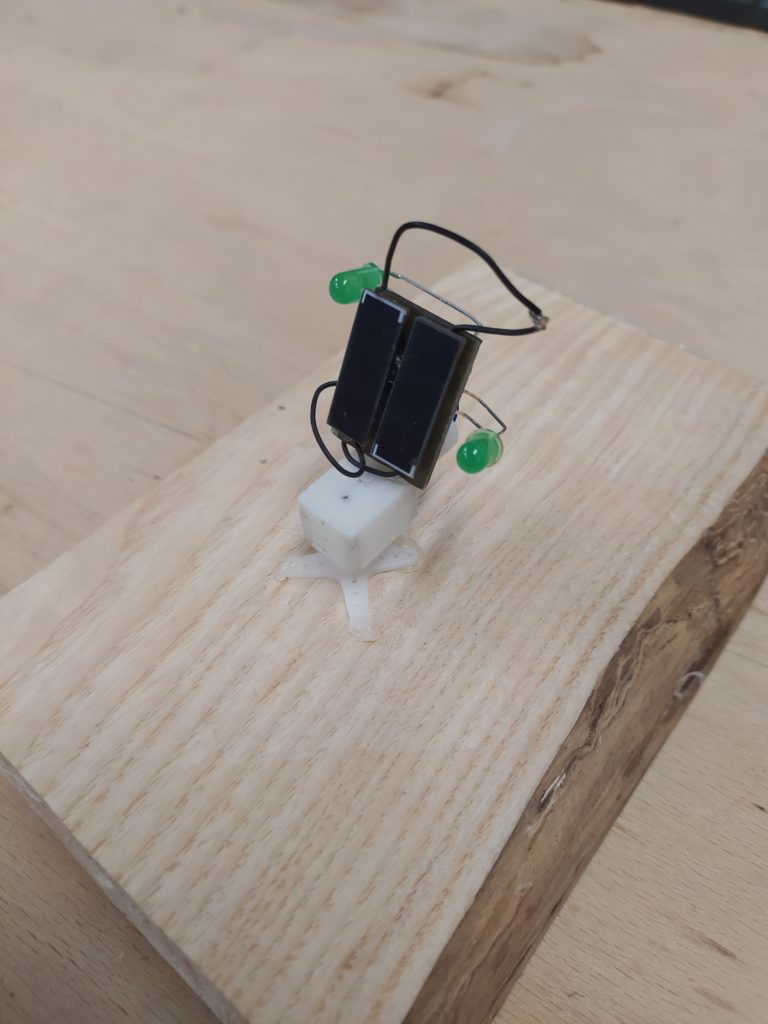

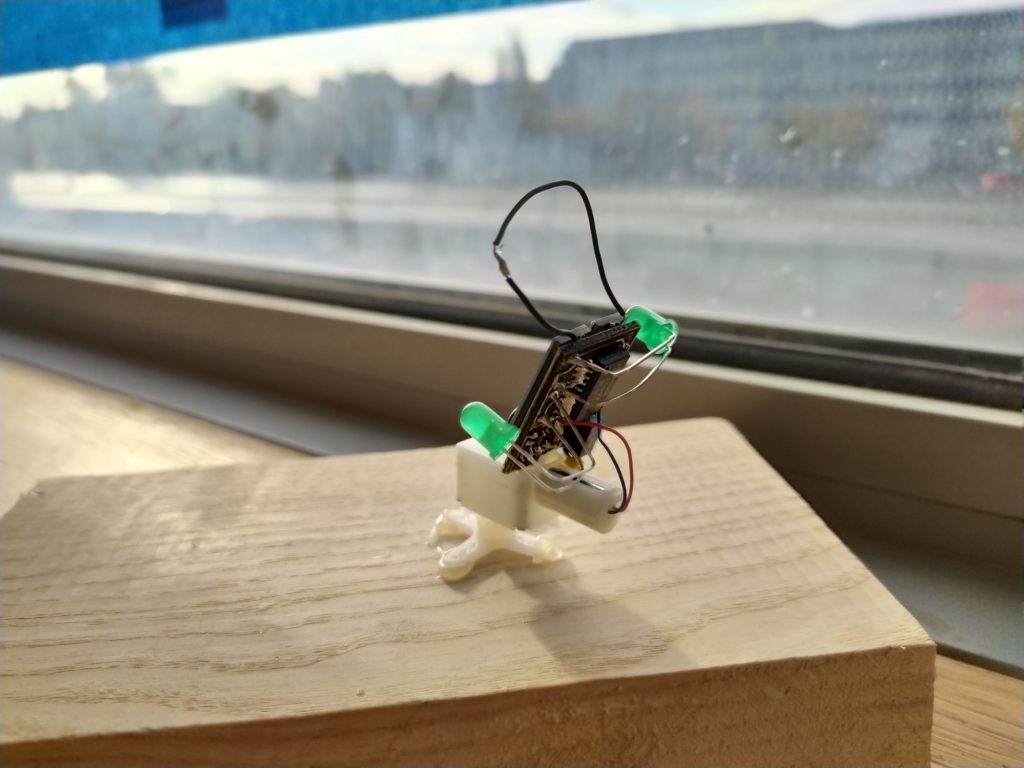

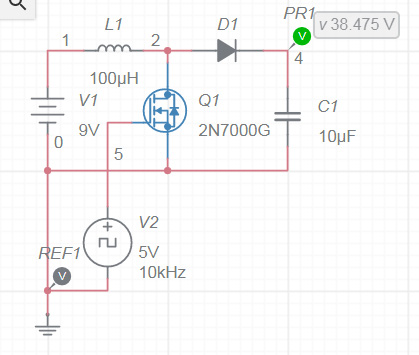

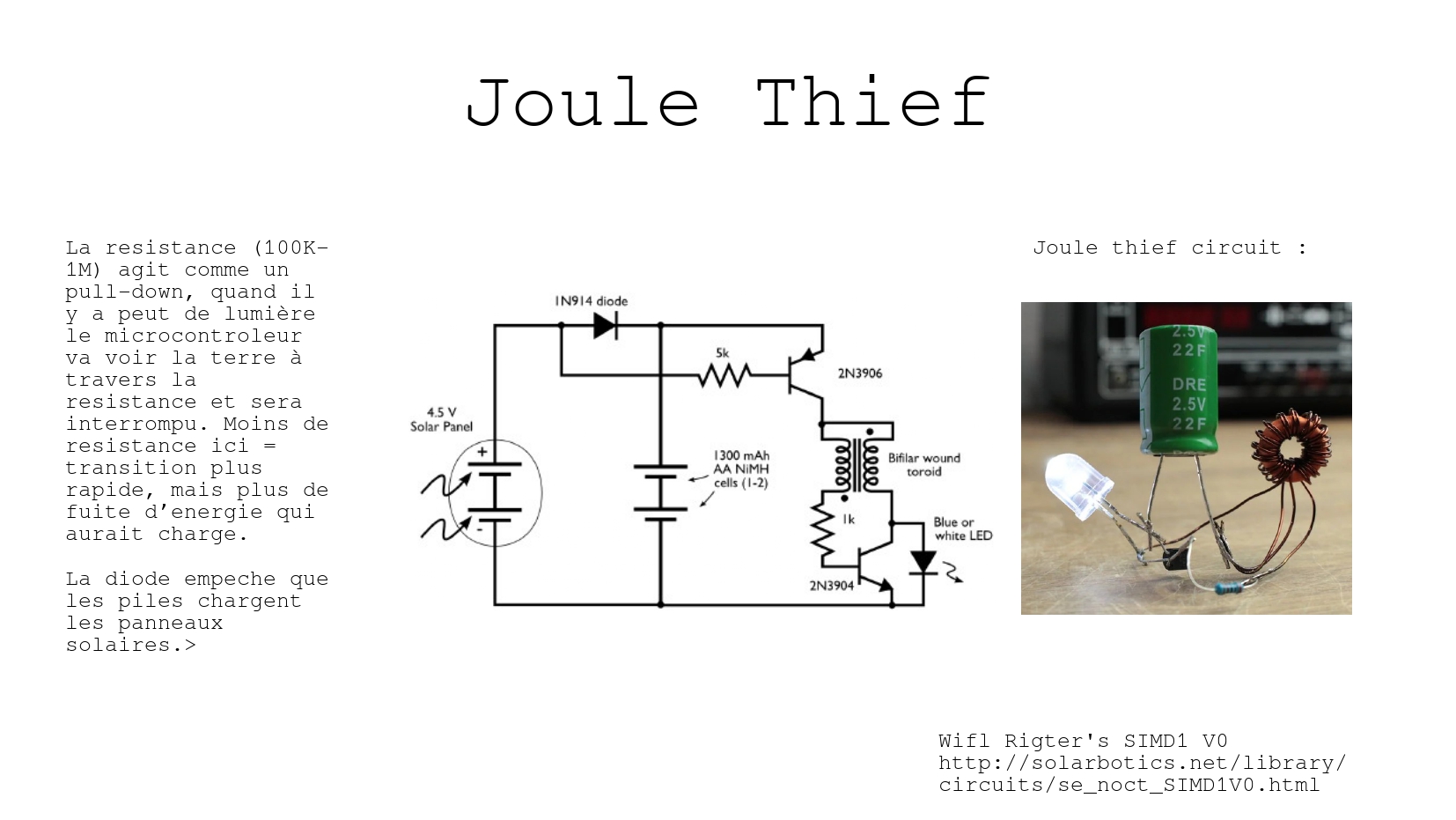

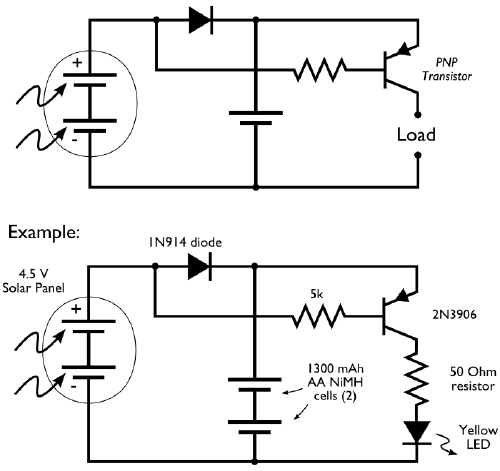

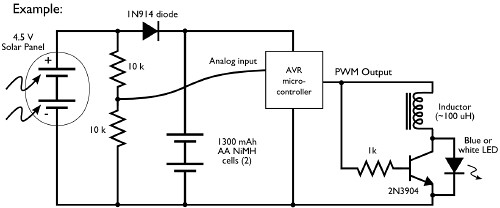

…and with a joule thief:

…and with a joule thief:

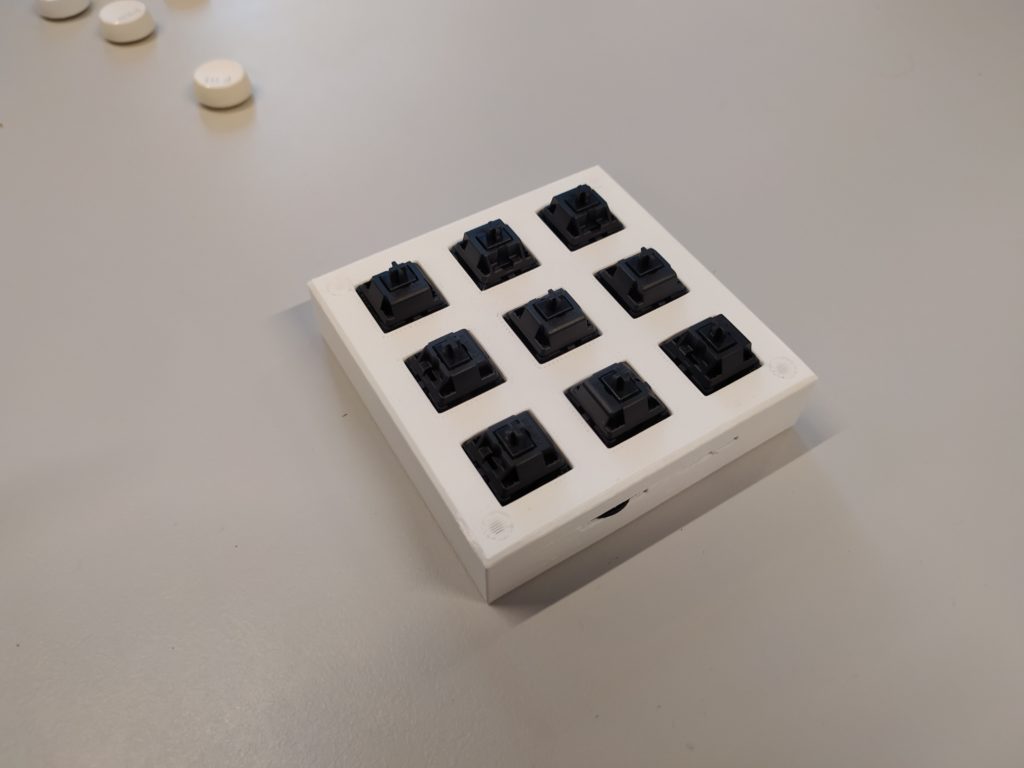

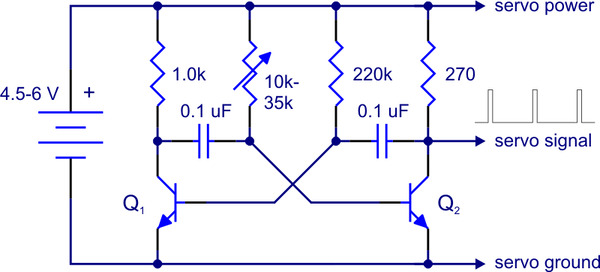

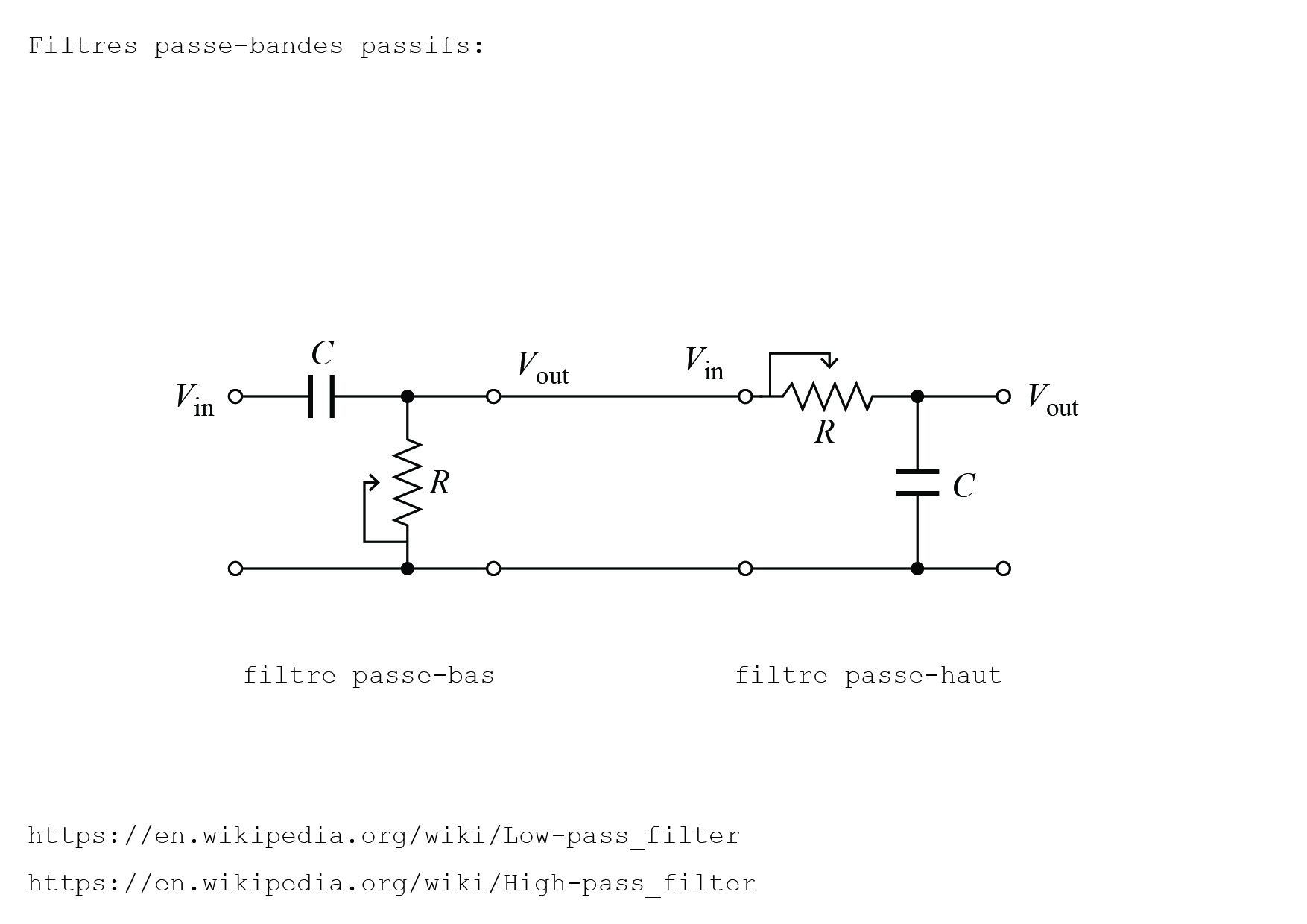

Microchips exist at a different time scale from humans, their electronics “hearts” can beat millions of times a second – think of them as extremely hyperactive brains. Microchip pins can either “listen” (take input) or send voltage signals (output).When in input mode, a microchip pin can detect the state of a button (button pushed, or button unpushed) and in output mode it can turn on or off an LED.When a human pushes down on a mechanical button and lifts their finger away, the spring inside the button pushes the button back up to its initial position. During this process there may be micro-bounces of the metal contacts inside the button. A microchip listening to the input at this time can interpret these micro bounces as changes of button states, and if the number of these bounces is odd, the microchip can conclude that the button has settled into a state other than the one that it is from the perspective of a human being.To resolve this issue, known as bouncing, there are two approaches: software or hardware. In software, the microchip can effectively check the state of the button twice, after a delay which exeeds the period of time that a button can bounce for. This code essentially detects a change in button state, then waits a few milliseconds and checks to see that the button is in the same state. This effectively rules out the possibility of having detected a button debounce.The second possibility is to do the debouncing with hardware, that is, electronically. In this approach, we stop the erroneous button state signals from arriving at the microchip in the first place. This typically involves using a small capacitor, the hardware equivalent of a delay in our code.

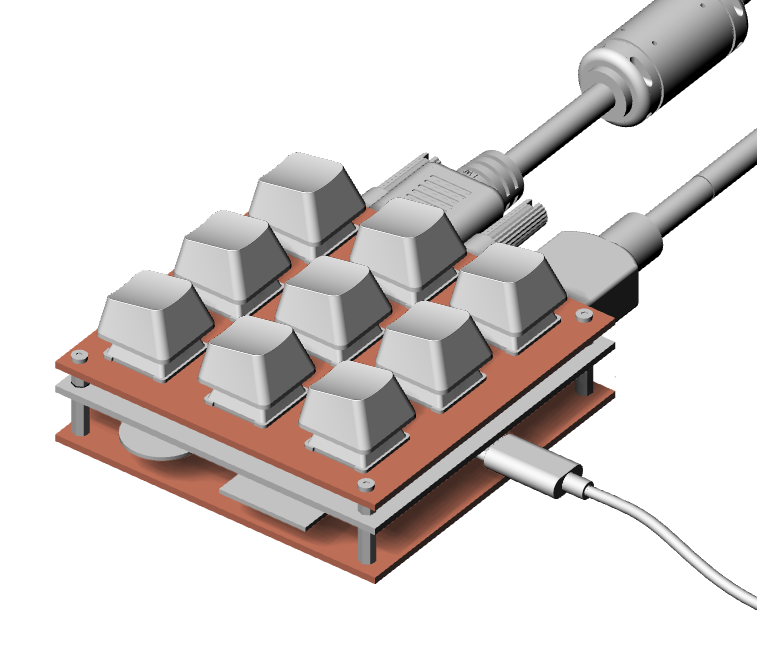

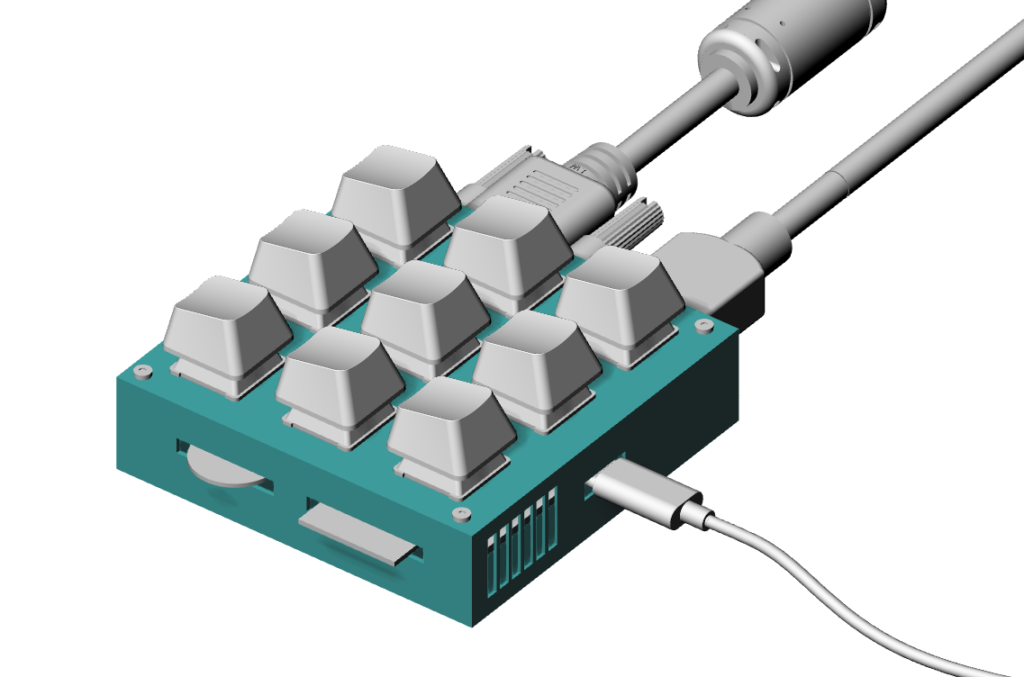

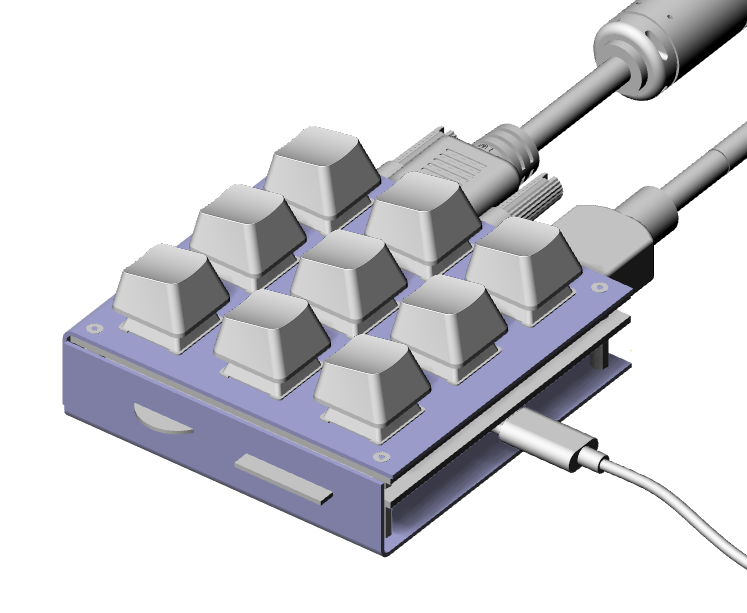

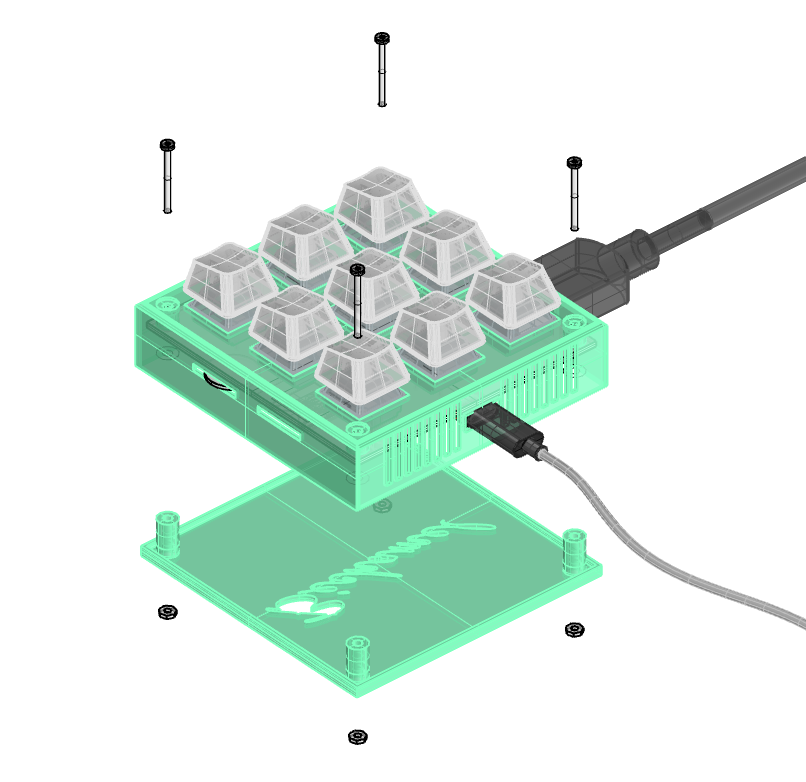

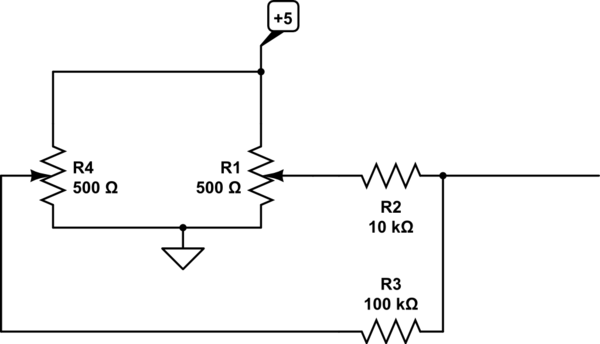

Microchips exist at a different time scale from humans, their electronics “hearts” can beat millions of times a second – think of them as extremely hyperactive brains. Microchip pins can either “listen” (take input) or send voltage signals (output).When in input mode, a microchip pin can detect the state of a button (button pushed, or button unpushed) and in output mode it can turn on or off an LED.When a human pushes down on a mechanical button and lifts their finger away, the spring inside the button pushes the button back up to its initial position. During this process there may be micro-bounces of the metal contacts inside the button. A microchip listening to the input at this time can interpret these micro bounces as changes of button states, and if the number of these bounces is odd, the microchip can conclude that the button has settled into a state other than the one that it is from the perspective of a human being.To resolve this issue, known as bouncing, there are two approaches: software or hardware. In software, the microchip can effectively check the state of the button twice, after a delay which exeeds the period of time that a button can bounce for. This code essentially detects a change in button state, then waits a few milliseconds and checks to see that the button is in the same state. This effectively rules out the possibility of having detected a button debounce.The second possibility is to do the debouncing with hardware, that is, electronically. In this approach, we stop the erroneous button state signals from arriving at the microchip in the first place. This typically involves using a small capacitor, the hardware equivalent of a delay in our code. Top and bottom rows of the button are connected when the switch is activated (pushed on).

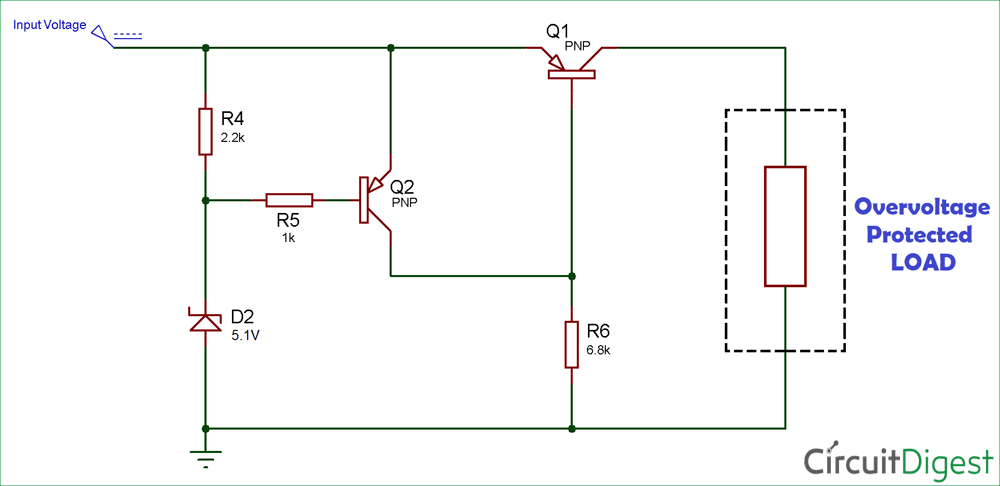

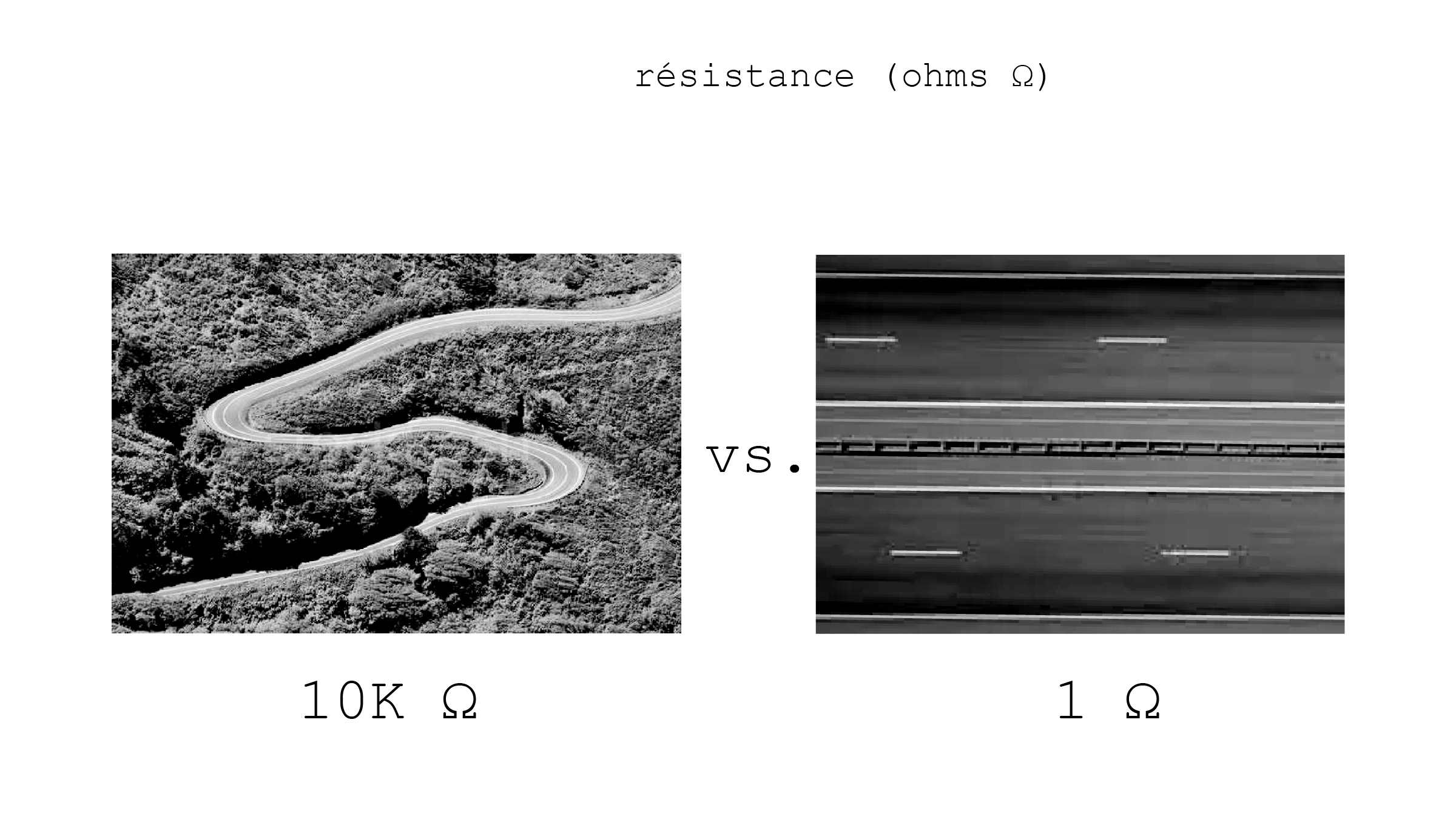

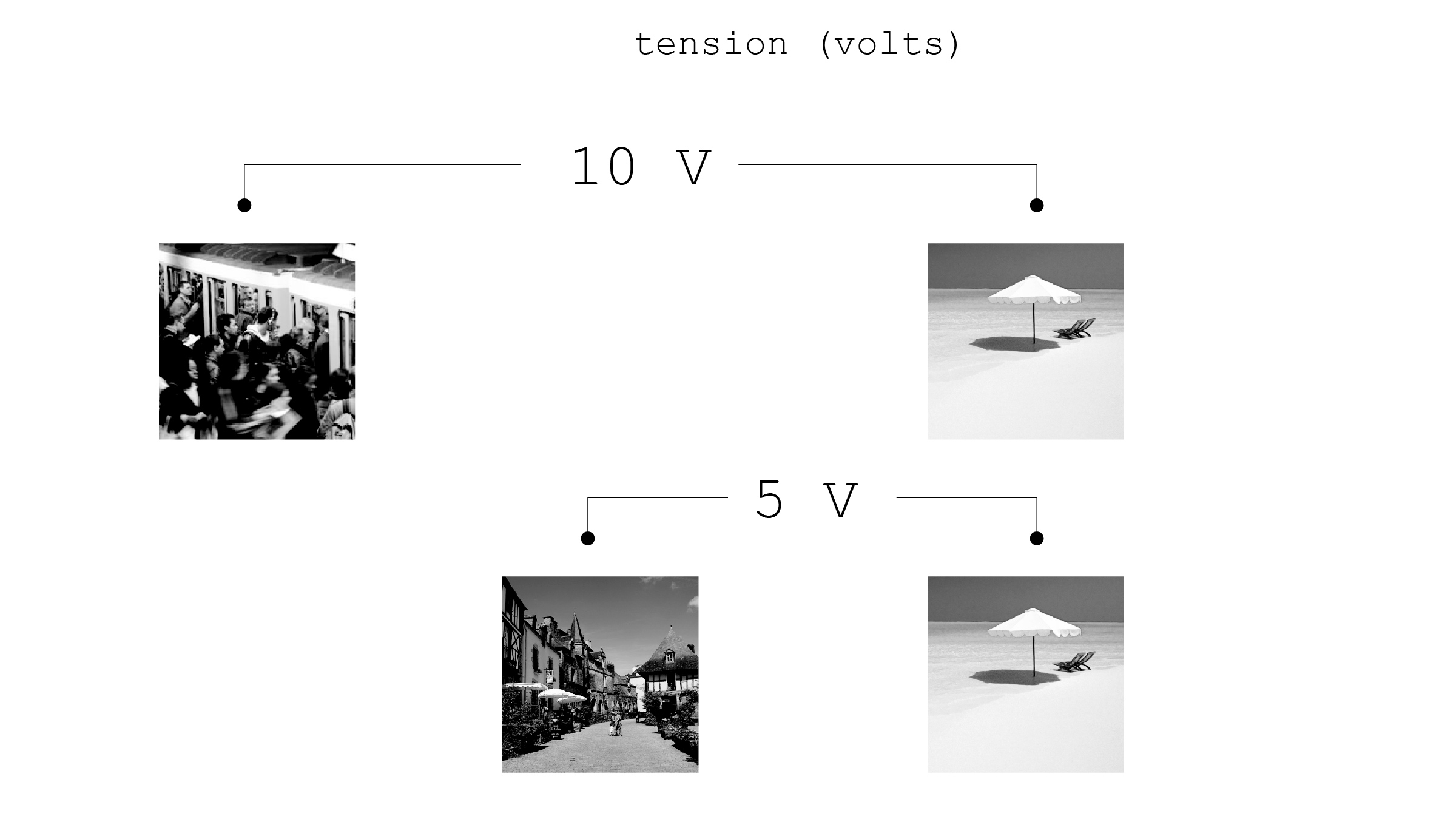

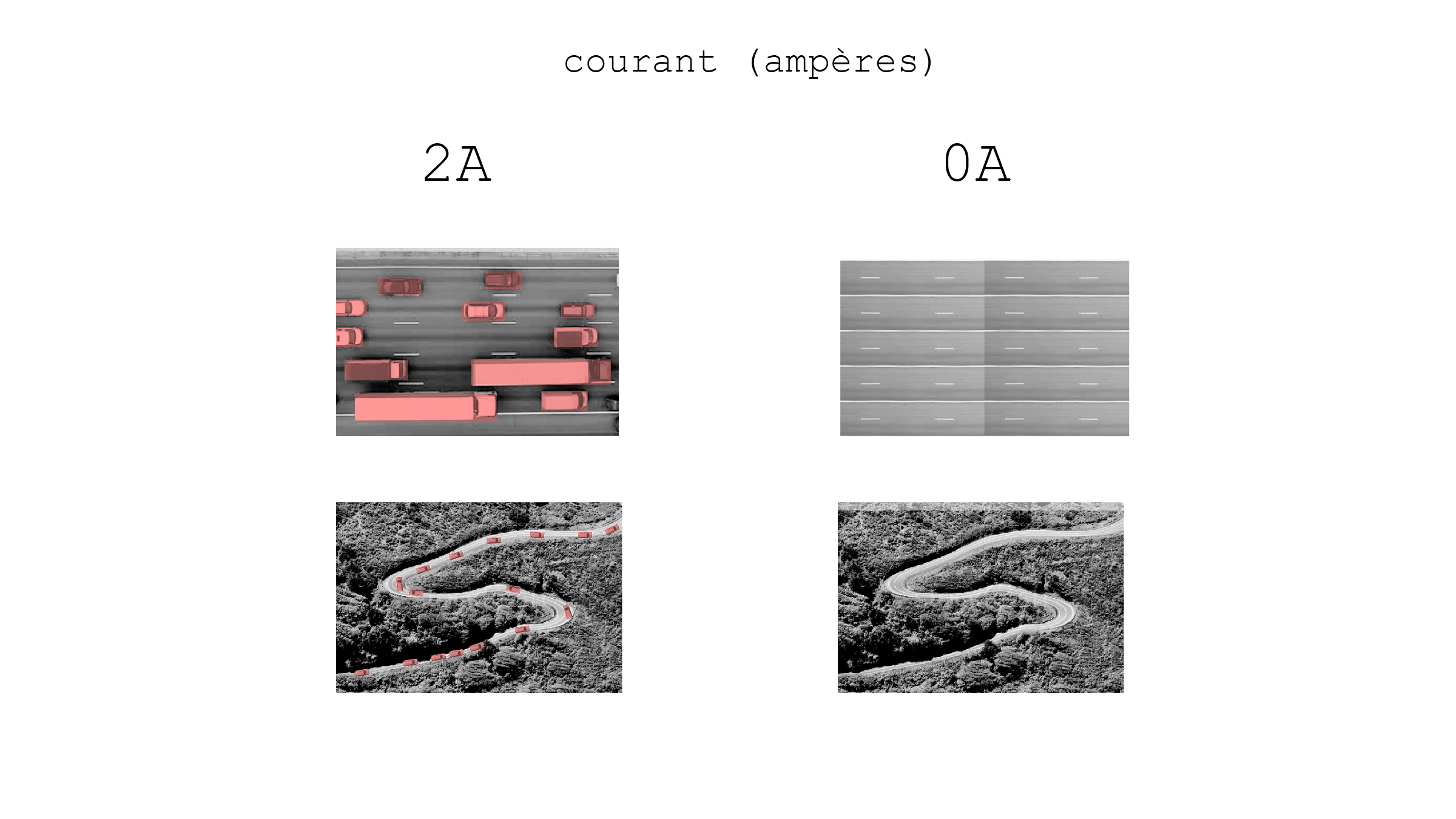

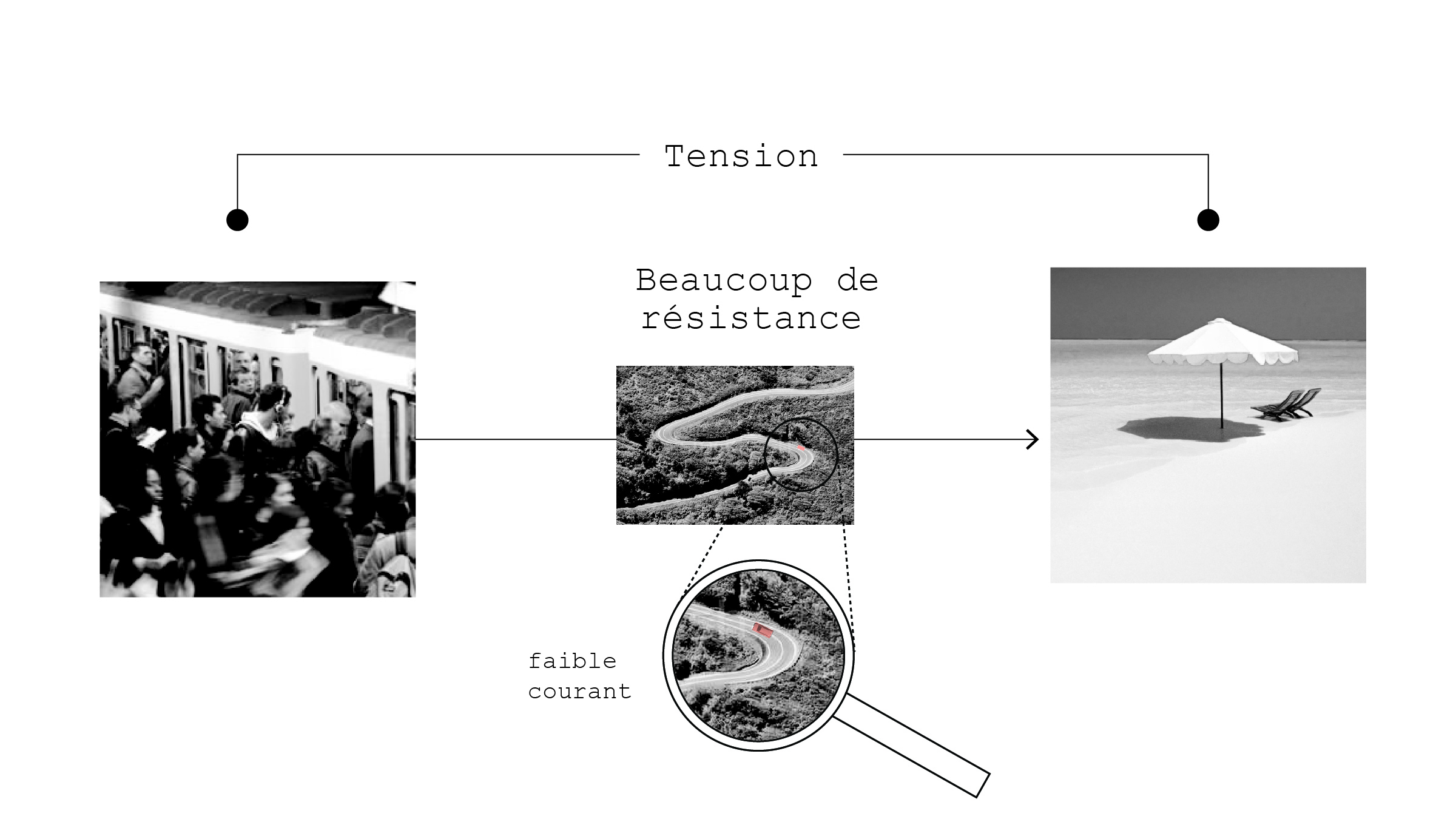

Top and bottom rows of the button are connected when the switch is activated (pushed on). We want the microchip to read two distinct states: HIGH or LOW. When the button is unpressed, the 10K pull-down resistor connects PB0 to GND. When the button is pressed, the pin is connected to 5V directly, a more appealing option for the electrons than the large resistor towards ground. This circuit is NOT debounced.

We want the microchip to read two distinct states: HIGH or LOW. When the button is unpressed, the 10K pull-down resistor connects PB0 to GND. When the button is pressed, the pin is connected to 5V directly, a more appealing option for the electrons than the large resistor towards ground. This circuit is NOT debounced.